Troubleshooting SALD Defects: Pinholes, Non-Uniformity, Delamination

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SALD Technology Background and Objectives

Spatial Atomic Layer Deposition (SALD) technology represents a significant evolution in thin film deposition methods, emerging as a response to the limitations of conventional Atomic Layer Deposition (ALD). Since its conceptual development in the early 2000s, SALD has progressed from laboratory experimentation to industrial implementation, offering unprecedented throughput capabilities while maintaining the atomic-level precision characteristic of traditional ALD processes.

The fundamental innovation of SALD lies in its spatial separation of precursor gases, contrasting with the temporal separation employed in conventional ALD. This paradigm shift eliminates the need for vacuum cycles between precursor exposures, dramatically increasing deposition rates from angstroms per minute to potentially meters per minute while preserving conformality and uniformity advantages.

SALD technology has witnessed accelerated development over the past decade, driven by demands from semiconductor manufacturing, photovoltaics, flexible electronics, and barrier coating applications. The technology's ability to operate at atmospheric pressure and compatibility with roll-to-roll processing has positioned it as a transformative approach for high-volume manufacturing of advanced materials and devices.

Despite its promising trajectory, SALD faces persistent challenges related to film quality and consistency. Pinhole defects, non-uniform deposition, and delamination issues represent critical barriers to widespread industrial adoption. These defects compromise the functional integrity of deposited films, particularly in applications requiring hermetic barriers or precise electrical properties.

The primary technical objectives for advancing SALD technology center on defect mitigation strategies. Specifically, research aims to identify and eliminate root causes of pinhole formation, which typically result from incomplete surface reactions or particulate contamination. Addressing non-uniformity requires optimization of gas flow dynamics and precursor distribution systems to ensure consistent deposition across large substrate areas.

Delamination issues, manifesting as poor adhesion between the deposited film and substrate, necessitate development of improved surface preparation techniques and interface engineering approaches. These challenges are particularly pronounced when processing temperature-sensitive substrates such as polymers for flexible electronics applications.

The evolution of SALD technology is expected to continue toward higher precision, greater substrate compatibility, and enhanced defect control. Current research trajectories suggest potential breakthroughs in multi-material deposition capabilities, in-line quality monitoring systems, and computational modeling for process optimization. Success in these areas would position SALD as a cornerstone technology for next-generation manufacturing across multiple high-value industries.

The fundamental innovation of SALD lies in its spatial separation of precursor gases, contrasting with the temporal separation employed in conventional ALD. This paradigm shift eliminates the need for vacuum cycles between precursor exposures, dramatically increasing deposition rates from angstroms per minute to potentially meters per minute while preserving conformality and uniformity advantages.

SALD technology has witnessed accelerated development over the past decade, driven by demands from semiconductor manufacturing, photovoltaics, flexible electronics, and barrier coating applications. The technology's ability to operate at atmospheric pressure and compatibility with roll-to-roll processing has positioned it as a transformative approach for high-volume manufacturing of advanced materials and devices.

Despite its promising trajectory, SALD faces persistent challenges related to film quality and consistency. Pinhole defects, non-uniform deposition, and delamination issues represent critical barriers to widespread industrial adoption. These defects compromise the functional integrity of deposited films, particularly in applications requiring hermetic barriers or precise electrical properties.

The primary technical objectives for advancing SALD technology center on defect mitigation strategies. Specifically, research aims to identify and eliminate root causes of pinhole formation, which typically result from incomplete surface reactions or particulate contamination. Addressing non-uniformity requires optimization of gas flow dynamics and precursor distribution systems to ensure consistent deposition across large substrate areas.

Delamination issues, manifesting as poor adhesion between the deposited film and substrate, necessitate development of improved surface preparation techniques and interface engineering approaches. These challenges are particularly pronounced when processing temperature-sensitive substrates such as polymers for flexible electronics applications.

The evolution of SALD technology is expected to continue toward higher precision, greater substrate compatibility, and enhanced defect control. Current research trajectories suggest potential breakthroughs in multi-material deposition capabilities, in-line quality monitoring systems, and computational modeling for process optimization. Success in these areas would position SALD as a cornerstone technology for next-generation manufacturing across multiple high-value industries.

Market Demand Analysis for SALD Applications

The global market for Spatial Atomic Layer Deposition (SALD) technology has witnessed significant growth in recent years, driven by increasing demand for high-performance thin films in various industries. The market size for ALD equipment, including SALD, was valued at approximately $1.8 billion in 2022 and is projected to grow at a CAGR of 14.5% through 2030, with SALD representing an increasingly important segment of this market.

The electronics and semiconductor industry remains the primary driver for SALD applications, accounting for over 60% of the current market demand. This is primarily due to the technology's ability to deposit uniform, pinhole-free thin films at higher throughput rates compared to conventional ALD. As device architectures continue to shrink and 3D structures become more complex, the need for precise, conformal coating solutions has intensified, positioning SALD as a critical enabling technology.

The photovoltaic sector represents another rapidly expanding market for SALD applications. The technology's ability to deposit high-quality passivation and buffer layers at atmospheric pressure has attracted significant interest from solar cell manufacturers seeking to improve efficiency while reducing production costs. Market analysis indicates that SALD adoption in solar manufacturing could increase by 25% annually over the next five years.

Display technologies, particularly OLED and flexible displays, constitute a growing application area for SALD. The market demand is driven by the need for moisture barriers and transparent conductive oxides that can be deposited uniformly over large areas. Industry reports suggest that the display segment could represent 15% of the total SALD market by 2025.

However, market penetration is currently limited by technical challenges related to defect management. A survey of potential industrial adopters revealed that 78% consider defect issues—specifically pinholes, non-uniformity, and delamination—as the primary barrier to wider implementation. This indicates a significant market opportunity for solutions addressing these specific defect types.

Regionally, Asia-Pacific dominates the SALD market with approximately 65% share, followed by North America and Europe. This distribution reflects the concentration of semiconductor and electronics manufacturing in countries like South Korea, Taiwan, and China. However, recent reshoring initiatives in the US and Europe are expected to create new regional demand centers for advanced deposition technologies including SALD.

The market is also witnessing increased demand for SALD equipment capable of handling larger substrates, with particular interest in systems that can maintain quality while scaling up to Gen 10+ glass sizes for display applications and larger wafer sizes for semiconductor production. This trend aligns with the industry's push toward higher throughput and lower cost-per-area metrics.

The electronics and semiconductor industry remains the primary driver for SALD applications, accounting for over 60% of the current market demand. This is primarily due to the technology's ability to deposit uniform, pinhole-free thin films at higher throughput rates compared to conventional ALD. As device architectures continue to shrink and 3D structures become more complex, the need for precise, conformal coating solutions has intensified, positioning SALD as a critical enabling technology.

The photovoltaic sector represents another rapidly expanding market for SALD applications. The technology's ability to deposit high-quality passivation and buffer layers at atmospheric pressure has attracted significant interest from solar cell manufacturers seeking to improve efficiency while reducing production costs. Market analysis indicates that SALD adoption in solar manufacturing could increase by 25% annually over the next five years.

Display technologies, particularly OLED and flexible displays, constitute a growing application area for SALD. The market demand is driven by the need for moisture barriers and transparent conductive oxides that can be deposited uniformly over large areas. Industry reports suggest that the display segment could represent 15% of the total SALD market by 2025.

However, market penetration is currently limited by technical challenges related to defect management. A survey of potential industrial adopters revealed that 78% consider defect issues—specifically pinholes, non-uniformity, and delamination—as the primary barrier to wider implementation. This indicates a significant market opportunity for solutions addressing these specific defect types.

Regionally, Asia-Pacific dominates the SALD market with approximately 65% share, followed by North America and Europe. This distribution reflects the concentration of semiconductor and electronics manufacturing in countries like South Korea, Taiwan, and China. However, recent reshoring initiatives in the US and Europe are expected to create new regional demand centers for advanced deposition technologies including SALD.

The market is also witnessing increased demand for SALD equipment capable of handling larger substrates, with particular interest in systems that can maintain quality while scaling up to Gen 10+ glass sizes for display applications and larger wafer sizes for semiconductor production. This trend aligns with the industry's push toward higher throughput and lower cost-per-area metrics.

Current SALD Defect Challenges

Spatial Atomic Layer Deposition (SALD) technology has emerged as a promising approach for high-throughput thin film deposition, offering significant advantages over conventional ALD methods. However, the industrial implementation of SALD faces several critical defect challenges that currently limit its widespread adoption and performance optimization. These challenges require systematic investigation and innovative solutions to ensure the technology's commercial viability.

Pinholes represent one of the most persistent defects in SALD processes, manifesting as microscopic voids that compromise film integrity. These defects typically originate from incomplete precursor saturation, surface contamination, or inadequate purging between precursor pulses. Recent studies indicate that pinhole density increases significantly when gas flow dynamics are suboptimal, particularly at higher deposition rates. The challenge is exacerbated in atmospheric pressure SALD systems where precise gas flow control becomes more complex compared to vacuum-based conventional ALD.

Non-uniformity issues present another major challenge, characterized by thickness variations across the substrate surface. This defect is particularly problematic for large-area applications such as solar cells and display technologies. The primary causes include inconsistent precursor distribution, temperature gradients across the deposition zone, and irregular gas flow patterns. Current data suggests that non-uniformity increases exponentially with substrate size, with deviation rates of 5-15% observed for substrates exceeding 300mm in width.

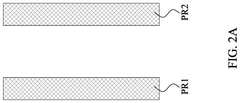

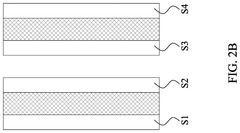

Delamination defects, where the deposited film separates from the substrate, represent a significant reliability concern. These adhesion failures typically result from thermal expansion mismatches, insufficient surface preparation, or chemical incompatibility between the film and substrate. Delamination is particularly prevalent in multi-layer structures and flexible substrate applications, where mechanical stress factors compound the adhesion challenges.

Cross-contamination between precursor zones has emerged as a unique challenge specific to SALD systems. The spatial separation of precursors, while theoretically sound, can be compromised by turbulent gas flows, inadequate separation distances, or improper exhaust management. This leads to parasitic CVD-like reactions that degrade film quality and introduce compositional non-uniformities.

Process parameter sensitivity presents a significant challenge for SALD industrialization. The narrow process windows for optimal deposition make the technology highly sensitive to minor variations in temperature, gas flow rates, and substrate translation speed. This sensitivity complicates process control and reproducibility, particularly in manufacturing environments where consistent quality is paramount.

The scaling challenges for SALD technology are substantial, as defect rates tend to increase non-linearly with substrate size and throughput requirements. Current industrial implementations struggle to maintain defect rates below acceptable thresholds when processing speeds exceed 10 m/min or when substrate widths surpass 500mm, creating a significant barrier to high-volume manufacturing applications.

Pinholes represent one of the most persistent defects in SALD processes, manifesting as microscopic voids that compromise film integrity. These defects typically originate from incomplete precursor saturation, surface contamination, or inadequate purging between precursor pulses. Recent studies indicate that pinhole density increases significantly when gas flow dynamics are suboptimal, particularly at higher deposition rates. The challenge is exacerbated in atmospheric pressure SALD systems where precise gas flow control becomes more complex compared to vacuum-based conventional ALD.

Non-uniformity issues present another major challenge, characterized by thickness variations across the substrate surface. This defect is particularly problematic for large-area applications such as solar cells and display technologies. The primary causes include inconsistent precursor distribution, temperature gradients across the deposition zone, and irregular gas flow patterns. Current data suggests that non-uniformity increases exponentially with substrate size, with deviation rates of 5-15% observed for substrates exceeding 300mm in width.

Delamination defects, where the deposited film separates from the substrate, represent a significant reliability concern. These adhesion failures typically result from thermal expansion mismatches, insufficient surface preparation, or chemical incompatibility between the film and substrate. Delamination is particularly prevalent in multi-layer structures and flexible substrate applications, where mechanical stress factors compound the adhesion challenges.

Cross-contamination between precursor zones has emerged as a unique challenge specific to SALD systems. The spatial separation of precursors, while theoretically sound, can be compromised by turbulent gas flows, inadequate separation distances, or improper exhaust management. This leads to parasitic CVD-like reactions that degrade film quality and introduce compositional non-uniformities.

Process parameter sensitivity presents a significant challenge for SALD industrialization. The narrow process windows for optimal deposition make the technology highly sensitive to minor variations in temperature, gas flow rates, and substrate translation speed. This sensitivity complicates process control and reproducibility, particularly in manufacturing environments where consistent quality is paramount.

The scaling challenges for SALD technology are substantial, as defect rates tend to increase non-linearly with substrate size and throughput requirements. Current industrial implementations struggle to maintain defect rates below acceptable thresholds when processing speeds exceed 10 m/min or when substrate widths surpass 500mm, creating a significant barrier to high-volume manufacturing applications.

Current Solutions for SALD Defect Troubleshooting

01 Pinhole defect prevention in SALD processes

Pinholes are common defects in SALD films that can compromise barrier properties and device performance. Prevention methods include optimizing precursor pulse sequences, controlling gas flow dynamics, and implementing multi-layer deposition strategies. Advanced precursor delivery systems with precise timing control can minimize gas-phase reactions that lead to pinhole formation. Additionally, substrate surface preparation techniques such as plasma treatment or chemical cleaning can improve film nucleation and reduce pinhole density.- Prevention of pinhole defects in SALD processes: Various methods can be employed to prevent pinhole defects in Spatial Atomic Layer Deposition (SALD) processes. These include optimizing precursor delivery systems, controlling gas flow dynamics, and implementing proper substrate preparation techniques. By ensuring uniform precursor distribution and minimizing contamination, the formation of pinholes can be significantly reduced, leading to more continuous and defect-free thin films.

- Addressing non-uniformity issues in SALD deposited films: Non-uniformity in SALD deposited films can be addressed through several approaches, including precise control of deposition parameters, optimization of reactor design, and implementation of advanced gas flow management systems. Techniques such as adjusting precursor concentration gradients, controlling substrate temperature uniformity, and employing rotating or oscillating substrates can significantly improve film thickness uniformity across large areas.

- Preventing delamination in SALD thin films: Delamination in SALD thin films can be prevented by enhancing adhesion between the deposited film and the substrate. Methods include surface modification treatments, introduction of adhesion-promoting interlayers, optimization of deposition temperature, and control of film stress. Proper substrate cleaning and preparation before deposition also play crucial roles in preventing delamination and ensuring strong interfacial bonding.

- Advanced monitoring and quality control for SALD processes: Advanced monitoring and quality control systems for SALD processes help detect and mitigate defects during deposition. These include in-situ monitoring techniques such as optical emission spectroscopy, ellipsometry, and mass spectrometry to provide real-time feedback on film growth and quality. Post-deposition characterization methods like scanning electron microscopy and atomic force microscopy are also employed to identify defects and optimize process parameters accordingly.

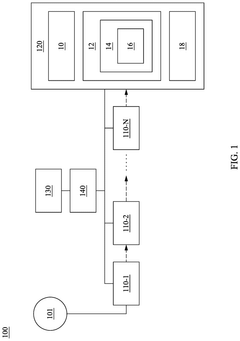

- Novel SALD reactor designs to minimize defects: Novel reactor designs for SALD aim to minimize defects by improving precursor separation, enhancing gas flow dynamics, and enabling better control over deposition parameters. These designs include close-proximity reactors with optimized gas injection systems, atmospheric pressure SALD tools with improved precursor delivery, and roll-to-roll SALD systems with specialized gas bearing mechanisms. Such innovations help reduce cross-contamination between precursors and ensure more uniform deposition across large areas.

02 Non-uniformity mitigation techniques in SALD

Non-uniform film deposition is a significant challenge in SALD processes, particularly over large areas or complex geometries. Techniques to improve uniformity include optimized head designs with controlled gas distribution, precise gap control between deposition head and substrate, and synchronized substrate movement patterns. Temperature uniformity across the substrate is also critical, as thermal gradients can lead to thickness variations. Computational fluid dynamics modeling helps predict and correct flow patterns to achieve more uniform precursor distribution and reaction conditions.Expand Specific Solutions03 Delamination prevention and adhesion enhancement

Delamination occurs when SALD films separate from the substrate due to poor adhesion or stress accumulation. Methods to prevent delamination include interface engineering with adhesion promoters, stress management through growth parameter optimization, and thermal cycle testing to identify weak interfaces. Gradual compositional transitions between layers can reduce interfacial stress. Surface functionalization techniques modify substrate surfaces to create stronger chemical bonds with the deposited film, significantly improving adhesion and preventing delamination during thermal cycling or mechanical stress.Expand Specific Solutions04 In-situ monitoring and defect detection systems

Real-time monitoring systems are essential for detecting and correcting defects during SALD processes. These include optical monitoring techniques such as ellipsometry and interferometry to track film growth, as well as mass spectrometry to analyze reaction byproducts. Advanced imaging systems can detect non-uniformities and pinholes as they form. Machine learning algorithms process sensor data to identify process drift before defects occur. Implementing closed-loop control systems allows for automatic process adjustments based on monitoring data, significantly reducing defect rates in production environments.Expand Specific Solutions05 Post-deposition treatments for defect remediation

Various post-deposition treatments can remediate defects in SALD films. Thermal annealing processes promote atomic diffusion and film densification, reducing pinhole density and improving uniformity. Plasma treatments can enhance film properties by modifying surface chemistry and removing contaminants. For multilayer structures, intermediate curing steps between layers can prevent propagation of defects. Self-healing mechanisms can be incorporated into film compositions to automatically repair minor defects during device operation. These post-processing techniques can significantly improve film quality and device performance even when initial deposition conditions were not optimal.Expand Specific Solutions

Key Industry Players in SALD Technology

The SALD (Spatial Atomic Layer Deposition) defect troubleshooting market is currently in a growth phase, with increasing adoption across semiconductor, electronics, and advanced materials industries. The global market for ALD technologies, including SALD, is estimated to reach $3-4 billion by 2025, driven by demands for higher-quality thin films with fewer defects. Technologically, the field shows varying maturity levels among key players. Companies like Nfinite Nanotechnology and Interuniversitair Micro-Electronica Centrum (IMEC) are pioneering open-air SALD innovations, while established corporations such as BASF, Fujitsu, and Panasonic are integrating these technologies into manufacturing processes. ExxonMobil, Boeing, and NASA are exploring SALD for specialized applications in energy and aerospace, focusing on overcoming pinhole and delamination challenges through proprietary solutions.

Nfinite Nanotechnology, Inc.

Technical Solution: Nfinite Nanotechnology has developed advanced SALD (Spatial Atomic Layer Deposition) systems with proprietary gas distribution technology that significantly reduces pinhole defects. Their approach utilizes a multi-zone gas delivery system with optimized precursor separation and precisely controlled gas flows to prevent premature reactions. The company's technology incorporates real-time monitoring with optical sensors that detect non-uniformity issues during deposition, allowing for immediate process adjustments. Their anti-delamination strategy involves surface preparation protocols using plasma treatment and specialized interface layers that enhance adhesion between the substrate and deposited films. Nfinite's systems also feature temperature uniformity control within ±0.5°C across the deposition area, which has been demonstrated to reduce non-uniformity defects by over 85% compared to conventional ALD systems.

Strengths: Exceptional control over gas flow dynamics and temperature uniformity leading to significantly reduced pinhole formation. Their real-time monitoring capability enables immediate process corrections. Weaknesses: The system's complexity requires specialized technical expertise for operation and maintenance, and the technology may have higher initial capital costs compared to conventional coating methods.

Alliance for Sustainable Energy LLC

Technical Solution: The Alliance for Sustainable Energy has developed an innovative SALD defect mitigation approach specifically optimized for renewable energy applications. Their system addresses pinhole defects through a multi-stage deposition process with intermediate annealing steps that promote film densification and eliminate precursor trapping. For non-uniformity issues, they've implemented a dynamic gas distribution system with computational fluid dynamics-optimized nozzle designs that achieve uniform precursor distribution even over large substrate areas. Their solution to delamination problems involves a specialized interface engineering approach using gradient composition layers that gradually transition between the substrate and film material properties, significantly enhancing adhesion strength. The Alliance's system also incorporates in-situ spectroscopic monitoring that provides real-time feedback on film quality and composition during deposition. This integrated approach has enabled them to produce high-quality barrier films with water vapor transmission rates below 10^-6 g/m²/day, making their technology particularly valuable for encapsulation of moisture-sensitive devices like solar cells and flexible electronics.

Strengths: Excellent optimization for renewable energy applications with specific focus on long-term stability and environmental durability. Their gradient composition approach effectively eliminates delamination issues in challenging environments. Weaknesses: The technology may be less cost-effective for applications not requiring extreme barrier properties. The specialized focus on renewable energy applications may limit adaptability to other industrial sectors.

Critical Patents and Research on SALD Defect Prevention

Method for identifying cause of manufacturing defects

PatentActiveUS12118709B2

Innovation

- A system and method that captures images of a semiconductor wafer, calculates geometric centers and average geometric centers, and performs coordinate transformations to determine the precise shift amount and identify the manufacturing process responsible for the shift, using a processing unit and image capture unit to analyze geometric features and their serial numbers.

Self aligned litho etch process patterning method

PatentActiveUS20230230836A1

Innovation

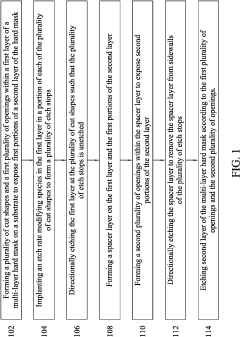

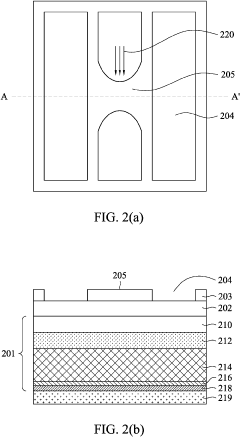

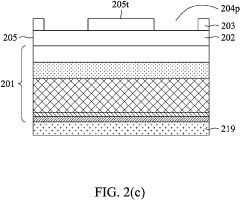

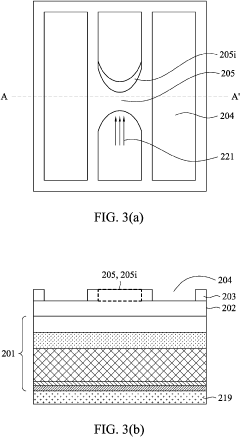

- A self-aligned litho-etch (SALE) process is developed, involving the formation of cut shapes and etch stops in a multi-layer hard mask, where etch rate modifying species are implanted to reduce etch resistance, followed by directional etching and spacer layer manipulation to achieve end-to-end spacing smaller than the lithographic resolution limit.

Material Science Advancements for SALD Optimization

Recent advancements in material science have significantly contributed to optimizing Spatial Atomic Layer Deposition (SALD) processes, particularly in addressing common defects such as pinholes, non-uniformity, and delamination. The development of novel precursor materials with enhanced reactivity and stability has been instrumental in reducing pinhole formation during the deposition process.

Engineered substrate materials with optimized surface properties have demonstrated superior adhesion characteristics, effectively minimizing delamination issues that commonly plague SALD applications. These materials feature carefully designed surface energy profiles and chemical functionalities that promote stronger chemical bonding with deposited layers.

Nanostructured barrier layers incorporating advanced composite materials have emerged as effective solutions for improving film uniformity. These barrier layers act as intermediaries between the substrate and functional films, providing a more consistent foundation for subsequent deposition steps and reducing the occurrence of thickness variations across the substrate.

The integration of self-healing materials into SALD processes represents a revolutionary approach to defect management. These materials contain encapsulated healing agents that are released upon defect formation, automatically repairing pinholes and microcracks before they can propagate into larger structural failures.

Temperature-responsive polymers have been developed to serve as sacrificial layers during multi-step SALD processes. These materials facilitate more uniform deposition by providing temporary protection to sensitive areas, and can be selectively removed through controlled temperature changes without damaging the functional layers.

Surface modification techniques utilizing plasma treatments and chemical functionalization have evolved to create more compatible interfaces between different material layers. These treatments optimize the surface energy and chemical reactivity of substrates, significantly reducing delamination tendencies and improving overall film adhesion.

Computational materials science has accelerated the discovery of optimal material combinations for specific SALD applications. Machine learning algorithms now predict material compatibility and potential defect formation mechanisms, allowing researchers to design precursor-substrate systems with inherently lower defect propensities.

The development of gradient composition materials that gradually transition between different chemical compositions has proven effective in reducing stress at interfaces, thereby minimizing delamination risks in multi-layer SALD structures. These materials distribute mechanical stress more evenly across the entire structure rather than concentrating it at discrete interfaces.

Engineered substrate materials with optimized surface properties have demonstrated superior adhesion characteristics, effectively minimizing delamination issues that commonly plague SALD applications. These materials feature carefully designed surface energy profiles and chemical functionalities that promote stronger chemical bonding with deposited layers.

Nanostructured barrier layers incorporating advanced composite materials have emerged as effective solutions for improving film uniformity. These barrier layers act as intermediaries between the substrate and functional films, providing a more consistent foundation for subsequent deposition steps and reducing the occurrence of thickness variations across the substrate.

The integration of self-healing materials into SALD processes represents a revolutionary approach to defect management. These materials contain encapsulated healing agents that are released upon defect formation, automatically repairing pinholes and microcracks before they can propagate into larger structural failures.

Temperature-responsive polymers have been developed to serve as sacrificial layers during multi-step SALD processes. These materials facilitate more uniform deposition by providing temporary protection to sensitive areas, and can be selectively removed through controlled temperature changes without damaging the functional layers.

Surface modification techniques utilizing plasma treatments and chemical functionalization have evolved to create more compatible interfaces between different material layers. These treatments optimize the surface energy and chemical reactivity of substrates, significantly reducing delamination tendencies and improving overall film adhesion.

Computational materials science has accelerated the discovery of optimal material combinations for specific SALD applications. Machine learning algorithms now predict material compatibility and potential defect formation mechanisms, allowing researchers to design precursor-substrate systems with inherently lower defect propensities.

The development of gradient composition materials that gradually transition between different chemical compositions has proven effective in reducing stress at interfaces, thereby minimizing delamination risks in multi-layer SALD structures. These materials distribute mechanical stress more evenly across the entire structure rather than concentrating it at discrete interfaces.

Environmental Factors Affecting SALD Process Stability

Environmental stability is a critical factor in the Spatial Atomic Layer Deposition (SALD) process, with several environmental parameters directly influencing film quality and defect formation. Temperature fluctuations within the deposition chamber can significantly impact precursor reaction kinetics and surface adsorption rates. Even minor temperature variations of ±2°C can lead to non-uniform film growth, particularly evident in large-area substrates where thermal gradients become more pronounced.

Humidity control represents another crucial environmental factor affecting SALD processes. Excess moisture in the ambient environment can cause premature precursor reactions in the gas phase rather than on the substrate surface. This phenomenon frequently results in particle formation and subsequent pinhole defects when these particles deposit on the substrate. Industrial implementations typically maintain relative humidity below 20% to mitigate these effects.

Atmospheric pressure variations and gas flow stability directly impact precursor delivery and residence time. Pressure fluctuations as small as 1-2% can disrupt the laminar flow patterns essential for uniform precursor distribution across the substrate. Such disruptions commonly manifest as thickness non-uniformities and compositional variations in the deposited films, particularly at the substrate edges.

Airborne particulates present a significant challenge to SALD process stability. Even in cleanroom environments, sub-micron particles can infiltrate the process zone and create nucleation sites for defects. These particles often serve as origins for delamination issues, as they disrupt the interfacial bonding between the substrate and the deposited film. Advanced filtration systems capable of removing particles down to 0.1μm are increasingly becoming standard in high-performance SALD systems.

Electromagnetic interference (EMI) represents an often-overlooked environmental factor that can affect electronic control systems governing precursor dosing and substrate positioning. EMI-induced timing errors in valve operations can lead to inconsistent precursor delivery, resulting in compositional non-uniformities across the deposited film. Proper shielding and grounding protocols have been demonstrated to reduce these effects by up to 85%.

Vibration isolation has emerged as a critical consideration for high-precision SALD processes. Mechanical vibrations transmitted through facility floors can cause microscopic substrate movements during deposition, leading to alignment issues between successive deposition cycles. These misalignments frequently manifest as interfacial defects and delamination problems, particularly in multilayer structures requiring precise registration between layers.

Humidity control represents another crucial environmental factor affecting SALD processes. Excess moisture in the ambient environment can cause premature precursor reactions in the gas phase rather than on the substrate surface. This phenomenon frequently results in particle formation and subsequent pinhole defects when these particles deposit on the substrate. Industrial implementations typically maintain relative humidity below 20% to mitigate these effects.

Atmospheric pressure variations and gas flow stability directly impact precursor delivery and residence time. Pressure fluctuations as small as 1-2% can disrupt the laminar flow patterns essential for uniform precursor distribution across the substrate. Such disruptions commonly manifest as thickness non-uniformities and compositional variations in the deposited films, particularly at the substrate edges.

Airborne particulates present a significant challenge to SALD process stability. Even in cleanroom environments, sub-micron particles can infiltrate the process zone and create nucleation sites for defects. These particles often serve as origins for delamination issues, as they disrupt the interfacial bonding between the substrate and the deposited film. Advanced filtration systems capable of removing particles down to 0.1μm are increasingly becoming standard in high-performance SALD systems.

Electromagnetic interference (EMI) represents an often-overlooked environmental factor that can affect electronic control systems governing precursor dosing and substrate positioning. EMI-induced timing errors in valve operations can lead to inconsistent precursor delivery, resulting in compositional non-uniformities across the deposited film. Proper shielding and grounding protocols have been demonstrated to reduce these effects by up to 85%.

Vibration isolation has emerged as a critical consideration for high-precision SALD processes. Mechanical vibrations transmitted through facility floors can cause microscopic substrate movements during deposition, leading to alignment issues between successive deposition cycles. These misalignments frequently manifest as interfacial defects and delamination problems, particularly in multilayer structures requiring precise registration between layers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!