How Flame Shape Affects the Precision of Gas Welding

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Flame Evolution

The evolution of gas welding flame shapes has been a critical factor in enhancing the precision and efficiency of welding processes. Over the years, advancements in flame technology have led to significant improvements in weld quality, control, and versatility. The journey of flame shape evolution can be traced back to the early 20th century when oxy-fuel welding was first introduced.

Initially, gas welding flames were relatively simple and uncontrolled, often resulting in inconsistent welds and limited precision. The basic flame shape was a single conical structure, which provided limited heat distribution and control. As the demand for more precise welding techniques grew, researchers and engineers began to explore ways to manipulate and optimize flame shapes.

The 1930s and 1940s saw the development of multi-cone flame structures, which allowed for better heat distribution and improved control over the welding process. These advancements led to the introduction of the neutral, oxidizing, and carburizing flames, each serving specific purposes in different welding applications. The neutral flame, characterized by its balanced mixture of fuel and oxygen, became the standard for most welding operations due to its versatility and consistent heat output.

In the 1950s and 1960s, further refinements in flame shape design focused on creating more stable and focused flames. The introduction of the inner cone and outer envelope concept allowed for better heat concentration and reduced heat-affected zones. This development significantly improved the precision of gas welding, particularly in thin material applications and intricate joint configurations.

The late 20th century brought about computerized flame control systems, enabling real-time adjustments to flame shape and intensity. This technological leap allowed welders to fine-tune flame characteristics based on specific material properties and joint geometries. The ability to dynamically modify flame shapes during the welding process greatly enhanced the overall quality and consistency of welds across various industries.

Recent advancements in gas welding flame technology have focused on optimizing flame shapes for specific alloys and welding positions. Researchers have developed specialized flame configurations that cater to the unique properties of advanced materials, such as high-strength steels and exotic alloys. These tailored flame shapes ensure optimal heat input and distribution, resulting in superior weld quality and reduced defects.

The ongoing evolution of gas welding flame shapes continues to push the boundaries of precision and efficiency in welding applications. Current research is exploring the potential of plasma-assisted flames and hybrid flame configurations to further enhance control and versatility. As new materials and manufacturing techniques emerge, the development of innovative flame shapes will remain crucial in meeting the ever-increasing demands for precision and quality in the welding industry.

Initially, gas welding flames were relatively simple and uncontrolled, often resulting in inconsistent welds and limited precision. The basic flame shape was a single conical structure, which provided limited heat distribution and control. As the demand for more precise welding techniques grew, researchers and engineers began to explore ways to manipulate and optimize flame shapes.

The 1930s and 1940s saw the development of multi-cone flame structures, which allowed for better heat distribution and improved control over the welding process. These advancements led to the introduction of the neutral, oxidizing, and carburizing flames, each serving specific purposes in different welding applications. The neutral flame, characterized by its balanced mixture of fuel and oxygen, became the standard for most welding operations due to its versatility and consistent heat output.

In the 1950s and 1960s, further refinements in flame shape design focused on creating more stable and focused flames. The introduction of the inner cone and outer envelope concept allowed for better heat concentration and reduced heat-affected zones. This development significantly improved the precision of gas welding, particularly in thin material applications and intricate joint configurations.

The late 20th century brought about computerized flame control systems, enabling real-time adjustments to flame shape and intensity. This technological leap allowed welders to fine-tune flame characteristics based on specific material properties and joint geometries. The ability to dynamically modify flame shapes during the welding process greatly enhanced the overall quality and consistency of welds across various industries.

Recent advancements in gas welding flame technology have focused on optimizing flame shapes for specific alloys and welding positions. Researchers have developed specialized flame configurations that cater to the unique properties of advanced materials, such as high-strength steels and exotic alloys. These tailored flame shapes ensure optimal heat input and distribution, resulting in superior weld quality and reduced defects.

The ongoing evolution of gas welding flame shapes continues to push the boundaries of precision and efficiency in welding applications. Current research is exploring the potential of plasma-assisted flames and hybrid flame configurations to further enhance control and versatility. As new materials and manufacturing techniques emerge, the development of innovative flame shapes will remain crucial in meeting the ever-increasing demands for precision and quality in the welding industry.

Market Demand Analysis

The market demand for precision gas welding has been steadily increasing across various industries, driven by the growing need for high-quality, reliable welding processes. The automotive sector, in particular, has shown a significant surge in demand for precise gas welding techniques. As vehicle manufacturers strive to produce lighter, more fuel-efficient cars, the importance of accurate welding in joining lightweight materials has become paramount.

In the aerospace industry, the demand for precision gas welding has reached new heights. The construction of aircraft and spacecraft requires exceptionally high standards of welding quality to ensure structural integrity and safety. The ability to control flame shape precisely has become a critical factor in meeting these stringent requirements, leading to increased investment in advanced gas welding technologies.

The construction and infrastructure sectors have also contributed to the rising market demand for precision gas welding. Large-scale projects, such as bridges, pipelines, and high-rise buildings, require robust and accurate welding techniques to ensure long-term durability and safety. The focus on flame shape control has become increasingly important in these applications, as it directly impacts the strength and quality of the welds.

In the manufacturing industry, the push towards automation and Industry 4.0 has further fueled the demand for precision gas welding technologies. Companies are seeking solutions that can integrate seamlessly with robotic systems and provide consistent, high-quality welds. The ability to precisely control flame shape plays a crucial role in achieving this level of automation and consistency.

Market analysis indicates that the global gas welding equipment market is expected to grow significantly in the coming years. This growth is largely attributed to the increasing adoption of advanced welding technologies in emerging economies and the ongoing modernization of manufacturing processes in developed nations. The emphasis on flame shape control as a means to enhance welding precision is a key driver of this market expansion.

The energy sector, particularly in oil and gas industries, has also shown a strong demand for precision gas welding. As exploration and production activities move into more challenging environments, the need for highly reliable welding techniques has intensified. The ability to maintain precise flame shapes under varying conditions has become a critical factor in ensuring the integrity of pipelines and offshore structures.

Overall, the market demand for precision gas welding, with a specific focus on flame shape control, is robust and diverse. Industries across the board are recognizing the importance of this technology in improving product quality, enhancing safety, and increasing operational efficiency. As technological advancements continue to refine flame shape control methods, the market is expected to respond with sustained growth and innovation.

In the aerospace industry, the demand for precision gas welding has reached new heights. The construction of aircraft and spacecraft requires exceptionally high standards of welding quality to ensure structural integrity and safety. The ability to control flame shape precisely has become a critical factor in meeting these stringent requirements, leading to increased investment in advanced gas welding technologies.

The construction and infrastructure sectors have also contributed to the rising market demand for precision gas welding. Large-scale projects, such as bridges, pipelines, and high-rise buildings, require robust and accurate welding techniques to ensure long-term durability and safety. The focus on flame shape control has become increasingly important in these applications, as it directly impacts the strength and quality of the welds.

In the manufacturing industry, the push towards automation and Industry 4.0 has further fueled the demand for precision gas welding technologies. Companies are seeking solutions that can integrate seamlessly with robotic systems and provide consistent, high-quality welds. The ability to precisely control flame shape plays a crucial role in achieving this level of automation and consistency.

Market analysis indicates that the global gas welding equipment market is expected to grow significantly in the coming years. This growth is largely attributed to the increasing adoption of advanced welding technologies in emerging economies and the ongoing modernization of manufacturing processes in developed nations. The emphasis on flame shape control as a means to enhance welding precision is a key driver of this market expansion.

The energy sector, particularly in oil and gas industries, has also shown a strong demand for precision gas welding. As exploration and production activities move into more challenging environments, the need for highly reliable welding techniques has intensified. The ability to maintain precise flame shapes under varying conditions has become a critical factor in ensuring the integrity of pipelines and offshore structures.

Overall, the market demand for precision gas welding, with a specific focus on flame shape control, is robust and diverse. Industries across the board are recognizing the importance of this technology in improving product quality, enhancing safety, and increasing operational efficiency. As technological advancements continue to refine flame shape control methods, the market is expected to respond with sustained growth and innovation.

Flame Shape Challenges

Gas welding precision is significantly influenced by flame shape, presenting several challenges that welders must overcome to achieve optimal results. One of the primary difficulties lies in maintaining a consistent flame shape throughout the welding process. Fluctuations in gas pressure, nozzle wear, and environmental factors can all contribute to variations in flame geometry, leading to inconsistent heat distribution and potentially compromising weld quality.

The complexity of flame shape control is further compounded by the diverse range of welding applications, each requiring specific flame characteristics. For instance, a neutral flame is typically desired for most welding operations, but achieving and maintaining this ideal balance between oxygen and fuel gas can be challenging, especially in dynamic welding environments.

Another significant challenge is the impact of flame shape on heat affected zone (HAZ) formation. An improperly shaped flame can lead to excessive heat input, resulting in a larger HAZ and potentially altering the material properties of the welded joint. Conversely, insufficient heat due to an inadequate flame shape may result in incomplete fusion or lack of penetration, compromising the structural integrity of the weld.

The relationship between flame shape and welding speed also presents a notable challenge. An optimal flame shape at one welding speed may become ineffective when the speed is altered, requiring constant adjustments and a high level of skill from the welder. This interdependence makes it difficult to standardize welding procedures across different applications and materials.

Furthermore, the visual assessment of flame shape, which is crucial for maintaining welding precision, can be subjective and prone to human error. Experienced welders may interpret flame characteristics differently, leading to inconsistencies in weld quality across operators. This subjectivity highlights the need for more objective measurement and control methods for flame shape in gas welding.

The challenge of flame shape control is exacerbated in automated welding systems, where real-time adjustments based on visual cues are not possible. Developing sensors and control systems capable of accurately monitoring and adjusting flame shape in automated environments remains an ongoing technical challenge in the field of gas welding.

Lastly, the environmental impact of different flame shapes must be considered. Certain flame configurations may produce higher levels of emissions or consume more fuel, conflicting with increasing demands for environmentally friendly and efficient welding processes. Balancing precision welding requirements with environmental considerations adds another layer of complexity to the flame shape challenge in gas welding.

The complexity of flame shape control is further compounded by the diverse range of welding applications, each requiring specific flame characteristics. For instance, a neutral flame is typically desired for most welding operations, but achieving and maintaining this ideal balance between oxygen and fuel gas can be challenging, especially in dynamic welding environments.

Another significant challenge is the impact of flame shape on heat affected zone (HAZ) formation. An improperly shaped flame can lead to excessive heat input, resulting in a larger HAZ and potentially altering the material properties of the welded joint. Conversely, insufficient heat due to an inadequate flame shape may result in incomplete fusion or lack of penetration, compromising the structural integrity of the weld.

The relationship between flame shape and welding speed also presents a notable challenge. An optimal flame shape at one welding speed may become ineffective when the speed is altered, requiring constant adjustments and a high level of skill from the welder. This interdependence makes it difficult to standardize welding procedures across different applications and materials.

Furthermore, the visual assessment of flame shape, which is crucial for maintaining welding precision, can be subjective and prone to human error. Experienced welders may interpret flame characteristics differently, leading to inconsistencies in weld quality across operators. This subjectivity highlights the need for more objective measurement and control methods for flame shape in gas welding.

The challenge of flame shape control is exacerbated in automated welding systems, where real-time adjustments based on visual cues are not possible. Developing sensors and control systems capable of accurately monitoring and adjusting flame shape in automated environments remains an ongoing technical challenge in the field of gas welding.

Lastly, the environmental impact of different flame shapes must be considered. Certain flame configurations may produce higher levels of emissions or consume more fuel, conflicting with increasing demands for environmentally friendly and efficient welding processes. Balancing precision welding requirements with environmental considerations adds another layer of complexity to the flame shape challenge in gas welding.

Current Flame Shaping

01 Precision control systems for gas welding

Advanced control systems are implemented to enhance the precision of gas welding processes. These systems may include computerized controls, sensors, and feedback mechanisms to regulate gas flow, temperature, and torch positioning. Such precision control allows for more accurate and consistent welds, particularly in applications requiring high precision.- Precision control systems for gas welding: Advanced control systems are implemented to enhance the precision of gas welding processes. These systems may include computerized controls, sensors, and feedback mechanisms to regulate gas flow, temperature, and torch positioning. Such precision control allows for more accurate and consistent welds, particularly in applications requiring high precision.

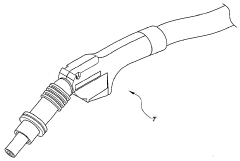

- Specialized gas welding torches for precision work: Innovative torch designs are developed specifically for precision gas welding. These torches may feature fine-tip nozzles, adjustable flame settings, and ergonomic designs to allow welders greater control and accuracy. Some designs may incorporate cooling systems or heat shields to maintain stability during delicate operations.

- Automated gas welding systems for high-precision applications: Robotic and automated gas welding systems are utilized to achieve high levels of precision in welding operations. These systems can be programmed to perform complex welding patterns with consistent accuracy, eliminating human error and fatigue factors. They often incorporate advanced vision systems and real-time monitoring for quality control.

- Gas mixture optimization for precision welding: Research focuses on optimizing gas mixtures to enhance welding precision. This involves developing specific blends of gases tailored to different materials and welding requirements. Precise gas compositions can improve arc stability, reduce spatter, and allow for finer control of the weld pool, resulting in higher quality and more precise welds.

- Micro-gas welding techniques for miniature components: Specialized micro-gas welding techniques are developed for joining extremely small or delicate components. These methods may involve ultra-fine flame control, microscope-assisted welding, and the use of specialized micro-torches. Such techniques are crucial in industries like electronics, jewelry making, and medical device manufacturing where precision at a microscopic level is required.

02 Specialized gas welding torches for precision work

Innovative torch designs are developed specifically for precision gas welding. These torches may feature fine-tip nozzles, adjustable flame settings, and ergonomic designs to improve control and accuracy. Some designs incorporate cooling systems or heat shields to maintain stability during prolonged use in precision applications.Expand Specific Solutions03 Automated gas welding systems for enhanced precision

Robotic and automated systems are employed to increase the precision of gas welding processes. These systems can execute complex welding patterns with high repeatability and accuracy. They often integrate vision systems and real-time monitoring to ensure consistent weld quality and precision across large production runs.Expand Specific Solutions04 Precision gas mixing and flow control

Advanced gas mixing and flow control technologies are developed to achieve precise gas ratios and consistent flow rates. These systems may use digital flow meters, pressure regulators, and mixing chambers to maintain optimal gas compositions for specific welding applications, contributing to improved weld quality and precision.Expand Specific Solutions05 Micro-welding techniques for high-precision applications

Specialized micro-welding techniques are developed for extremely precise gas welding applications. These methods may involve miniaturized torch designs, ultra-fine gas control, and magnification systems to achieve welds on very small components or in intricate geometries. Such techniques are particularly valuable in industries like electronics and medical device manufacturing.Expand Specific Solutions

Key Industry Players

The gas welding precision market is in a mature stage, with established players and well-defined technologies. The global market size for welding equipment and consumables is estimated to be around $20 billion, with gas welding representing a significant portion. Technological advancements in flame shape control are driving innovation, as companies like JFE Steel, Daihen Corp, and ESAB Group focus on improving precision and efficiency. The technology's maturity is evident in the diverse applications across industries, from automotive to aerospace. However, there's ongoing research to enhance flame stability and heat distribution, with companies like Siemens AG and Panasonic Intellectual Property Management Co. Ltd. investing in advanced control systems and sensors to optimize flame shape for higher precision welding processes.

The ESAB Group, Inc.

Technical Solution: ESAB has developed advanced gas welding technologies that focus on optimizing flame shape for improved precision. Their approach involves using digital gas flow control systems that allow for precise adjustment of the flame characteristics[1]. This technology enables welders to fine-tune the flame shape based on the specific material and welding requirements. ESAB's research has shown that a properly shaped flame can significantly enhance heat distribution, resulting in more consistent weld quality and reduced defects[2]. They have also implemented computer vision systems to analyze flame shape in real-time, providing feedback to the welder or automated welding system to maintain optimal flame geometry throughout the welding process[3].

Strengths: Precise control over flame shape, real-time monitoring and adjustment capabilities, improved weld quality. Weaknesses: May require additional training for operators, potentially higher initial equipment costs.

Siemens AG

Technical Solution: Siemens has developed an innovative approach to gas welding that incorporates AI-driven flame shape optimization. Their system uses advanced sensors and machine learning algorithms to analyze the flame characteristics and their impact on weld quality[4]. The technology continuously adjusts gas flow rates and mixture ratios to maintain the ideal flame shape for different materials and welding conditions. Siemens' research has demonstrated that this adaptive flame control can lead to up to 20% improvement in weld precision and a 15% reduction in gas consumption[5]. Additionally, they have integrated this technology with their digital twin platforms, allowing for predictive modeling of flame behavior and its effects on weld outcomes[6].

Strengths: AI-driven optimization, significant improvements in precision and efficiency, integration with digital twin technology. Weaknesses: Complexity of implementation, potential reliance on proprietary software and hardware.

Flame Shape Innovations

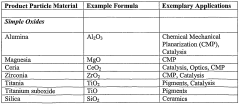

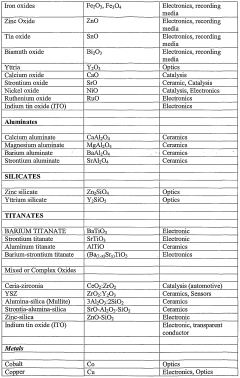

Processes for forming nanoparticles in a flame spray system

PatentWO2006078826A2

Innovation

- A flame spray process that involves introducing a precursor medium into a flame reactor, where the precursor medium comprises a liquid vehicle and a precursor component, and the process is optimized to form nanoparticles with specific characteristics, including a unimodal size distribution and high conversion rates, to produce nanoparticles with controlled size, shape, and composition.

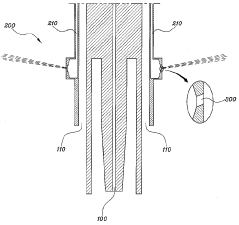

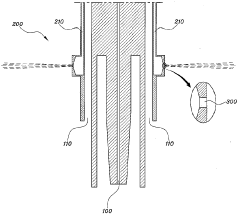

Torch structure of carbon dioxide gas welding machine

PatentInactiveKR1020140072510A

Innovation

- A torch structure with a suction passage around the welding rod body and an air injection path that directs air upward to prevent fume scattering and guide it into the suction path, ensuring efficient welding and improved working conditions.

Welding Safety Standards

Welding safety standards play a crucial role in ensuring the precision and safety of gas welding processes, particularly when considering the impact of flame shape. These standards are designed to address various aspects of welding operations, including equipment specifications, personal protective gear, and proper techniques for flame control.

The American Welding Society (AWS) and the Occupational Safety and Health Administration (OSHA) have established comprehensive guidelines for gas welding safety. These standards emphasize the importance of maintaining a proper flame shape to achieve optimal welding results while minimizing risks. A well-controlled flame shape is essential for achieving precise welds and reducing the likelihood of accidents or defects.

One key aspect of welding safety standards related to flame shape is the proper adjustment of gas flow rates. Standards typically specify acceptable ranges for oxygen and fuel gas pressures, which directly influence the flame's shape and characteristics. Welders are required to follow these guidelines to maintain a neutral flame, which is crucial for most welding applications.

Safety standards also address the importance of proper torch handling techniques. This includes guidelines on how to manipulate the torch to maintain the desired flame shape throughout the welding process. Proper torch angle and distance from the workpiece are critical factors that affect both the precision of the weld and the safety of the operator.

Furthermore, welding safety standards often include provisions for regular equipment maintenance and inspection. This ensures that gas welding equipment, including torches and regulators, remains in optimal condition to produce consistent and safe flame shapes. Regular checks for gas leaks and proper functioning of valves are mandated to prevent accidents related to irregular flame behavior.

Training and certification requirements are another crucial component of welding safety standards. These programs often include specific modules on flame control and shape manipulation. Welders are trained to recognize different flame types (neutral, oxidizing, and carburizing) and understand their effects on weld quality and safety.

Environmental considerations are also addressed in modern welding safety standards. Proper ventilation requirements are specified to manage fumes and gases produced during the welding process, which can be affected by flame shape and intensity. This aspect of safety standards not only protects the welder but also ensures compliance with broader occupational health regulations.

In conclusion, welding safety standards provide a comprehensive framework for managing the risks associated with gas welding, with particular attention to the critical role of flame shape. By adhering to these standards, welders can significantly improve the precision of their work while maintaining a safe working environment.

The American Welding Society (AWS) and the Occupational Safety and Health Administration (OSHA) have established comprehensive guidelines for gas welding safety. These standards emphasize the importance of maintaining a proper flame shape to achieve optimal welding results while minimizing risks. A well-controlled flame shape is essential for achieving precise welds and reducing the likelihood of accidents or defects.

One key aspect of welding safety standards related to flame shape is the proper adjustment of gas flow rates. Standards typically specify acceptable ranges for oxygen and fuel gas pressures, which directly influence the flame's shape and characteristics. Welders are required to follow these guidelines to maintain a neutral flame, which is crucial for most welding applications.

Safety standards also address the importance of proper torch handling techniques. This includes guidelines on how to manipulate the torch to maintain the desired flame shape throughout the welding process. Proper torch angle and distance from the workpiece are critical factors that affect both the precision of the weld and the safety of the operator.

Furthermore, welding safety standards often include provisions for regular equipment maintenance and inspection. This ensures that gas welding equipment, including torches and regulators, remains in optimal condition to produce consistent and safe flame shapes. Regular checks for gas leaks and proper functioning of valves are mandated to prevent accidents related to irregular flame behavior.

Training and certification requirements are another crucial component of welding safety standards. These programs often include specific modules on flame control and shape manipulation. Welders are trained to recognize different flame types (neutral, oxidizing, and carburizing) and understand their effects on weld quality and safety.

Environmental considerations are also addressed in modern welding safety standards. Proper ventilation requirements are specified to manage fumes and gases produced during the welding process, which can be affected by flame shape and intensity. This aspect of safety standards not only protects the welder but also ensures compliance with broader occupational health regulations.

In conclusion, welding safety standards provide a comprehensive framework for managing the risks associated with gas welding, with particular attention to the critical role of flame shape. By adhering to these standards, welders can significantly improve the precision of their work while maintaining a safe working environment.

Environmental Impact

Gas welding, while an effective joining technique, has notable environmental impacts that warrant careful consideration. The shape of the flame in gas welding significantly influences not only the precision of the weld but also its environmental footprint. The combustion process in gas welding releases various pollutants, including carbon dioxide, nitrogen oxides, and particulate matter, which contribute to air pollution and climate change.

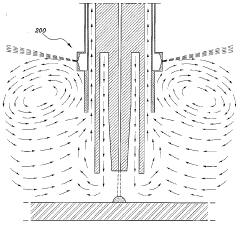

The flame shape directly affects the efficiency of the welding process, which in turn impacts fuel consumption and emissions. A well-controlled, focused flame typically results in a more efficient weld, reducing overall gas usage and minimizing unnecessary emissions. Conversely, an improperly shaped or excessively large flame can lead to increased fuel consumption and higher levels of pollutant release.

Flame shape also influences the formation of harmful by-products during welding. For instance, a reducing flame with excess acetylene can produce more carbon monoxide, a toxic gas that poses both environmental and health risks. On the other hand, an oxidizing flame may generate higher levels of nitrogen oxides, which contribute to smog formation and acid rain.

The precision afforded by proper flame shape control can reduce material waste, an often-overlooked environmental benefit. Accurate welds require fewer reworks and repairs, minimizing the need for additional materials and energy consumption associated with corrective processes. This efficiency not only reduces waste but also decreases the overall environmental impact of the welding operation.

Furthermore, the flame shape affects the heat-affected zone (HAZ) of the weld, which can influence the longevity and performance of the welded joint. A more precise flame shape can result in a smaller HAZ, potentially improving the durability of the weld and reducing the likelihood of premature failure. This increased longevity can lead to less frequent replacements and repairs, further reducing the long-term environmental impact of the welded product.

In industrial settings, the cumulative effect of flame shape on environmental impact can be substantial. Large-scale welding operations that optimize flame shape for precision can achieve significant reductions in gas consumption and emissions. This not only aligns with environmental regulations but also offers economic benefits through reduced resource usage and improved energy efficiency.

As environmental concerns continue to grow, the welding industry is increasingly focusing on developing techniques and technologies that minimize ecological impact. Advancements in gas welding equipment and practices that allow for more precise control of flame shape are contributing to these efforts, helping to create a more sustainable approach to this essential industrial process.

The flame shape directly affects the efficiency of the welding process, which in turn impacts fuel consumption and emissions. A well-controlled, focused flame typically results in a more efficient weld, reducing overall gas usage and minimizing unnecessary emissions. Conversely, an improperly shaped or excessively large flame can lead to increased fuel consumption and higher levels of pollutant release.

Flame shape also influences the formation of harmful by-products during welding. For instance, a reducing flame with excess acetylene can produce more carbon monoxide, a toxic gas that poses both environmental and health risks. On the other hand, an oxidizing flame may generate higher levels of nitrogen oxides, which contribute to smog formation and acid rain.

The precision afforded by proper flame shape control can reduce material waste, an often-overlooked environmental benefit. Accurate welds require fewer reworks and repairs, minimizing the need for additional materials and energy consumption associated with corrective processes. This efficiency not only reduces waste but also decreases the overall environmental impact of the welding operation.

Furthermore, the flame shape affects the heat-affected zone (HAZ) of the weld, which can influence the longevity and performance of the welded joint. A more precise flame shape can result in a smaller HAZ, potentially improving the durability of the weld and reducing the likelihood of premature failure. This increased longevity can lead to less frequent replacements and repairs, further reducing the long-term environmental impact of the welded product.

In industrial settings, the cumulative effect of flame shape on environmental impact can be substantial. Large-scale welding operations that optimize flame shape for precision can achieve significant reductions in gas consumption and emissions. This not only aligns with environmental regulations but also offers economic benefits through reduced resource usage and improved energy efficiency.

As environmental concerns continue to grow, the welding industry is increasingly focusing on developing techniques and technologies that minimize ecological impact. Advancements in gas welding equipment and practices that allow for more precise control of flame shape are contributing to these efforts, helping to create a more sustainable approach to this essential industrial process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!