Substrate Handling And Web Tension Control For R2R SALD

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

R2R SALD Substrate Handling Technology Background and Objectives

Roll-to-Roll Spatial Atomic Layer Deposition (R2R SALD) technology has evolved significantly over the past two decades, transforming from laboratory-scale experiments to industrial applications. This evolution has been driven by the increasing demand for high-throughput, cost-effective manufacturing of thin-film devices with precise atomic-level control. The substrate handling and web tension control systems represent critical components in this technological advancement, directly impacting production efficiency and film quality.

The historical development of R2R SALD began in the early 2000s when researchers first attempted to adapt conventional batch ALD processes to continuous manufacturing formats. Initial systems faced significant challenges in maintaining precise gas separation and ensuring uniform deposition across moving substrates. By 2010, pioneering work by Kodak and Eastman demonstrated the first viable R2R ALD systems, though substrate handling remained rudimentary.

Between 2010-2015, substantial improvements in web handling mechanisms emerged, particularly in tension control systems that could maintain consistent substrate positioning within the narrow process windows required for SALD. The introduction of advanced servo motors and digital control systems marked a significant technological milestone, enabling more precise substrate movement and reduced defect rates.

Current technological trends indicate a convergence of advanced materials science with precision engineering in substrate handling systems. Multi-zone tension control, real-time feedback mechanisms, and adaptive algorithms have become essential features in state-of-the-art R2R SALD equipment. These developments allow for processing increasingly sensitive and flexible substrates, including ultra-thin polymers and composite materials.

The primary technical objectives for next-generation substrate handling systems include achieving sub-micron positioning accuracy at web speeds exceeding 50 meters per minute, maintaining tension variations below ±1% across the entire substrate width, and developing intelligent systems capable of compensating for material property variations in real-time. Additionally, there is a growing focus on energy efficiency and reduced environmental impact in system design.

Industry projections suggest that advancements in substrate handling technology will be a key enabler for expanding R2R SALD applications beyond current markets. Particular emphasis is being placed on developing systems compatible with temperature-sensitive substrates and capable of seamless integration with pre- and post-processing steps in manufacturing lines.

The ultimate goal of current R2R SALD substrate handling research is to establish a technological foundation that can support high-volume manufacturing of next-generation electronic devices, energy storage systems, and advanced barrier films with unprecedented quality and cost metrics.

The historical development of R2R SALD began in the early 2000s when researchers first attempted to adapt conventional batch ALD processes to continuous manufacturing formats. Initial systems faced significant challenges in maintaining precise gas separation and ensuring uniform deposition across moving substrates. By 2010, pioneering work by Kodak and Eastman demonstrated the first viable R2R ALD systems, though substrate handling remained rudimentary.

Between 2010-2015, substantial improvements in web handling mechanisms emerged, particularly in tension control systems that could maintain consistent substrate positioning within the narrow process windows required for SALD. The introduction of advanced servo motors and digital control systems marked a significant technological milestone, enabling more precise substrate movement and reduced defect rates.

Current technological trends indicate a convergence of advanced materials science with precision engineering in substrate handling systems. Multi-zone tension control, real-time feedback mechanisms, and adaptive algorithms have become essential features in state-of-the-art R2R SALD equipment. These developments allow for processing increasingly sensitive and flexible substrates, including ultra-thin polymers and composite materials.

The primary technical objectives for next-generation substrate handling systems include achieving sub-micron positioning accuracy at web speeds exceeding 50 meters per minute, maintaining tension variations below ±1% across the entire substrate width, and developing intelligent systems capable of compensating for material property variations in real-time. Additionally, there is a growing focus on energy efficiency and reduced environmental impact in system design.

Industry projections suggest that advancements in substrate handling technology will be a key enabler for expanding R2R SALD applications beyond current markets. Particular emphasis is being placed on developing systems compatible with temperature-sensitive substrates and capable of seamless integration with pre- and post-processing steps in manufacturing lines.

The ultimate goal of current R2R SALD substrate handling research is to establish a technological foundation that can support high-volume manufacturing of next-generation electronic devices, energy storage systems, and advanced barrier films with unprecedented quality and cost metrics.

Market Analysis for R2R SALD Manufacturing Solutions

The Roll-to-Roll Spatial Atomic Layer Deposition (R2R SALD) manufacturing market is experiencing significant growth, driven by increasing demand for flexible electronics, photovoltaics, and barrier films. Current market estimates value the global R2R SALD equipment sector at approximately $450 million, with projections indicating a compound annual growth rate of 17.3% through 2028.

The market landscape is characterized by several distinct segments. Equipment manufacturers represent the primary segment, with companies developing specialized R2R SALD systems commanding premium pricing due to the technical complexity and precision requirements. Material suppliers constitute another crucial segment, providing precursors and substrates specifically formulated for SALD processes. Integration service providers form the third major segment, offering expertise in incorporating R2R SALD into existing manufacturing lines.

Geographically, Asia-Pacific dominates the market with over 45% share, particularly driven by investments in South Korea, Japan, and Taiwan. North America follows at 28%, with Europe representing 22% of the global market. The remaining regions account for 5%, though showing accelerated growth rates as manufacturing capabilities expand globally.

Key market drivers include the miniaturization trend in electronics, which necessitates more precise deposition techniques. The push toward sustainable manufacturing processes also favors R2R SALD, as it typically requires fewer chemicals and generates less waste compared to traditional deposition methods. Additionally, the growing demand for flexible and wearable electronics creates a natural market pull for R2R processes capable of handling delicate substrates.

Customer segments show distinct requirements. Consumer electronics manufacturers prioritize high throughput and consistency for mass production. Medical device manufacturers emphasize precision and contamination control. Renewable energy companies focus on cost-effectiveness and scalability for large-area applications like solar panels.

Market challenges include high initial capital investment requirements, with typical R2R SALD systems ranging from $2 million to $8 million depending on specifications. Technical barriers to adoption persist, particularly regarding substrate handling and web tension control—the focus of this research. Additionally, competition from alternative deposition technologies like sputtering and evaporation creates market pressure.

The competitive landscape features established equipment manufacturers like Applied Materials and Beneq, alongside specialized players such as Lotus Applied Technology and TNO/Holst Centre. Recent market consolidation through acquisitions indicates growing recognition of R2R SALD's strategic importance in advanced manufacturing ecosystems.

The market landscape is characterized by several distinct segments. Equipment manufacturers represent the primary segment, with companies developing specialized R2R SALD systems commanding premium pricing due to the technical complexity and precision requirements. Material suppliers constitute another crucial segment, providing precursors and substrates specifically formulated for SALD processes. Integration service providers form the third major segment, offering expertise in incorporating R2R SALD into existing manufacturing lines.

Geographically, Asia-Pacific dominates the market with over 45% share, particularly driven by investments in South Korea, Japan, and Taiwan. North America follows at 28%, with Europe representing 22% of the global market. The remaining regions account for 5%, though showing accelerated growth rates as manufacturing capabilities expand globally.

Key market drivers include the miniaturization trend in electronics, which necessitates more precise deposition techniques. The push toward sustainable manufacturing processes also favors R2R SALD, as it typically requires fewer chemicals and generates less waste compared to traditional deposition methods. Additionally, the growing demand for flexible and wearable electronics creates a natural market pull for R2R processes capable of handling delicate substrates.

Customer segments show distinct requirements. Consumer electronics manufacturers prioritize high throughput and consistency for mass production. Medical device manufacturers emphasize precision and contamination control. Renewable energy companies focus on cost-effectiveness and scalability for large-area applications like solar panels.

Market challenges include high initial capital investment requirements, with typical R2R SALD systems ranging from $2 million to $8 million depending on specifications. Technical barriers to adoption persist, particularly regarding substrate handling and web tension control—the focus of this research. Additionally, competition from alternative deposition technologies like sputtering and evaporation creates market pressure.

The competitive landscape features established equipment manufacturers like Applied Materials and Beneq, alongside specialized players such as Lotus Applied Technology and TNO/Holst Centre. Recent market consolidation through acquisitions indicates growing recognition of R2R SALD's strategic importance in advanced manufacturing ecosystems.

Current Challenges in Web Tension Control for SALD Processes

Roll-to-roll spatial atomic layer deposition (R2R SALD) processes face significant challenges in web tension control that directly impact deposition quality and production efficiency. The primary challenge stems from the inherent sensitivity of SALD to substrate positioning and stability. Unlike traditional batch ALD, the continuous movement of flexible substrates through precursor zones requires precise tension management to maintain uniform precursor exposure and consistent film growth.

Temperature variations across the deposition system create substantial difficulties for tension control. As substrates pass through different temperature zones—from ambient conditions to heated deposition areas and back—thermal expansion and contraction occur, altering the mechanical properties of the web material. These thermal gradients induce non-uniform tension distribution that can lead to substrate deformation, wrinkling, or even catastrophic web breaks during high-speed operation.

Material heterogeneity presents another significant challenge. Different substrate materials (polymers, metal foils, textiles) exhibit varying elastic properties, thickness uniformities, and responses to environmental conditions. This variability necessitates adaptive tension control systems capable of real-time adjustments based on material-specific parameters, which adds complexity to system design and operation.

The multi-zone nature of SALD processes compounds these challenges. As substrates travel through sequential deposition zones with different precursor chemistries, each zone may require specific tension profiles to optimize precursor-substrate interactions. Transitioning between these zones without disrupting the delicate balance of tension remains problematic, particularly at production-relevant speeds exceeding 10 m/min.

Measurement accuracy and control response time constitute critical limitations in current systems. Traditional tension sensors often lack the precision required for nanoscale deposition processes, while control algorithms struggle to respond quickly enough to prevent tension fluctuations during high-speed operation or direction changes. The industry standard of ±1% tension variation tolerance proves insufficient for high-quality SALD films, where even minor substrate position variations can cause significant thickness non-uniformities.

Edge effects and width-direction tension variations further complicate control strategies. Uneven tension distribution across the substrate width leads to lateral movement, misalignment, and edge-specific defects. Current edge-guiding systems often fail to compensate for these variations without introducing additional stress points that can initiate web defects.

Finally, scaling challenges persist when transitioning from laboratory to industrial implementation. Tension control systems that perform adequately at small scales or slow speeds often fail to maintain performance when scaled to production widths (>1m) and speeds (>100 m/min), creating a significant barrier to commercial viability of R2R SALD technology.

Temperature variations across the deposition system create substantial difficulties for tension control. As substrates pass through different temperature zones—from ambient conditions to heated deposition areas and back—thermal expansion and contraction occur, altering the mechanical properties of the web material. These thermal gradients induce non-uniform tension distribution that can lead to substrate deformation, wrinkling, or even catastrophic web breaks during high-speed operation.

Material heterogeneity presents another significant challenge. Different substrate materials (polymers, metal foils, textiles) exhibit varying elastic properties, thickness uniformities, and responses to environmental conditions. This variability necessitates adaptive tension control systems capable of real-time adjustments based on material-specific parameters, which adds complexity to system design and operation.

The multi-zone nature of SALD processes compounds these challenges. As substrates travel through sequential deposition zones with different precursor chemistries, each zone may require specific tension profiles to optimize precursor-substrate interactions. Transitioning between these zones without disrupting the delicate balance of tension remains problematic, particularly at production-relevant speeds exceeding 10 m/min.

Measurement accuracy and control response time constitute critical limitations in current systems. Traditional tension sensors often lack the precision required for nanoscale deposition processes, while control algorithms struggle to respond quickly enough to prevent tension fluctuations during high-speed operation or direction changes. The industry standard of ±1% tension variation tolerance proves insufficient for high-quality SALD films, where even minor substrate position variations can cause significant thickness non-uniformities.

Edge effects and width-direction tension variations further complicate control strategies. Uneven tension distribution across the substrate width leads to lateral movement, misalignment, and edge-specific defects. Current edge-guiding systems often fail to compensate for these variations without introducing additional stress points that can initiate web defects.

Finally, scaling challenges persist when transitioning from laboratory to industrial implementation. Tension control systems that perform adequately at small scales or slow speeds often fail to maintain performance when scaled to production widths (>1m) and speeds (>100 m/min), creating a significant barrier to commercial viability of R2R SALD technology.

Current Web Tension Control Solutions for Thin Film Deposition

01 Tension control systems for web handling

Tension control systems are essential for maintaining proper tension in web handling processes. These systems typically include sensors to measure tension, controllers to process the data, and actuators to adjust tension. Advanced systems may incorporate feedback loops for real-time adjustments, ensuring consistent tension throughout the process. Proper tension control prevents web breaks, wrinkles, and registration issues, leading to improved product quality and reduced waste.- Tension control systems for web handling: Various systems have been developed to control tension in web handling processes. These systems typically include sensors to measure web tension, controllers to process this information, and actuators to adjust tension accordingly. Advanced control algorithms can be implemented to maintain consistent tension throughout the process, which is critical for preventing web breaks, wrinkles, and ensuring product quality in continuous processing operations.

- Mechanical tension regulation devices: Mechanical devices such as dancer rolls, load cells, and pneumatic cylinders are commonly used to regulate web tension. These components physically interact with the web material to maintain proper tension levels. Dancer rolls, in particular, serve as both tension sensors and regulators by moving in response to tension changes, while providing a reservoir of material to accommodate speed variations between different sections of the web handling system.

- Electronic and computerized tension control: Modern web handling systems incorporate electronic and computerized control systems for precise tension management. These systems use digital controllers, programmable logic controllers (PLCs), and specialized software to monitor and adjust web tension in real-time. Advanced features include automatic calibration, tension profiling across the web width, and integration with other process control systems for comprehensive production management.

- Multi-zone tension control for continuous processing: In continuous web processing operations, maintaining appropriate tension across multiple zones is essential. Systems have been developed to independently control tension in different sections of the web path, allowing for optimal processing conditions throughout the entire line. This approach is particularly important in applications involving multiple operations such as printing, coating, laminating, and converting, where tension requirements may vary between processes.

- Specialized tension control for delicate substrates: Handling delicate or sensitive web materials requires specialized tension control approaches. These systems feature high-precision sensors, gentle contact mechanisms, and sophisticated control algorithms designed to maintain minimal yet consistent tension. Applications include processing of thin films, fragile textiles, and specialty papers where conventional tension control methods might cause damage or deformation to the substrate.

02 Mechanical devices for web tension regulation

Various mechanical devices are employed to regulate web tension in substrate handling systems. These include dancer rollers, load cells, pneumatic cylinders, and mechanical brakes. Dancer rollers act as buffers to absorb tension variations, while load cells directly measure the force applied to the web. Pneumatic cylinders provide controlled pressure for tension adjustment, and mechanical brakes offer resistance for tension control. These devices can be used individually or in combination to achieve precise tension control across different web materials and processing speeds.Expand Specific Solutions03 Electronic and computerized tension control methods

Modern web handling systems utilize electronic and computerized methods for tension control. These include digital controllers, programmable logic controllers (PLCs), and specialized software algorithms that can adapt to changing process conditions. Some systems incorporate machine learning capabilities to optimize tension settings based on historical data. Electronic systems offer advantages such as faster response times, higher precision, and the ability to store multiple tension profiles for different substrate types and production requirements.Expand Specific Solutions04 Multi-zone tension control for complex web paths

Complex web handling systems often require multi-zone tension control to manage tension across different sections of the web path. This approach divides the web path into separate zones, each with its own tension control system. Zone isolation is achieved through driven rollers or nip points that prevent tension disturbances from propagating between zones. This method is particularly important in processes involving multiple operations such as printing, coating, and laminating, where tension requirements may differ significantly between process stages.Expand Specific Solutions05 Tension control for specialty applications

Specialty applications such as thin film processing, delicate substrate handling, and high-speed operations require customized tension control solutions. These may include ultra-sensitive tension sensors, specialized algorithms for dynamic tension adjustment, and hybrid systems combining multiple control technologies. For temperature-sensitive materials, systems may incorporate compensation for thermal expansion effects. In applications involving extensible materials, strain measurement and compensation techniques are employed to maintain proper registration and dimensional stability throughout the process.Expand Specific Solutions

Key Industry Players in R2R SALD Equipment Manufacturing

The roll-to-roll spatial atomic layer deposition (R2R SALD) market is currently in its early growth phase, with increasing adoption across electronics, photovoltaics, and energy storage applications. The global market size is estimated to reach $300-400 million by 2025, driven by demand for high-throughput, cost-effective thin film deposition. Technologically, the substrate handling and web tension control systems are advancing rapidly, with key players demonstrating varying levels of maturity. ULVAC, Picosun, and SCREEN Holdings lead with commercial R2R SALD systems featuring advanced tension control, while Carpe Diem Tech and Industrial Technology Research Institute focus on modular approaches. Traditional web handling experts like Erhardt+Leimer and Eastman Kodak contribute established tension control technologies, creating a competitive landscape where specialized expertise in both ALD chemistry and precision web handling determines market position.

SCREEN Holdings Co. Ltd.

Technical Solution: SCREEN Holdings has developed a comprehensive R2R SALD substrate handling system specifically designed for high-precision electronic applications. Their technology features a multi-zone tension control architecture with dedicated servo drives for each roller, allowing precise tension profiling throughout the deposition process. The system incorporates advanced load cell technology with temperature compensation to maintain accurate tension measurements despite thermal variations during the SALD process. SCREEN's innovation includes a proprietary "floating roller" design that isolates the substrate from mechanical vibrations during transport, critical for maintaining uniform deposition thickness. Their web handling system features automatic splice detection and tension adjustment capabilities that can maintain process continuity during roll changes. The control system employs a sophisticated algorithm that continuously calculates optimal tension based on substrate properties, current roll diameter, and process parameters. Additionally, SCREEN has integrated their tension control system with their SALD precursor delivery system, allowing coordinated adjustments between web speed, tension, and precursor flow rates to maintain coating uniformity[8][9].

Strengths: Superior precision for high-value electronic applications; excellent vibration isolation improving coating uniformity; integrated approach coordinating tension control with deposition parameters. Weaknesses: Higher system complexity requiring specialized maintenance; premium pricing compared to standard web handling solutions.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has developed an innovative R2R SALD system with advanced substrate handling capabilities focused on flexible electronics applications. Their technology features a hybrid tension control system that combines load cell feedback with dancer position control, providing both rapid response to sudden changes and long-term stability. ITRI's system incorporates segmented tension zones with independent control parameters optimized for different stages of the SALD process, including pre-cleaning, deposition, and post-treatment zones. A key innovation is their non-contact optical tension measurement system that uses laser triangulation to monitor web deflection without physically contacting sensitive substrates. The system also features an intelligent web guiding mechanism that uses machine vision to detect and correct lateral movement in real-time. ITRI's control architecture employs a hierarchical approach with local tension controllers supervised by a master system that coordinates overall web transport while optimizing for deposition quality parameters[6][7].

Strengths: Excellent handling of ultra-thin and sensitive substrates; non-contact measurement preserving coating integrity; sophisticated coordination between tension control and deposition parameters. Weaknesses: Higher technical complexity requiring specialized expertise; more expensive than conventional tension systems.

Critical Patents in Substrate Handling for Atomic Layer Deposition

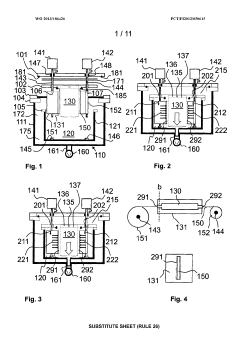

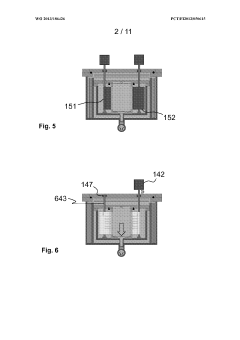

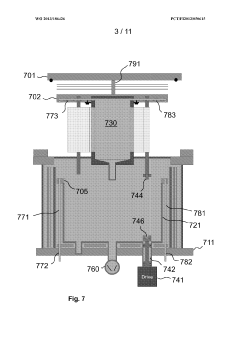

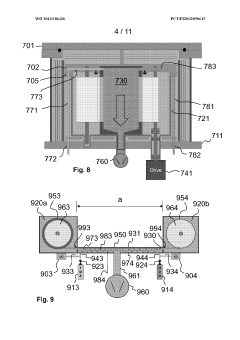

Coating a substrate web by atomic layer deposition

PatentWO2013186426A1

Innovation

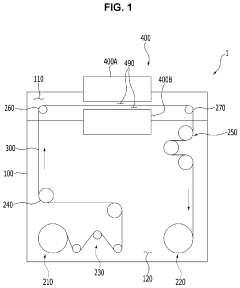

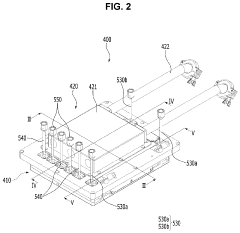

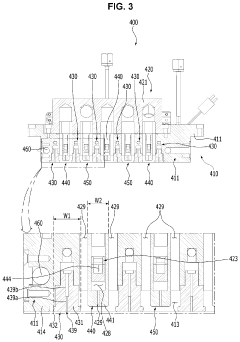

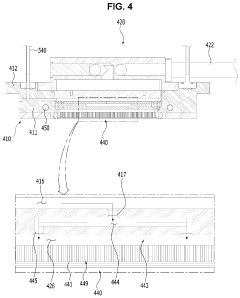

- The method involves driving a substrate web through a reaction space in an ALD reactor, where it is exposed to temporally separated precursor pulses, allowing for sequential self-saturating surface reactions, and controlling material growth by adjusting the web speed, with the reactor design featuring a single processing chamber and pressure management through slits to prevent precursor vapor backflow.

Roll-to-roll atomic layer deposition apparatus

PatentPendingUS20220364237A1

Innovation

- A roll-to-roll atomic layer deposition apparatus is designed with a casing, substrate transfer assembly, and gas supply modules that include upper and lower gas supply modules, purge gas, reaction gas, and source gas units, optimized for efficient gas distribution and heating, operating at pressures between 0.5 and 1.5 atm with inert gas, to ensure uniform deposition on flexible substrates.

Materials Compatibility and Process Integration Considerations

The successful implementation of Roll-to-Roll Spatial Atomic Layer Deposition (R2R SALD) processes critically depends on materials compatibility and process integration considerations. The substrate material selection must account for both the chemical reactions occurring during deposition and the mechanical stresses imposed by the R2R handling system. Polymeric substrates such as PET, PEN, and PI (polyimide) remain popular choices due to their flexibility and cost-effectiveness, but each presents unique challenges when exposed to SALD precursors and processing temperatures.

Temperature sensitivity represents a primary concern, as many flexible substrates have relatively low glass transition temperatures. For instance, PET begins to deform at approximately 70-80°C, while polyimide can withstand temperatures up to 300-350°C. This thermal limitation directly impacts process parameters, potentially necessitating lower deposition temperatures that may compromise film quality or deposition rate. Implementing active cooling systems at critical points in the R2R pathway can mitigate thermal degradation risks.

Chemical compatibility between substrates and precursors demands careful evaluation. Certain precursor chemistries, particularly those containing highly reactive organometallic compounds, may cause substrate degradation through unwanted side reactions. Pre-treatment processes such as plasma activation or application of barrier layers can enhance chemical resistance while improving adhesion properties of the deposited films. These treatments must be integrated into the process flow without disrupting web tension control or throughput rates.

Surface roughness and morphology of the substrate significantly influence film nucleation and growth mechanisms. Excessive roughness can lead to non-uniform film formation, while extremely smooth surfaces may present adhesion challenges. Characterization techniques such as AFM and profilometry should be employed to establish substrate quality control parameters that ensure consistent film properties across production batches.

The integration of in-situ monitoring systems presents another critical consideration. Optical sensors for thickness measurement, tension monitoring devices, and temperature probes must be strategically positioned without interfering with the deposition process. These systems should provide real-time feedback to the tension control mechanisms, allowing for dynamic adjustments that maintain optimal substrate positioning throughout the deposition zone.

Post-deposition handling requirements further complicate process integration. Newly deposited films may require specific environmental conditions during winding to prevent degradation or contamination. Controlled atmosphere in post-deposition zones and specialized winding techniques that minimize contact with sensitive surfaces can preserve film integrity until subsequent processing steps or final application.

Temperature sensitivity represents a primary concern, as many flexible substrates have relatively low glass transition temperatures. For instance, PET begins to deform at approximately 70-80°C, while polyimide can withstand temperatures up to 300-350°C. This thermal limitation directly impacts process parameters, potentially necessitating lower deposition temperatures that may compromise film quality or deposition rate. Implementing active cooling systems at critical points in the R2R pathway can mitigate thermal degradation risks.

Chemical compatibility between substrates and precursors demands careful evaluation. Certain precursor chemistries, particularly those containing highly reactive organometallic compounds, may cause substrate degradation through unwanted side reactions. Pre-treatment processes such as plasma activation or application of barrier layers can enhance chemical resistance while improving adhesion properties of the deposited films. These treatments must be integrated into the process flow without disrupting web tension control or throughput rates.

Surface roughness and morphology of the substrate significantly influence film nucleation and growth mechanisms. Excessive roughness can lead to non-uniform film formation, while extremely smooth surfaces may present adhesion challenges. Characterization techniques such as AFM and profilometry should be employed to establish substrate quality control parameters that ensure consistent film properties across production batches.

The integration of in-situ monitoring systems presents another critical consideration. Optical sensors for thickness measurement, tension monitoring devices, and temperature probes must be strategically positioned without interfering with the deposition process. These systems should provide real-time feedback to the tension control mechanisms, allowing for dynamic adjustments that maintain optimal substrate positioning throughout the deposition zone.

Post-deposition handling requirements further complicate process integration. Newly deposited films may require specific environmental conditions during winding to prevent degradation or contamination. Controlled atmosphere in post-deposition zones and specialized winding techniques that minimize contact with sensitive surfaces can preserve film integrity until subsequent processing steps or final application.

Scalability and Cost Analysis of R2R SALD Implementation

The economic viability of Roll-to-Roll Spatial Atomic Layer Deposition (R2R SALD) implementation hinges on scalability factors and cost considerations that determine its industrial adoption. When analyzing production capacity, R2R SALD demonstrates significant advantages over conventional batch ALD processes, with throughput increases of 10-100 times depending on implementation specifics. This scalability is primarily achieved through continuous processing capabilities that eliminate the chamber evacuation cycles required in traditional ALD.

Capital expenditure analysis reveals that initial investment for R2R SALD systems ranges from $500,000 for basic research configurations to $5-10 million for industrial-scale production lines. While this represents a substantial upfront cost, the amortization period is typically 30-40% shorter than conventional vacuum-based ALD systems due to higher throughput capabilities.

Operational expenditure considerations show that web tension control systems, critical for substrate handling, contribute approximately 15-20% to the total operational costs. Energy consumption metrics indicate that R2R SALD processes operate at 40-60% lower energy requirements compared to vacuum-based alternatives, primarily due to atmospheric pressure operation that eliminates vacuum pumping systems.

Material utilization efficiency in optimized R2R SALD systems reaches 80-90%, significantly higher than the 30-50% typical in conventional ALD. This efficiency is directly correlated with precise web tension control that maintains optimal substrate positioning during deposition cycles. Precursor consumption analysis indicates that well-calibrated web handling systems can reduce precursor waste by 25-35%, representing substantial cost savings for expensive chemical precursors.

Scale-up challenges primarily revolve around maintaining uniform web tension across increasing substrate widths. Economic modeling suggests that the cost-per-unit-area decreases exponentially as substrate width increases, with the inflection point for maximum cost efficiency occurring at approximately 500-600mm width for most applications. Beyond this width, tension control complexity increases disproportionately to throughput gains.

Return on investment calculations demonstrate that R2R SALD implementations typically achieve break-even within 2-3 years for high-volume applications such as barrier films and flexible electronics. This timeline is heavily dependent on maintaining consistent production quality through precise substrate handling and tension control systems that minimize defect rates and material waste.

Capital expenditure analysis reveals that initial investment for R2R SALD systems ranges from $500,000 for basic research configurations to $5-10 million for industrial-scale production lines. While this represents a substantial upfront cost, the amortization period is typically 30-40% shorter than conventional vacuum-based ALD systems due to higher throughput capabilities.

Operational expenditure considerations show that web tension control systems, critical for substrate handling, contribute approximately 15-20% to the total operational costs. Energy consumption metrics indicate that R2R SALD processes operate at 40-60% lower energy requirements compared to vacuum-based alternatives, primarily due to atmospheric pressure operation that eliminates vacuum pumping systems.

Material utilization efficiency in optimized R2R SALD systems reaches 80-90%, significantly higher than the 30-50% typical in conventional ALD. This efficiency is directly correlated with precise web tension control that maintains optimal substrate positioning during deposition cycles. Precursor consumption analysis indicates that well-calibrated web handling systems can reduce precursor waste by 25-35%, representing substantial cost savings for expensive chemical precursors.

Scale-up challenges primarily revolve around maintaining uniform web tension across increasing substrate widths. Economic modeling suggests that the cost-per-unit-area decreases exponentially as substrate width increases, with the inflection point for maximum cost efficiency occurring at approximately 500-600mm width for most applications. Beyond this width, tension control complexity increases disproportionately to throughput gains.

Return on investment calculations demonstrate that R2R SALD implementations typically achieve break-even within 2-3 years for high-volume applications such as barrier films and flexible electronics. This timeline is heavily dependent on maintaining consistent production quality through precise substrate handling and tension control systems that minimize defect rates and material waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!