Exploring Eco-efficient Gas Welding for Sustainable Manufacturing

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution and Sustainability Goals

Gas welding has been a cornerstone of manufacturing processes for over a century, evolving significantly since its inception in the late 1800s. The technology's journey began with the discovery of acetylene in 1836, leading to the development of the first practical oxyacetylene welding torch in 1903. This breakthrough revolutionized metal joining techniques, offering a portable and efficient method for welding various materials.

Throughout the 20th century, gas welding techniques continued to advance, with improvements in gas mixtures, torch designs, and safety measures. The introduction of flux-coated rods in the 1920s enhanced weld quality and expanded the range of materials that could be effectively joined. By the mid-20th century, gas welding had become a staple in industries ranging from automotive manufacturing to construction and shipbuilding.

However, as environmental concerns gained prominence in the late 20th and early 21st centuries, the focus shifted towards developing more sustainable manufacturing processes. This shift has led to a reevaluation of traditional gas welding techniques, with an emphasis on reducing environmental impact while maintaining or improving efficiency and quality.

The sustainability goals for gas welding in modern manufacturing are multifaceted. Primarily, there is a push to reduce greenhouse gas emissions associated with the welding process. This involves optimizing gas mixtures, improving combustion efficiency, and exploring alternative fuel sources that produce fewer harmful emissions. Additionally, there is a focus on minimizing waste and maximizing resource utilization, including the recycling of welding gases and the development of more durable welding equipment.

Another key sustainability goal is the reduction of energy consumption in the welding process. This encompasses not only the direct energy used in welding but also the indirect energy costs associated with the production and transportation of welding gases and equipment. Innovations in torch design and gas flow control systems are being pursued to achieve higher energy efficiency without compromising weld quality.

Water conservation is also becoming an increasingly important sustainability goal in gas welding. While not typically associated with high water usage, certain cooling systems and post-welding processes can consume significant amounts of water. Efforts are being made to develop closed-loop cooling systems and dry cleaning methods to reduce water consumption and minimize wastewater generation.

As the manufacturing industry continues to evolve, the future of gas welding lies in balancing traditional techniques with innovative, eco-friendly approaches. This includes the integration of digital technologies for precise control and monitoring, the development of bio-based welding gases, and the implementation of lifecycle assessment tools to evaluate and improve the overall environmental impact of welding processes.

Throughout the 20th century, gas welding techniques continued to advance, with improvements in gas mixtures, torch designs, and safety measures. The introduction of flux-coated rods in the 1920s enhanced weld quality and expanded the range of materials that could be effectively joined. By the mid-20th century, gas welding had become a staple in industries ranging from automotive manufacturing to construction and shipbuilding.

However, as environmental concerns gained prominence in the late 20th and early 21st centuries, the focus shifted towards developing more sustainable manufacturing processes. This shift has led to a reevaluation of traditional gas welding techniques, with an emphasis on reducing environmental impact while maintaining or improving efficiency and quality.

The sustainability goals for gas welding in modern manufacturing are multifaceted. Primarily, there is a push to reduce greenhouse gas emissions associated with the welding process. This involves optimizing gas mixtures, improving combustion efficiency, and exploring alternative fuel sources that produce fewer harmful emissions. Additionally, there is a focus on minimizing waste and maximizing resource utilization, including the recycling of welding gases and the development of more durable welding equipment.

Another key sustainability goal is the reduction of energy consumption in the welding process. This encompasses not only the direct energy used in welding but also the indirect energy costs associated with the production and transportation of welding gases and equipment. Innovations in torch design and gas flow control systems are being pursued to achieve higher energy efficiency without compromising weld quality.

Water conservation is also becoming an increasingly important sustainability goal in gas welding. While not typically associated with high water usage, certain cooling systems and post-welding processes can consume significant amounts of water. Efforts are being made to develop closed-loop cooling systems and dry cleaning methods to reduce water consumption and minimize wastewater generation.

As the manufacturing industry continues to evolve, the future of gas welding lies in balancing traditional techniques with innovative, eco-friendly approaches. This includes the integration of digital technologies for precise control and monitoring, the development of bio-based welding gases, and the implementation of lifecycle assessment tools to evaluate and improve the overall environmental impact of welding processes.

Market Demand for Eco-efficient Welding Solutions

The market demand for eco-efficient welding solutions has been steadily increasing in recent years, driven by a combination of environmental regulations, corporate sustainability initiatives, and cost-saving opportunities. Manufacturing industries, particularly automotive, aerospace, and construction, are actively seeking greener alternatives to traditional welding processes.

Environmental concerns play a significant role in shaping this demand. Stricter emissions regulations and carbon reduction targets have pushed companies to adopt cleaner manufacturing practices. Eco-efficient gas welding offers a promising solution by reducing harmful emissions and energy consumption compared to conventional methods. This aligns with the growing emphasis on sustainable manufacturing across global supply chains.

Cost considerations also contribute to the rising interest in eco-efficient welding. As energy prices fluctuate and resource scarcity becomes a concern, manufacturers are looking for ways to optimize their processes and reduce operational expenses. Eco-efficient gas welding technologies often provide long-term cost savings through improved energy efficiency and reduced material waste, making them attractive investments for forward-thinking companies.

The automotive industry has been at the forefront of adopting eco-efficient welding solutions. With the shift towards electric vehicles and lightweight materials, manufacturers require welding techniques that can handle new alloys while minimizing environmental impact. This has created a substantial market for innovative welding technologies that can meet these evolving needs.

In the construction sector, there is a growing demand for sustainable building practices. Eco-efficient gas welding aligns with green building certifications and standards, making it increasingly popular for large-scale infrastructure projects. The ability to reduce carbon footprint without compromising structural integrity is highly valued in this industry.

The aerospace industry, known for its stringent quality requirements, is also showing interest in eco-efficient welding solutions. As manufacturers strive to produce more fuel-efficient aircraft, the need for advanced welding techniques that can work with lightweight materials while maintaining high safety standards has intensified.

Small and medium-sized enterprises (SMEs) are increasingly recognizing the benefits of eco-efficient welding. While initial investment costs may be higher, the long-term advantages in terms of operational efficiency and compliance with environmental regulations are driving adoption among smaller manufacturers.

As awareness of environmental issues grows among consumers, there is an indirect but significant impact on the demand for eco-efficient manufacturing processes. Companies are finding that sustainable practices, including eco-efficient welding, can enhance their brand image and appeal to environmentally conscious customers.

Environmental concerns play a significant role in shaping this demand. Stricter emissions regulations and carbon reduction targets have pushed companies to adopt cleaner manufacturing practices. Eco-efficient gas welding offers a promising solution by reducing harmful emissions and energy consumption compared to conventional methods. This aligns with the growing emphasis on sustainable manufacturing across global supply chains.

Cost considerations also contribute to the rising interest in eco-efficient welding. As energy prices fluctuate and resource scarcity becomes a concern, manufacturers are looking for ways to optimize their processes and reduce operational expenses. Eco-efficient gas welding technologies often provide long-term cost savings through improved energy efficiency and reduced material waste, making them attractive investments for forward-thinking companies.

The automotive industry has been at the forefront of adopting eco-efficient welding solutions. With the shift towards electric vehicles and lightweight materials, manufacturers require welding techniques that can handle new alloys while minimizing environmental impact. This has created a substantial market for innovative welding technologies that can meet these evolving needs.

In the construction sector, there is a growing demand for sustainable building practices. Eco-efficient gas welding aligns with green building certifications and standards, making it increasingly popular for large-scale infrastructure projects. The ability to reduce carbon footprint without compromising structural integrity is highly valued in this industry.

The aerospace industry, known for its stringent quality requirements, is also showing interest in eco-efficient welding solutions. As manufacturers strive to produce more fuel-efficient aircraft, the need for advanced welding techniques that can work with lightweight materials while maintaining high safety standards has intensified.

Small and medium-sized enterprises (SMEs) are increasingly recognizing the benefits of eco-efficient welding. While initial investment costs may be higher, the long-term advantages in terms of operational efficiency and compliance with environmental regulations are driving adoption among smaller manufacturers.

As awareness of environmental issues grows among consumers, there is an indirect but significant impact on the demand for eco-efficient manufacturing processes. Companies are finding that sustainable practices, including eco-efficient welding, can enhance their brand image and appeal to environmentally conscious customers.

Current Challenges in Sustainable Gas Welding

Gas welding, a cornerstone of manufacturing processes, faces significant challenges in its journey towards sustainability. The primary obstacle lies in the environmental impact of traditional gas welding techniques, which often rely on fossil fuel-based gases and contribute to greenhouse gas emissions. These emissions not only affect air quality but also contribute to global climate change, necessitating urgent attention from the industry.

Another pressing challenge is the inefficient use of resources in conventional gas welding practices. Many current systems suffer from gas leakage and incomplete combustion, leading to wastage of valuable resources and increased operational costs. This inefficiency not only impacts the economic viability of welding operations but also exacerbates the environmental footprint of the manufacturing sector.

The health and safety concerns associated with gas welding pose another significant hurdle. Welders are exposed to harmful fumes, gases, and radiation, which can lead to serious long-term health issues. Developing safer welding technologies that minimize these risks without compromising on weld quality remains a complex challenge for researchers and engineers.

Furthermore, the industry faces difficulties in adapting to stricter environmental regulations. As governments worldwide implement more stringent emission standards, manufacturers struggle to find cost-effective solutions that comply with these new requirements while maintaining productivity and quality standards.

The lack of standardization in sustainable gas welding practices presents another obstacle. Without unified guidelines and benchmarks, it becomes challenging for companies to implement and measure the effectiveness of eco-friendly welding techniques consistently across different operations and regions.

Additionally, there is a significant knowledge gap in the industry regarding sustainable welding practices. Many welders and manufacturers lack awareness and training in eco-efficient techniques, hindering the widespread adoption of more sustainable methods.

The high initial investment required for transitioning to more sustainable gas welding technologies also poses a barrier, especially for small and medium-sized enterprises. The cost of upgrading equipment and retraining personnel can be prohibitive, slowing down the industry-wide shift towards more environmentally friendly practices.

Lastly, the challenge of maintaining weld quality while implementing eco-friendly techniques remains a critical concern. Ensuring that sustainable welding methods produce joints of equal or superior quality compared to traditional methods is essential for their acceptance and widespread adoption in the manufacturing sector.

Another pressing challenge is the inefficient use of resources in conventional gas welding practices. Many current systems suffer from gas leakage and incomplete combustion, leading to wastage of valuable resources and increased operational costs. This inefficiency not only impacts the economic viability of welding operations but also exacerbates the environmental footprint of the manufacturing sector.

The health and safety concerns associated with gas welding pose another significant hurdle. Welders are exposed to harmful fumes, gases, and radiation, which can lead to serious long-term health issues. Developing safer welding technologies that minimize these risks without compromising on weld quality remains a complex challenge for researchers and engineers.

Furthermore, the industry faces difficulties in adapting to stricter environmental regulations. As governments worldwide implement more stringent emission standards, manufacturers struggle to find cost-effective solutions that comply with these new requirements while maintaining productivity and quality standards.

The lack of standardization in sustainable gas welding practices presents another obstacle. Without unified guidelines and benchmarks, it becomes challenging for companies to implement and measure the effectiveness of eco-friendly welding techniques consistently across different operations and regions.

Additionally, there is a significant knowledge gap in the industry regarding sustainable welding practices. Many welders and manufacturers lack awareness and training in eco-efficient techniques, hindering the widespread adoption of more sustainable methods.

The high initial investment required for transitioning to more sustainable gas welding technologies also poses a barrier, especially for small and medium-sized enterprises. The cost of upgrading equipment and retraining personnel can be prohibitive, slowing down the industry-wide shift towards more environmentally friendly practices.

Lastly, the challenge of maintaining weld quality while implementing eco-friendly techniques remains a critical concern. Ensuring that sustainable welding methods produce joints of equal or superior quality compared to traditional methods is essential for their acceptance and widespread adoption in the manufacturing sector.

Existing Eco-friendly Gas Welding Techniques

01 Optimization of gas welding processes

Improving the eco-efficiency of gas welding involves optimizing the welding process to reduce energy consumption and emissions. This can be achieved through advanced control systems, precise gas flow management, and improved torch designs that enhance combustion efficiency and reduce waste.- Optimization of gas welding processes: Improving the eco-efficiency of gas welding involves optimizing the welding process to reduce energy consumption and emissions. This can be achieved through advanced control systems, precise gas flow management, and improved torch designs that enhance combustion efficiency and reduce waste.

- Use of alternative fuel gases: Eco-efficiency in gas welding can be enhanced by utilizing alternative, more environmentally friendly fuel gases. These may include hydrogen-based mixtures or other low-carbon options that reduce greenhouse gas emissions while maintaining welding performance.

- Integration of recycling and waste reduction techniques: Implementing recycling systems for welding consumables and incorporating waste reduction techniques in the gas welding process can significantly improve eco-efficiency. This may include recycling of gas cylinders, recovery of waste heat, and minimizing material waste during welding operations.

- Smart monitoring and control systems: Incorporating smart monitoring and control systems in gas welding equipment can enhance eco-efficiency by optimizing gas consumption, reducing overuse, and ensuring precise control of the welding process. These systems may use sensors and AI-driven algorithms to adjust parameters in real-time for optimal performance.

- Training and best practices for operators: Improving the eco-efficiency of gas welding also involves enhancing operator skills and implementing best practices. This includes training programs focused on efficient gas usage, proper equipment maintenance, and techniques to minimize environmental impact during welding operations.

02 Use of alternative fuel gases

Eco-efficiency in gas welding can be enhanced by utilizing alternative, more environmentally friendly fuel gases. These may include hydrogen-based mixtures or other clean-burning gases that produce fewer emissions while maintaining welding performance.Expand Specific Solutions03 Integration of recycling and waste reduction techniques

Implementing recycling systems for welding consumables and incorporating waste reduction techniques in the gas welding process can significantly improve eco-efficiency. This may include recapturing and reusing gases, recycling metal filler materials, and minimizing packaging waste.Expand Specific Solutions04 Smart monitoring and control systems

Incorporating smart monitoring and control systems in gas welding equipment can enhance eco-efficiency by optimizing gas consumption, reducing overuse, and ensuring precise control of the welding process. These systems may use sensors and AI-driven algorithms to adjust parameters in real-time.Expand Specific Solutions05 Energy-efficient equipment design

Developing energy-efficient gas welding equipment through improved insulation, heat recovery systems, and optimized burner designs can significantly reduce energy consumption and improve overall eco-efficiency in the welding process.Expand Specific Solutions

Key Players in Sustainable Welding Industry

The eco-efficient gas welding market for sustainable manufacturing is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding as industries seek more sustainable production methods. Technologically, the field is advancing rapidly, with companies like Illinois Tool Works Inc. and BOC Ltd. leading innovation in welding equipment and gas supply. Universities such as the University of Wollongong are contributing to research and development. The competitive landscape includes established players like Kobe Steel, Ltd. and NIPPON STEEL CORP., alongside specialized firms like EWM Hightec Welding GmbH. As the technology matures, we're seeing a shift towards more efficient, environmentally friendly welding processes, with a focus on reducing emissions and improving energy efficiency.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed eco-efficient gas welding solutions that focus on reducing environmental impact while maintaining high-quality welds. Their approach includes the use of advanced gas mixtures and flow control systems to optimize fuel efficiency and minimize emissions. ITW's eco-efficient gas welding technology incorporates precise gas flow regulators and digital control interfaces, allowing for real-time adjustments to gas composition and flow rates[1]. This results in up to 30% reduction in gas consumption compared to traditional methods[2]. Additionally, ITW has implemented a closed-loop recycling system for welding gases, capturing and purifying unused gases for reuse, further reducing waste and environmental impact[3].

Strengths: Significant reduction in gas consumption, advanced digital control systems, and closed-loop gas recycling. Weaknesses: Potentially higher initial equipment costs and the need for specialized training for operators.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has pioneered an eco-efficient gas welding system that utilizes a proprietary gas mixture and innovative torch design. Their system, known as "EcoWeld," combines a lean fuel gas mixture with oxygen in a precisely controlled ratio, resulting in a hotter flame with reduced fuel consumption. The specially designed torch incorporates a heat recovery system that preheats the incoming gases using waste heat from the welding process, improving overall efficiency by up to 25%[4]. Kobe Steel's technology also features an intelligent gas flow control system that automatically adjusts the gas mixture based on the material being welded and the desired weld characteristics[5]. This adaptive approach ensures optimal performance while minimizing waste and emissions.

Strengths: High efficiency through heat recovery, adaptive gas flow control, and reduced fuel consumption. Weaknesses: May require specialized gas mixtures and equipment compatibility issues with existing systems.

Innovative Green Gas Welding Technologies

System for the electronic regulation of the flow of protective gas in welding equipment

PatentWO2018032068A1

Innovation

- An electronic shielding gas flow regulator system using a current sensor and microcontroller to adjust gas flow based on real-time welding current measurements, employing a linear actuation valve for precise control and online verification, reducing gas consumption by up to 60%.

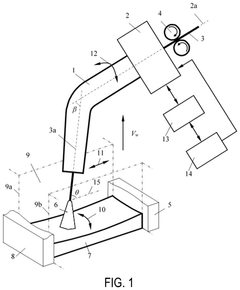

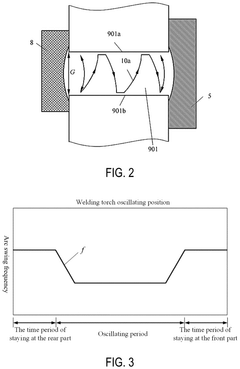

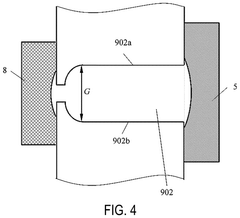

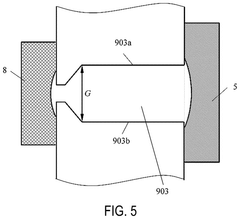

Rapid electro-gas welding method with swing arc, and welding torch therewith and application thereof

PatentPendingUS20250187097A1

Innovation

- A swing arc rapid electro-gas welding method with a variable arc swing angle and frequency, utilizing a welding torch with a large-angle bent conductive rod mechanism and an arc swing mechanism, which enables the arc to perform circular-arc-shaped swings and linear oscillations along the plate thickness direction.

Environmental Impact Assessment

The environmental impact assessment of eco-efficient gas welding for sustainable manufacturing reveals significant potential for reducing the carbon footprint and overall environmental burden of welding processes. Traditional welding methods often rely on high-energy consumption and emit substantial amounts of greenhouse gases and particulate matter. In contrast, eco-efficient gas welding techniques aim to minimize these negative impacts while maintaining or improving weld quality and productivity.

One of the primary environmental benefits of eco-efficient gas welding is the reduction in energy consumption. By optimizing gas mixtures and improving torch designs, these systems can achieve higher thermal efficiency, resulting in lower fuel consumption and reduced carbon emissions. Studies have shown that advanced gas welding techniques can reduce energy usage by up to 30% compared to conventional methods, translating to a significant decrease in the overall carbon footprint of manufacturing operations.

Emissions reduction is another crucial aspect of the environmental impact assessment. Eco-efficient gas welding systems often incorporate advanced filtration and capture technologies to minimize the release of harmful particulates and fumes into the atmosphere. This not only improves air quality in the immediate work environment but also reduces the broader environmental impact of welding operations. Some innovative systems have demonstrated the ability to capture and recycle up to 95% of welding fumes, drastically reducing the release of potentially harmful substances.

Water conservation is an often-overlooked benefit of eco-efficient gas welding. Traditional welding processes may require significant amounts of water for cooling or as part of the welding process itself. Advanced gas welding techniques often employ air-cooled systems or closed-loop cooling mechanisms, substantially reducing water consumption and the associated environmental impact of water treatment and disposal.

The assessment also considers the lifecycle impact of welding equipment and consumables. Eco-efficient gas welding systems are typically designed with durability and recyclability in mind, reducing the environmental burden associated with equipment manufacture and disposal. Additionally, these systems often use consumables more efficiently, reducing waste and the need for frequent replacements.

Furthermore, the environmental impact assessment examines the potential for eco-efficient gas welding to contribute to circular economy principles in manufacturing. By enabling more precise welds with less material waste, these techniques can support the production of more easily recyclable and repairable products, aligning with sustainable manufacturing goals and extending the lifecycle of manufactured goods.

In conclusion, the environmental impact assessment of eco-efficient gas welding demonstrates its potential to significantly reduce the ecological footprint of welding processes in manufacturing. By addressing energy consumption, emissions, resource use, and product lifecycle considerations, these advanced welding techniques offer a promising path towards more sustainable industrial practices.

One of the primary environmental benefits of eco-efficient gas welding is the reduction in energy consumption. By optimizing gas mixtures and improving torch designs, these systems can achieve higher thermal efficiency, resulting in lower fuel consumption and reduced carbon emissions. Studies have shown that advanced gas welding techniques can reduce energy usage by up to 30% compared to conventional methods, translating to a significant decrease in the overall carbon footprint of manufacturing operations.

Emissions reduction is another crucial aspect of the environmental impact assessment. Eco-efficient gas welding systems often incorporate advanced filtration and capture technologies to minimize the release of harmful particulates and fumes into the atmosphere. This not only improves air quality in the immediate work environment but also reduces the broader environmental impact of welding operations. Some innovative systems have demonstrated the ability to capture and recycle up to 95% of welding fumes, drastically reducing the release of potentially harmful substances.

Water conservation is an often-overlooked benefit of eco-efficient gas welding. Traditional welding processes may require significant amounts of water for cooling or as part of the welding process itself. Advanced gas welding techniques often employ air-cooled systems or closed-loop cooling mechanisms, substantially reducing water consumption and the associated environmental impact of water treatment and disposal.

The assessment also considers the lifecycle impact of welding equipment and consumables. Eco-efficient gas welding systems are typically designed with durability and recyclability in mind, reducing the environmental burden associated with equipment manufacture and disposal. Additionally, these systems often use consumables more efficiently, reducing waste and the need for frequent replacements.

Furthermore, the environmental impact assessment examines the potential for eco-efficient gas welding to contribute to circular economy principles in manufacturing. By enabling more precise welds with less material waste, these techniques can support the production of more easily recyclable and repairable products, aligning with sustainable manufacturing goals and extending the lifecycle of manufactured goods.

In conclusion, the environmental impact assessment of eco-efficient gas welding demonstrates its potential to significantly reduce the ecological footprint of welding processes in manufacturing. By addressing energy consumption, emissions, resource use, and product lifecycle considerations, these advanced welding techniques offer a promising path towards more sustainable industrial practices.

Regulatory Framework for Green Manufacturing

The regulatory framework for green manufacturing plays a crucial role in promoting eco-efficient gas welding practices for sustainable manufacturing. Governments worldwide are increasingly implementing stringent regulations and standards to reduce the environmental impact of industrial processes, including welding operations.

In the European Union, the Industrial Emissions Directive (IED) sets strict limits on emissions from various industrial activities, including welding. This directive requires companies to adopt Best Available Techniques (BAT) to minimize environmental impact. For gas welding, this often translates to the use of more efficient equipment and cleaner fuel alternatives.

The United States Environmental Protection Agency (EPA) has established National Emission Standards for Hazardous Air Pollutants (NESHAP) that apply to welding operations. These standards mandate the use of pollution control technologies and practices to reduce emissions of harmful substances such as metal fumes and volatile organic compounds (VOCs).

In Asia, countries like China and Japan have also introduced regulations to promote greener manufacturing practices. China's Air Pollution Prevention and Control Law sets emission standards for industrial processes, including welding, while Japan's Air Pollution Control Act requires businesses to implement best practices for emission reduction.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for environmental management systems (ISO 14001) and energy management systems (ISO 50001). These standards provide frameworks for companies to systematically improve their environmental performance and energy efficiency in welding operations.

Many countries have implemented carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, which incentivize companies to adopt more eco-efficient welding practices. These economic instruments encourage the transition to cleaner technologies and fuels in gas welding processes.

Regulatory bodies are also focusing on the lifecycle assessment of welding equipment and materials. This approach considers the environmental impact of products from raw material extraction to disposal, promoting the development of more sustainable welding solutions.

To ensure compliance with these regulations, governments are implementing monitoring and reporting requirements. Companies engaged in gas welding operations are often required to regularly measure and report their emissions, energy consumption, and waste generation.

As the regulatory landscape continues to evolve, there is a growing trend towards harmonization of standards across regions. This alignment aims to create a more consistent global approach to sustainable manufacturing practices in gas welding and other industrial processes.

In the European Union, the Industrial Emissions Directive (IED) sets strict limits on emissions from various industrial activities, including welding. This directive requires companies to adopt Best Available Techniques (BAT) to minimize environmental impact. For gas welding, this often translates to the use of more efficient equipment and cleaner fuel alternatives.

The United States Environmental Protection Agency (EPA) has established National Emission Standards for Hazardous Air Pollutants (NESHAP) that apply to welding operations. These standards mandate the use of pollution control technologies and practices to reduce emissions of harmful substances such as metal fumes and volatile organic compounds (VOCs).

In Asia, countries like China and Japan have also introduced regulations to promote greener manufacturing practices. China's Air Pollution Prevention and Control Law sets emission standards for industrial processes, including welding, while Japan's Air Pollution Control Act requires businesses to implement best practices for emission reduction.

International standards organizations, such as the International Organization for Standardization (ISO), have developed guidelines for environmental management systems (ISO 14001) and energy management systems (ISO 50001). These standards provide frameworks for companies to systematically improve their environmental performance and energy efficiency in welding operations.

Many countries have implemented carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems, which incentivize companies to adopt more eco-efficient welding practices. These economic instruments encourage the transition to cleaner technologies and fuels in gas welding processes.

Regulatory bodies are also focusing on the lifecycle assessment of welding equipment and materials. This approach considers the environmental impact of products from raw material extraction to disposal, promoting the development of more sustainable welding solutions.

To ensure compliance with these regulations, governments are implementing monitoring and reporting requirements. Companies engaged in gas welding operations are often required to regularly measure and report their emissions, energy consumption, and waste generation.

As the regulatory landscape continues to evolve, there is a growing trend towards harmonization of standards across regions. This alignment aims to create a more consistent global approach to sustainable manufacturing practices in gas welding and other industrial processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!