Precursor Design Criteria For APALD On Flexible Substrates

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

APALD Precursor Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly over the past decades, with Atmospheric Pressure Atomic Layer Deposition (APALD) emerging as a promising variant for flexible substrate applications. The evolution of APALD precursors represents a critical aspect of this technology's development, transitioning from traditional vacuum-based ALD precursors to specialized compounds capable of functioning effectively at atmospheric pressure conditions while maintaining compatibility with temperature-sensitive flexible substrates.

Early APALD precursor development focused primarily on metal-organic compounds with sufficient volatility and reactivity at lower temperatures. These initial precursors, however, often suffered from thermal decomposition issues, limited shelf life, and inadequate film quality when applied to flexible substrates. The technological trajectory shifted toward developing precursors with enhanced thermal stability, improved reaction kinetics, and reduced purging requirements specifically tailored for the open-air processing environment of APALD.

The current objectives in APALD precursor design for flexible substrates center on several key parameters. First, precursors must exhibit appropriate volatility at temperatures below 150°C to prevent thermal damage to polymer-based flexible substrates. Second, they must demonstrate rapid and complete surface reactions to enable high throughput manufacturing processes. Third, the precursors should produce minimal by-products that could potentially contaminate the growing film or damage sensitive substrate materials.

Another critical objective involves developing precursors that can achieve conformal coating on complex three-dimensional flexible structures with high aspect ratios. This requires precursors with excellent diffusion characteristics and controlled surface reactivity. Additionally, environmental and safety considerations have driven research toward less toxic and more environmentally benign precursor chemistries, moving away from traditional halide-based compounds toward amino, alkoxide, and cyclopentadienyl ligand systems.

Recent advancements have focused on creating multi-functional precursors capable of depositing composite or doped films in fewer processing steps, thereby reducing manufacturing complexity and cost. These "smart precursors" incorporate multiple reactive sites or co-reactant capabilities, enabling more sophisticated material deposition without compromising the low-temperature processing requirements of flexible substrates.

The ultimate goal of APALD precursor evolution is to enable roll-to-roll manufacturing compatibility, where continuous deposition on flexible substrates can occur at atmospheric pressure with minimal energy input. This requires precursors with unprecedented reaction efficiency, stability during storage and handling, and compatibility with a wide range of substrate materials including polymers, textiles, and hybrid flexible composites.

Early APALD precursor development focused primarily on metal-organic compounds with sufficient volatility and reactivity at lower temperatures. These initial precursors, however, often suffered from thermal decomposition issues, limited shelf life, and inadequate film quality when applied to flexible substrates. The technological trajectory shifted toward developing precursors with enhanced thermal stability, improved reaction kinetics, and reduced purging requirements specifically tailored for the open-air processing environment of APALD.

The current objectives in APALD precursor design for flexible substrates center on several key parameters. First, precursors must exhibit appropriate volatility at temperatures below 150°C to prevent thermal damage to polymer-based flexible substrates. Second, they must demonstrate rapid and complete surface reactions to enable high throughput manufacturing processes. Third, the precursors should produce minimal by-products that could potentially contaminate the growing film or damage sensitive substrate materials.

Another critical objective involves developing precursors that can achieve conformal coating on complex three-dimensional flexible structures with high aspect ratios. This requires precursors with excellent diffusion characteristics and controlled surface reactivity. Additionally, environmental and safety considerations have driven research toward less toxic and more environmentally benign precursor chemistries, moving away from traditional halide-based compounds toward amino, alkoxide, and cyclopentadienyl ligand systems.

Recent advancements have focused on creating multi-functional precursors capable of depositing composite or doped films in fewer processing steps, thereby reducing manufacturing complexity and cost. These "smart precursors" incorporate multiple reactive sites or co-reactant capabilities, enabling more sophisticated material deposition without compromising the low-temperature processing requirements of flexible substrates.

The ultimate goal of APALD precursor evolution is to enable roll-to-roll manufacturing compatibility, where continuous deposition on flexible substrates can occur at atmospheric pressure with minimal energy input. This requires precursors with unprecedented reaction efficiency, stability during storage and handling, and compatibility with a wide range of substrate materials including polymers, textiles, and hybrid flexible composites.

Market Analysis for Flexible Electronics Applications

The flexible electronics market is experiencing unprecedented growth, with a projected market value reaching $48.5 billion by 2028, growing at a CAGR of 15.3% from 2023. This surge is primarily driven by increasing demand for lightweight, portable, and bendable electronic devices across multiple industries. The integration of Atomic Layer Deposition (ALD) technologies, particularly Area-Selective ALD (APALD), on flexible substrates represents a critical advancement enabling this market expansion.

Consumer electronics remains the dominant application segment, accounting for approximately 38% of the flexible electronics market. Smartphones with flexible displays, wearable fitness trackers, and foldable tablets are driving consumer adoption. The healthcare sector follows closely, with flexible biosensors, smart patches, and implantable devices growing at 18.7% annually, highlighting the critical importance of biocompatible precursor designs for APALD processes.

Automotive applications represent the fastest-growing segment at 22.4% CAGR, with demand for flexible displays in dashboards, lighting systems, and sensor arrays. Military and aerospace sectors are investing heavily in flexible electronics for lightweight communication devices and monitoring systems, emphasizing the need for precursors that enable high-temperature stability and mechanical durability.

Geographically, Asia-Pacific dominates manufacturing with 45% market share, led by South Korea, Japan, and Taiwan. North America leads in innovation and R&D investment, while Europe focuses on sustainable and eco-friendly flexible electronics solutions, influencing precursor design criteria toward environmentally benign chemistries.

Key market challenges include high production costs, with APALD processes currently adding 15-30% to manufacturing expenses compared to traditional electronics fabrication. Technical barriers in scaling APALD for mass production and ensuring consistent performance across large flexible substrates remain significant hurdles that appropriate precursor design must address.

Customer requirements are evolving toward thinner, more durable flexible devices with longer lifespans. This drives demand for APALD precursors that can deposit uniform, defect-free films at lower temperatures (below 120°C) to accommodate temperature-sensitive polymer substrates while maintaining excellent adhesion properties and barrier performance against oxygen and moisture.

The market analysis indicates that companies investing in specialized precursor development for flexible substrate APALD applications can expect to capture premium pricing, with potential profit margins 25-40% higher than standard electronic materials, reflecting the technical sophistication and value-add these materials provide to the rapidly expanding flexible electronics ecosystem.

Consumer electronics remains the dominant application segment, accounting for approximately 38% of the flexible electronics market. Smartphones with flexible displays, wearable fitness trackers, and foldable tablets are driving consumer adoption. The healthcare sector follows closely, with flexible biosensors, smart patches, and implantable devices growing at 18.7% annually, highlighting the critical importance of biocompatible precursor designs for APALD processes.

Automotive applications represent the fastest-growing segment at 22.4% CAGR, with demand for flexible displays in dashboards, lighting systems, and sensor arrays. Military and aerospace sectors are investing heavily in flexible electronics for lightweight communication devices and monitoring systems, emphasizing the need for precursors that enable high-temperature stability and mechanical durability.

Geographically, Asia-Pacific dominates manufacturing with 45% market share, led by South Korea, Japan, and Taiwan. North America leads in innovation and R&D investment, while Europe focuses on sustainable and eco-friendly flexible electronics solutions, influencing precursor design criteria toward environmentally benign chemistries.

Key market challenges include high production costs, with APALD processes currently adding 15-30% to manufacturing expenses compared to traditional electronics fabrication. Technical barriers in scaling APALD for mass production and ensuring consistent performance across large flexible substrates remain significant hurdles that appropriate precursor design must address.

Customer requirements are evolving toward thinner, more durable flexible devices with longer lifespans. This drives demand for APALD precursors that can deposit uniform, defect-free films at lower temperatures (below 120°C) to accommodate temperature-sensitive polymer substrates while maintaining excellent adhesion properties and barrier performance against oxygen and moisture.

The market analysis indicates that companies investing in specialized precursor development for flexible substrate APALD applications can expect to capture premium pricing, with potential profit margins 25-40% higher than standard electronic materials, reflecting the technical sophistication and value-add these materials provide to the rapidly expanding flexible electronics ecosystem.

Current Challenges in APALD Precursor Technology

Despite significant advancements in Atomic Layer Deposition (ALD) technology, the adaptation of Area-Selective ALD (APALD) for flexible substrates faces several critical precursor-related challenges. The thermal instability of many conventional precursors presents a fundamental obstacle, as flexible substrates typically require lower processing temperatures (below 150°C) to prevent deformation or degradation. This temperature constraint severely limits the range of viable precursor options and often results in incomplete reactions and poor film quality.

Precursor volatility and delivery mechanisms represent another significant hurdle. Many high-performance precursors exhibit insufficient vapor pressure at the reduced temperatures compatible with flexible substrates, leading to inconsistent delivery rates and non-uniform deposition. This issue is particularly pronounced when scaling to larger substrate dimensions, where maintaining uniform precursor distribution becomes increasingly difficult.

The chemical compatibility between precursors and flexible substrate materials introduces additional complications. Flexible substrates often contain organic components or surface treatments that can react undesirably with aggressive precursors, causing substrate damage or contamination of the deposited films. This incompatibility narrows the selection of suitable precursor chemistries and may necessitate the development of specialized precursor molecules.

Precursor adsorption selectivity remains inadequate on many flexible substrate surfaces. The inherent surface chemistry of polymeric and other flexible materials often lacks the distinct functional group differentiation needed for truly selective deposition. Current precursors struggle to achieve the necessary discrimination between growth and non-growth regions without additional surface modification steps, which add complexity and cost to the manufacturing process.

The stability and shelf-life of precursors optimized for flexible substrate applications present ongoing challenges. Many promising candidates that function well at lower temperatures exhibit problematic degradation during storage or premature decomposition during delivery, limiting their practical implementation in industrial settings. This instability necessitates specialized handling protocols and storage conditions that complicate manufacturing logistics.

Precursor byproduct management is particularly challenging in APALD processes on flexible substrates. The reaction byproducts can become trapped within the flexible material or adsorb differently than on rigid substrates, potentially causing contamination, delamination, or other film defects. Current precursor systems often generate byproducts that require more aggressive purging conditions than flexible substrates can tolerate.

Precursor volatility and delivery mechanisms represent another significant hurdle. Many high-performance precursors exhibit insufficient vapor pressure at the reduced temperatures compatible with flexible substrates, leading to inconsistent delivery rates and non-uniform deposition. This issue is particularly pronounced when scaling to larger substrate dimensions, where maintaining uniform precursor distribution becomes increasingly difficult.

The chemical compatibility between precursors and flexible substrate materials introduces additional complications. Flexible substrates often contain organic components or surface treatments that can react undesirably with aggressive precursors, causing substrate damage or contamination of the deposited films. This incompatibility narrows the selection of suitable precursor chemistries and may necessitate the development of specialized precursor molecules.

Precursor adsorption selectivity remains inadequate on many flexible substrate surfaces. The inherent surface chemistry of polymeric and other flexible materials often lacks the distinct functional group differentiation needed for truly selective deposition. Current precursors struggle to achieve the necessary discrimination between growth and non-growth regions without additional surface modification steps, which add complexity and cost to the manufacturing process.

The stability and shelf-life of precursors optimized for flexible substrate applications present ongoing challenges. Many promising candidates that function well at lower temperatures exhibit problematic degradation during storage or premature decomposition during delivery, limiting their practical implementation in industrial settings. This instability necessitates specialized handling protocols and storage conditions that complicate manufacturing logistics.

Precursor byproduct management is particularly challenging in APALD processes on flexible substrates. The reaction byproducts can become trapped within the flexible material or adsorb differently than on rigid substrates, potentially causing contamination, delamination, or other film defects. Current precursor systems often generate byproducts that require more aggressive purging conditions than flexible substrates can tolerate.

Existing Precursor Solutions for Flexible Substrates

01 Volatility and thermal stability requirements for APALD precursors

APALD precursors must have sufficient volatility to be delivered as vapor at atmospheric pressure while maintaining thermal stability to prevent decomposition before reaching the substrate. Ideal precursors have high vapor pressure at moderate temperatures, allowing efficient transport without decomposition. The thermal window between vaporization and decomposition temperatures should be wide enough to ensure stable delivery and controlled reactions at the substrate surface.- Volatility and thermal stability requirements for APALD precursors: APALD precursors must have sufficient volatility to be delivered in vapor form at atmospheric pressure while maintaining thermal stability to prevent decomposition before reaching the substrate. Ideal precursors have appropriate vapor pressure at operating temperatures, good thermal stability window, and controlled decomposition pathways to ensure uniform film deposition. These properties are critical for achieving consistent layer growth in atmospheric pressure conditions.

- Reactivity and surface chemistry optimization: Precursors for APALD must exhibit controlled reactivity with substrate surfaces and co-reactants while avoiding gas-phase reactions. The surface chemistry should promote complete, self-limiting reactions that form uniform monolayers. Precursors need to achieve rapid saturation of surface sites, complete ligand exchange, and minimal steric hindrance. Optimized reactivity ensures efficient purge cycles and prevents CVD-like growth that would compromise film quality and conformality.

- Metal-organic compound design for specific film compositions: Metal-organic compounds are designed with specific ligand structures to control decomposition pathways and film composition in APALD processes. These precursors incorporate ligands such as alkylamides, cyclopentadienyls, beta-diketonates, or alkoxides that influence reactivity, stability, and purity of the resulting films. The molecular structure is engineered to achieve clean surface reactions, minimize impurity incorporation, and enable precise control over film stoichiometry for applications in semiconductor, energy storage, and optical coating industries.

- Delivery and handling considerations for atmospheric pressure conditions: APALD precursors require specialized delivery systems and handling protocols due to atmospheric pressure operation. Precursors must maintain stability during storage, transport through delivery lines, and vaporization processes. Considerations include container design, carrier gas selection, flow rate optimization, and prevention of premature reactions or condensation. Effective precursor delivery systems may incorporate heated lines, specialized bubblers or direct liquid injection systems, and precise flow controllers to ensure consistent precursor supply to the reaction chamber.

- Environmental and safety considerations in precursor design: Modern APALD precursor design incorporates environmental and safety considerations alongside performance requirements. Precursors are developed to minimize toxicity, reduce environmental impact, and improve handling safety. This includes designing compounds with lower pyrophoricity, reduced air/moisture sensitivity, and decreased hazardous waste generation. Green chemistry principles guide the development of precursors with higher atom efficiency, lower energy requirements, and reduced use of hazardous elements or solvents while maintaining the performance needed for high-quality film deposition.

02 Reactivity and self-limiting behavior of precursors

Effective APALD precursors must exhibit appropriate reactivity with surface sites while demonstrating self-limiting behavior to ensure true atomic layer deposition. The precursors should react rapidly and completely with the substrate surface but not with themselves in the gas phase. This controlled reactivity enables the formation of uniform, conformal films with precise thickness control even at atmospheric pressure conditions, where higher collision frequencies could otherwise lead to CVD-like growth.Expand Specific Solutions03 Precursor purity and byproduct considerations

High purity precursors are essential for APALD processes to prevent film contamination. The precursors should produce volatile, non-reactive byproducts that can be easily removed from the reaction chamber without incorporating into the growing film. Minimizing non-volatile residues and particle formation is particularly important in atmospheric pressure conditions where purging is more challenging than in vacuum-based ALD systems.Expand Specific Solutions04 Atmospheric pressure compatibility and gas phase stability

APALD precursors must maintain stability in the gas phase at atmospheric pressure without premature reactions or decomposition. This requires careful molecular design to prevent oligomerization or condensation reactions that commonly occur at higher pressures. Precursors should have appropriate steric hindrance and bonding characteristics to remain stable during transport through the delivery system and reaction chamber at atmospheric conditions.Expand Specific Solutions05 Safety and environmental considerations for precursor selection

APALD precursor design must account for safety and environmental factors, especially important for atmospheric pressure processes where containment is more challenging. Ideal precursors should have low toxicity, minimal environmental impact, and reduced flammability or reactivity hazards. Additionally, precursors should be compatible with standard handling equipment and procedures, with reasonable shelf-life under proper storage conditions to ensure process reliability and reproducibility.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The APALD (Atomic Layer Deposition) on flexible substrates market is currently in a growth phase, with increasing applications in flexible electronics, displays, and barrier films. The global market size for ALD technology is expanding rapidly, projected to reach several billion dollars by 2025, with flexible substrate applications representing a significant growth segment. Technologically, the field shows varying maturity levels across players. Industry leaders like Applied Materials, Micron Technology, and Intel have established robust APALD capabilities for flexible applications, while specialized firms such as Picosun, Beneq, and Lotus Applied Technology offer innovative precursor solutions. Research institutions including Argonne National Laboratory and universities like Jilin University are advancing fundamental precursor design criteria. The competitive landscape features both semiconductor giants and specialized ALD equipment manufacturers competing to overcome temperature limitations and achieve uniform deposition on temperature-sensitive flexible substrates.

Lotus Applied Technology LLC

Technical Solution: Lotus Applied Technology has developed a specialized APALD system called FlexAL™ specifically designed for flexible substrate applications. Their approach utilizes a proprietary low-temperature plasma-enhanced ALD process that operates effectively below 100°C, making it compatible with temperature-sensitive polymer substrates including PET, PEN, and various polyimides. The system features a unique curved deposition chamber design that minimizes mechanical stress on flexible materials during processing by maintaining natural substrate curvature rather than forcing flatness. Lotus has engineered specialized precursor delivery systems that provide highly uniform distribution across varying substrate topographies, addressing one of the key challenges in flexible electronics manufacturing. Their technology incorporates pulsed plasma modes that deliver precise energy control, preventing substrate damage while ensuring complete surface reactions. The FlexAL™ system includes integrated stress management features that compensate for film-induced substrate deformation during growth, maintaining dimensional stability throughout the deposition process. Additionally, Lotus has developed specialized interface engineering techniques that enhance adhesion between inorganic ALD films and organic flexible substrates, addressing a critical failure point in flexible electronics.

Strengths: Specialized focus on flexible electronics applications; innovative chamber design specifically optimized for flexible materials; demonstrated ability to produce high-quality barrier films with water vapor transmission rates below 10^-6 g/m²/day. Their technology enables conformal coating on substrates with pre-existing 3D features. Weaknesses: Smaller company with more limited production capacity compared to industry giants; narrower global support network; technology may require significant customization for specific customer applications.

Picosun Oy

Technical Solution: Picosun has pioneered specialized APALD technology for flexible electronics applications through their PICOSUN® Morpher ALD systems. These systems feature a unique roll-to-roll processing capability specifically designed for continuous deposition on flexible substrates, enabling industrial-scale production. Their technology employs proprietary hot-wall reactor designs that maintain precise temperature uniformity across flexible substrates, preventing thermal gradients that could cause warping or deformation. Picosun's approach incorporates spatial ALD concepts where precursors are physically separated and the substrate moves between them, reducing cycle times significantly compared to conventional temporal ALD. The company has developed specialized precursor chemistry optimized for low-temperature deposition (80-150°C range), making it compatible with polymer substrates like PET, PEN, and polyimide. Their systems include tension control mechanisms that maintain optimal substrate flatness during deposition while preventing mechanical damage, and utilize plasma enhancement techniques that enable high-quality film formation at lower temperatures without substrate damage.

Strengths: Specialized expertise in ALD technology with over 15 years of experience; flexible system designs adaptable to various substrate types; proven track record in industrial applications with high throughput capabilities. Their roll-to-roll processing enables cost-effective manufacturing for large-area flexible electronics. Weaknesses: More limited global service network compared to larger equipment manufacturers; higher initial investment costs; process optimization can require significant customer-specific development work.

Key Technical Innovations in Precursor Chemistry

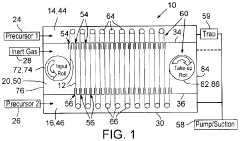

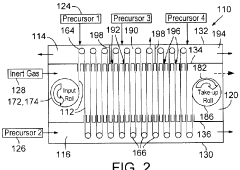

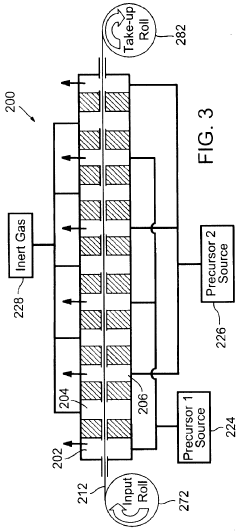

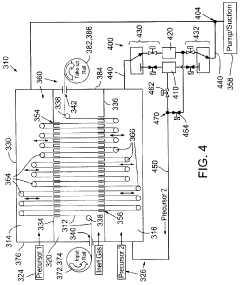

Atomic layer deposition method utilizing multiple precursor zones for coating flexible substrates

PatentActiveUS20120219708A1

Innovation

- A system and method utilizing first, second, and third precursor zones with isolation regions and flow-restricting passageways to prevent precursor gas mixing, allowing a flexible substrate to traverse multiple times through these zones, achieving thin film deposition by controlling pressure differentials and using an inert gas to inhibit precursor gas migration and mixing.

Atomic layer deposition on fibrous materials

PatentInactiveUS20080119098A1

Innovation

- The application of a conformal encapsulation layer deposited via atomic layer deposition (ALD) onto polymeric fibers, which improves fiber surface properties and resistance without compromising flexibility.

Material Compatibility and Interface Engineering

Material compatibility and interface engineering represent critical challenges in the development of Atomic Layer Deposition (ALD) processes for flexible substrates, particularly when implementing Area-Selective ALD (APALD) techniques. The selection of appropriate precursors must account for the unique thermal and mechanical constraints imposed by polymer-based flexible substrates, which typically cannot withstand the high temperatures used in conventional ALD processes.

The interface between the deposited film and flexible substrate requires careful engineering to ensure strong adhesion while maintaining the mechanical flexibility of the underlying material. Surface modification techniques, including plasma treatments and self-assembled monolayers (SAMs), have emerged as effective approaches for enhancing adhesion properties without compromising substrate integrity. These modifications create functional groups that facilitate stronger chemical bonding with the initial ALD precursor molecules.

Chemical compatibility between precursors and flexible substrates presents another significant challenge. Many conventional ALD precursors contain reactive functional groups that may attack or degrade polymer substrates. For instance, trimethylaluminum (TMA), commonly used for Al2O3 deposition, can react with certain polymer functional groups, causing substrate degradation. Therefore, precursor selection must prioritize molecules with selective reactivity toward intended growth surfaces while remaining inert to the substrate material.

Thermal expansion coefficient mismatch between deposited films and flexible substrates can lead to film cracking or delamination during thermal cycling. This necessitates the development of buffer layers or gradient composition interfaces that can accommodate the differential expansion. Recent research has demonstrated that inserting ultrathin organic interlayers can significantly improve adhesion and reduce mechanical stress at the interface.

Water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) at the interface region significantly impact the long-term stability of flexible electronic devices. Precursors that enable the formation of dense, defect-free films with minimal pinhole formation are essential for creating effective barrier properties. Metal-organic precursors containing bulky ligands have shown promise in creating smoother interfaces with fewer defects.

The development of area-selective deposition strategies requires precise control over surface chemistry at the nanoscale. Precursors must exhibit differential reactivity between growth and non-growth regions. Recent advances in precursor design have focused on molecules with tailored steric hindrance properties that can discriminate between different surface terminations, enabling bottom-up patterning on flexible substrates without damaging their inherent properties.

The interface between the deposited film and flexible substrate requires careful engineering to ensure strong adhesion while maintaining the mechanical flexibility of the underlying material. Surface modification techniques, including plasma treatments and self-assembled monolayers (SAMs), have emerged as effective approaches for enhancing adhesion properties without compromising substrate integrity. These modifications create functional groups that facilitate stronger chemical bonding with the initial ALD precursor molecules.

Chemical compatibility between precursors and flexible substrates presents another significant challenge. Many conventional ALD precursors contain reactive functional groups that may attack or degrade polymer substrates. For instance, trimethylaluminum (TMA), commonly used for Al2O3 deposition, can react with certain polymer functional groups, causing substrate degradation. Therefore, precursor selection must prioritize molecules with selective reactivity toward intended growth surfaces while remaining inert to the substrate material.

Thermal expansion coefficient mismatch between deposited films and flexible substrates can lead to film cracking or delamination during thermal cycling. This necessitates the development of buffer layers or gradient composition interfaces that can accommodate the differential expansion. Recent research has demonstrated that inserting ultrathin organic interlayers can significantly improve adhesion and reduce mechanical stress at the interface.

Water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) at the interface region significantly impact the long-term stability of flexible electronic devices. Precursors that enable the formation of dense, defect-free films with minimal pinhole formation are essential for creating effective barrier properties. Metal-organic precursors containing bulky ligands have shown promise in creating smoother interfaces with fewer defects.

The development of area-selective deposition strategies requires precise control over surface chemistry at the nanoscale. Precursors must exhibit differential reactivity between growth and non-growth regions. Recent advances in precursor design have focused on molecules with tailored steric hindrance properties that can discriminate between different surface terminations, enabling bottom-up patterning on flexible substrates without damaging their inherent properties.

Sustainability Aspects of APALD Precursor Development

The development of sustainable APALD precursors for flexible substrates represents a critical frontier in green electronics manufacturing. Current precursor design approaches often rely on environmentally problematic chemicals, including volatile organic compounds (VOCs) and heavy metal derivatives that pose significant ecological risks throughout their lifecycle. The environmental footprint of APALD processes must be comprehensively evaluated through life cycle assessment (LCA) methodologies that account for precursor synthesis, transportation, utilization efficiency, and waste management.

Water consumption represents a particular concern in APALD precursor development, as conventional synthesis routes often require substantial quantities of ultra-pure water for both production and purification stages. Innovative approaches utilizing green chemistry principles have demonstrated promising alternatives, including aqueous-based precursor systems that reduce organic solvent dependence by 40-65% compared to traditional methods.

Energy efficiency metrics indicate that precursor volatility characteristics directly impact the overall sustainability profile of APALD processes. Lower volatility precursors typically require elevated delivery temperatures, increasing energy consumption by approximately 0.4-0.7 kWh per deposition cycle. Research into novel delivery systems utilizing supercritical CO2 as a transport medium shows potential for reducing these energy requirements by up to 30% while simultaneously improving precursor utilization efficiency.

Regulatory frameworks increasingly influence precursor development trajectories, with the European Union's REACH regulations and similar global initiatives restricting certain chemical classes commonly employed in APALD precursor synthesis. Forward-looking precursor design must anticipate these evolving regulatory landscapes, particularly regarding persistent, bioaccumulative substances that may face future restrictions despite current technical advantages.

Circular economy principles are gradually being incorporated into precursor development strategies, with emerging research focused on recovery and regeneration pathways for spent precursors. Preliminary studies demonstrate that certain metalorganic precursors can be reclaimed at rates of 50-70% through specialized condensation and purification processes, significantly reducing waste streams and raw material requirements.

Biodegradable ligand structures represent another promising direction for sustainable precursor development. Recent advances in bio-derived chelating agents have yielded precursor compounds with comparable performance characteristics to conventional options while demonstrating enhanced environmental degradability. These bio-inspired approaches may offer viable pathways toward reducing the persistent environmental impacts associated with traditional APALD precursor chemistry while maintaining the performance requirements necessary for flexible substrate applications.

Water consumption represents a particular concern in APALD precursor development, as conventional synthesis routes often require substantial quantities of ultra-pure water for both production and purification stages. Innovative approaches utilizing green chemistry principles have demonstrated promising alternatives, including aqueous-based precursor systems that reduce organic solvent dependence by 40-65% compared to traditional methods.

Energy efficiency metrics indicate that precursor volatility characteristics directly impact the overall sustainability profile of APALD processes. Lower volatility precursors typically require elevated delivery temperatures, increasing energy consumption by approximately 0.4-0.7 kWh per deposition cycle. Research into novel delivery systems utilizing supercritical CO2 as a transport medium shows potential for reducing these energy requirements by up to 30% while simultaneously improving precursor utilization efficiency.

Regulatory frameworks increasingly influence precursor development trajectories, with the European Union's REACH regulations and similar global initiatives restricting certain chemical classes commonly employed in APALD precursor synthesis. Forward-looking precursor design must anticipate these evolving regulatory landscapes, particularly regarding persistent, bioaccumulative substances that may face future restrictions despite current technical advantages.

Circular economy principles are gradually being incorporated into precursor development strategies, with emerging research focused on recovery and regeneration pathways for spent precursors. Preliminary studies demonstrate that certain metalorganic precursors can be reclaimed at rates of 50-70% through specialized condensation and purification processes, significantly reducing waste streams and raw material requirements.

Biodegradable ligand structures represent another promising direction for sustainable precursor development. Recent advances in bio-derived chelating agents have yielded precursor compounds with comparable performance characteristics to conventional options while demonstrating enhanced environmental degradability. These bio-inspired approaches may offer viable pathways toward reducing the persistent environmental impacts associated with traditional APALD precursor chemistry while maintaining the performance requirements necessary for flexible substrate applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!