APALD For Barrier Coatings In Packaging Applications

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

APALD Barrier Coating Technology Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly over the past decades, with its origins dating back to the 1970s when it was first developed for thin-film electroluminescent displays. The progression toward Atmospheric Pressure Atomic Layer Deposition (APALD) represents a critical advancement in barrier coating technology, particularly for packaging applications. This evolution has been driven by increasing demands for more efficient, cost-effective, and environmentally sustainable packaging solutions across various industries including food, pharmaceuticals, and electronics.

Traditional barrier coating methods such as vacuum metallization and chemical vapor deposition have long dominated the packaging industry. However, these techniques often require high vacuum conditions, resulting in significant energy consumption and limited throughput. The development of APALD addresses these limitations by enabling the deposition of ultra-thin, highly conformal barrier layers at atmospheric pressure, eliminating the need for costly vacuum equipment and significantly improving production efficiency.

The technical trajectory of APALD has been characterized by continuous improvements in precursor chemistry, reaction mechanisms, and process control. Early iterations faced challenges with deposition uniformity and cycle time, but recent advancements have substantially enhanced these parameters. Modern APALD systems can achieve nanometer-scale thickness control while maintaining excellent barrier properties against oxygen, water vapor, and other permeants that compromise product integrity.

A key milestone in APALD evolution was the development of spatial ALD concepts, which separated precursor exposure zones spatially rather than temporally. This innovation dramatically increased deposition rates from angstroms per minute to nanometers per minute, making the technology commercially viable for high-volume packaging applications. Further refinements in gas delivery systems and substrate handling have enabled continuous roll-to-roll processing, essential for flexible packaging materials.

The primary technical objectives for APALD barrier coatings in packaging applications include achieving oxygen transmission rates below 0.1 cm³/m²/day and water vapor transmission rates below 0.01 g/m²/day while maintaining coating thicknesses under 50 nanometers. Additional goals include enhancing adhesion to various substrate materials, improving mechanical flexibility to prevent cracking during package forming operations, and ensuring compatibility with food contact regulations.

Looking forward, the technology aims to further reduce processing temperatures to accommodate heat-sensitive substrates, increase deposition speeds to match commercial production requirements, and develop multi-layer architectures that combine barrier properties with additional functionalities such as antimicrobial activity or intelligent packaging features. These advancements will position APALD as a transformative technology in the sustainable packaging landscape, enabling significant reductions in material usage while extending product shelf life.

Traditional barrier coating methods such as vacuum metallization and chemical vapor deposition have long dominated the packaging industry. However, these techniques often require high vacuum conditions, resulting in significant energy consumption and limited throughput. The development of APALD addresses these limitations by enabling the deposition of ultra-thin, highly conformal barrier layers at atmospheric pressure, eliminating the need for costly vacuum equipment and significantly improving production efficiency.

The technical trajectory of APALD has been characterized by continuous improvements in precursor chemistry, reaction mechanisms, and process control. Early iterations faced challenges with deposition uniformity and cycle time, but recent advancements have substantially enhanced these parameters. Modern APALD systems can achieve nanometer-scale thickness control while maintaining excellent barrier properties against oxygen, water vapor, and other permeants that compromise product integrity.

A key milestone in APALD evolution was the development of spatial ALD concepts, which separated precursor exposure zones spatially rather than temporally. This innovation dramatically increased deposition rates from angstroms per minute to nanometers per minute, making the technology commercially viable for high-volume packaging applications. Further refinements in gas delivery systems and substrate handling have enabled continuous roll-to-roll processing, essential for flexible packaging materials.

The primary technical objectives for APALD barrier coatings in packaging applications include achieving oxygen transmission rates below 0.1 cm³/m²/day and water vapor transmission rates below 0.01 g/m²/day while maintaining coating thicknesses under 50 nanometers. Additional goals include enhancing adhesion to various substrate materials, improving mechanical flexibility to prevent cracking during package forming operations, and ensuring compatibility with food contact regulations.

Looking forward, the technology aims to further reduce processing temperatures to accommodate heat-sensitive substrates, increase deposition speeds to match commercial production requirements, and develop multi-layer architectures that combine barrier properties with additional functionalities such as antimicrobial activity or intelligent packaging features. These advancements will position APALD as a transformative technology in the sustainable packaging landscape, enabling significant reductions in material usage while extending product shelf life.

Market Demand Analysis for Advanced Packaging Barrier Solutions

The global market for advanced barrier coatings in packaging applications has witnessed substantial growth in recent years, driven primarily by increasing consumer demand for extended shelf life of products and sustainable packaging solutions. The food and beverage industry represents the largest market segment, accounting for approximately 60% of barrier coating applications, followed by pharmaceuticals and electronics at 25% and 15% respectively.

Consumer preferences have shifted dramatically toward convenience foods and ready-to-eat meals, necessitating packaging that maintains product freshness and quality for longer periods. This trend has accelerated during the COVID-19 pandemic, with retail food packaging demand increasing by 5-7% annually since 2020, compared to pre-pandemic growth rates of 3-4%.

Sustainability concerns have become a significant market driver, with over 70% of consumers expressing willingness to pay premium prices for environmentally friendly packaging. This has created a substantial demand for barrier coatings that maintain performance while reducing material usage and improving recyclability. Traditional barrier materials like aluminum foil and metallized films face increasing scrutiny due to their environmental impact and recycling challenges.

The pharmaceutical packaging segment demands exceptionally high barrier properties to protect sensitive medications from moisture, oxygen, and light. This sector is projected to grow at a CAGR of 6.8% through 2028, outpacing the overall packaging market growth rate of 4.2%. Stringent regulatory requirements in this sector create significant opportunities for advanced barrier technologies like APALD coatings.

Geographically, North America and Europe currently dominate the market for advanced barrier coatings, but Asia-Pacific represents the fastest-growing region with increasing disposable incomes and changing consumption patterns. China and India are expected to be key growth markets, with annual growth rates exceeding 8% for high-performance barrier packaging.

The flexible packaging segment, particularly for applications requiring high oxygen and moisture barriers, presents the most promising opportunity for APALD technology adoption. This segment is valued at approximately $25 billion globally and is growing at 5-6% annually, with barrier properties being a key differentiator and value driver.

Cost remains a significant consideration for widespread adoption, with packaging manufacturers highly sensitive to production economics. Current barrier coating solutions add between 15-30% to packaging costs, creating a clear market opportunity for more cost-effective technologies that can maintain or improve performance while reducing overall material usage and production complexity.

Consumer preferences have shifted dramatically toward convenience foods and ready-to-eat meals, necessitating packaging that maintains product freshness and quality for longer periods. This trend has accelerated during the COVID-19 pandemic, with retail food packaging demand increasing by 5-7% annually since 2020, compared to pre-pandemic growth rates of 3-4%.

Sustainability concerns have become a significant market driver, with over 70% of consumers expressing willingness to pay premium prices for environmentally friendly packaging. This has created a substantial demand for barrier coatings that maintain performance while reducing material usage and improving recyclability. Traditional barrier materials like aluminum foil and metallized films face increasing scrutiny due to their environmental impact and recycling challenges.

The pharmaceutical packaging segment demands exceptionally high barrier properties to protect sensitive medications from moisture, oxygen, and light. This sector is projected to grow at a CAGR of 6.8% through 2028, outpacing the overall packaging market growth rate of 4.2%. Stringent regulatory requirements in this sector create significant opportunities for advanced barrier technologies like APALD coatings.

Geographically, North America and Europe currently dominate the market for advanced barrier coatings, but Asia-Pacific represents the fastest-growing region with increasing disposable incomes and changing consumption patterns. China and India are expected to be key growth markets, with annual growth rates exceeding 8% for high-performance barrier packaging.

The flexible packaging segment, particularly for applications requiring high oxygen and moisture barriers, presents the most promising opportunity for APALD technology adoption. This segment is valued at approximately $25 billion globally and is growing at 5-6% annually, with barrier properties being a key differentiator and value driver.

Cost remains a significant consideration for widespread adoption, with packaging manufacturers highly sensitive to production economics. Current barrier coating solutions add between 15-30% to packaging costs, creating a clear market opportunity for more cost-effective technologies that can maintain or improve performance while reducing overall material usage and production complexity.

Current APALD Technology Landscape and Implementation Challenges

The current APALD (Atmospheric Pressure Atomic Layer Deposition) technology landscape for barrier coatings in packaging applications is characterized by significant advancements in recent years, yet faces several implementation challenges. APALD represents a breakthrough adaptation of traditional ALD technology, operating at atmospheric pressure rather than requiring vacuum conditions, which substantially reduces equipment complexity and operational costs.

Leading equipment manufacturers such as Beneq, Picosun, and Applied Materials have developed commercial APALD systems specifically targeting the packaging industry. These systems demonstrate deposition rates approximately 10-20 times faster than conventional vacuum-based ALD, making them more economically viable for high-throughput packaging applications. The technology enables the creation of ultra-thin (typically 10-100 nm) aluminum oxide (Al2O3) and silicon oxide (SiO2) barrier layers that provide exceptional protection against oxygen and moisture permeation.

Despite these advancements, several technical challenges persist in industrial implementation. Scale-up remains problematic, with current APALD systems typically limited to web widths of 500-600 mm, whereas packaging industry standards often require widths exceeding 1500 mm. This dimensional limitation restricts widespread adoption in high-volume production environments.

Process stability presents another significant challenge. APALD is highly sensitive to environmental conditions, with humidity fluctuations and airborne contaminants potentially compromising barrier quality. Maintaining consistent film properties across large substrate areas requires sophisticated process control systems that add complexity and cost to manufacturing operations.

Integration with existing production lines poses additional difficulties. The sequential nature of APALD processes often creates bottlenecks in continuous production environments. Current line speeds for APALD coating typically range from 10-50 m/min, whereas conventional packaging lines operate at 100-300 m/min, creating significant throughput disparities.

Cost considerations remain a major barrier to widespread adoption. While APALD eliminates vacuum equipment expenses, the precursor chemicals required (typically trimethylaluminum and water for Al2O3 barriers) represent a significant operational cost. Industry analysis indicates that precursor consumption accounts for 40-60% of total operational expenses in APALD processes.

Recent technological innovations are addressing these challenges through the development of spatial APALD systems that separate precursor zones physically rather than temporally, potentially increasing throughput. Additionally, hybrid approaches combining APALD with other deposition techniques show promise for optimizing both barrier performance and production efficiency.

Leading equipment manufacturers such as Beneq, Picosun, and Applied Materials have developed commercial APALD systems specifically targeting the packaging industry. These systems demonstrate deposition rates approximately 10-20 times faster than conventional vacuum-based ALD, making them more economically viable for high-throughput packaging applications. The technology enables the creation of ultra-thin (typically 10-100 nm) aluminum oxide (Al2O3) and silicon oxide (SiO2) barrier layers that provide exceptional protection against oxygen and moisture permeation.

Despite these advancements, several technical challenges persist in industrial implementation. Scale-up remains problematic, with current APALD systems typically limited to web widths of 500-600 mm, whereas packaging industry standards often require widths exceeding 1500 mm. This dimensional limitation restricts widespread adoption in high-volume production environments.

Process stability presents another significant challenge. APALD is highly sensitive to environmental conditions, with humidity fluctuations and airborne contaminants potentially compromising barrier quality. Maintaining consistent film properties across large substrate areas requires sophisticated process control systems that add complexity and cost to manufacturing operations.

Integration with existing production lines poses additional difficulties. The sequential nature of APALD processes often creates bottlenecks in continuous production environments. Current line speeds for APALD coating typically range from 10-50 m/min, whereas conventional packaging lines operate at 100-300 m/min, creating significant throughput disparities.

Cost considerations remain a major barrier to widespread adoption. While APALD eliminates vacuum equipment expenses, the precursor chemicals required (typically trimethylaluminum and water for Al2O3 barriers) represent a significant operational cost. Industry analysis indicates that precursor consumption accounts for 40-60% of total operational expenses in APALD processes.

Recent technological innovations are addressing these challenges through the development of spatial APALD systems that separate precursor zones physically rather than temporally, potentially increasing throughput. Additionally, hybrid approaches combining APALD with other deposition techniques show promise for optimizing both barrier performance and production efficiency.

Current APALD Barrier Coating Implementation Strategies

01 APALD process parameters and optimization

Atmospheric Pressure Atomic Layer Deposition (APALD) processes can be optimized through careful control of parameters such as temperature, precursor exposure time, and purge duration. These optimizations enhance the quality and properties of barrier coatings by ensuring complete surface reactions and minimizing defects. The process typically involves sequential exposure of the substrate to different precursor gases at atmospheric pressure, allowing for conformal coating deposition without the need for vacuum equipment.- APALD process parameters and optimization: Atmospheric Pressure Atomic Layer Deposition (APALD) processes can be optimized through careful control of parameters such as temperature, precursor exposure time, and purge duration. These optimizations enhance the quality and uniformity of barrier coatings while maintaining the benefits of operating at atmospheric pressure. The process allows for faster deposition rates compared to vacuum-based ALD while still achieving conformal coatings with excellent barrier properties.

- Barrier coating materials for moisture and oxygen protection: Various materials can be deposited via APALD to create effective barrier coatings that protect against moisture and oxygen permeation. Common materials include metal oxides such as aluminum oxide (Al2O3), titanium dioxide (TiO2), and silicon dioxide (SiO2), as well as nitrides and composite layers. These materials provide excellent barrier properties with minimal thickness, making them ideal for applications requiring protection against environmental degradation.

- Flexible and transparent barrier applications: APALD barrier coatings are particularly valuable for flexible electronics and displays, where traditional vacuum-based deposition methods may be challenging to implement. These coatings can be applied to polymer substrates to create transparent, flexible barriers with excellent gas impermeability while maintaining optical clarity. The low-temperature deposition capability of APALD makes it compatible with temperature-sensitive substrates like plastics and organic materials.

- Roll-to-roll and large-area coating techniques: APALD can be implemented in roll-to-roll and other large-area coating systems, enabling continuous production of barrier-coated materials. This scalability makes APALD commercially viable for mass production of barrier films and coatings. The atmospheric pressure operation eliminates the need for complex vacuum systems, reducing equipment costs and simplifying the manufacturing process while maintaining the atomic-level precision characteristic of ALD.

- Multi-layer and nanolaminate barrier structures: Enhanced barrier performance can be achieved through multi-layer and nanolaminate structures deposited via APALD. These structures combine different materials in alternating layers to create tortuous paths for gas molecules, significantly improving barrier properties beyond what single-layer coatings can achieve. The precise thickness control inherent to ALD allows for optimization of each layer in the stack, resulting in superior barrier performance with minimal overall coating thickness.

02 Barrier coating materials for moisture and gas protection

Various materials can be deposited using APALD to create effective barrier coatings that protect against moisture and gas permeation. These materials include metal oxides (such as Al2O3, TiO2, ZrO2), nitrides, and hybrid organic-inorganic layers. The barrier properties can be enhanced by creating multilayer structures that increase the diffusion path length for penetrating molecules. These coatings are particularly valuable for protecting sensitive electronic components, food packaging, and pharmaceutical products.Expand Specific Solutions03 APALD equipment and delivery systems

Specialized equipment and precursor delivery systems have been developed for APALD processes that operate at atmospheric pressure. These systems include spatial ALD reactors, roll-to-roll processing equipment, and precursor delivery mechanisms designed to work without vacuum conditions. The equipment often features separated reaction zones, gas curtains to prevent precursor mixing, and precise temperature control systems to enable efficient deposition at atmospheric pressure while maintaining the self-limiting nature of ALD reactions.Expand Specific Solutions04 Flexible and roll-to-roll APALD applications

APALD technology has been adapted for coating flexible substrates and implementation in roll-to-roll manufacturing processes. This adaptation enables high-throughput production of barrier coatings on polymer films, textiles, and other flexible materials. The atmospheric pressure operation eliminates the need for complex vacuum chambers, making the process more compatible with continuous manufacturing. These developments have expanded the application of barrier coatings to flexible electronics, solar cells, and packaging materials.Expand Specific Solutions05 Enhanced barrier performance through nanolaminate structures

Nanolaminate structures created by alternating different materials in thin layers using APALD can significantly enhance barrier performance. These structures combine the benefits of different materials and create tortuous paths for diffusing molecules. The interfaces between layers act as additional barriers to gas and moisture permeation. By carefully designing the composition, thickness, and sequence of these nanolaminates, the barrier properties can be tailored for specific applications while maintaining a thin overall coating thickness.Expand Specific Solutions

Key Industry Players in APALD Packaging Applications

The APALD (Atmospheric Pressure Atomic Layer Deposition) barrier coating market for packaging applications is in its growth phase, with increasing adoption driven by demands for enhanced shelf life and sustainability. The global market is expanding as companies seek superior barrier properties against oxygen and moisture. Technologically, industry leaders like Applied Materials, Picosun, and Forge Nano have established strong positions with advanced APALD systems, while packaging specialists such as DuPont, BASF, and Albéa are integrating these solutions into commercial applications. The technology is approaching maturity in high-value applications but remains in development for mass-market packaging. Collaboration between equipment manufacturers (Lam Research, ASM IP Holding) and materials companies (3M, Eastman Kodak) is accelerating commercialization, with significant patent activity indicating competitive innovation.

Picosun Oy

Technical Solution: Picosun has developed advanced APALD (Atomic and Plasma-Enhanced Atomic Layer Deposition) technology specifically optimized for barrier coatings in packaging applications. Their PICOSUN® Sprinter system enables high-volume ALD production with unprecedented throughput for large-area substrates. The technology creates ultra-thin, pinhole-free barrier films with excellent uniformity at atomic level precision. For packaging applications, Picosun's APALD solutions deliver moisture and oxygen barriers with WVTR (Water Vapor Transmission Rate) values below 10^-6 g/m²/day, significantly extending shelf life for sensitive products. Their plasma-enhanced processes operate at lower temperatures (as low as 80°C), making them compatible with temperature-sensitive packaging materials including polymers and biopolymers. The company has also pioneered spatial ALD techniques that increase deposition speed by up to 100 times compared to conventional ALD, addressing previous throughput limitations for industrial-scale packaging applications.

Strengths: Industry-leading throughput capabilities for large-area substrates; ultra-low temperature processing compatible with heat-sensitive materials; exceptional barrier performance with minimal material usage. Weaknesses: Higher initial capital investment compared to conventional barrier coating technologies; requires specialized expertise for process optimization; more complex implementation than traditional vacuum deposition methods.

ASM IP Holding BV

Technical Solution: ASM IP Holding has developed proprietary APALD technology specifically engineered for high-performance barrier coatings in packaging applications. Their platform utilizes a spatial ALD approach that separates precursor and co-reactant exposure zones, enabling continuous processing without vacuum chamber cycling. This architecture achieves deposition rates up to 10 nm/min while maintaining atomic-level precision. For packaging applications, ASM's technology creates ultra-thin (5-20 nm) aluminum oxide and silicon nitride barrier layers with oxygen transmission rates below 0.01 cm³/m²/day and water vapor transmission rates under 10^-4 g/m²/day. Their plasma-enhanced processes operate at temperatures as low as 50°C, making them compatible with heat-sensitive packaging substrates including PET, PP, and biodegradable polymers. The company has also developed specialized precursor chemistries that enhance adhesion to polymer substrates without requiring separate adhesion layers, improving manufacturing efficiency and reducing costs for packaging manufacturers.

Strengths: Continuous processing capability enables higher throughput than conventional ALD; extremely low temperature processing expands substrate compatibility; excellent barrier performance with minimal material usage. Weaknesses: Technology requires specialized precursors that may increase operational costs; system complexity demands higher maintenance expertise; initial implementation requires significant process optimization.

Critical Patents and Innovations in APALD Barrier Technology

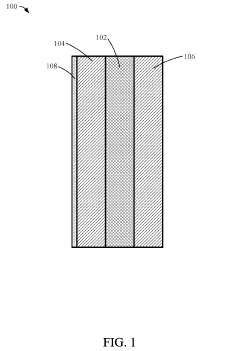

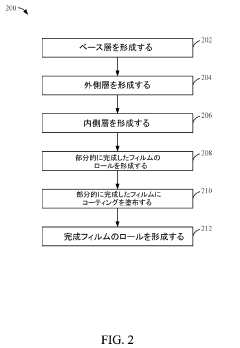

Package wrapping including PLA film with moisture barrier layer by atomic layer deposition

PatentActiveJP2024042036A

Innovation

- A biodegradable PLA film with multiple layers, including a base layer with a high melting point and outer layers with low melting points, coated with a metal oxide layer using ALD, offering a moisture barrier and heat-sealing capabilities.

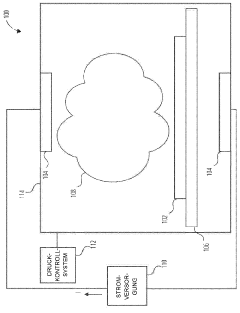

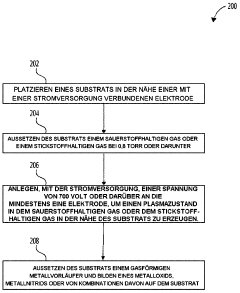

plasma-enhanced deposition of atomic layers at high voltage and low pressure

PatentPendingDE112020002193T5

Innovation

- The use of low-pressure, high-voltage plasma-enhanced ALD processes, where a substrate is exposed to oxygen or nitrogen-containing gases at pressures between 0.1 to 0.8 torr and voltages above 700 volts, combined with specific metal precursors, to form films with enhanced density and reduced permeability.

Sustainability Impact of APALD in Packaging Industry

The implementation of APALD (Atmospheric Pressure Atomic Layer Deposition) technology in packaging applications represents a significant advancement in sustainable packaging solutions. This innovative barrier coating technology substantially reduces the environmental footprint of packaging materials across their entire lifecycle, from production to disposal.

APALD processes operate at ambient pressure and lower temperatures compared to traditional vacuum-based ALD methods, resulting in significantly reduced energy consumption. Studies indicate that APALD can achieve up to 40% energy savings compared to conventional barrier coating technologies, directly translating to lower carbon emissions in manufacturing operations.

The ultra-thin nature of APALD barrier coatings (typically 10-100 nanometers) dramatically reduces raw material requirements while maintaining or enhancing barrier properties. This material efficiency contributes to resource conservation and waste reduction in the production phase. Additionally, the precision of atomic layer deposition minimizes chemical waste generation during the coating process, as precursors react completely on substrate surfaces.

From a circular economy perspective, APALD coatings offer compelling advantages. The technology enables the development of mono-material packaging structures by replacing multi-material laminates with single-substrate solutions enhanced by functional barrier layers. This simplification of material composition significantly improves recyclability and addresses one of the most challenging aspects of packaging waste management.

Water-based APALD processes further enhance sustainability by eliminating the need for organic solvents, reducing VOC emissions and associated environmental impacts. This aligns with increasingly stringent environmental regulations worldwide and corporate sustainability commitments across the packaging value chain.

Life Cycle Assessment (LCA) studies comparing APALD-coated packaging with conventional alternatives demonstrate notable improvements in key environmental indicators. These include reduced global warming potential, decreased water usage, and lower ecotoxicity scores. For instance, preliminary assessments suggest that APALD-enhanced flexible packaging can reduce the carbon footprint by 15-25% compared to conventional metallized or multi-layer barrier structures.

The extended shelf life provided by APALD barrier coatings also contributes to sustainability by reducing food waste, which represents a significant environmental challenge globally. By maintaining product freshness longer, these advanced barrier solutions help mitigate the environmental impact associated with premature food spoilage and disposal.

As packaging sustainability becomes increasingly critical for consumer goods companies, APALD technology offers a promising pathway to meet ambitious environmental targets while maintaining or improving packaging functionality and product protection.

APALD processes operate at ambient pressure and lower temperatures compared to traditional vacuum-based ALD methods, resulting in significantly reduced energy consumption. Studies indicate that APALD can achieve up to 40% energy savings compared to conventional barrier coating technologies, directly translating to lower carbon emissions in manufacturing operations.

The ultra-thin nature of APALD barrier coatings (typically 10-100 nanometers) dramatically reduces raw material requirements while maintaining or enhancing barrier properties. This material efficiency contributes to resource conservation and waste reduction in the production phase. Additionally, the precision of atomic layer deposition minimizes chemical waste generation during the coating process, as precursors react completely on substrate surfaces.

From a circular economy perspective, APALD coatings offer compelling advantages. The technology enables the development of mono-material packaging structures by replacing multi-material laminates with single-substrate solutions enhanced by functional barrier layers. This simplification of material composition significantly improves recyclability and addresses one of the most challenging aspects of packaging waste management.

Water-based APALD processes further enhance sustainability by eliminating the need for organic solvents, reducing VOC emissions and associated environmental impacts. This aligns with increasingly stringent environmental regulations worldwide and corporate sustainability commitments across the packaging value chain.

Life Cycle Assessment (LCA) studies comparing APALD-coated packaging with conventional alternatives demonstrate notable improvements in key environmental indicators. These include reduced global warming potential, decreased water usage, and lower ecotoxicity scores. For instance, preliminary assessments suggest that APALD-enhanced flexible packaging can reduce the carbon footprint by 15-25% compared to conventional metallized or multi-layer barrier structures.

The extended shelf life provided by APALD barrier coatings also contributes to sustainability by reducing food waste, which represents a significant environmental challenge globally. By maintaining product freshness longer, these advanced barrier solutions help mitigate the environmental impact associated with premature food spoilage and disposal.

As packaging sustainability becomes increasingly critical for consumer goods companies, APALD technology offers a promising pathway to meet ambitious environmental targets while maintaining or improving packaging functionality and product protection.

Cost-Benefit Analysis of APALD Implementation

Implementing APALD (Atmospheric Pressure Atomic Layer Deposition) technology for barrier coatings in packaging applications requires careful cost-benefit analysis to determine its economic viability. Initial capital expenditure for APALD equipment represents a significant investment, typically ranging from $500,000 to $2 million depending on production scale and configuration requirements. This includes specialized deposition chambers, precursor delivery systems, and control infrastructure necessary for precise atomic layer formation.

Operational costs must be evaluated against traditional barrier coating methods. APALD processes consume specialized precursor chemicals that can cost between $200-1,000 per kilogram, though their efficient utilization partially offsets this expense. Energy consumption averages 30-50 kWh per production hour, which is comparable to conventional vacuum-based ALD but without the additional vacuum system maintenance costs.

Labor requirements present a mixed profile. While APALD systems demand skilled operators commanding higher wages ($25-40 per hour), the high degree of automation reduces the total labor hours needed compared to conventional coating methods. Maintenance costs typically run at 5-8% of capital equipment value annually, which is slightly higher than conventional technologies but justified by superior performance.

The benefits side of the equation reveals compelling advantages. APALD barrier coatings demonstrate oxygen transmission rates below 0.1 cm³/m²/day and water vapor transmission rates under 0.01 g/m²/day, representing a 40-60% improvement over conventional barrier technologies. This translates directly to extended shelf life for packaged products, with studies showing 30-50% longer preservation periods for oxygen-sensitive foods and pharmaceuticals.

Production efficiency gains include reduced material waste (typically 15-25% less than conventional methods), faster processing speeds for thin barriers, and significantly lower defect rates. The ultra-thin nature of APALD coatings (typically 10-50 nm) reduces raw material consumption by up to 90% compared to traditional barrier layers while maintaining or improving performance.

Return on investment calculations indicate payback periods of 2-4 years for high-volume packaging applications, with the most favorable economics in premium food, pharmaceutical, and electronic packaging segments where extended shelf life and superior protection command premium pricing. Sensitivity analysis suggests that APALD implementation becomes increasingly economical as production volumes increase beyond 10 million packaging units annually.

Operational costs must be evaluated against traditional barrier coating methods. APALD processes consume specialized precursor chemicals that can cost between $200-1,000 per kilogram, though their efficient utilization partially offsets this expense. Energy consumption averages 30-50 kWh per production hour, which is comparable to conventional vacuum-based ALD but without the additional vacuum system maintenance costs.

Labor requirements present a mixed profile. While APALD systems demand skilled operators commanding higher wages ($25-40 per hour), the high degree of automation reduces the total labor hours needed compared to conventional coating methods. Maintenance costs typically run at 5-8% of capital equipment value annually, which is slightly higher than conventional technologies but justified by superior performance.

The benefits side of the equation reveals compelling advantages. APALD barrier coatings demonstrate oxygen transmission rates below 0.1 cm³/m²/day and water vapor transmission rates under 0.01 g/m²/day, representing a 40-60% improvement over conventional barrier technologies. This translates directly to extended shelf life for packaged products, with studies showing 30-50% longer preservation periods for oxygen-sensitive foods and pharmaceuticals.

Production efficiency gains include reduced material waste (typically 15-25% less than conventional methods), faster processing speeds for thin barriers, and significantly lower defect rates. The ultra-thin nature of APALD coatings (typically 10-50 nm) reduces raw material consumption by up to 90% compared to traditional barrier layers while maintaining or improving performance.

Return on investment calculations indicate payback periods of 2-4 years for high-volume packaging applications, with the most favorable economics in premium food, pharmaceutical, and electronic packaging segments where extended shelf life and superior protection command premium pricing. Sensitivity analysis suggests that APALD implementation becomes increasingly economical as production volumes increase beyond 10 million packaging units annually.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!