APALD For Anti-Reflective Coatings On Glass And Plastics

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

APALD Anti-Reflective Coating Technology Background and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, with Atomic Precision ALD (APALD) representing the latest advancement in this field. The evolution of ALD technology has been driven by the increasing demand for precise nanoscale coatings across various industries, particularly in optics and electronics. APALD specifically addresses the need for ultra-thin, uniform anti-reflective coatings on glass and plastic substrates, which has become crucial for high-performance optical applications.

The development trajectory of anti-reflective coating technologies has moved from traditional vacuum deposition methods to more sophisticated approaches like APALD, which offers atomic-level precision and superior conformality. This progression has been necessitated by the growing requirements for higher optical performance, durability, and cost-effectiveness in industries ranging from consumer electronics to advanced optics.

APALD for anti-reflective coatings represents a convergence of several technological trends, including nanoscale material engineering, precision deposition techniques, and surface chemistry advancements. The technology enables the creation of multi-layer coatings with precisely controlled thickness and composition, allowing for optimized light transmission across specific wavelength ranges.

The primary technical objectives of APALD anti-reflective coating development include achieving ultra-low reflectance (less than 0.5%) across broad wavelength ranges, enhancing durability against environmental factors, reducing production costs, and enabling application on temperature-sensitive substrates like plastics. Additionally, there is a focus on developing environmentally friendly processes that minimize the use of hazardous materials and reduce energy consumption.

Recent research has demonstrated that APALD can create anti-reflective coatings with reflectance values approaching the theoretical minimum, particularly when utilizing gradient-index designs that smoothly transition between the refractive indices of air and the substrate. This capability has opened new possibilities for high-performance optical components in applications such as smartphone displays, camera lenses, solar panels, and augmented reality devices.

The technology aims to overcome several persistent challenges in anti-reflective coating production, including adhesion issues on plastic substrates, coating durability, process scalability, and cost-effectiveness for mass production. APALD's precise control over film growth mechanisms offers promising pathways to address these challenges through tailored interface engineering and novel material combinations.

Looking forward, the technical trajectory for APALD anti-reflective coatings is focused on expanding material compatibility, increasing deposition rates while maintaining precision, and developing specialized formulations for emerging applications in flexible electronics, automotive displays, and advanced photovoltaics. The ultimate goal is to establish APALD as the standard technology for next-generation optical coatings that combine superior performance with economic viability.

The development trajectory of anti-reflective coating technologies has moved from traditional vacuum deposition methods to more sophisticated approaches like APALD, which offers atomic-level precision and superior conformality. This progression has been necessitated by the growing requirements for higher optical performance, durability, and cost-effectiveness in industries ranging from consumer electronics to advanced optics.

APALD for anti-reflective coatings represents a convergence of several technological trends, including nanoscale material engineering, precision deposition techniques, and surface chemistry advancements. The technology enables the creation of multi-layer coatings with precisely controlled thickness and composition, allowing for optimized light transmission across specific wavelength ranges.

The primary technical objectives of APALD anti-reflective coating development include achieving ultra-low reflectance (less than 0.5%) across broad wavelength ranges, enhancing durability against environmental factors, reducing production costs, and enabling application on temperature-sensitive substrates like plastics. Additionally, there is a focus on developing environmentally friendly processes that minimize the use of hazardous materials and reduce energy consumption.

Recent research has demonstrated that APALD can create anti-reflective coatings with reflectance values approaching the theoretical minimum, particularly when utilizing gradient-index designs that smoothly transition between the refractive indices of air and the substrate. This capability has opened new possibilities for high-performance optical components in applications such as smartphone displays, camera lenses, solar panels, and augmented reality devices.

The technology aims to overcome several persistent challenges in anti-reflective coating production, including adhesion issues on plastic substrates, coating durability, process scalability, and cost-effectiveness for mass production. APALD's precise control over film growth mechanisms offers promising pathways to address these challenges through tailored interface engineering and novel material combinations.

Looking forward, the technical trajectory for APALD anti-reflective coatings is focused on expanding material compatibility, increasing deposition rates while maintaining precision, and developing specialized formulations for emerging applications in flexible electronics, automotive displays, and advanced photovoltaics. The ultimate goal is to establish APALD as the standard technology for next-generation optical coatings that combine superior performance with economic viability.

Market Analysis for APALD Anti-Reflective Solutions

The global market for anti-reflective coatings has been experiencing significant growth, driven by increasing demand across multiple industries including electronics, eyewear, solar panels, automotive displays, and architectural glass. The APALD (Atomic Layer Deposition with Plasma Enhancement) technology represents a cutting-edge approach to creating high-performance anti-reflective coatings that offers superior optical properties compared to traditional coating methods.

Current market valuations place the global anti-reflective coating market at approximately 4.8 billion USD in 2023, with projections indicating growth to reach 7.2 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.5%. Within this broader market, APALD-based solutions are positioned as premium offerings, currently occupying a specialized segment estimated at 380 million USD, but showing accelerated growth potential.

The eyewear segment remains the largest application area for anti-reflective coatings, accounting for roughly 32% of the total market share. However, the electronics display segment is demonstrating the fastest growth rate at 10.2% annually, particularly driven by increasing adoption of high-resolution displays in consumer electronics and automotive applications where glare reduction is critical for user experience and safety.

Regionally, Asia-Pacific dominates the market with approximately 42% share, attributed to the concentration of electronics manufacturing and growing consumer markets in China, Japan, South Korea, and Taiwan. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-value applications such as precision optics and specialized industrial equipment.

Consumer demand trends indicate growing preference for multi-functional coatings that combine anti-reflective properties with additional benefits such as scratch resistance, hydrophobicity, and anti-fingerprint capabilities. This trend aligns perfectly with APALD technology's ability to create multi-layer, multi-functional thin films with precise thickness control.

Price sensitivity varies significantly by application segment. While consumer eyewear remains highly price-competitive, high-tech applications in aerospace, defense, and scientific instrumentation demonstrate willingness to pay premium prices for superior optical performance, creating favorable market conditions for advanced APALD solutions.

Market penetration challenges include the higher initial capital investment required for APALD equipment compared to conventional coating technologies, and the need for specialized technical expertise. However, the long-term value proposition centered on superior coating quality, reduced material waste, and enhanced product performance is gradually overcoming these adoption barriers.

Current market valuations place the global anti-reflective coating market at approximately 4.8 billion USD in 2023, with projections indicating growth to reach 7.2 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.5%. Within this broader market, APALD-based solutions are positioned as premium offerings, currently occupying a specialized segment estimated at 380 million USD, but showing accelerated growth potential.

The eyewear segment remains the largest application area for anti-reflective coatings, accounting for roughly 32% of the total market share. However, the electronics display segment is demonstrating the fastest growth rate at 10.2% annually, particularly driven by increasing adoption of high-resolution displays in consumer electronics and automotive applications where glare reduction is critical for user experience and safety.

Regionally, Asia-Pacific dominates the market with approximately 42% share, attributed to the concentration of electronics manufacturing and growing consumer markets in China, Japan, South Korea, and Taiwan. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-value applications such as precision optics and specialized industrial equipment.

Consumer demand trends indicate growing preference for multi-functional coatings that combine anti-reflective properties with additional benefits such as scratch resistance, hydrophobicity, and anti-fingerprint capabilities. This trend aligns perfectly with APALD technology's ability to create multi-layer, multi-functional thin films with precise thickness control.

Price sensitivity varies significantly by application segment. While consumer eyewear remains highly price-competitive, high-tech applications in aerospace, defense, and scientific instrumentation demonstrate willingness to pay premium prices for superior optical performance, creating favorable market conditions for advanced APALD solutions.

Market penetration challenges include the higher initial capital investment required for APALD equipment compared to conventional coating technologies, and the need for specialized technical expertise. However, the long-term value proposition centered on superior coating quality, reduced material waste, and enhanced product performance is gradually overcoming these adoption barriers.

Global APALD Technology Status and Challenges

Atomic Layer Deposition (ALD) technology has evolved significantly over the past decade, with Atmospheric Pressure Atomic Layer Deposition (APALD) emerging as a promising variant for industrial applications. Currently, APALD technology for anti-reflective coatings is at varying stages of development across different regions globally, with notable advancements in North America, Europe, and East Asia.

In North America, research institutions and companies like Applied Materials and Lam Research have made substantial progress in APALD technology development. These entities have successfully demonstrated the feasibility of creating uniform anti-reflective coatings on both glass and plastic substrates at atmospheric pressure, eliminating the need for complex vacuum systems.

European research centers, particularly in Finland, Germany, and the Netherlands, have focused on enhancing the scalability of APALD processes. Companies like ASML and Oxford Instruments have invested significantly in developing equipment capable of high-throughput APALD processing for large-area substrates, addressing one of the key challenges in commercial implementation.

East Asian countries, led by South Korea and Japan, have made remarkable advancements in precursor chemistry for APALD processes. Samsung and Tokyo Electron have pioneered the development of novel precursors that enable faster deposition rates while maintaining the exceptional conformality characteristic of ALD processes.

Despite these advancements, several technical challenges persist in the global APALD landscape. The primary challenge remains achieving commercially viable deposition rates without compromising film quality. Current APALD processes for anti-reflective coatings typically operate at rates of 1-2 nm/minute, which is significantly slower than conventional coating methods.

Another significant challenge is the development of suitable precursors that can react efficiently at atmospheric pressure while producing minimal by-products. The precursor chemistry must be optimized to ensure complete surface reactions without gas-phase reactions that could lead to particle formation and film defects.

Temperature sensitivity of plastic substrates presents another hurdle, as many high-performance APALD processes require temperatures that exceed the thermal stability limits of common plastics. Researchers are exploring plasma-enhanced APALD techniques to lower process temperatures, but these approaches introduce additional complexity to the equipment design.

Uniformity across large areas remains problematic, particularly for architectural glass applications where coating thickness variations must be kept below 1% across several square meters. Current APALD technologies struggle to maintain this level of uniformity without sophisticated gas flow management systems.

The geographical distribution of APALD technology development shows concentration in technology hubs with strong semiconductor industry presence, creating potential barriers to global adoption in regions with less developed technical infrastructure.

In North America, research institutions and companies like Applied Materials and Lam Research have made substantial progress in APALD technology development. These entities have successfully demonstrated the feasibility of creating uniform anti-reflective coatings on both glass and plastic substrates at atmospheric pressure, eliminating the need for complex vacuum systems.

European research centers, particularly in Finland, Germany, and the Netherlands, have focused on enhancing the scalability of APALD processes. Companies like ASML and Oxford Instruments have invested significantly in developing equipment capable of high-throughput APALD processing for large-area substrates, addressing one of the key challenges in commercial implementation.

East Asian countries, led by South Korea and Japan, have made remarkable advancements in precursor chemistry for APALD processes. Samsung and Tokyo Electron have pioneered the development of novel precursors that enable faster deposition rates while maintaining the exceptional conformality characteristic of ALD processes.

Despite these advancements, several technical challenges persist in the global APALD landscape. The primary challenge remains achieving commercially viable deposition rates without compromising film quality. Current APALD processes for anti-reflective coatings typically operate at rates of 1-2 nm/minute, which is significantly slower than conventional coating methods.

Another significant challenge is the development of suitable precursors that can react efficiently at atmospheric pressure while producing minimal by-products. The precursor chemistry must be optimized to ensure complete surface reactions without gas-phase reactions that could lead to particle formation and film defects.

Temperature sensitivity of plastic substrates presents another hurdle, as many high-performance APALD processes require temperatures that exceed the thermal stability limits of common plastics. Researchers are exploring plasma-enhanced APALD techniques to lower process temperatures, but these approaches introduce additional complexity to the equipment design.

Uniformity across large areas remains problematic, particularly for architectural glass applications where coating thickness variations must be kept below 1% across several square meters. Current APALD technologies struggle to maintain this level of uniformity without sophisticated gas flow management systems.

The geographical distribution of APALD technology development shows concentration in technology hubs with strong semiconductor industry presence, creating potential barriers to global adoption in regions with less developed technical infrastructure.

Current APALD Implementation on Glass and Plastics

01 APALD techniques for anti-reflective coatings

Atmospheric Pressure Atomic Layer Deposition (APALD) can be used to create anti-reflective coatings with precise thickness control. This technique allows for the deposition of thin films at atmospheric pressure, eliminating the need for vacuum equipment and reducing manufacturing costs. The resulting anti-reflective coatings have excellent uniformity and conformality, even on complex surface geometries.- APALD techniques for anti-reflective coatings: Atmospheric Pressure Atomic Layer Deposition (APALD) can be used to create high-quality anti-reflective coatings. This technique allows for precise control over film thickness and composition at atmospheric pressure, eliminating the need for vacuum systems. The resulting anti-reflective layers have excellent uniformity and conformality, even on complex surface geometries, leading to improved optical performance in various applications.

- Multi-layer anti-reflective structures using APALD: Multi-layer anti-reflective structures can be fabricated using APALD to achieve enhanced optical properties. By depositing alternating layers of materials with different refractive indices, broadband anti-reflective properties can be achieved. These multi-layer structures can be precisely controlled at the nanometer scale, allowing for optimization of the optical response across specific wavelength ranges. The atmospheric pressure process enables cost-effective production of these sophisticated optical structures.

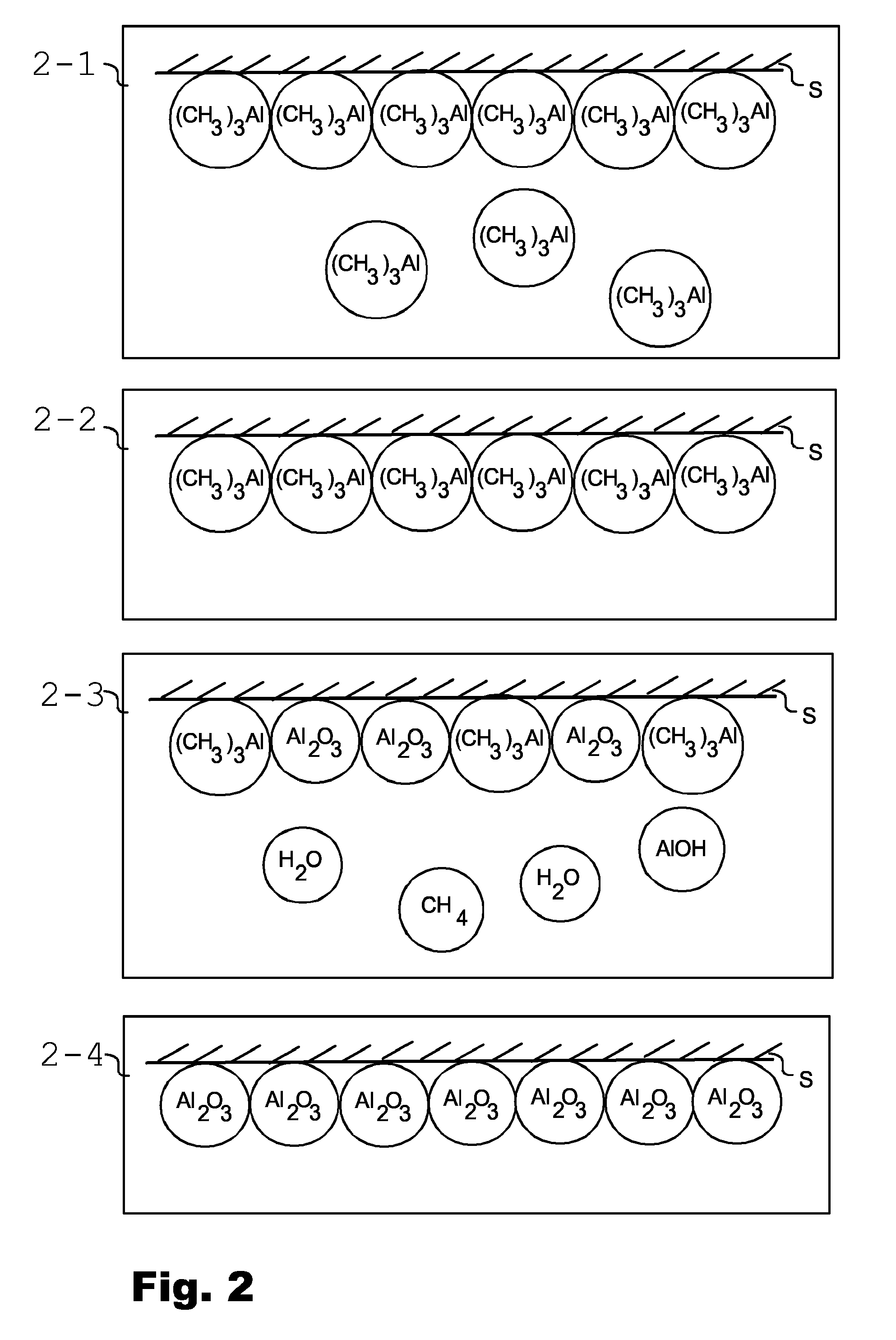

- Material selection for APALD anti-reflective coatings: Various materials can be deposited via APALD to create effective anti-reflective coatings. Metal oxides such as Al2O3, TiO2, SiO2, and ZnO are commonly used due to their suitable optical properties and compatibility with the APALD process. Nitrides and oxynitrides can also be deposited to achieve specific refractive indices. The selection of materials and their precise thickness control enables customization of the anti-reflective properties for specific applications, including solar cells, displays, and optical lenses.

- Process optimization for APALD anti-reflective coatings: Optimizing the APALD process parameters is crucial for producing high-quality anti-reflective coatings. Parameters such as precursor selection, pulse duration, purge time, substrate temperature, and gas flow rates significantly impact the coating properties. Advanced process control techniques can be implemented to ensure consistent film quality and optical performance. Real-time monitoring systems can be integrated to maintain precise thickness control during the deposition process.

- Applications of APALD anti-reflective coatings: APALD anti-reflective coatings find applications in various fields requiring enhanced optical performance. In photovoltaics, these coatings increase light absorption and improve solar cell efficiency. For display technologies, they reduce glare and improve visibility. In optical instruments, they minimize reflection losses and enhance image quality. The APALD process allows for conformal coating on complex 3D structures, enabling anti-reflective properties on curved surfaces and textured substrates that are challenging for conventional deposition methods.

02 Multi-layer anti-reflective structures using APALD

Multi-layer anti-reflective structures can be fabricated using APALD to achieve enhanced optical performance. By depositing alternating layers of materials with different refractive indices, broadband anti-reflective properties can be achieved. The precise thickness control offered by APALD ensures optimal optical interference effects, resulting in superior anti-reflective performance across a wide range of wavelengths.Expand Specific Solutions03 Material selection for APALD anti-reflective coatings

Various materials can be deposited using APALD to create effective anti-reflective coatings. Metal oxides such as Al2O3, TiO2, and SiO2 are commonly used due to their suitable optical properties and compatibility with the APALD process. The selection of materials with appropriate refractive indices is crucial for achieving the desired anti-reflective effect, and APALD allows for precise control over the composition and properties of these materials.Expand Specific Solutions04 Process optimization for APALD anti-reflective coatings

Optimizing the APALD process parameters is essential for producing high-quality anti-reflective coatings. Factors such as precursor selection, pulse and purge times, substrate temperature, and gas flow rates significantly impact the deposition rate, film quality, and optical properties. Advanced process control strategies can be implemented to ensure consistent coating performance and maximize throughput in manufacturing environments.Expand Specific Solutions05 Applications of APALD anti-reflective coatings

APALD anti-reflective coatings find applications in various fields including photovoltaics, optoelectronics, and display technologies. In solar cells, these coatings enhance light absorption and improve energy conversion efficiency. In optical devices, they reduce unwanted reflections and improve image quality. The ability of APALD to coat complex 3D structures makes it particularly valuable for advanced optical components and integrated photonic devices.Expand Specific Solutions

Key Industry Players in APALD Coating Market

The anti-reflective coating market using Atomic Layer Deposition (APALD) technology is in a growth phase, with increasing applications across glass and plastic substrates. The global market is expanding due to rising demand in electronics, optics, and automotive sectors, estimated to reach several billion dollars by 2025. Technologically, APALD offers superior thin film uniformity and precision compared to traditional coating methods. Leading players include Beneq Group Oy, which specializes in ALD equipment and thin film services; Corning, Inc., leveraging its glass expertise; 3M Innovative Properties Co., with broad coating technology applications; and AGC, Inc., focusing on architectural and automotive glass solutions. Other significant competitors include SCHOTT AG, DuPont, and First Solar, each bringing specialized expertise to different market segments within the anti-reflective coating ecosystem.

3M Innovative Properties Co.

Technical Solution: 3M has developed a multi-component APALD system for anti-reflective coatings that leverages their expertise in thin film technology and materials science. Their approach utilizes a spatially separated reaction zone configuration where substrates move through discrete precursor and reactant areas, enabling continuous processing without cross-contamination. The technology incorporates proprietary organosilicon and metal-organic precursors designed specifically for atmospheric pressure conditions, achieving deposition rates up to 5nm/minute while maintaining sub-nanometer thickness control. 3M's APALD process creates gradient-index AR structures by progressively varying the composition of mixed oxide layers (typically combinations of SiO2, Al2O3, and ZrO2), resulting in reflectance values below 0.3% across a wide angular range. For plastic substrates, 3M employs a specialized surface activation step using their plasma technology prior to APALD coating, enhancing adhesion and durability. The company has integrated this technology with their roll-to-roll manufacturing capabilities, allowing for high-throughput production of flexible optical films with anti-reflective properties for displays, photovoltaics, and automotive applications.

Strengths: Exceptional materials expertise and established manufacturing infrastructure for scaling production. Their diversified market presence provides multiple commercialization pathways across consumer, industrial, and specialty applications. Weaknesses: The technology may require more complex process control systems compared to vacuum-based approaches, potentially increasing operational complexity and maintenance requirements.

Corning, Inc.

Technical Solution: Corning has developed a hybrid APALD approach for anti-reflective coatings that combines atmospheric pressure atomic layer deposition with their proprietary fusion draw glass manufacturing process. Their technology utilizes a specialized precursor delivery system that creates sequential, self-limiting surface reactions directly in the glass cooling zone. This integration allows for in-line AR coating application during glass production, significantly reducing manufacturing steps and handling. Corning's APALD process deposits precisely engineered multilayer stacks of SiO2 and high-index materials (including proprietary compositions) to create broadband anti-reflective properties with reflectance below 0.4% across the visible spectrum. The company has optimized precursor chemistries that enable rapid deposition rates while maintaining the atomic-level precision characteristic of ALD. For plastic substrates, Corning employs a modified low-temperature APALD process with plasma enhancement to ensure adhesion and film quality without thermal damage to the substrate. This technology has been implemented in their Gorilla® Glass products for displays and is being extended to architectural and automotive applications.

Strengths: Vertical integration with glass manufacturing provides unique capability for high-volume, cost-effective production. Their established position in display and consumer electronics markets offers ready commercialization pathways. Weaknesses: The technology may be more optimized for glass than for plastic substrates, potentially limiting performance on polymeric materials that require different surface preparation and processing conditions.

Critical Patents and Technical Literature in APALD Coatings

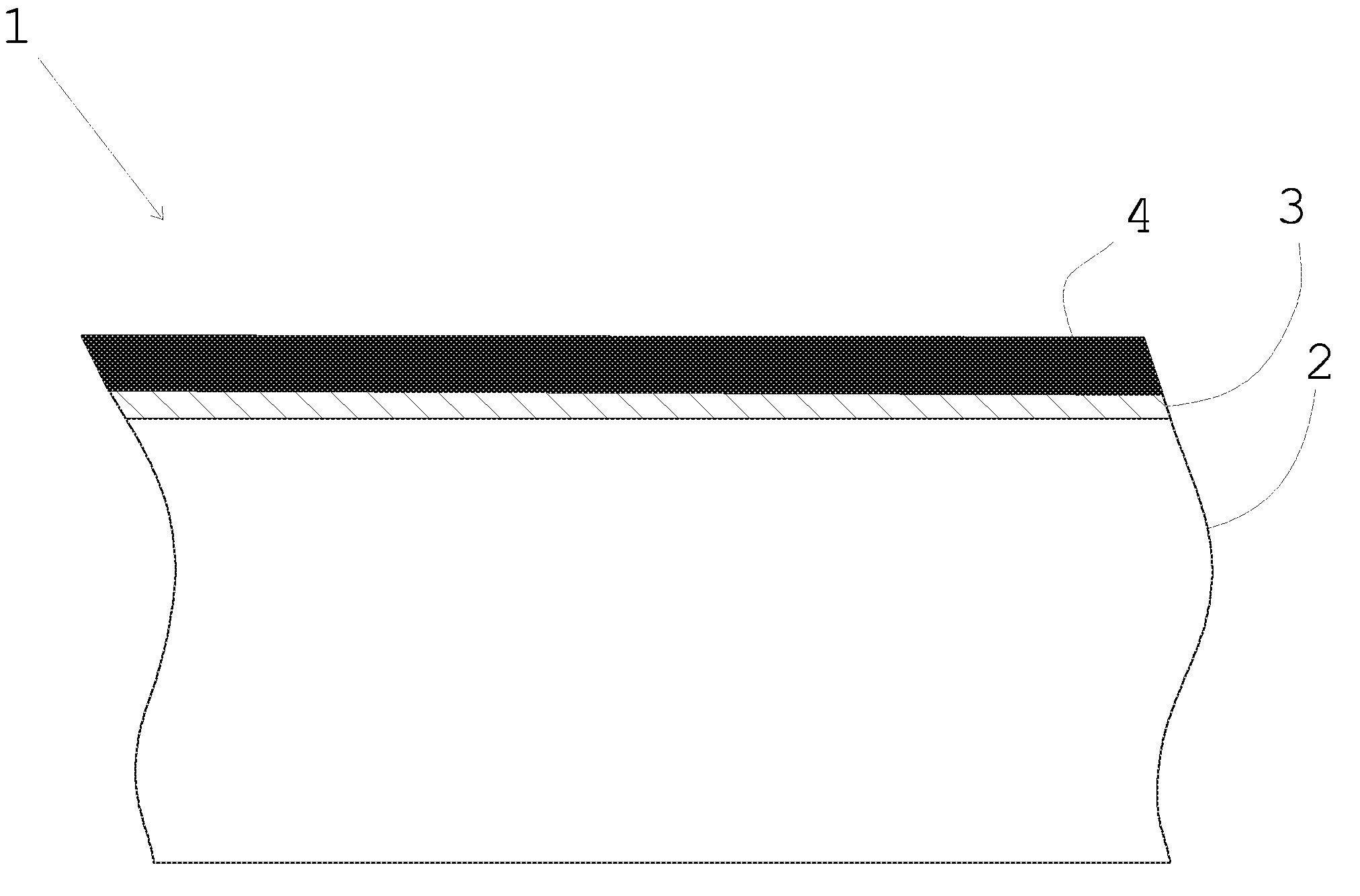

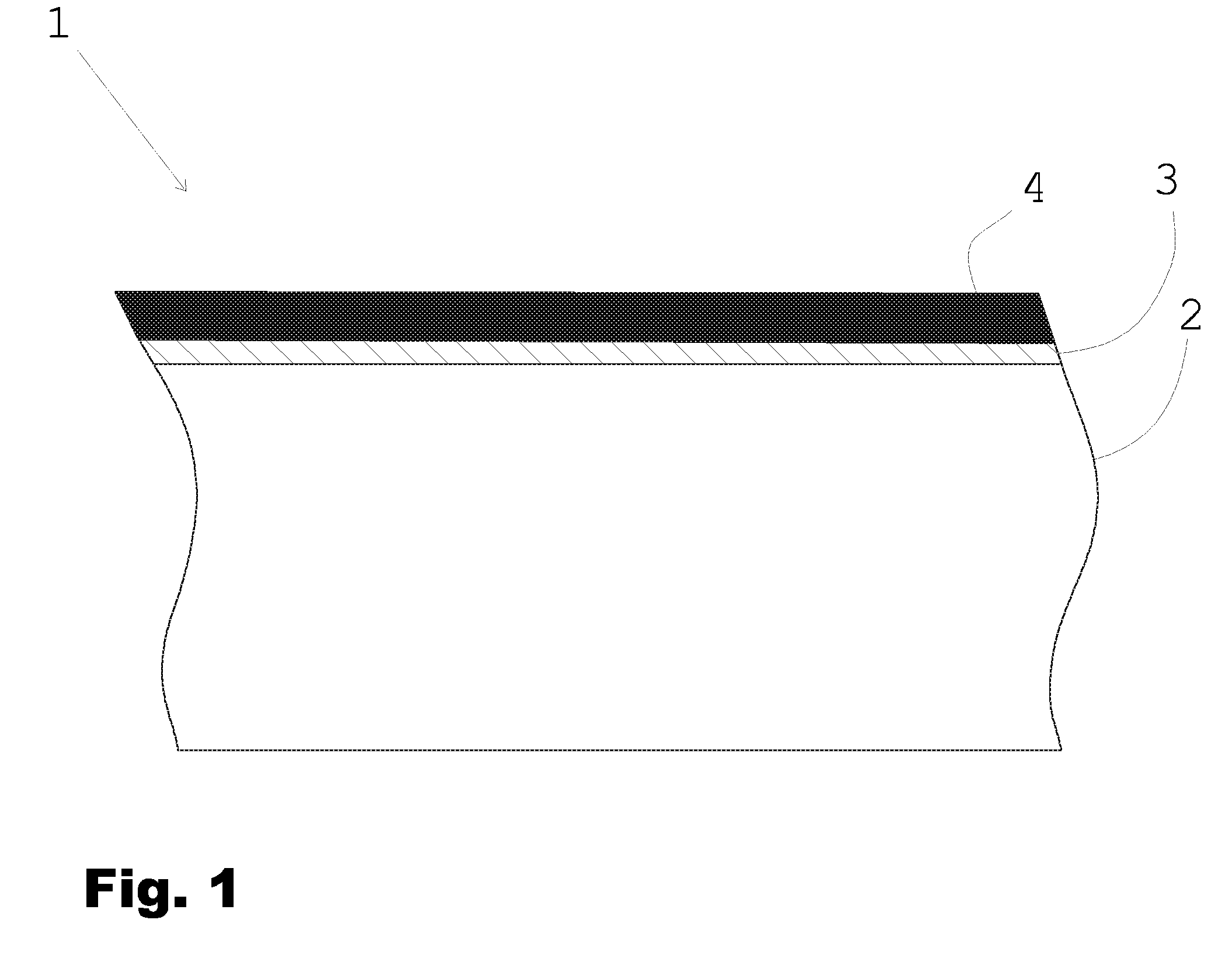

Glass product and a method for manufacturing a glass product

PatentInactiveUS20110003125A1

Innovation

- The use of Atomic Layer Deposition (ALD) to create a conformal and uniformly thick metal oxide passivation layer directly on the reflective metal layer, ensuring strong chemical bonding and minimizing thickness variations, thereby enhancing protection against corrosion and maintaining optical performance.

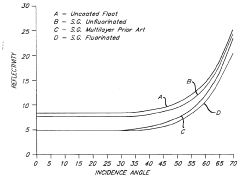

Anti-reflective coatings comprising light metal fluorides

PatentInactiveUS5208101A

Innovation

- A sol-gel process is used to form a coating with a concentration gradient of light metal fluorides on the substrate, where a reactive composition of light metal oxide precursors, solvents, and water is applied and then densified, followed by exposure to a fluorine atmosphere to replace oxygen atoms with fluoride atoms, creating a coating with varying refractive indices that maintains low reflectivity even at large angles and across the visible spectrum.

Environmental Impact and Sustainability of APALD Processes

The environmental impact of Atmospheric Pressure Atomic Layer Deposition (APALD) processes for anti-reflective coatings represents a critical consideration in the broader adoption of this technology. Traditional coating methods often involve significant use of solvents and generate substantial waste, whereas APALD offers notable improvements in resource efficiency. The process utilizes precursor chemicals more effectively, with reaction efficiency rates typically exceeding 90% compared to conventional methods that may achieve only 40-60% utilization.

APALD processes operate at atmospheric pressure, eliminating the need for energy-intensive vacuum systems that contribute to the carbon footprint of traditional ALD methods. Energy consumption analyses indicate potential reductions of 30-45% in overall energy requirements when implementing APALD for anti-reflective coating applications on glass and plastic substrates. This energy efficiency translates directly to reduced greenhouse gas emissions throughout the production lifecycle.

Water consumption represents another significant environmental factor. APALD techniques typically require 50-70% less water than wet chemical deposition methods commonly used for anti-reflective coatings. This reduction becomes particularly important in regions facing water scarcity challenges, where manufacturing sustainability increasingly influences facility location decisions.

Chemical waste generation from APALD processes shows marked improvement over conventional techniques. Studies indicate that APALD can reduce hazardous waste output by approximately 60-80% compared to solution-based coating methods. The precise nature of atomic layer deposition allows for minimal material wastage, with nearly all precursor materials participating in the coating formation rather than becoming waste byproducts.

Life cycle assessments of APALD-produced anti-reflective coatings demonstrate additional sustainability benefits through extended product lifespans. The superior durability and performance of these coatings on both glass and plastic substrates mean less frequent replacement and refurbishment, reducing the cumulative environmental impact across the product lifecycle.

Regulatory compliance represents an increasingly important consideration for coating technologies. APALD processes generally align well with stringent environmental regulations, including REACH in Europe and similar frameworks globally. The reduced use of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) positions APALD favorably as regulatory requirements continue to tighten across major manufacturing markets.

Future sustainability improvements for APALD focus on precursor chemistry development, with research targeting bio-based precursors that could further reduce the environmental footprint. Additionally, integration with renewable energy sources could potentially create near-zero emission coating operations, particularly beneficial for large-scale glass coating facilities that require significant energy inputs.

APALD processes operate at atmospheric pressure, eliminating the need for energy-intensive vacuum systems that contribute to the carbon footprint of traditional ALD methods. Energy consumption analyses indicate potential reductions of 30-45% in overall energy requirements when implementing APALD for anti-reflective coating applications on glass and plastic substrates. This energy efficiency translates directly to reduced greenhouse gas emissions throughout the production lifecycle.

Water consumption represents another significant environmental factor. APALD techniques typically require 50-70% less water than wet chemical deposition methods commonly used for anti-reflective coatings. This reduction becomes particularly important in regions facing water scarcity challenges, where manufacturing sustainability increasingly influences facility location decisions.

Chemical waste generation from APALD processes shows marked improvement over conventional techniques. Studies indicate that APALD can reduce hazardous waste output by approximately 60-80% compared to solution-based coating methods. The precise nature of atomic layer deposition allows for minimal material wastage, with nearly all precursor materials participating in the coating formation rather than becoming waste byproducts.

Life cycle assessments of APALD-produced anti-reflective coatings demonstrate additional sustainability benefits through extended product lifespans. The superior durability and performance of these coatings on both glass and plastic substrates mean less frequent replacement and refurbishment, reducing the cumulative environmental impact across the product lifecycle.

Regulatory compliance represents an increasingly important consideration for coating technologies. APALD processes generally align well with stringent environmental regulations, including REACH in Europe and similar frameworks globally. The reduced use of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) positions APALD favorably as regulatory requirements continue to tighten across major manufacturing markets.

Future sustainability improvements for APALD focus on precursor chemistry development, with research targeting bio-based precursors that could further reduce the environmental footprint. Additionally, integration with renewable energy sources could potentially create near-zero emission coating operations, particularly beneficial for large-scale glass coating facilities that require significant energy inputs.

Material Compatibility and Adhesion Challenges

The implementation of APALD (Atmospheric Pressure Atomic Layer Deposition) for anti-reflective coatings presents significant material compatibility and adhesion challenges across diverse substrate materials. Glass and plastic substrates exhibit fundamentally different surface chemistries and physical properties, necessitating tailored approaches to ensure coating durability and performance.

For glass substrates, the primary challenge stems from their silica-based composition, which typically features hydroxyl-terminated surfaces. These surfaces can form strong bonds with metal oxides commonly used in APALD processes, yet the thermal expansion coefficient mismatch between coating and substrate often leads to stress accumulation during temperature cycling. This stress can manifest as microscopic cracks or delamination, particularly when coating thickness exceeds critical thresholds.

Plastic substrates present even greater compatibility challenges due to their inherently hydrophobic nature and low surface energy. Polymers such as polycarbonate, PMMA, and PET—commonly used in optical applications—lack the reactive surface groups necessary for strong chemical bonding with metal oxide layers. Additionally, these materials have significantly lower thermal stability compared to glass, limiting the processing temperature window for APALD to approximately 80-120°C, which constrains precursor selection and reaction kinetics.

Surface pretreatment methodologies have emerged as critical enablers for enhancing adhesion. Plasma activation using oxygen or argon plasmas can introduce polar functional groups on plastic surfaces, increasing surface energy and creating anchor points for subsequent coating layers. Alternative approaches include wet chemical treatments with dilute acids or bases, UV-ozone exposure, and the application of specialized adhesion promoters or primer layers that serve as chemical bridges between substrate and coating.

The mechanical flexibility requirements of plastic substrates introduce additional complexity. Anti-reflective coatings must maintain adhesion during bending and flexing without cracking or spalling. This necessitates careful engineering of coating stress through compositional gradients or multilayer architectures that distribute mechanical strain effectively.

Recent research has demonstrated promising results with organosilane coupling agents that form covalent bonds between inorganic coating materials and organic substrates. These molecules typically feature hydrolyzable groups that react with the coating material and organic functional groups compatible with the substrate surface, creating a robust interfacial layer that significantly enhances adhesion strength and durability.

Environmental stability represents another dimension of the compatibility challenge. Coatings must maintain adhesion under varying humidity conditions, temperature fluctuations, and UV exposure. Moisture ingress at the coating-substrate interface is particularly problematic for hydrophilic coating materials on hydrophobic substrates, often requiring additional barrier layers or hydrophobic modifications to prevent progressive delamination over time.

For glass substrates, the primary challenge stems from their silica-based composition, which typically features hydroxyl-terminated surfaces. These surfaces can form strong bonds with metal oxides commonly used in APALD processes, yet the thermal expansion coefficient mismatch between coating and substrate often leads to stress accumulation during temperature cycling. This stress can manifest as microscopic cracks or delamination, particularly when coating thickness exceeds critical thresholds.

Plastic substrates present even greater compatibility challenges due to their inherently hydrophobic nature and low surface energy. Polymers such as polycarbonate, PMMA, and PET—commonly used in optical applications—lack the reactive surface groups necessary for strong chemical bonding with metal oxide layers. Additionally, these materials have significantly lower thermal stability compared to glass, limiting the processing temperature window for APALD to approximately 80-120°C, which constrains precursor selection and reaction kinetics.

Surface pretreatment methodologies have emerged as critical enablers for enhancing adhesion. Plasma activation using oxygen or argon plasmas can introduce polar functional groups on plastic surfaces, increasing surface energy and creating anchor points for subsequent coating layers. Alternative approaches include wet chemical treatments with dilute acids or bases, UV-ozone exposure, and the application of specialized adhesion promoters or primer layers that serve as chemical bridges between substrate and coating.

The mechanical flexibility requirements of plastic substrates introduce additional complexity. Anti-reflective coatings must maintain adhesion during bending and flexing without cracking or spalling. This necessitates careful engineering of coating stress through compositional gradients or multilayer architectures that distribute mechanical strain effectively.

Recent research has demonstrated promising results with organosilane coupling agents that form covalent bonds between inorganic coating materials and organic substrates. These molecules typically feature hydrolyzable groups that react with the coating material and organic functional groups compatible with the substrate surface, creating a robust interfacial layer that significantly enhances adhesion strength and durability.

Environmental stability represents another dimension of the compatibility challenge. Coatings must maintain adhesion under varying humidity conditions, temperature fluctuations, and UV exposure. Moisture ingress at the coating-substrate interface is particularly problematic for hydrophilic coating materials on hydrophobic substrates, often requiring additional barrier layers or hydrophobic modifications to prevent progressive delamination over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!