SALD For Uniform Coatings On Particulate And 3D Substrates

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SALD Technology Evolution and Objectives

Spatial Atomic Layer Deposition (SALD) technology has evolved significantly since its conceptualization as an extension of conventional Atomic Layer Deposition (ALD). While traditional ALD processes have been utilized since the 1970s for creating uniform thin films, SALD emerged in the early 2000s as a response to the industrial need for higher throughput deposition techniques that maintain the precision of ALD while overcoming its inherent speed limitations.

The evolution of SALD can be traced through several key developmental phases. Initially, SALD was primarily focused on flat substrates, with early prototypes demonstrating the feasibility of spatial separation rather than temporal separation of precursors. By 2010, researchers had begun exploring atmospheric pressure SALD systems, eliminating the need for vacuum environments and significantly reducing equipment complexity and operational costs.

A pivotal advancement occurred around 2015 when SALD technology began to be adapted specifically for particulate substrates, addressing the growing demand for functionalized particles in various industries including energy storage, catalysis, and pharmaceuticals. This adaptation required innovative reactor designs that could maintain precursor separation while ensuring uniform exposure of all particle surfaces.

The most recent evolutionary phase, beginning around 2018, has focused on extending SALD capabilities to complex 3D substrates with high aspect ratios and intricate geometries. This development has been driven by emerging applications in microelectronics, medical devices, and advanced manufacturing where conformal coatings on complex shapes are essential.

The primary technical objective of current SALD research for particulate and 3D substrates is achieving uniform precursor distribution throughout the entire substrate surface area, regardless of geometry complexity. This involves optimizing gas flow dynamics, precursor delivery systems, and substrate movement mechanisms to ensure consistent coating thickness and composition.

Secondary objectives include increasing throughput rates while maintaining coating quality, developing in-situ monitoring techniques for real-time process control, and expanding the range of compatible materials and chemistries. Researchers are particularly focused on enabling multi-component films and graded compositions to create advanced functional materials.

Long-term strategic goals for SALD technology include establishing it as the standard manufacturing process for high-value coated particles and complex 3D components, reducing energy consumption compared to conventional coating methods, and enabling novel device architectures that were previously impossible due to manufacturing limitations. The ultimate vision is to develop fully automated, high-throughput SALD systems capable of continuous production of precisely engineered surfaces on virtually any substrate geometry.

The evolution of SALD can be traced through several key developmental phases. Initially, SALD was primarily focused on flat substrates, with early prototypes demonstrating the feasibility of spatial separation rather than temporal separation of precursors. By 2010, researchers had begun exploring atmospheric pressure SALD systems, eliminating the need for vacuum environments and significantly reducing equipment complexity and operational costs.

A pivotal advancement occurred around 2015 when SALD technology began to be adapted specifically for particulate substrates, addressing the growing demand for functionalized particles in various industries including energy storage, catalysis, and pharmaceuticals. This adaptation required innovative reactor designs that could maintain precursor separation while ensuring uniform exposure of all particle surfaces.

The most recent evolutionary phase, beginning around 2018, has focused on extending SALD capabilities to complex 3D substrates with high aspect ratios and intricate geometries. This development has been driven by emerging applications in microelectronics, medical devices, and advanced manufacturing where conformal coatings on complex shapes are essential.

The primary technical objective of current SALD research for particulate and 3D substrates is achieving uniform precursor distribution throughout the entire substrate surface area, regardless of geometry complexity. This involves optimizing gas flow dynamics, precursor delivery systems, and substrate movement mechanisms to ensure consistent coating thickness and composition.

Secondary objectives include increasing throughput rates while maintaining coating quality, developing in-situ monitoring techniques for real-time process control, and expanding the range of compatible materials and chemistries. Researchers are particularly focused on enabling multi-component films and graded compositions to create advanced functional materials.

Long-term strategic goals for SALD technology include establishing it as the standard manufacturing process for high-value coated particles and complex 3D components, reducing energy consumption compared to conventional coating methods, and enabling novel device architectures that were previously impossible due to manufacturing limitations. The ultimate vision is to develop fully automated, high-throughput SALD systems capable of continuous production of precisely engineered surfaces on virtually any substrate geometry.

Market Applications for SALD Coatings

Spatial Atomic Layer Deposition (SALD) technology is rapidly expanding its footprint across multiple industries due to its unique ability to create uniform, conformal coatings on complex 3D structures and particulate substrates. The energy sector represents one of the most promising application areas, with SALD coatings being increasingly utilized in battery manufacturing to enhance electrode performance. By applying uniform protective layers on battery particles, SALD significantly improves cycle life, capacity retention, and safety characteristics of lithium-ion and next-generation batteries. This application alone is projected to grow substantially as electric vehicle adoption accelerates globally.

In the semiconductor industry, SALD offers compelling advantages for creating high-quality dielectric and barrier layers on complex 3D architectures. As device miniaturization continues and 3D integration becomes more prevalent, SALD's ability to coat high-aspect-ratio structures uniformly addresses critical challenges in advanced node manufacturing. The technology enables precise deposition of functional materials for memory devices, logic circuits, and emerging quantum computing components.

Medical and pharmaceutical applications represent another high-value market for SALD coatings. The technology allows for controlled surface modification of drug particles, medical implants, and diagnostic devices. By creating uniform biocompatible or bioactive coatings on medical implants, SALD enhances integration with biological tissues while reducing rejection risks. In drug delivery, SALD-coated pharmaceutical particles demonstrate improved dissolution profiles, bioavailability, and targeted release characteristics.

The catalysis sector benefits significantly from SALD's ability to deposit precise, uniform active layers on catalyst particles and structures. This capability translates to higher catalytic efficiency, improved selectivity, and extended catalyst lifetime in applications ranging from automotive catalytic converters to industrial chemical processing. The environmental technology market also leverages SALD for creating functional coatings on filtration media, sensors, and remediation materials.

Consumer electronics manufacturers are increasingly exploring SALD for creating moisture barriers, optical coatings, and functional surfaces on complex device components. The technology's compatibility with temperature-sensitive substrates makes it particularly valuable for flexible electronics, displays, and wearable devices. Additionally, the textile industry is beginning to adopt SALD for creating durable functional finishes on fabrics, including water-repellent, antimicrobial, and UV-protective treatments.

Aerospace and defense applications are emerging as high-value niches for SALD technology, with applications in thermal barrier coatings, optical systems, and specialized electronic components. The ability to create precise multilayer structures with tailored properties addresses demanding requirements for components operating in extreme environments.

In the semiconductor industry, SALD offers compelling advantages for creating high-quality dielectric and barrier layers on complex 3D architectures. As device miniaturization continues and 3D integration becomes more prevalent, SALD's ability to coat high-aspect-ratio structures uniformly addresses critical challenges in advanced node manufacturing. The technology enables precise deposition of functional materials for memory devices, logic circuits, and emerging quantum computing components.

Medical and pharmaceutical applications represent another high-value market for SALD coatings. The technology allows for controlled surface modification of drug particles, medical implants, and diagnostic devices. By creating uniform biocompatible or bioactive coatings on medical implants, SALD enhances integration with biological tissues while reducing rejection risks. In drug delivery, SALD-coated pharmaceutical particles demonstrate improved dissolution profiles, bioavailability, and targeted release characteristics.

The catalysis sector benefits significantly from SALD's ability to deposit precise, uniform active layers on catalyst particles and structures. This capability translates to higher catalytic efficiency, improved selectivity, and extended catalyst lifetime in applications ranging from automotive catalytic converters to industrial chemical processing. The environmental technology market also leverages SALD for creating functional coatings on filtration media, sensors, and remediation materials.

Consumer electronics manufacturers are increasingly exploring SALD for creating moisture barriers, optical coatings, and functional surfaces on complex device components. The technology's compatibility with temperature-sensitive substrates makes it particularly valuable for flexible electronics, displays, and wearable devices. Additionally, the textile industry is beginning to adopt SALD for creating durable functional finishes on fabrics, including water-repellent, antimicrobial, and UV-protective treatments.

Aerospace and defense applications are emerging as high-value niches for SALD technology, with applications in thermal barrier coatings, optical systems, and specialized electronic components. The ability to create precise multilayer structures with tailored properties addresses demanding requirements for components operating in extreme environments.

Technical Barriers in Uniform SALD Coating

Spatial Atomic Layer Deposition (SALD) technology faces significant technical barriers when applied to particulate and 3D substrates, primarily due to the complex geometries involved. The fundamental challenge lies in achieving uniform precursor distribution across all surfaces of the substrate, especially in high-aspect-ratio features and intricate 3D structures. Traditional ALD processes rely on sequential self-limiting reactions, but when scaled to complex geometries, diffusion limitations become pronounced.

Gas flow dynamics present a major obstacle in SALD applications. In conventional ALD, precursor molecules must reach all surfaces through diffusion, which becomes increasingly difficult in confined spaces. For particulate substrates, the challenge is compounded by particle-to-particle interactions that can lead to agglomeration and uneven exposure to precursor gases. The residence time of precursors varies significantly across different regions of complex substrates, resulting in thickness variations.

Temperature uniformity across the substrate represents another critical barrier. Temperature gradients can lead to varying reaction rates and incomplete precursor saturation, directly affecting coating uniformity. For particulate substrates, maintaining consistent temperature throughout the particle bed is particularly challenging due to limited thermal conductivity between particles and potential heat transfer barriers.

Precursor chemistry compatibility with diverse substrate materials poses additional challenges. Different surface chemistries can result in varying nucleation behaviors and growth rates. Some materials may exhibit preferential adsorption sites, leading to island growth rather than uniform film formation. This becomes especially problematic when coating heterogeneous materials or composite structures.

Scaling SALD processes for industrial applications introduces further complications. Batch-to-batch consistency becomes difficult to maintain as substrate quantities increase. The trade-off between throughput and coating quality remains a significant hurdle, with faster processing often compromising uniformity. Current reactor designs struggle to accommodate large volumes of particulate matter while ensuring uniform gas distribution.

Characterization and quality control of SALD coatings on complex geometries present methodological challenges. Traditional film thickness measurement techniques are often inadequate for analyzing coatings on particles or in recessed areas of 3D structures. Non-destructive evaluation methods capable of assessing coating uniformity throughout complex geometries remain limited.

Overcoming these barriers requires interdisciplinary approaches combining fluid dynamics modeling, advanced reactor designs, and novel precursor delivery systems. Recent innovations in fluidized bed reactors and rotary systems show promise but still face limitations in achieving truly uniform coatings across all substrate geometries.

Gas flow dynamics present a major obstacle in SALD applications. In conventional ALD, precursor molecules must reach all surfaces through diffusion, which becomes increasingly difficult in confined spaces. For particulate substrates, the challenge is compounded by particle-to-particle interactions that can lead to agglomeration and uneven exposure to precursor gases. The residence time of precursors varies significantly across different regions of complex substrates, resulting in thickness variations.

Temperature uniformity across the substrate represents another critical barrier. Temperature gradients can lead to varying reaction rates and incomplete precursor saturation, directly affecting coating uniformity. For particulate substrates, maintaining consistent temperature throughout the particle bed is particularly challenging due to limited thermal conductivity between particles and potential heat transfer barriers.

Precursor chemistry compatibility with diverse substrate materials poses additional challenges. Different surface chemistries can result in varying nucleation behaviors and growth rates. Some materials may exhibit preferential adsorption sites, leading to island growth rather than uniform film formation. This becomes especially problematic when coating heterogeneous materials or composite structures.

Scaling SALD processes for industrial applications introduces further complications. Batch-to-batch consistency becomes difficult to maintain as substrate quantities increase. The trade-off between throughput and coating quality remains a significant hurdle, with faster processing often compromising uniformity. Current reactor designs struggle to accommodate large volumes of particulate matter while ensuring uniform gas distribution.

Characterization and quality control of SALD coatings on complex geometries present methodological challenges. Traditional film thickness measurement techniques are often inadequate for analyzing coatings on particles or in recessed areas of 3D structures. Non-destructive evaluation methods capable of assessing coating uniformity throughout complex geometries remain limited.

Overcoming these barriers requires interdisciplinary approaches combining fluid dynamics modeling, advanced reactor designs, and novel precursor delivery systems. Recent innovations in fluidized bed reactors and rotary systems show promise but still face limitations in achieving truly uniform coatings across all substrate geometries.

Current SALD Solutions for Complex Substrates

01 SALD equipment design for uniform coatings

Specialized equipment designs for Spatial Atomic Layer Deposition that enable uniform coating deposition. These designs include optimized gas flow systems, precise distance control between substrate and deposition head, and mechanical configurations that ensure consistent precursor delivery across the substrate surface. Such equipment innovations help achieve highly uniform thin films without the vacuum requirements of conventional ALD.- SALD equipment design for uniform coatings: Specialized equipment designs for Spatial Atomic Layer Deposition (SALD) focus on achieving uniform coatings across substrates. These designs incorporate precise gas flow management systems, optimized deposition heads, and controlled substrate movement mechanisms. The equipment often features separated precursor zones with inert gas barriers to prevent mixing while maintaining proximity for rapid processing. Advanced designs include rotary systems, linear translation mechanisms, or stationary arrangements with moving gas distribution heads to ensure coating uniformity.

- Precursor delivery systems for SALD uniform coatings: Precursor delivery systems in SALD technology are crucial for achieving uniform coatings. These systems control the precise timing, concentration, and distribution of chemical precursors across the substrate surface. Advanced delivery mechanisms include pulsed injection systems, vapor draw arrangements, and carrier gas distribution networks that ensure consistent precursor availability throughout the deposition process. Innovations in precursor chemistry and delivery sequencing help minimize thickness variations and improve coating uniformity across large areas.

- Temperature and pressure control for SALD uniformity: Temperature and pressure control systems are essential for maintaining uniform SALD coatings. These systems regulate substrate temperature profiles to prevent thermal gradients that could cause thickness variations. Pressure management across the deposition zone ensures consistent gas-phase reactions and precursor adsorption. Advanced systems incorporate real-time monitoring and feedback loops to make dynamic adjustments during the deposition process, compensating for environmental fluctuations and ensuring coating uniformity across the entire substrate surface.

- SALD for large-area and flexible substrate coating: SALD technologies have been adapted for uniform coating deposition on large-area and flexible substrates. These adaptations include roll-to-roll processing systems, flexible gas distribution manifolds, and specialized substrate handling mechanisms that maintain consistent precursor exposure while accommodating substrate movement or deformation. The techniques enable uniform atomic layer deposition on substrates with complex geometries or dimensional instability, making them suitable for applications in flexible electronics, solar cells, and barrier films where coating uniformity is critical despite substrate challenges.

- In-situ monitoring and process control for SALD uniformity: In-situ monitoring and process control systems enhance SALD coating uniformity through real-time measurement and adjustment capabilities. These systems incorporate optical sensors, thickness monitors, and spectroscopic tools that provide immediate feedback on coating characteristics during deposition. Advanced control algorithms analyze this data to make dynamic adjustments to process parameters such as precursor flow rates, exposure times, and substrate positioning. This closed-loop approach enables consistent film quality across large areas and compensates for variations in operating conditions that might otherwise compromise coating uniformity.

02 Precursor delivery systems for SALD uniformity

Advanced precursor delivery systems that enhance coating uniformity in SALD processes. These systems include innovative gas distribution mechanisms, precise flow controllers, and specialized injection methods that ensure homogeneous precursor distribution. By optimizing the delivery of reactive chemicals to the substrate surface, these systems minimize thickness variations and improve the overall quality of deposited films.Expand Specific Solutions03 Temperature control strategies for uniform SALD coatings

Temperature management techniques that improve coating uniformity in SALD processes. These strategies include substrate heating systems, thermal gradient control, and temperature-stabilized deposition zones. Maintaining precise and consistent temperature across the deposition area prevents uneven reaction rates and ensures uniform film growth, which is critical for applications requiring precise thickness control.Expand Specific Solutions04 SALD process parameters optimization for uniformity

Methodologies for optimizing SALD process parameters to achieve uniform coatings. These include adjustments to precursor exposure times, purge durations, substrate movement speeds, and deposition cycles. By fine-tuning these parameters based on substrate geometry and material properties, manufacturers can achieve highly uniform thin films with precise thickness control across large areas or complex surfaces.Expand Specific Solutions05 Multi-layer and composite SALD coating techniques

Advanced techniques for depositing multi-layer and composite coatings using SALD to enhance uniformity. These methods involve sequential deposition of different materials, gradient compositions, or doped layers to achieve specific functional properties while maintaining coating uniformity. The approaches include synchronized precursor switching, multi-head deposition systems, and programmed deposition sequences that enable complex yet uniform coating architectures.Expand Specific Solutions

Leading Companies in SALD Technology

The SALD (Spatial Atomic Layer Deposition) for uniform coatings on particulate and 3D substrates market is in a growth phase, with increasing adoption across industries requiring precision nano-coatings. The global market is expanding rapidly as manufacturers seek solutions for complex surface engineering challenges. Technologically, the field shows varying maturity levels, with established players like Beneq Group, Picosun, and Forge Nano offering commercial solutions, while innovative companies such as Nfinite Nanotechnology are advancing open-air ALD technologies. Research institutions including Northwestern University and CNRS are driving fundamental innovations, while industrial giants like Samsung, DuPont, and 3M are integrating SALD into manufacturing processes, indicating the technology's transition from specialized applications to mainstream industrial adoption.

3M Innovative Properties Co.

Technical Solution: 3M has developed a proprietary SALD technology for uniform coatings on particulate and 3D substrates that leverages their expertise in roll-to-roll manufacturing processes. Their approach utilizes a continuous web-based system where the substrate passes through spatially separated precursor zones maintained at atmospheric pressure. For particulate substrates, 3M employs a fluidized bed reactor design integrated with their spatial ALD architecture, allowing particles to be suspended and circulated through discrete precursor regions. This system achieves conformal nanoscale coatings (5-100nm) with excellent uniformity (±3%) at significantly higher throughput than conventional ALD. The technology incorporates advanced gas flow management using computational fluid dynamics to optimize precursor delivery and separation, ensuring minimal cross-contamination between reaction zones. 3M's SALD process has been successfully applied to optical films, barrier layers, and functional coatings for various industries, with particular success in coating temperature-sensitive polymeric materials and particles for enhanced durability, barrier properties, and surface functionality.

Strengths: Seamless integration with existing roll-to-roll manufacturing infrastructure; expertise in scaling to industrial production volumes; ability to coat flexible and temperature-sensitive substrates. Weaknesses: Less experience with high aspect ratio structures compared to specialized ALD providers; system design may require significant customization for certain particle types; more limited material library compared to dedicated ALD companies.

Nfinite Nanotechnology, Inc.

Technical Solution: Nfinite Nanotechnology has developed an innovative SALD platform specifically designed for high-throughput coating of particulate and 3D substrates. Their technology employs a rotary spatial ALD reactor where substrates move through discrete precursor zones separated by inert gas barriers, enabling continuous processing at atmospheric pressure. For particulate materials, they utilize a proprietary fluidized bed design with controlled gas flows that suspend particles in a manner ensuring uniform exposure to precursor chemicals. This approach achieves conformal nanoscale coatings (2-50nm thickness) with excellent uniformity across complex geometries while maintaining production rates up to 80 times faster than conventional ALD. Their system incorporates real-time monitoring using optical sensors to verify coating quality during processing. Nfinite's technology has been successfully applied to battery materials, catalysts, and advanced ceramics, demonstrating the ability to deposit various functional materials including Al2O3, TiO2, ZnO, and SiO2 at temperatures ranging from 80-300°C with precise thickness control (±2nm).

Strengths: Highly specialized in particulate coating with demonstrated scale-up capability; innovative reactor design minimizing gas consumption; integrated quality monitoring systems. Weaknesses: Relatively newer company with less established market presence; more limited material library compared to industry veterans; system complexity may require specialized technical support.

Key Patents in Particulate SALD Coating

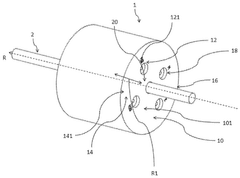

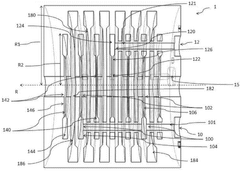

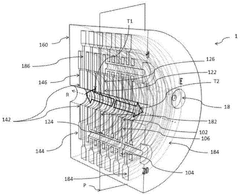

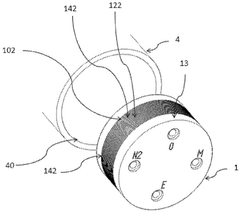

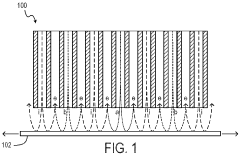

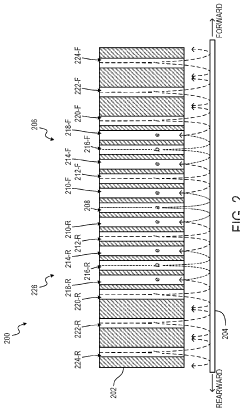

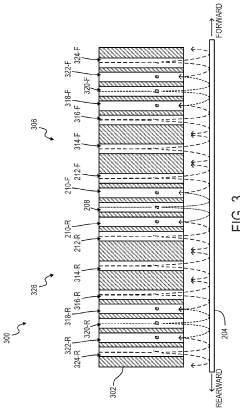

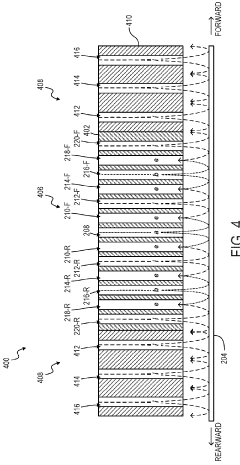

Deposition head for tubular/non-planar coatings

PatentPendingUS20240360556A1

Innovation

- A deposition head designed for tubular substrates that operates in the vapor phase, allowing for the simultaneous delivery of precursors and inert gas streams to the substrate without the need for a vacuum, ensuring precise control over film thickness and homogeneity through a network of distribution ducts and expansion prechambers, enabling efficient deposition at ambient pressure.

Powder mitigation and exhaust management for thin film deposition

PatentWO2024075062A1

Innovation

- The implementation of a spatial atomic layer deposition (SALD) system with a coating head featuring precursor and reactant gas channels, inert gas channels for purging, and exhaust channels for managing unwanted materials, along with surface treatments and environmental control to prevent powder formation and ensure gas isolation.

Scalability Challenges for Industrial Implementation

The transition from laboratory-scale SALD processes to industrial-scale manufacturing presents significant challenges that must be addressed for commercial viability. Current industrial implementation of Spatial Atomic Layer Deposition (SALD) for coating particulate and 3D substrates faces several bottlenecks related to throughput, equipment design, and process control.

Throughput limitations represent a primary concern for industrial adoption. While conventional ALD processes typically achieve deposition rates of 0.1-1.0 nm/min, SALD can theoretically reach 10-100 nm/min. However, when coating large volumes of particulate matter or complex 3D geometries, these rates often decrease substantially due to gas flow limitations and precursor diffusion constraints within intricate structures.

Equipment scaling presents another major hurdle. Industrial implementation requires specialized reactors capable of handling large substrate volumes while maintaining precise gas separation zones. Current fluidized bed SALD systems struggle to maintain uniform fluidization for particles with varying sizes and densities, leading to coating inconsistencies across production batches. Rotary reactors show promise but face challenges in achieving consistent precursor exposure times for all particles.

Process control complexity increases exponentially with scale. Monitoring and maintaining uniform temperature profiles across large reaction chambers becomes increasingly difficult. Precise gas flow management across multiple precursor zones requires sophisticated control systems that can rapidly adjust to changing conditions. Real-time monitoring of coating thickness and uniformity remains technically challenging at industrial scales.

Energy efficiency concerns also impact scalability. SALD processes require substantial energy for heating, gas flow management, and vacuum systems. As reactor sizes increase, energy consumption rises disproportionately, affecting operational costs and environmental impact. Current industrial systems struggle to optimize energy utilization while maintaining coating quality.

Material handling logistics present practical challenges for continuous production. Loading and unloading large quantities of particulate matter or 3D components requires specialized automation systems. Cross-contamination risks increase with scale, necessitating robust cleaning protocols between production runs.

Economic viability remains uncertain at industrial scales. The capital expenditure for large-scale SALD equipment is substantial, with current estimates ranging from $2-10 million for production-scale systems. Operating costs, including precursor materials, energy, and maintenance, must be balanced against the value added by the SALD coating process. Many potential industrial applications have yet to demonstrate convincing return-on-investment models.

Throughput limitations represent a primary concern for industrial adoption. While conventional ALD processes typically achieve deposition rates of 0.1-1.0 nm/min, SALD can theoretically reach 10-100 nm/min. However, when coating large volumes of particulate matter or complex 3D geometries, these rates often decrease substantially due to gas flow limitations and precursor diffusion constraints within intricate structures.

Equipment scaling presents another major hurdle. Industrial implementation requires specialized reactors capable of handling large substrate volumes while maintaining precise gas separation zones. Current fluidized bed SALD systems struggle to maintain uniform fluidization for particles with varying sizes and densities, leading to coating inconsistencies across production batches. Rotary reactors show promise but face challenges in achieving consistent precursor exposure times for all particles.

Process control complexity increases exponentially with scale. Monitoring and maintaining uniform temperature profiles across large reaction chambers becomes increasingly difficult. Precise gas flow management across multiple precursor zones requires sophisticated control systems that can rapidly adjust to changing conditions. Real-time monitoring of coating thickness and uniformity remains technically challenging at industrial scales.

Energy efficiency concerns also impact scalability. SALD processes require substantial energy for heating, gas flow management, and vacuum systems. As reactor sizes increase, energy consumption rises disproportionately, affecting operational costs and environmental impact. Current industrial systems struggle to optimize energy utilization while maintaining coating quality.

Material handling logistics present practical challenges for continuous production. Loading and unloading large quantities of particulate matter or 3D components requires specialized automation systems. Cross-contamination risks increase with scale, necessitating robust cleaning protocols between production runs.

Economic viability remains uncertain at industrial scales. The capital expenditure for large-scale SALD equipment is substantial, with current estimates ranging from $2-10 million for production-scale systems. Operating costs, including precursor materials, energy, and maintenance, must be balanced against the value added by the SALD coating process. Many potential industrial applications have yet to demonstrate convincing return-on-investment models.

Environmental Impact and Sustainability Aspects

Spatial Atomic Layer Deposition (SALD) technology for uniform coatings on particulate and 3D substrates presents significant environmental and sustainability implications that warrant careful consideration. The process fundamentally offers reduced environmental footprint compared to conventional vacuum-based ALD methods, primarily due to its atmospheric pressure operation that eliminates the need for energy-intensive vacuum systems.

SALD demonstrates remarkable material efficiency, with precursor utilization rates typically exceeding 90% compared to 10-30% in conventional ALD. This dramatic reduction in chemical waste directly translates to decreased environmental burden and lower disposal costs for hazardous materials. Additionally, the elimination of vacuum pumping systems reduces energy consumption by approximately 40-60%, contributing significantly to lower carbon emissions throughout the coating process lifecycle.

Water-based precursor systems being developed for SALD further enhance its environmental profile by replacing traditional organometallic precursors that often contain volatile organic compounds (VOCs). These water-based alternatives reduce air pollution potential and minimize worker exposure to hazardous substances, aligning with global chemical safety regulations such as REACH in Europe and similar frameworks in other regions.

The scalability of SALD for high-throughput manufacturing enables more efficient resource utilization across production lines. Continuous processing capabilities reduce start-up and shut-down waste compared to batch processes, while precise thickness control minimizes material overuse common in conventional coating technologies. Studies indicate that SALD can reduce overall material consumption by 15-25% for equivalent functional performance.

Life cycle assessments of SALD-coated products reveal extended durability and performance, particularly in applications such as corrosion protection and barrier films. This longevity translates to reduced replacement frequency and associated resource consumption. For particulate coatings specifically, SALD enables thinner functional layers that maintain performance while using substantially less material.

Challenges remain in recycling and end-of-life management for SALD-coated materials, particularly for complex 3D substrates with multi-material compositions. Research into delamination techniques and selective dissolution methods shows promise for recovering valuable coating materials from end-of-life products, though commercial implementation remains limited.

As regulatory frameworks increasingly emphasize circular economy principles, SALD technology's precision and material efficiency position it favorably against conventional coating technologies. Companies implementing SALD processes can potentially benefit from reduced environmental compliance costs and improved sustainability metrics, offering competitive advantages in markets where environmental performance is increasingly valued.

SALD demonstrates remarkable material efficiency, with precursor utilization rates typically exceeding 90% compared to 10-30% in conventional ALD. This dramatic reduction in chemical waste directly translates to decreased environmental burden and lower disposal costs for hazardous materials. Additionally, the elimination of vacuum pumping systems reduces energy consumption by approximately 40-60%, contributing significantly to lower carbon emissions throughout the coating process lifecycle.

Water-based precursor systems being developed for SALD further enhance its environmental profile by replacing traditional organometallic precursors that often contain volatile organic compounds (VOCs). These water-based alternatives reduce air pollution potential and minimize worker exposure to hazardous substances, aligning with global chemical safety regulations such as REACH in Europe and similar frameworks in other regions.

The scalability of SALD for high-throughput manufacturing enables more efficient resource utilization across production lines. Continuous processing capabilities reduce start-up and shut-down waste compared to batch processes, while precise thickness control minimizes material overuse common in conventional coating technologies. Studies indicate that SALD can reduce overall material consumption by 15-25% for equivalent functional performance.

Life cycle assessments of SALD-coated products reveal extended durability and performance, particularly in applications such as corrosion protection and barrier films. This longevity translates to reduced replacement frequency and associated resource consumption. For particulate coatings specifically, SALD enables thinner functional layers that maintain performance while using substantially less material.

Challenges remain in recycling and end-of-life management for SALD-coated materials, particularly for complex 3D substrates with multi-material compositions. Research into delamination techniques and selective dissolution methods shows promise for recovering valuable coating materials from end-of-life products, though commercial implementation remains limited.

As regulatory frameworks increasingly emphasize circular economy principles, SALD technology's precision and material efficiency position it favorably against conventional coating technologies. Companies implementing SALD processes can potentially benefit from reduced environmental compliance costs and improved sustainability metrics, offering competitive advantages in markets where environmental performance is increasingly valued.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!