Optimizing Film Densification In Atmospheric ALD Conditions

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ALD Film Densification Background and Objectives

Atomic Layer Deposition (ALD) has emerged as a pivotal thin film deposition technique in semiconductor manufacturing, offering unparalleled conformality and thickness control at the atomic scale. The evolution of ALD technology spans several decades, originating from early work on Atomic Layer Epitaxy (ALE) in the 1970s and gradually maturing into a mainstream industrial process by the early 2000s. As device architectures continue to shrink and three-dimensional structures become more complex, the quality and performance of ALD films have become increasingly critical to device functionality.

Film densification represents a fundamental challenge in ALD processes, particularly under atmospheric conditions where traditional vacuum-based densification methods prove inadequate. Historically, ALD has been predominantly performed under vacuum conditions, but atmospheric ALD (AALD) offers significant advantages in terms of throughput, cost reduction, and integration flexibility. However, films deposited under atmospheric pressure often exhibit lower density, increased impurity incorporation, and compromised electrical and mechanical properties compared to their vacuum-processed counterparts.

The technological trajectory indicates a growing demand for atmospheric ALD solutions across multiple industries, including semiconductor, display, photovoltaic, and emerging flexible electronics sectors. This trend is driven by the need for high-throughput, cost-effective deposition processes that maintain the precision of traditional ALD while eliminating vacuum requirements. Recent advancements in precursor chemistry and reactor design have partially addressed these challenges, yet film densification remains a persistent obstacle.

The primary objective of this technical research is to systematically investigate and optimize film densification methodologies specifically tailored for atmospheric ALD conditions. We aim to develop novel approaches that can achieve film densities comparable to vacuum-processed films while maintaining the economic and throughput advantages of atmospheric processing. This includes exploring innovative precursor designs, reaction enhancement techniques, and post-deposition treatments compatible with atmospheric pressure environments.

Secondary objectives include quantifying the relationship between process parameters and film density, establishing standardized metrics for density evaluation, and developing predictive models to guide process optimization. Additionally, we seek to understand the fundamental mechanisms governing densification under atmospheric conditions, including the roles of precursor diffusion, surface reactions, and byproduct removal in determining final film structure.

The successful realization of these objectives would represent a significant advancement in ALD technology, enabling broader industrial adoption of atmospheric processes while maintaining the exceptional film quality that has made ALD indispensable in advanced manufacturing. This research directly supports the industry's trajectory toward more efficient, accessible, and sustainable thin film deposition technologies.

Film densification represents a fundamental challenge in ALD processes, particularly under atmospheric conditions where traditional vacuum-based densification methods prove inadequate. Historically, ALD has been predominantly performed under vacuum conditions, but atmospheric ALD (AALD) offers significant advantages in terms of throughput, cost reduction, and integration flexibility. However, films deposited under atmospheric pressure often exhibit lower density, increased impurity incorporation, and compromised electrical and mechanical properties compared to their vacuum-processed counterparts.

The technological trajectory indicates a growing demand for atmospheric ALD solutions across multiple industries, including semiconductor, display, photovoltaic, and emerging flexible electronics sectors. This trend is driven by the need for high-throughput, cost-effective deposition processes that maintain the precision of traditional ALD while eliminating vacuum requirements. Recent advancements in precursor chemistry and reactor design have partially addressed these challenges, yet film densification remains a persistent obstacle.

The primary objective of this technical research is to systematically investigate and optimize film densification methodologies specifically tailored for atmospheric ALD conditions. We aim to develop novel approaches that can achieve film densities comparable to vacuum-processed films while maintaining the economic and throughput advantages of atmospheric processing. This includes exploring innovative precursor designs, reaction enhancement techniques, and post-deposition treatments compatible with atmospheric pressure environments.

Secondary objectives include quantifying the relationship between process parameters and film density, establishing standardized metrics for density evaluation, and developing predictive models to guide process optimization. Additionally, we seek to understand the fundamental mechanisms governing densification under atmospheric conditions, including the roles of precursor diffusion, surface reactions, and byproduct removal in determining final film structure.

The successful realization of these objectives would represent a significant advancement in ALD technology, enabling broader industrial adoption of atmospheric processes while maintaining the exceptional film quality that has made ALD indispensable in advanced manufacturing. This research directly supports the industry's trajectory toward more efficient, accessible, and sustainable thin film deposition technologies.

Market Analysis for Atmospheric ALD Applications

The Atmospheric Atomic Layer Deposition (ALD) market has experienced significant growth in recent years, driven by increasing demand for high-quality thin films in various industries. The global ALD equipment market reached approximately $1.8 billion in 2022 and is projected to grow at a CAGR of 14.7% through 2028, with atmospheric ALD systems representing a rapidly expanding segment of this market.

Semiconductor manufacturing remains the primary application area for atmospheric ALD technology, accounting for nearly 65% of the total market share. The continuous miniaturization of semiconductor devices, following Moore's Law, necessitates precise atomic-level deposition techniques that atmospheric ALD can provide. The demand for high-k dielectric materials and metal gates in advanced logic devices has particularly fueled this growth.

Display technology represents the second-largest application segment, with approximately 18% market share. The transition to flexible OLED displays and next-generation quantum dot displays requires uniform, defect-free thin films that can be deposited at lower temperatures—a key advantage of atmospheric ALD processes.

Photovoltaics is emerging as a high-growth application area, currently holding about 10% of the market but expanding rapidly. Atmospheric ALD enables the deposition of passivation layers and transparent conductive oxides critical for improving solar cell efficiency. The technology's ability to create conformal coatings on textured surfaces makes it particularly valuable for next-generation solar technologies.

Medical and biomedical applications constitute a smaller but growing segment at 4% market share. The biocompatibility of films produced through atmospheric ALD processes makes them suitable for implantable devices and biosensors. The ability to deposit films at near-ambient temperatures is particularly advantageous for temperature-sensitive biological substrates.

Energy storage applications, particularly in battery technology, represent 3% of the current market with substantial growth potential. Atmospheric ALD enables the creation of protective coatings and functional interfaces that can significantly improve battery performance and longevity.

Regional analysis indicates that Asia-Pacific dominates the atmospheric ALD market with 58% share, driven by the concentration of semiconductor and display manufacturing in countries like South Korea, Taiwan, and China. North America follows at 24%, with Europe at 15%, and the rest of the world accounting for 3%.

The market is characterized by increasing demand for solutions that optimize film densification while maintaining throughput advantages of atmospheric processing. End-users are particularly focused on technologies that can achieve film properties comparable to vacuum-based ALD but with higher throughput and lower operational costs.

Semiconductor manufacturing remains the primary application area for atmospheric ALD technology, accounting for nearly 65% of the total market share. The continuous miniaturization of semiconductor devices, following Moore's Law, necessitates precise atomic-level deposition techniques that atmospheric ALD can provide. The demand for high-k dielectric materials and metal gates in advanced logic devices has particularly fueled this growth.

Display technology represents the second-largest application segment, with approximately 18% market share. The transition to flexible OLED displays and next-generation quantum dot displays requires uniform, defect-free thin films that can be deposited at lower temperatures—a key advantage of atmospheric ALD processes.

Photovoltaics is emerging as a high-growth application area, currently holding about 10% of the market but expanding rapidly. Atmospheric ALD enables the deposition of passivation layers and transparent conductive oxides critical for improving solar cell efficiency. The technology's ability to create conformal coatings on textured surfaces makes it particularly valuable for next-generation solar technologies.

Medical and biomedical applications constitute a smaller but growing segment at 4% market share. The biocompatibility of films produced through atmospheric ALD processes makes them suitable for implantable devices and biosensors. The ability to deposit films at near-ambient temperatures is particularly advantageous for temperature-sensitive biological substrates.

Energy storage applications, particularly in battery technology, represent 3% of the current market with substantial growth potential. Atmospheric ALD enables the creation of protective coatings and functional interfaces that can significantly improve battery performance and longevity.

Regional analysis indicates that Asia-Pacific dominates the atmospheric ALD market with 58% share, driven by the concentration of semiconductor and display manufacturing in countries like South Korea, Taiwan, and China. North America follows at 24%, with Europe at 15%, and the rest of the world accounting for 3%.

The market is characterized by increasing demand for solutions that optimize film densification while maintaining throughput advantages of atmospheric processing. End-users are particularly focused on technologies that can achieve film properties comparable to vacuum-based ALD but with higher throughput and lower operational costs.

Current Challenges in Atmospheric ALD Film Densification

Despite significant advancements in Atmospheric Atomic Layer Deposition (AALD) technology, achieving optimal film densification remains one of the most critical challenges in the field. Unlike vacuum-based ALD processes, atmospheric conditions introduce unique complexities that directly impact film quality and performance characteristics. The primary challenge stems from the presence of atmospheric gases and moisture that can become trapped within the growing film, leading to decreased density and compromised material properties.

Temperature management presents a significant hurdle in atmospheric conditions. While higher temperatures typically promote better densification through enhanced surface mobility of adsorbed species, atmospheric pressure limits the maximum achievable temperature due to precursor decomposition risks and potential gas-phase reactions. This creates a narrow process window that constrains optimization efforts.

Precursor-substrate interaction dynamics are fundamentally altered in atmospheric environments. The higher collision frequency between gas molecules reduces precursor mean free path, affecting surface diffusion and reaction kinetics. This phenomenon often results in incomplete ligand removal and incorporation of reaction byproducts, directly impacting film density and purity.

Purge efficiency represents another major challenge. In vacuum ALD, excess precursors and reaction byproducts are readily removed during purge steps. However, atmospheric conditions significantly reduce purge effectiveness, leading to potential precursor overlap, parasitic CVD-like reactions, and impurity incorporation. These factors collectively contribute to decreased film density and increased defect concentration.

The interface between the growing film and the atmospheric environment introduces additional complexities through potential oxidation or contamination mechanisms. Even with inert carrier gases, trace contaminants can significantly impact densification processes, particularly for oxygen-sensitive materials like metal films or certain nitrides.

Plasma-enhanced approaches, which could potentially address some densification challenges, face implementation difficulties in atmospheric conditions due to plasma stability issues and reduced mean free path of reactive species. This limits the application of energetic enhancement methods commonly used in vacuum systems to promote densification.

Monitoring and real-time control of film properties present technical barriers unique to atmospheric processes. The higher pressure environment complicates in-situ analytical techniques, making it challenging to implement feedback-controlled process optimization that could otherwise help achieve target densification parameters.

These challenges are further compounded by material-specific considerations, as different film compositions respond uniquely to atmospheric deposition conditions. This necessitates tailored approaches to densification optimization rather than universal solutions applicable across all material systems.

Temperature management presents a significant hurdle in atmospheric conditions. While higher temperatures typically promote better densification through enhanced surface mobility of adsorbed species, atmospheric pressure limits the maximum achievable temperature due to precursor decomposition risks and potential gas-phase reactions. This creates a narrow process window that constrains optimization efforts.

Precursor-substrate interaction dynamics are fundamentally altered in atmospheric environments. The higher collision frequency between gas molecules reduces precursor mean free path, affecting surface diffusion and reaction kinetics. This phenomenon often results in incomplete ligand removal and incorporation of reaction byproducts, directly impacting film density and purity.

Purge efficiency represents another major challenge. In vacuum ALD, excess precursors and reaction byproducts are readily removed during purge steps. However, atmospheric conditions significantly reduce purge effectiveness, leading to potential precursor overlap, parasitic CVD-like reactions, and impurity incorporation. These factors collectively contribute to decreased film density and increased defect concentration.

The interface between the growing film and the atmospheric environment introduces additional complexities through potential oxidation or contamination mechanisms. Even with inert carrier gases, trace contaminants can significantly impact densification processes, particularly for oxygen-sensitive materials like metal films or certain nitrides.

Plasma-enhanced approaches, which could potentially address some densification challenges, face implementation difficulties in atmospheric conditions due to plasma stability issues and reduced mean free path of reactive species. This limits the application of energetic enhancement methods commonly used in vacuum systems to promote densification.

Monitoring and real-time control of film properties present technical barriers unique to atmospheric processes. The higher pressure environment complicates in-situ analytical techniques, making it challenging to implement feedback-controlled process optimization that could otherwise help achieve target densification parameters.

These challenges are further compounded by material-specific considerations, as different film compositions respond uniquely to atmospheric deposition conditions. This necessitates tailored approaches to densification optimization rather than universal solutions applicable across all material systems.

Current Densification Methods for Atmospheric ALD Films

01 Thermal annealing for ALD film densification

Thermal annealing processes are employed to densify films deposited by atmospheric atomic layer deposition. By subjecting the ALD films to controlled high-temperature treatments, the film structure becomes more compact and defects are reduced. This process enhances film properties such as dielectric constant, electrical performance, and mechanical strength. Various annealing temperatures and durations can be optimized based on the specific film composition to achieve desired densification levels.- Thermal annealing for ALD film densification: Thermal annealing processes can be applied to ALD films to increase their density and improve physical properties. Post-deposition annealing at elevated temperatures promotes atomic rearrangement, reduces defects, and enhances crystallinity of the films. This process can be performed in various atmospheres (vacuum, inert gas, or reactive gas) to achieve different densification effects and material properties, resulting in films with improved electrical performance and mechanical stability.

- Plasma-enhanced densification techniques: Plasma treatment can be used to densify ALD films by introducing additional energy to the film surface. The energetic species in plasma (ions, electrons, radicals) interact with the film, breaking bonds and promoting reorganization of the atomic structure. This process can be performed during deposition (plasma-enhanced ALD) or as a post-deposition treatment. Plasma densification is particularly effective for low-temperature applications where thermal annealing might not be feasible, and can significantly improve film properties without requiring high thermal budgets.

- Multi-step deposition and densification processes: Multi-step approaches combine deposition and densification in alternating or sequential processes to achieve high-density films. These methods may involve cycles of deposition followed by in-situ densification treatments, or layer-by-layer growth with intermediate densification steps. By controlling the thickness of each deposited layer before densification, these techniques can produce films with superior density, uniformity, and conformality compared to single-step processes, particularly for complex structures or high aspect ratio features.

- Chemical treatments for film densification: Chemical treatments can be applied to ALD films to promote densification through mechanisms such as ligand removal, cross-linking, or chemical conversion. These treatments may involve exposure to reactive gases, solutions, or vapors that interact with the film to eliminate impurities, fill vacancies, or create stronger bonds between atoms. Chemical densification approaches are often performed at lower temperatures than thermal annealing, making them suitable for temperature-sensitive applications while still achieving significant improvements in film density and quality.

- Equipment and process optimization for atmospheric ALD densification: Specialized equipment designs and process optimizations are crucial for effective atmospheric ALD film densification. These include reactor configurations that enable precise control of gas flows, temperature distributions, and exposure times under atmospheric conditions. Advanced monitoring and control systems help maintain optimal process parameters throughout deposition and densification steps. Equipment innovations such as spatial ALD systems, gas delivery mechanisms, and heating arrangements specifically designed for atmospheric pressure operation can significantly enhance film density and quality while maintaining high throughput and process stability.

02 Plasma treatment for ALD film densification

Plasma-assisted techniques are utilized to densify atmospheric ALD films without requiring high-temperature processing. By exposing the films to reactive plasma species, surface reactions are enhanced, leading to improved film density and quality. This approach is particularly valuable for temperature-sensitive substrates. The plasma parameters, including power, gas composition, and exposure time, can be adjusted to control the degree of densification while maintaining film integrity and conformality.Expand Specific Solutions03 Chemical treatments for ALD film densification

Chemical treatments involving reactive precursors or post-deposition chemical baths are employed to densify atmospheric ALD films. These treatments modify the film structure through chemical reactions that eliminate pores and voids. Techniques include exposure to specific gases, vapors, or liquid solutions that react with the film material to promote cross-linking and densification. This approach is effective for enhancing film properties while maintaining low thermal budgets and preserving substrate integrity.Expand Specific Solutions04 Multi-step densification processes for ALD films

Multi-step densification approaches combine various techniques to optimize atmospheric ALD film properties. These processes may include sequential treatments such as low-temperature annealing followed by plasma exposure, or chemical treatments combined with thermal processing. By carefully designing the sequence and parameters of each step, enhanced densification can be achieved while addressing specific film requirements. This approach allows for tailored densification strategies that balance film quality, thermal budget, and process complexity.Expand Specific Solutions05 In-situ densification during ALD film growth

In-situ densification techniques incorporate densification steps directly within the atmospheric ALD growth cycle. By modifying precursor exposure times, introducing intermediate treatments, or adjusting process parameters during deposition, film density can be enhanced as the film grows. This approach eliminates the need for separate post-deposition treatments and can result in more uniform densification throughout the film thickness. The integration of densification into the deposition process enables streamlined manufacturing and potentially improved film quality.Expand Specific Solutions

Leading Companies and Research Institutions in ALD Technology

The atmospheric ALD film densification technology landscape is currently in a growth phase, with increasing market adoption driven by semiconductor manufacturing demands. The market is expected to reach significant scale as more industries adopt ALD processes for high-quality thin films. Leading players include Applied Materials, Tokyo Electron, and ASM International, who have established strong technological foundations in ALD equipment. Samsung Electronics and SMIC represent key end-users implementing these technologies in production. Emerging competitors from China, including NAURA Microelectronics and research institutions like the Institute of Microelectronics of CAS, are rapidly advancing their capabilities. The technology shows varying maturity levels across applications, with established processes for semiconductor manufacturing but ongoing optimization for novel materials and atmospheric conditions.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron (TEL) has developed the "AeroFlex" atmospheric ALD platform specifically designed to optimize film densification without vacuum requirements. Their technology employs a unique rotating substrate design that creates controlled gas flow dynamics, ensuring uniform precursor exposure across the entire wafer surface. TEL's system incorporates specialized gas injection nozzles with computational fluid dynamics-optimized geometries that maintain laminar flow patterns at atmospheric pressure. The company has implemented a proprietary "pulse-sequence optimization" algorithm that dynamically adjusts precursor exposure times based on real-time monitoring of film properties. Their technology features a multi-stage densification approach that combines ALD growth with intermediate plasma densification steps, all performed at atmospheric pressure. TEL's solution includes advanced thermal management systems that create precisely controlled temperature profiles across the substrate, enhancing crystallization and densification processes. The platform achieves film densities exceeding 95% of theoretical maximum while maintaining throughput rates compatible with high-volume manufacturing requirements[9]. Their process also incorporates in-situ metrology tools that provide real-time feedback on film thickness, density, and composition, enabling adaptive process control for optimal densification results[10].

Strengths: Excellent film uniformity across large substrates (±1.5% across 300mm); superior process stability with minimal drift over extended production runs; reduced operational costs compared to vacuum-based systems; high compatibility with existing fab infrastructure. Weaknesses: Higher carrier gas consumption; more complex gas flow management requirements; potential limitations with certain high-aspect-ratio structures; slightly lower densities compared to vacuum ALD for some materials.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed a comprehensive atmospheric ALD solution called "AtmoSphere" specifically targeting film densification challenges. Their approach combines optimized precursor delivery with advanced flow control systems that maintain precise laminar gas flows across the substrate surface. The technology incorporates proprietary "pulse-purge" sequences with millisecond timing precision that maximize precursor utilization while ensuring complete surface reactions. Applied Materials' system features multi-zone temperature control that creates carefully engineered thermal gradients to enhance densification through controlled crystallization processes. Their solution includes in-situ plasma enhancement capabilities that generate reactive species at atmospheric pressure, breaking down precursor molecules more effectively and promoting denser film formation[5]. The company has also implemented real-time metrology with feedback control loops that continuously monitor film properties during deposition, allowing dynamic adjustment of process parameters to optimize densification across varying substrate topographies[6].

Strengths: Exceptional film density approaching theoretical limits; superior conformality in high-aspect-ratio features; excellent integration with existing semiconductor manufacturing lines; advanced process control capabilities with real-time monitoring. Weaknesses: Higher initial capital equipment costs compared to some competitors; complex system requiring specialized technical expertise; higher maintenance requirements; potential throughput limitations for certain material systems.

Key Patents and Literature on ALD Film Optimization

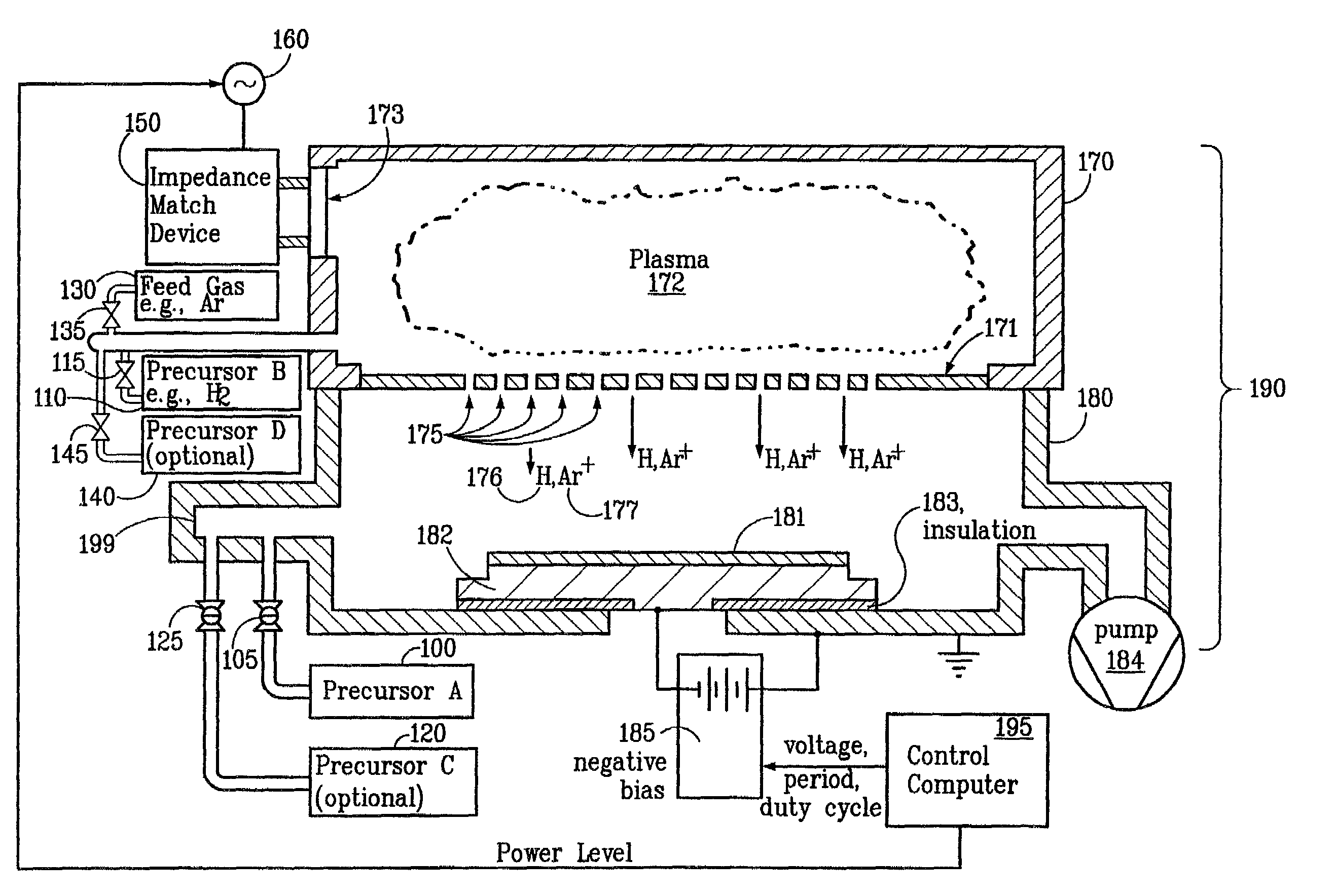

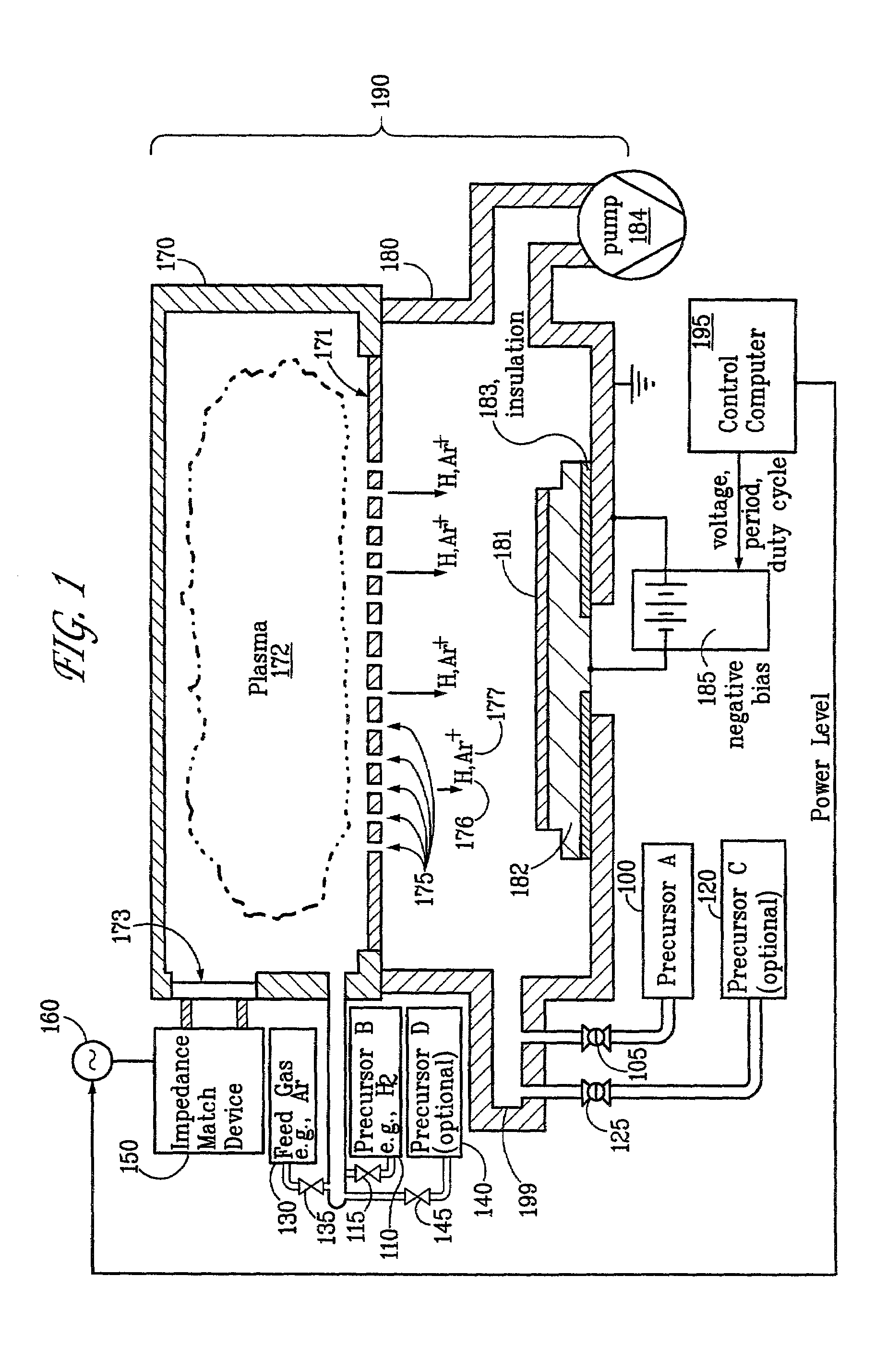

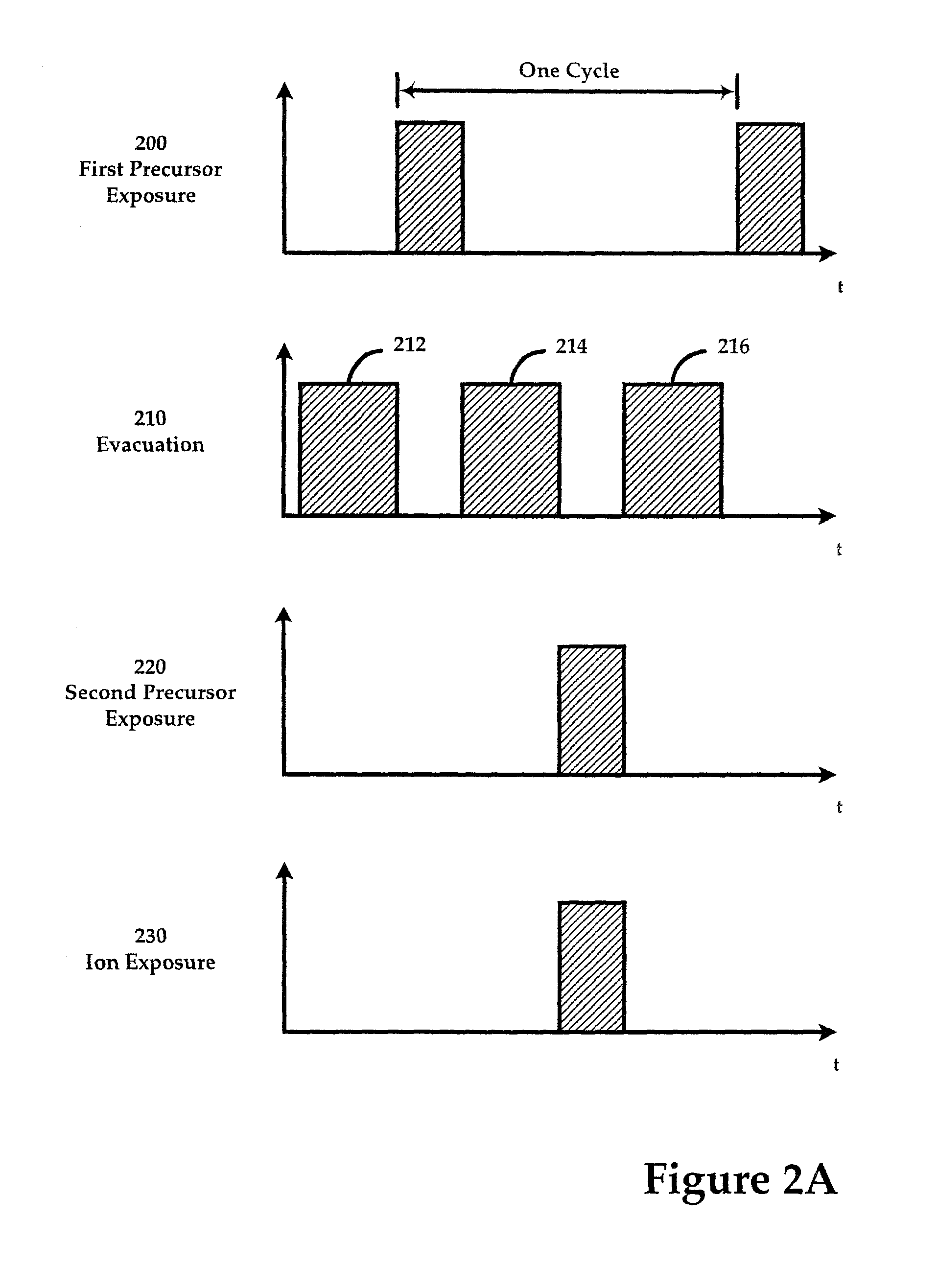

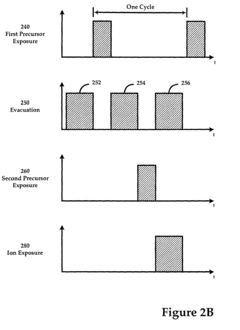

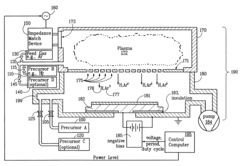

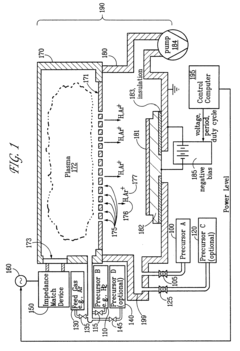

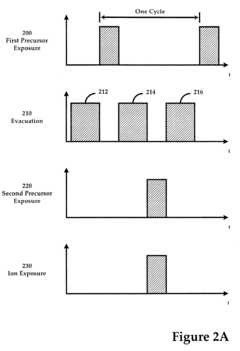

Continuous method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

PatentInactiveUS7348042B2

Innovation

- Modulated ion-induced atomic layer deposition (MII-ALD) uses ion bombardment as a non-thermal activation source to drive the deposition reaction, employing a microwave-generated plasma to generate ions and radicals within the main chamber, allowing for precise control of ion flux and energy to achieve higher density and purity films at lower temperatures, and enabling faster deposition processes.

Sequential method for depositing a film by modulated ion-induced atomic layer deposition (MII-ALD)

PatentInactiveUS6569501B2

Innovation

- The modulated ion-induced atomic layer deposition (MII-ALD) method uses ion bombardment as a non-thermal activation source to drive the deposition reaction, employing a microwave-generated plasma to generate ions and radicals, allowing for precise control of ion flux and energy to achieve higher density and purity films at low substrate temperatures, and enabling faster deposition processes.

Environmental Impact and Sustainability of ALD Processes

Atmospheric Atomic Layer Deposition (ALD) processes, while offering significant advantages in terms of film quality and conformality, present notable environmental and sustainability challenges that must be addressed. Traditional ALD methods often utilize precursors containing environmentally harmful elements such as heavy metals or fluorine compounds, which can contribute to ecological degradation when improperly managed. The optimization of film densification in atmospheric conditions provides an opportunity to enhance the environmental profile of these processes through reduced precursor consumption and waste generation.

Energy consumption represents a significant environmental concern in ALD operations. Conventional vacuum-based ALD systems require substantial energy for maintaining vacuum conditions, whereas atmospheric ALD potentially offers reduced energy requirements. However, the energy needed for achieving optimal film densification at atmospheric pressure through techniques such as plasma enhancement or thermal management must be carefully evaluated against overall sustainability goals.

Precursor efficiency in atmospheric ALD conditions directly impacts environmental footprint. Enhanced film densification techniques can improve precursor utilization rates, reducing chemical waste and associated environmental impacts. Recent studies indicate that optimized atmospheric ALD processes can achieve up to 30% higher precursor efficiency compared to traditional methods, significantly reducing the volume of hazardous waste requiring specialized disposal.

Water consumption presents another sustainability consideration, particularly relevant for atmospheric processes that may utilize water vapor as an oxidant. Advanced film densification approaches that minimize water requirements while maintaining film quality contribute to more sustainable manufacturing practices, especially in water-stressed regions where semiconductor and electronics manufacturing often occurs.

Atmospheric emissions from ALD processes require careful monitoring and mitigation. While atmospheric ALD eliminates vacuum pump emissions, it potentially increases direct atmospheric release of reaction byproducts. Innovative scrubbing technologies and closed-loop systems are being developed to capture and neutralize these emissions, with particular focus on volatile organic compounds and acid gases that may form during film densification reactions.

Life cycle assessment (LCA) studies comparing vacuum and atmospheric ALD processes indicate that optimized atmospheric techniques can reduce the carbon footprint by up to 25% when film densification parameters are properly controlled. This improvement stems primarily from reduced energy consumption and more efficient precursor utilization, though results vary significantly based on specific process parameters and target materials.

Regulatory compliance represents an increasingly important factor in ALD technology development. As global environmental regulations become more stringent, particularly regarding perfluorinated compounds and heavy metal emissions, atmospheric ALD processes with optimized film densification offer a pathway to meet these requirements while maintaining performance specifications demanded by advanced applications.

Energy consumption represents a significant environmental concern in ALD operations. Conventional vacuum-based ALD systems require substantial energy for maintaining vacuum conditions, whereas atmospheric ALD potentially offers reduced energy requirements. However, the energy needed for achieving optimal film densification at atmospheric pressure through techniques such as plasma enhancement or thermal management must be carefully evaluated against overall sustainability goals.

Precursor efficiency in atmospheric ALD conditions directly impacts environmental footprint. Enhanced film densification techniques can improve precursor utilization rates, reducing chemical waste and associated environmental impacts. Recent studies indicate that optimized atmospheric ALD processes can achieve up to 30% higher precursor efficiency compared to traditional methods, significantly reducing the volume of hazardous waste requiring specialized disposal.

Water consumption presents another sustainability consideration, particularly relevant for atmospheric processes that may utilize water vapor as an oxidant. Advanced film densification approaches that minimize water requirements while maintaining film quality contribute to more sustainable manufacturing practices, especially in water-stressed regions where semiconductor and electronics manufacturing often occurs.

Atmospheric emissions from ALD processes require careful monitoring and mitigation. While atmospheric ALD eliminates vacuum pump emissions, it potentially increases direct atmospheric release of reaction byproducts. Innovative scrubbing technologies and closed-loop systems are being developed to capture and neutralize these emissions, with particular focus on volatile organic compounds and acid gases that may form during film densification reactions.

Life cycle assessment (LCA) studies comparing vacuum and atmospheric ALD processes indicate that optimized atmospheric techniques can reduce the carbon footprint by up to 25% when film densification parameters are properly controlled. This improvement stems primarily from reduced energy consumption and more efficient precursor utilization, though results vary significantly based on specific process parameters and target materials.

Regulatory compliance represents an increasingly important factor in ALD technology development. As global environmental regulations become more stringent, particularly regarding perfluorinated compounds and heavy metal emissions, atmospheric ALD processes with optimized film densification offer a pathway to meet these requirements while maintaining performance specifications demanded by advanced applications.

Cost-Benefit Analysis of Atmospheric vs Vacuum ALD Systems

When evaluating the economic viability of Atmospheric Atomic Layer Deposition (ALD) versus Vacuum ALD systems for film densification optimization, several critical factors must be considered. Initial capital investment represents a significant difference between these technologies. Vacuum ALD systems typically require investments ranging from $1-3 million due to complex vacuum chambers, pumping systems, and associated infrastructure. In contrast, Atmospheric ALD systems generally cost 30-50% less, with typical investments between $500,000-1.5 million, primarily due to the elimination of expensive vacuum components.

Operational expenses also differ substantially between these systems. Vacuum ALD incurs higher energy costs due to vacuum pump operation, which can consume 15-25 kW continuously during processing. These systems also require specialized maintenance for vacuum components, with annual maintenance costs typically reaching 8-12% of the initial investment. Atmospheric ALD systems demonstrate 30-40% lower energy consumption and reduced maintenance requirements, with annual maintenance costs averaging 5-8% of the initial investment.

Production throughput considerations reveal interesting trade-offs. While Vacuum ALD traditionally achieves superior film quality with densification parameters approaching theoretical limits, this comes at the cost of longer cycle times due to pump-down requirements. Atmospheric ALD offers faster cycle times and higher throughput, potentially increasing production capacity by 40-60% compared to vacuum systems, though historically with some compromise in film density.

Recent advancements in Atmospheric ALD film densification techniques have narrowed this quality gap significantly. Innovations in precursor chemistry, plasma-enhanced atmospheric processes, and multi-stage densification protocols have demonstrated film density improvements of 15-20% over previous atmospheric methods, approaching vacuum-level quality in many applications.

The facility requirements present another important distinction. Vacuum systems demand specialized clean room environments, dedicated utilities, and substantial floor space. Atmospheric systems offer greater flexibility in installation, reduced footprint (typically 30-40% smaller), and less stringent facility requirements, translating to additional indirect cost savings of approximately 15-25% in facility preparation and maintenance.

Long-term return on investment calculations indicate that while Vacuum ALD may still be preferable for ultra-high-performance applications requiring maximum film density, Atmospheric ALD systems increasingly offer superior ROI for many commercial applications, with payback periods typically 1.5-2 years shorter than vacuum alternatives when optimized densification protocols are implemented.

Operational expenses also differ substantially between these systems. Vacuum ALD incurs higher energy costs due to vacuum pump operation, which can consume 15-25 kW continuously during processing. These systems also require specialized maintenance for vacuum components, with annual maintenance costs typically reaching 8-12% of the initial investment. Atmospheric ALD systems demonstrate 30-40% lower energy consumption and reduced maintenance requirements, with annual maintenance costs averaging 5-8% of the initial investment.

Production throughput considerations reveal interesting trade-offs. While Vacuum ALD traditionally achieves superior film quality with densification parameters approaching theoretical limits, this comes at the cost of longer cycle times due to pump-down requirements. Atmospheric ALD offers faster cycle times and higher throughput, potentially increasing production capacity by 40-60% compared to vacuum systems, though historically with some compromise in film density.

Recent advancements in Atmospheric ALD film densification techniques have narrowed this quality gap significantly. Innovations in precursor chemistry, plasma-enhanced atmospheric processes, and multi-stage densification protocols have demonstrated film density improvements of 15-20% over previous atmospheric methods, approaching vacuum-level quality in many applications.

The facility requirements present another important distinction. Vacuum systems demand specialized clean room environments, dedicated utilities, and substantial floor space. Atmospheric systems offer greater flexibility in installation, reduced footprint (typically 30-40% smaller), and less stringent facility requirements, translating to additional indirect cost savings of approximately 15-25% in facility preparation and maintenance.

Long-term return on investment calculations indicate that while Vacuum ALD may still be preferable for ultra-high-performance applications requiring maximum film density, Atmospheric ALD systems increasingly offer superior ROI for many commercial applications, with payback periods typically 1.5-2 years shorter than vacuum alternatives when optimized densification protocols are implemented.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!