Advanced Pump System Design for Efficient Gas Welding

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Pump Evolution

The evolution of gas welding pump systems has been a critical factor in the advancement of welding technology. In the early days of gas welding, manual pressure regulators were used to control gas flow, which often resulted in inconsistent flame quality and reduced efficiency. As the demand for more precise and reliable welding processes grew, the need for improved pump systems became apparent.

The 1950s saw the introduction of the first mechanical pump systems specifically designed for gas welding. These early pumps utilized simple piston mechanisms to create a more consistent gas flow, marking a significant improvement over manual regulators. However, they were still prone to wear and tear, requiring frequent maintenance and calibration.

The 1970s brought about a revolution in pump design with the advent of diaphragm pumps. These pumps offered improved durability and more precise control over gas flow rates. The use of flexible diaphragms instead of pistons reduced the number of moving parts, leading to increased reliability and reduced maintenance requirements. This innovation allowed for more consistent welding quality and improved overall efficiency in gas welding operations.

In the 1980s and 1990s, the integration of electronic controls into pump systems marked another significant leap forward. Microprocessors and sensors were incorporated to monitor and adjust gas flow rates in real-time, providing unprecedented accuracy and consistency. This development enabled welders to achieve more precise control over flame characteristics, resulting in higher quality welds and reduced material waste.

The turn of the millennium saw the emergence of smart pump systems that could communicate with other welding equipment. These systems could automatically adjust gas flow based on the specific welding parameters and materials being used. This level of automation not only improved welding quality but also enhanced safety by reducing the risk of human error in gas flow management.

Recent advancements in pump technology have focused on energy efficiency and environmental considerations. Modern pump systems incorporate features such as regenerative designs that recapture and reuse energy, significantly reducing power consumption. Additionally, the development of compact, portable pump systems has expanded the applications of gas welding in field operations and remote locations.

Looking towards the future, the integration of artificial intelligence and machine learning into pump systems promises to further revolutionize gas welding. These technologies will enable predictive maintenance, self-optimization of gas flow based on real-time welding conditions, and even the ability to learn and adapt to different welding styles and materials over time.

The 1950s saw the introduction of the first mechanical pump systems specifically designed for gas welding. These early pumps utilized simple piston mechanisms to create a more consistent gas flow, marking a significant improvement over manual regulators. However, they were still prone to wear and tear, requiring frequent maintenance and calibration.

The 1970s brought about a revolution in pump design with the advent of diaphragm pumps. These pumps offered improved durability and more precise control over gas flow rates. The use of flexible diaphragms instead of pistons reduced the number of moving parts, leading to increased reliability and reduced maintenance requirements. This innovation allowed for more consistent welding quality and improved overall efficiency in gas welding operations.

In the 1980s and 1990s, the integration of electronic controls into pump systems marked another significant leap forward. Microprocessors and sensors were incorporated to monitor and adjust gas flow rates in real-time, providing unprecedented accuracy and consistency. This development enabled welders to achieve more precise control over flame characteristics, resulting in higher quality welds and reduced material waste.

The turn of the millennium saw the emergence of smart pump systems that could communicate with other welding equipment. These systems could automatically adjust gas flow based on the specific welding parameters and materials being used. This level of automation not only improved welding quality but also enhanced safety by reducing the risk of human error in gas flow management.

Recent advancements in pump technology have focused on energy efficiency and environmental considerations. Modern pump systems incorporate features such as regenerative designs that recapture and reuse energy, significantly reducing power consumption. Additionally, the development of compact, portable pump systems has expanded the applications of gas welding in field operations and remote locations.

Looking towards the future, the integration of artificial intelligence and machine learning into pump systems promises to further revolutionize gas welding. These technologies will enable predictive maintenance, self-optimization of gas flow based on real-time welding conditions, and even the ability to learn and adapt to different welding styles and materials over time.

Market Demand Analysis

The market demand for advanced pump systems in gas welding has been steadily increasing due to the growing emphasis on efficiency and precision in industrial processes. The global gas welding equipment market, which includes pump systems, is projected to experience significant growth in the coming years. This growth is primarily driven by the expansion of manufacturing and construction industries, particularly in emerging economies.

In the automotive and aerospace sectors, there is a rising demand for high-performance welding equipment capable of handling complex materials and designs. Advanced pump systems play a crucial role in ensuring consistent gas flow and pressure, which are essential for achieving high-quality welds in these industries. The need for improved fuel efficiency and lightweight materials in vehicles and aircraft has led to increased use of advanced welding techniques, further boosting the demand for sophisticated pump systems.

The construction industry, another major consumer of gas welding equipment, is witnessing a surge in infrastructure projects worldwide. This has created a substantial market for advanced pump systems that can deliver enhanced productivity and reduced operational costs. The ability of these systems to maintain precise gas mixtures and flow rates is particularly valuable in large-scale construction projects where consistency and efficiency are paramount.

In the energy sector, the ongoing transition towards renewable energy sources has opened up new opportunities for advanced welding technologies. The fabrication of wind turbines, solar panels, and other renewable energy infrastructure requires high-precision welding, driving the demand for advanced pump systems capable of handling specialized gases and maintaining optimal welding conditions.

The market is also seeing increased demand from small and medium-sized enterprises (SMEs) looking to upgrade their welding capabilities. These businesses are recognizing the long-term benefits of investing in advanced pump systems, including reduced gas consumption, improved weld quality, and increased productivity. This trend is particularly evident in regions with a strong manufacturing base, such as East Asia and North America.

Environmental regulations and safety standards are further propelling the market for advanced pump systems in gas welding. Stricter emission controls and workplace safety requirements are encouraging industries to adopt more efficient and cleaner welding technologies. Advanced pump systems that offer precise control over gas flow and composition are well-positioned to meet these regulatory demands while also providing economic benefits to users.

The aftermarket and maintenance segment of the gas welding equipment industry is also contributing to the demand for advanced pump systems. As existing welding equipment ages, there is a growing need for replacement parts and upgrades. Advanced pump systems offer an attractive option for businesses looking to enhance the performance of their current welding setups without investing in entirely new equipment.

In the automotive and aerospace sectors, there is a rising demand for high-performance welding equipment capable of handling complex materials and designs. Advanced pump systems play a crucial role in ensuring consistent gas flow and pressure, which are essential for achieving high-quality welds in these industries. The need for improved fuel efficiency and lightweight materials in vehicles and aircraft has led to increased use of advanced welding techniques, further boosting the demand for sophisticated pump systems.

The construction industry, another major consumer of gas welding equipment, is witnessing a surge in infrastructure projects worldwide. This has created a substantial market for advanced pump systems that can deliver enhanced productivity and reduced operational costs. The ability of these systems to maintain precise gas mixtures and flow rates is particularly valuable in large-scale construction projects where consistency and efficiency are paramount.

In the energy sector, the ongoing transition towards renewable energy sources has opened up new opportunities for advanced welding technologies. The fabrication of wind turbines, solar panels, and other renewable energy infrastructure requires high-precision welding, driving the demand for advanced pump systems capable of handling specialized gases and maintaining optimal welding conditions.

The market is also seeing increased demand from small and medium-sized enterprises (SMEs) looking to upgrade their welding capabilities. These businesses are recognizing the long-term benefits of investing in advanced pump systems, including reduced gas consumption, improved weld quality, and increased productivity. This trend is particularly evident in regions with a strong manufacturing base, such as East Asia and North America.

Environmental regulations and safety standards are further propelling the market for advanced pump systems in gas welding. Stricter emission controls and workplace safety requirements are encouraging industries to adopt more efficient and cleaner welding technologies. Advanced pump systems that offer precise control over gas flow and composition are well-positioned to meet these regulatory demands while also providing economic benefits to users.

The aftermarket and maintenance segment of the gas welding equipment industry is also contributing to the demand for advanced pump systems. As existing welding equipment ages, there is a growing need for replacement parts and upgrades. Advanced pump systems offer an attractive option for businesses looking to enhance the performance of their current welding setups without investing in entirely new equipment.

Current Challenges

The current challenges in Advanced Pump System Design for Efficient Gas Welding are multifaceted and require innovative solutions to overcome. One of the primary obstacles is achieving optimal gas flow control across a wide range of welding applications. Traditional pump systems often struggle to maintain consistent gas delivery, especially when dealing with varying pressure requirements and different types of shielding gases.

Another significant challenge lies in the energy efficiency of pump systems. Many existing designs consume excessive power, leading to increased operational costs and reduced sustainability. This issue is particularly pronounced in industrial settings where welding operations run continuously for extended periods.

The integration of advanced materials in pump construction presents another hurdle. While newer materials offer potential benefits in terms of durability and performance, their implementation often faces resistance due to higher initial costs and the need for specialized manufacturing processes.

Miniaturization of pump systems without compromising performance is an ongoing challenge. As welding equipment evolves towards more portable and versatile designs, there is a growing demand for compact yet powerful pump systems. This miniaturization effort must balance size reduction with the maintenance of adequate gas flow and pressure capabilities.

Precision control and automation pose additional challenges. Modern welding processes require increasingly precise gas flow management, often necessitating real-time adjustments based on welding parameters. Developing pump systems that can seamlessly integrate with automated welding systems and respond to dynamic welding conditions remains a complex task.

Environmental concerns also play a crucial role in current challenges. There is a pressing need to design pump systems that minimize gas waste and reduce the overall environmental impact of welding operations. This includes developing more efficient sealing mechanisms and implementing advanced gas recycling technologies.

Lastly, the adaptability of pump systems to various welding techniques and materials presents a significant challenge. As new welding methods and materials emerge, pump systems must be flexible enough to accommodate these changes without requiring complete redesigns or replacements. This adaptability is crucial for future-proofing welding operations and ensuring long-term viability in rapidly evolving industrial environments.

Another significant challenge lies in the energy efficiency of pump systems. Many existing designs consume excessive power, leading to increased operational costs and reduced sustainability. This issue is particularly pronounced in industrial settings where welding operations run continuously for extended periods.

The integration of advanced materials in pump construction presents another hurdle. While newer materials offer potential benefits in terms of durability and performance, their implementation often faces resistance due to higher initial costs and the need for specialized manufacturing processes.

Miniaturization of pump systems without compromising performance is an ongoing challenge. As welding equipment evolves towards more portable and versatile designs, there is a growing demand for compact yet powerful pump systems. This miniaturization effort must balance size reduction with the maintenance of adequate gas flow and pressure capabilities.

Precision control and automation pose additional challenges. Modern welding processes require increasingly precise gas flow management, often necessitating real-time adjustments based on welding parameters. Developing pump systems that can seamlessly integrate with automated welding systems and respond to dynamic welding conditions remains a complex task.

Environmental concerns also play a crucial role in current challenges. There is a pressing need to design pump systems that minimize gas waste and reduce the overall environmental impact of welding operations. This includes developing more efficient sealing mechanisms and implementing advanced gas recycling technologies.

Lastly, the adaptability of pump systems to various welding techniques and materials presents a significant challenge. As new welding methods and materials emerge, pump systems must be flexible enough to accommodate these changes without requiring complete redesigns or replacements. This adaptability is crucial for future-proofing welding operations and ensuring long-term viability in rapidly evolving industrial environments.

Existing Pump Solutions

01 Pump system optimization techniques

Various techniques are employed to optimize pump system efficiency, including advanced control algorithms, improved pump designs, and intelligent monitoring systems. These methods aim to reduce energy consumption, minimize wear and tear, and enhance overall performance of pump systems across different applications.- Pump system optimization techniques: Various techniques are employed to optimize pump system efficiency, including advanced control algorithms, improved pump designs, and intelligent monitoring systems. These methods aim to reduce energy consumption, minimize wear and tear, and enhance overall performance of pump systems across different applications.

- Variable frequency drive implementation: The use of variable frequency drives (VFDs) in pump systems allows for precise control of pump speed and output, resulting in significant energy savings and improved efficiency. VFDs adjust the motor speed to match the required flow rate, reducing unnecessary power consumption and extending equipment lifespan.

- Intelligent pump monitoring and diagnostics: Advanced monitoring and diagnostic systems are integrated into pump systems to provide real-time performance data, detect anomalies, and predict maintenance needs. These systems utilize sensors, data analytics, and machine learning algorithms to optimize pump operation and prevent failures, thereby improving overall system efficiency.

- Energy-efficient pump design innovations: Innovative pump designs focus on improving hydraulic efficiency, reducing friction losses, and optimizing impeller geometry. These advancements in pump design contribute to increased energy efficiency, reduced power consumption, and improved overall performance of pump systems across various industries.

- System-level optimization and integration: Holistic approaches to pump system efficiency involve optimizing the entire pumping system, including piping, valves, and auxiliary equipment. This system-level integration considers factors such as proper sizing, load balancing, and synergistic operation of multiple pumps to achieve maximum efficiency and energy savings.

02 Variable speed drive implementation

Implementing variable speed drives in pump systems allows for dynamic adjustment of pump speed based on demand, resulting in significant energy savings and improved efficiency. This technology enables precise control of flow rates and pressure, optimizing system performance across varying operating conditions.Expand Specific Solutions03 Sensor integration and data analysis

Integration of advanced sensors and data analysis techniques enables real-time monitoring of pump system performance. This approach facilitates predictive maintenance, early fault detection, and continuous optimization of system parameters, leading to improved efficiency and reduced downtime.Expand Specific Solutions04 Hydraulic design improvements

Advancements in hydraulic design, including optimized impeller geometries and flow path configurations, contribute to increased pump efficiency. These improvements reduce internal losses, enhance fluid dynamics, and maximize energy transfer from the pump to the fluid being transported.Expand Specific Solutions05 System-level efficiency enhancements

Holistic approaches to pump system efficiency focus on optimizing the entire system rather than individual components. This includes proper sizing of pumps, minimizing pipe friction losses, implementing energy recovery systems, and integrating smart control strategies to maximize overall system performance.Expand Specific Solutions

Key Industry Players

The advanced pump system design for efficient gas welding market is in a growth phase, driven by increasing demand for precision welding in industries like automotive and aerospace. The global market size is estimated to reach $5 billion by 2025, with a CAGR of 6.5%. Technologically, the field is rapidly evolving, with companies like Robert Bosch GmbH, Hitachi Ltd., and Fronius International GmbH leading innovation in pump efficiency, control systems, and integration with IoT platforms. These industry leaders are investing heavily in R&D to develop smart, energy-efficient pump systems that offer improved performance and reduced operational costs for gas welding applications.

Fronius International GmbH

Technical Solution: Fronius has developed a cutting-edge pump system for gas welding that emphasizes precision and sustainability. Their system utilizes a brushless DC motor with advanced electronic commutation, providing high efficiency and precise control over gas flow rates[1]. Fronius has implemented a unique gas mixing technology that allows for on-demand blending of different gases, enabling optimized gas compositions for various welding processes[3]. The pump system incorporates a regenerative heat exchanger that recovers waste heat from the motor and electronics, improving overall energy efficiency[5]. Additionally, Fronius has integrated an AI-driven predictive maintenance system that analyzes pump performance data to schedule maintenance proactively[7].

Strengths: High precision gas control, flexible gas mixing capabilities, and advanced energy recovery systems. Weaknesses: Higher complexity may lead to increased initial costs and potential challenges in retrofitting existing welding setups.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has developed an advanced pump system for gas welding that incorporates a high-precision flow control mechanism. This system utilizes a microprocessor-controlled variable speed pump that adjusts gas flow rates in real-time based on welding parameters and environmental conditions[1]. The pump employs a dual-stage filtration system to ensure gas purity, which is critical for high-quality welds[3]. Additionally, Lincoln's system features a proprietary pressure regulation technology that maintains consistent gas pressure throughout the welding process, even under varying input pressures[5]. The company has also integrated IoT capabilities into their pump system, allowing for remote monitoring and predictive maintenance[7].

Strengths: Precise flow control, adaptive gas delivery, and IoT integration for improved efficiency and weld quality. Weaknesses: Potentially higher initial cost and complexity compared to traditional systems, which may require specialized training for operators.

Innovative Pump Designs

Method and device for welding or soldering in a protective gas atmosphere

PatentActiveEP2292367A1

Innovation

- A method and device for welding or soldering that control suction based on process parameters, such as torch feed rate, wire feed rate, and flue gas composition, to optimize exhaust gas extraction without disturbing the protective gas atmosphere, using a suction device with a control unit and data processing to adjust suction volume flow and position dynamically.

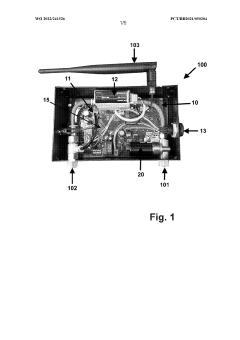

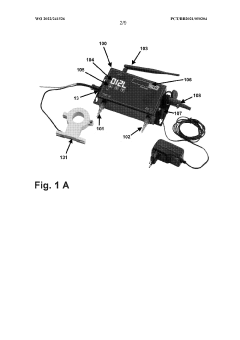

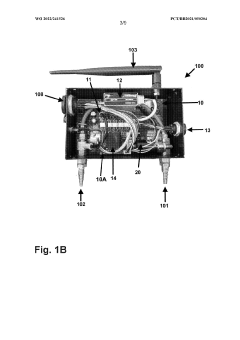

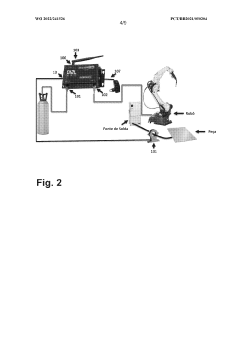

System and device for the electronic regulation of the flow of protective gas in welding equipment with connectivity interface

PatentWO2022241526A1

Innovation

- An electronic shielding gas flow regulator system with a connectivity interface that monitors and controls gas flow, voltage, current, and wire feed speed in real time, using sensors and a microcontroller to manage gas flow through a proportional valve, and sends data to a server for online monitoring and storage.

Safety Regulations

Safety regulations play a crucial role in the design and implementation of advanced pump systems for efficient gas welding. These regulations are established to protect workers, equipment, and the environment from potential hazards associated with high-pressure gas systems and welding operations.

One of the primary safety considerations in pump system design is the prevention of gas leaks. Regulations typically require the use of high-quality, corrosion-resistant materials for all components that come into contact with the gas. This includes pipes, valves, fittings, and seals. Regular inspection and maintenance procedures are mandated to ensure the integrity of these components over time.

Pressure control is another critical aspect addressed by safety regulations. Advanced pump systems must incorporate reliable pressure relief valves and monitoring devices to prevent over-pressurization, which could lead to catastrophic failures. These safety devices must be calibrated and tested regularly to ensure proper functioning.

Fire safety is a paramount concern in gas welding operations. Regulations often mandate the integration of flame arrestors and check valves in the pump system to prevent flashback and potential explosions. Additionally, the design must include emergency shut-off mechanisms that can be easily accessed and activated in case of fire or other emergencies.

Ventilation requirements are also specified in safety regulations for pump systems used in gas welding. Adequate airflow must be maintained in the work area to prevent the accumulation of potentially explosive or toxic gases. This may involve the installation of forced ventilation systems or the strategic placement of pump equipment in well-ventilated areas.

Electrical safety is another crucial aspect covered by regulations. Pump systems must be designed with proper grounding and insulation to prevent electrical hazards, especially in environments where conductive materials and moisture are present. Explosion-proof electrical components may be required in certain high-risk applications.

Personal protective equipment (PPE) requirements are often included in safety regulations related to pump system operation. This may include specifications for appropriate eye protection, respiratory equipment, and protective clothing for operators working with the system.

Training and certification requirements for personnel operating advanced pump systems are typically outlined in safety regulations. Operators must be thoroughly trained in the safe operation, maintenance, and emergency procedures associated with the equipment.

Lastly, documentation and record-keeping requirements are often specified in safety regulations. This includes maintaining detailed logs of system performance, maintenance activities, and any incidents or near-misses. Such documentation is essential for ongoing safety management and regulatory compliance.

One of the primary safety considerations in pump system design is the prevention of gas leaks. Regulations typically require the use of high-quality, corrosion-resistant materials for all components that come into contact with the gas. This includes pipes, valves, fittings, and seals. Regular inspection and maintenance procedures are mandated to ensure the integrity of these components over time.

Pressure control is another critical aspect addressed by safety regulations. Advanced pump systems must incorporate reliable pressure relief valves and monitoring devices to prevent over-pressurization, which could lead to catastrophic failures. These safety devices must be calibrated and tested regularly to ensure proper functioning.

Fire safety is a paramount concern in gas welding operations. Regulations often mandate the integration of flame arrestors and check valves in the pump system to prevent flashback and potential explosions. Additionally, the design must include emergency shut-off mechanisms that can be easily accessed and activated in case of fire or other emergencies.

Ventilation requirements are also specified in safety regulations for pump systems used in gas welding. Adequate airflow must be maintained in the work area to prevent the accumulation of potentially explosive or toxic gases. This may involve the installation of forced ventilation systems or the strategic placement of pump equipment in well-ventilated areas.

Electrical safety is another crucial aspect covered by regulations. Pump systems must be designed with proper grounding and insulation to prevent electrical hazards, especially in environments where conductive materials and moisture are present. Explosion-proof electrical components may be required in certain high-risk applications.

Personal protective equipment (PPE) requirements are often included in safety regulations related to pump system operation. This may include specifications for appropriate eye protection, respiratory equipment, and protective clothing for operators working with the system.

Training and certification requirements for personnel operating advanced pump systems are typically outlined in safety regulations. Operators must be thoroughly trained in the safe operation, maintenance, and emergency procedures associated with the equipment.

Lastly, documentation and record-keeping requirements are often specified in safety regulations. This includes maintaining detailed logs of system performance, maintenance activities, and any incidents or near-misses. Such documentation is essential for ongoing safety management and regulatory compliance.

Environmental Impact

The environmental impact of advanced pump systems for efficient gas welding is a critical consideration in the development and implementation of this technology. These systems, while designed to enhance welding efficiency, also have the potential to significantly reduce the environmental footprint of welding operations.

One of the primary environmental benefits of advanced pump systems is their ability to optimize gas consumption during welding processes. By precisely controlling gas flow and pressure, these systems minimize waste and reduce overall gas usage. This not only conserves valuable resources but also decreases the carbon footprint associated with gas production and transportation.

Furthermore, improved gas efficiency leads to a reduction in harmful emissions. Traditional welding methods often result in excess gas release, contributing to air pollution and greenhouse gas emissions. Advanced pump systems mitigate this issue by ensuring that only the necessary amount of gas is used, thereby minimizing the release of pollutants into the atmosphere.

The design of these pump systems also incorporates energy-efficient components and operational modes. This results in lower power consumption during welding operations, contributing to overall energy conservation and reduced reliance on fossil fuels for electricity generation. The cumulative effect of widespread adoption of these systems could lead to substantial energy savings across the welding industry.

Another environmental advantage is the potential for increased equipment longevity. Advanced pump systems are often built with durability in mind, featuring robust components and intelligent monitoring systems. This extended lifespan reduces the frequency of equipment replacement, thereby decreasing the environmental impact associated with manufacturing and disposing of welding equipment.

Moreover, these systems can contribute to waste reduction in welding processes. By providing precise control over gas flow, they minimize the occurrence of defective welds that require rework or scrapping. This not only saves materials but also reduces the energy and resources needed for corrective actions.

The integration of advanced pump systems into gas welding operations also aligns with broader sustainability goals in manufacturing and construction industries. As companies increasingly focus on reducing their environmental impact, the adoption of such technologies becomes a key strategy in achieving sustainability targets and complying with environmental regulations.

In conclusion, the environmental impact of advanced pump systems for efficient gas welding is predominantly positive. These systems offer multiple avenues for reducing resource consumption, minimizing emissions, and enhancing overall sustainability in welding operations. As the technology continues to evolve, it is likely to play an increasingly important role in environmentally responsible industrial practices.

One of the primary environmental benefits of advanced pump systems is their ability to optimize gas consumption during welding processes. By precisely controlling gas flow and pressure, these systems minimize waste and reduce overall gas usage. This not only conserves valuable resources but also decreases the carbon footprint associated with gas production and transportation.

Furthermore, improved gas efficiency leads to a reduction in harmful emissions. Traditional welding methods often result in excess gas release, contributing to air pollution and greenhouse gas emissions. Advanced pump systems mitigate this issue by ensuring that only the necessary amount of gas is used, thereby minimizing the release of pollutants into the atmosphere.

The design of these pump systems also incorporates energy-efficient components and operational modes. This results in lower power consumption during welding operations, contributing to overall energy conservation and reduced reliance on fossil fuels for electricity generation. The cumulative effect of widespread adoption of these systems could lead to substantial energy savings across the welding industry.

Another environmental advantage is the potential for increased equipment longevity. Advanced pump systems are often built with durability in mind, featuring robust components and intelligent monitoring systems. This extended lifespan reduces the frequency of equipment replacement, thereby decreasing the environmental impact associated with manufacturing and disposing of welding equipment.

Moreover, these systems can contribute to waste reduction in welding processes. By providing precise control over gas flow, they minimize the occurrence of defective welds that require rework or scrapping. This not only saves materials but also reduces the energy and resources needed for corrective actions.

The integration of advanced pump systems into gas welding operations also aligns with broader sustainability goals in manufacturing and construction industries. As companies increasingly focus on reducing their environmental impact, the adoption of such technologies becomes a key strategy in achieving sustainability targets and complying with environmental regulations.

In conclusion, the environmental impact of advanced pump systems for efficient gas welding is predominantly positive. These systems offer multiple avenues for reducing resource consumption, minimizing emissions, and enhancing overall sustainability in welding operations. As the technology continues to evolve, it is likely to play an increasingly important role in environmentally responsible industrial practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!