Gas Welding Applications in Advanced Marine Engineering

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution

Gas welding has undergone significant evolution in the field of marine engineering since its inception. The technology's journey began in the early 20th century when oxy-acetylene welding was first introduced to shipbuilding. This method quickly gained popularity due to its versatility and ability to join thick metal plates effectively.

As marine engineering advanced, so did the demands on welding techniques. The 1940s and 1950s saw the introduction of more sophisticated gas welding methods, including the use of shielding gases to improve weld quality and reduce oxidation. This period marked a crucial transition in shipbuilding, enabling the construction of larger and more complex vessels.

The 1960s and 1970s brought about a shift towards automation in gas welding processes. Automated welding systems were developed to increase efficiency and consistency in shipyard operations. These advancements allowed for faster production times and improved weld quality, particularly in repetitive welding tasks.

In the 1980s and 1990s, gas welding in marine engineering saw further refinements with the integration of computer-controlled systems. This era introduced precision gas welding techniques that could be programmed and monitored digitally, ensuring higher accuracy and repeatability in welding operations.

The turn of the millennium marked a new phase in gas welding evolution for marine applications. Environmental concerns and energy efficiency became paramount, leading to the development of cleaner burning gases and more efficient welding equipment. This period also saw the introduction of hybrid welding techniques, combining gas welding with other methods like laser welding for optimal results.

Recent years have witnessed the incorporation of smart technologies into gas welding systems used in advanced marine engineering. IoT-enabled welding equipment now allows for real-time monitoring and data analysis, enhancing quality control and predictive maintenance in shipyards. Additionally, the use of augmented reality in welding operations has begun to emerge, providing welders with enhanced visual guidance and improving overall accuracy.

The evolution of gas welding in marine engineering continues to be driven by the need for stronger, lighter, and more durable ship structures. Current research focuses on developing new gas mixtures and welding techniques that can handle advanced materials used in modern shipbuilding, such as high-strength steels and aluminum alloys. These ongoing advancements aim to meet the increasing demands of the marine industry for vessels that are more efficient, environmentally friendly, and capable of withstanding extreme oceanic conditions.

As marine engineering advanced, so did the demands on welding techniques. The 1940s and 1950s saw the introduction of more sophisticated gas welding methods, including the use of shielding gases to improve weld quality and reduce oxidation. This period marked a crucial transition in shipbuilding, enabling the construction of larger and more complex vessels.

The 1960s and 1970s brought about a shift towards automation in gas welding processes. Automated welding systems were developed to increase efficiency and consistency in shipyard operations. These advancements allowed for faster production times and improved weld quality, particularly in repetitive welding tasks.

In the 1980s and 1990s, gas welding in marine engineering saw further refinements with the integration of computer-controlled systems. This era introduced precision gas welding techniques that could be programmed and monitored digitally, ensuring higher accuracy and repeatability in welding operations.

The turn of the millennium marked a new phase in gas welding evolution for marine applications. Environmental concerns and energy efficiency became paramount, leading to the development of cleaner burning gases and more efficient welding equipment. This period also saw the introduction of hybrid welding techniques, combining gas welding with other methods like laser welding for optimal results.

Recent years have witnessed the incorporation of smart technologies into gas welding systems used in advanced marine engineering. IoT-enabled welding equipment now allows for real-time monitoring and data analysis, enhancing quality control and predictive maintenance in shipyards. Additionally, the use of augmented reality in welding operations has begun to emerge, providing welders with enhanced visual guidance and improving overall accuracy.

The evolution of gas welding in marine engineering continues to be driven by the need for stronger, lighter, and more durable ship structures. Current research focuses on developing new gas mixtures and welding techniques that can handle advanced materials used in modern shipbuilding, such as high-strength steels and aluminum alloys. These ongoing advancements aim to meet the increasing demands of the marine industry for vessels that are more efficient, environmentally friendly, and capable of withstanding extreme oceanic conditions.

Marine Market Demand

The marine industry has witnessed a growing demand for advanced welding technologies, particularly gas welding applications in advanced marine engineering. This demand is driven by the increasing complexity of marine structures, the need for more efficient and durable vessels, and stringent environmental regulations.

In the shipbuilding sector, there is a significant market for gas welding applications in the construction of large commercial vessels, naval ships, and offshore platforms. The global shipbuilding market is projected to grow steadily, with Asia-Pacific countries like China, South Korea, and Japan leading the industry. This growth directly translates to an increased demand for advanced welding technologies, including gas welding applications.

The offshore oil and gas industry also presents a substantial market for gas welding applications. As exploration and production activities move into deeper waters and more challenging environments, there is a growing need for robust welding solutions that can withstand extreme conditions. Gas welding techniques are particularly valued for their versatility and ability to join thick materials commonly used in offshore structures.

The marine renewable energy sector, including offshore wind farms and wave energy converters, is another emerging market for gas welding applications. As countries worldwide invest in clean energy solutions, the demand for specialized welding techniques in marine environments is expected to rise significantly.

Maintenance and repair services for existing marine structures and vessels constitute a substantial portion of the market demand. Gas welding applications are crucial for on-site repairs, retrofitting, and upgrading of ships and offshore installations. This segment of the market is driven by the aging global fleet and the need to extend the operational life of marine assets.

The market demand is further influenced by regulatory requirements and industry standards. International maritime organizations and classification societies are continuously updating welding standards to improve safety and reliability in marine applications. This drives the adoption of advanced gas welding techniques that can meet these stringent quality requirements.

Geographically, the market demand for gas welding applications in marine engineering is most pronounced in regions with strong maritime industries. These include East Asia, Europe (particularly Northern Europe), and North America. Emerging markets in Southeast Asia and the Middle East are also showing increased demand as they expand their shipbuilding and offshore capabilities.

In terms of technological trends, there is a growing market demand for automated and robotic gas welding systems in marine applications. These technologies offer improved precision, consistency, and efficiency, which are crucial in large-scale marine projects. Additionally, there is an increasing interest in hybrid welding techniques that combine gas welding with other methods to achieve optimal results in challenging marine environments.

In the shipbuilding sector, there is a significant market for gas welding applications in the construction of large commercial vessels, naval ships, and offshore platforms. The global shipbuilding market is projected to grow steadily, with Asia-Pacific countries like China, South Korea, and Japan leading the industry. This growth directly translates to an increased demand for advanced welding technologies, including gas welding applications.

The offshore oil and gas industry also presents a substantial market for gas welding applications. As exploration and production activities move into deeper waters and more challenging environments, there is a growing need for robust welding solutions that can withstand extreme conditions. Gas welding techniques are particularly valued for their versatility and ability to join thick materials commonly used in offshore structures.

The marine renewable energy sector, including offshore wind farms and wave energy converters, is another emerging market for gas welding applications. As countries worldwide invest in clean energy solutions, the demand for specialized welding techniques in marine environments is expected to rise significantly.

Maintenance and repair services for existing marine structures and vessels constitute a substantial portion of the market demand. Gas welding applications are crucial for on-site repairs, retrofitting, and upgrading of ships and offshore installations. This segment of the market is driven by the aging global fleet and the need to extend the operational life of marine assets.

The market demand is further influenced by regulatory requirements and industry standards. International maritime organizations and classification societies are continuously updating welding standards to improve safety and reliability in marine applications. This drives the adoption of advanced gas welding techniques that can meet these stringent quality requirements.

Geographically, the market demand for gas welding applications in marine engineering is most pronounced in regions with strong maritime industries. These include East Asia, Europe (particularly Northern Europe), and North America. Emerging markets in Southeast Asia and the Middle East are also showing increased demand as they expand their shipbuilding and offshore capabilities.

In terms of technological trends, there is a growing market demand for automated and robotic gas welding systems in marine applications. These technologies offer improved precision, consistency, and efficiency, which are crucial in large-scale marine projects. Additionally, there is an increasing interest in hybrid welding techniques that combine gas welding with other methods to achieve optimal results in challenging marine environments.

Challenges in Marine

Gas welding applications in advanced marine engineering face numerous challenges due to the unique and demanding environment of marine operations. One of the primary obstacles is the corrosive nature of seawater and marine atmospheres. The high salt content and humidity accelerate the degradation of welded joints, leading to reduced structural integrity and potential safety hazards. This necessitates the development of specialized welding techniques and materials that can withstand these harsh conditions.

Another significant challenge is the dynamic nature of marine structures. Ships and offshore platforms are subject to constant motion, vibrations, and stress from waves and currents. This movement can affect the quality of welds during the welding process and may lead to fatigue failure over time. Engineers must account for these dynamic loads when designing welding procedures and selecting appropriate materials to ensure long-term durability.

The limited accessibility of certain areas on marine vessels and structures poses additional difficulties for gas welding applications. Confined spaces, such as ballast tanks and engine rooms, require specialized equipment and techniques to ensure proper weld quality and worker safety. These constraints often necessitate the use of automated or semi-automated welding systems, which present their own set of challenges in terms of setup, operation, and maintenance in marine environments.

Environmental regulations and safety standards in the marine industry also impact gas welding applications. Strict emission controls and fire safety requirements demand the use of cleaner welding technologies and improved ventilation systems. This pushes engineers to develop more efficient and environmentally friendly welding processes while maintaining the required weld quality and productivity.

The need for underwater welding in marine engineering presents unique challenges. Gas welding techniques must be adapted for use in submerged conditions, requiring specialized equipment and highly skilled operators. The presence of water affects heat dissipation, gas bubble formation, and visibility, making it difficult to achieve consistent weld quality. Additionally, the increased pressure at depth further complicates the welding process and poses safety risks for divers.

Lastly, the integration of new materials in shipbuilding and offshore structures introduces challenges for gas welding applications. Advanced composites, high-strength steels, and aluminum alloys require specific welding parameters and techniques to ensure proper fusion and maintain material properties. Engineers must continuously update their knowledge and develop new welding procedures to accommodate these evolving material technologies in marine engineering applications.

Another significant challenge is the dynamic nature of marine structures. Ships and offshore platforms are subject to constant motion, vibrations, and stress from waves and currents. This movement can affect the quality of welds during the welding process and may lead to fatigue failure over time. Engineers must account for these dynamic loads when designing welding procedures and selecting appropriate materials to ensure long-term durability.

The limited accessibility of certain areas on marine vessels and structures poses additional difficulties for gas welding applications. Confined spaces, such as ballast tanks and engine rooms, require specialized equipment and techniques to ensure proper weld quality and worker safety. These constraints often necessitate the use of automated or semi-automated welding systems, which present their own set of challenges in terms of setup, operation, and maintenance in marine environments.

Environmental regulations and safety standards in the marine industry also impact gas welding applications. Strict emission controls and fire safety requirements demand the use of cleaner welding technologies and improved ventilation systems. This pushes engineers to develop more efficient and environmentally friendly welding processes while maintaining the required weld quality and productivity.

The need for underwater welding in marine engineering presents unique challenges. Gas welding techniques must be adapted for use in submerged conditions, requiring specialized equipment and highly skilled operators. The presence of water affects heat dissipation, gas bubble formation, and visibility, making it difficult to achieve consistent weld quality. Additionally, the increased pressure at depth further complicates the welding process and poses safety risks for divers.

Lastly, the integration of new materials in shipbuilding and offshore structures introduces challenges for gas welding applications. Advanced composites, high-strength steels, and aluminum alloys require specific welding parameters and techniques to ensure proper fusion and maintain material properties. Engineers must continuously update their knowledge and develop new welding procedures to accommodate these evolving material technologies in marine engineering applications.

Current Gas Solutions

01 Gas welding equipment and techniques

This category covers various aspects of gas welding equipment and techniques, including torch designs, gas mixing systems, and welding process improvements. Innovations in this area aim to enhance welding efficiency, precision, and safety for operators.- Gas welding equipment and techniques: This category covers various aspects of gas welding equipment and techniques, including torch designs, gas flow control systems, and welding methodologies. Innovations in this area focus on improving welding efficiency, precision, and safety for operators.

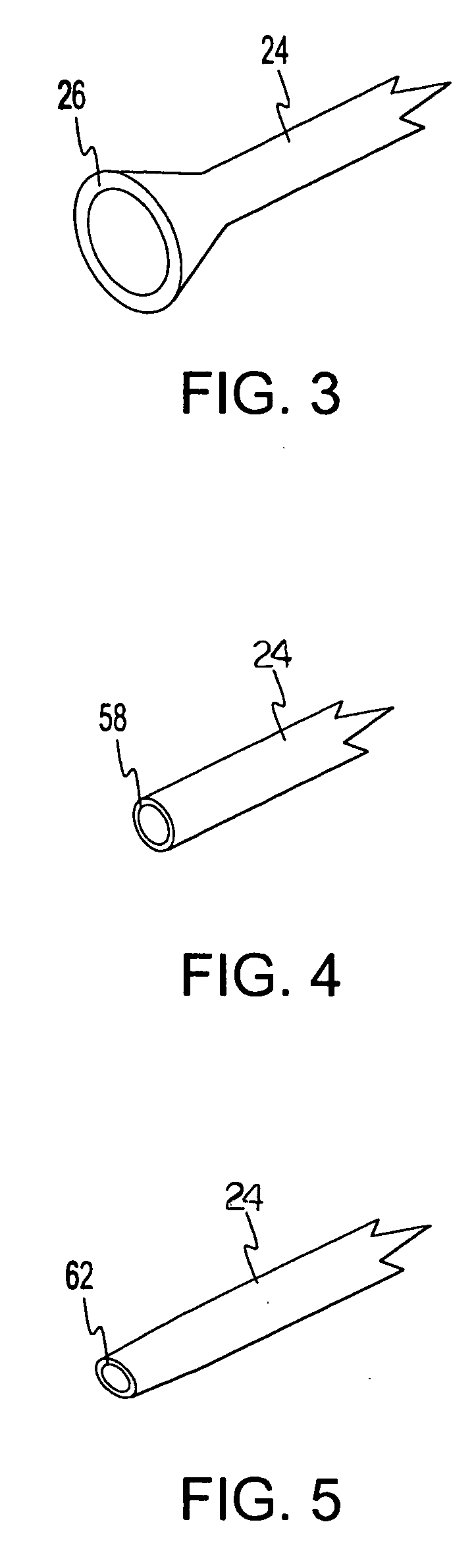

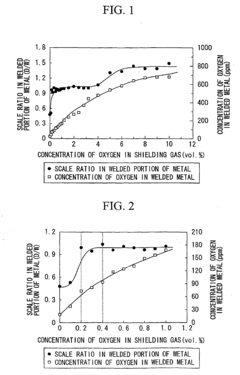

- Welding gas mixtures and compositions: This point addresses the development of specialized gas mixtures and compositions for gas welding applications. These innovations aim to enhance weld quality, reduce oxidation, and improve overall welding performance across different materials and conditions.

- Automated and robotic gas welding systems: This category focuses on the integration of automation and robotics in gas welding processes. These advancements aim to increase precision, repeatability, and productivity in welding operations, particularly in industrial settings.

- Gas welding safety and monitoring systems: This point covers innovations in safety features and monitoring systems for gas welding operations. These developments include gas leak detection, flame control mechanisms, and personal protective equipment to enhance operator safety and prevent accidents.

- Specialized gas welding applications: This category encompasses gas welding techniques and equipment designed for specific applications or materials. These innovations address unique challenges in welding certain metals, thin materials, or in specialized industries such as aerospace or automotive manufacturing.

02 Welding gas composition and control

This point focuses on the development of specialized gas mixtures and control systems for gas welding applications. It includes innovations in gas composition, flow regulation, and pressure control to optimize welding performance and quality across different materials and conditions.Expand Specific Solutions03 Automated and robotic gas welding systems

This category encompasses advancements in automated and robotic gas welding systems. It includes developments in computer-controlled welding processes, robotic arm integration, and sensor technologies for improved precision and consistency in welding operations.Expand Specific Solutions04 Safety features and protective equipment

This point addresses safety innovations in gas welding, including improved personal protective equipment, gas leak detection systems, and safety interlocks. These advancements aim to reduce the risks associated with gas welding and enhance operator safety.Expand Specific Solutions05 Specialized gas welding applications

This category covers gas welding techniques and equipment designed for specific applications or materials. It includes innovations in underwater welding, high-temperature welding, and welding of exotic materials, addressing unique challenges in various industries.Expand Specific Solutions

Key Marine Welders

The gas welding applications in advanced marine engineering sector is in a mature stage, with a well-established market and proven technologies. The global market size for this sector is substantial, driven by the growing demand for offshore structures and vessels. Key players like Illinois Tool Works Inc., China National Offshore Oil Corp., and Offshore Oil Engineering Co., Ltd. dominate the industry, leveraging their extensive experience and technological capabilities. These companies, along with others such as POSCO Holdings, Inc. and Kobe Steel, Ltd., continue to innovate and refine their welding technologies to meet the evolving needs of marine engineering projects, ensuring the sector's ongoing development and competitiveness.

Illinois Tool Works Inc.

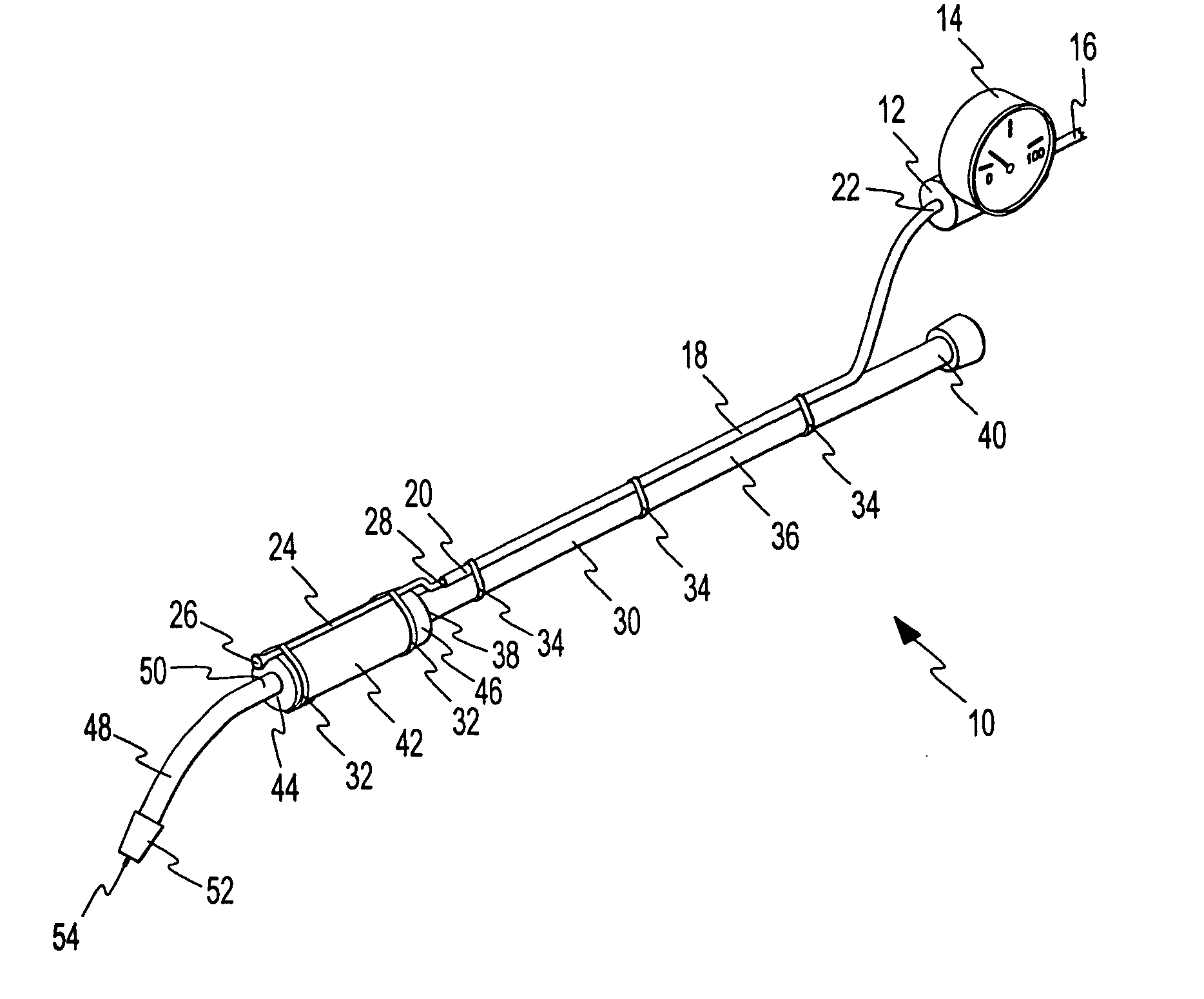

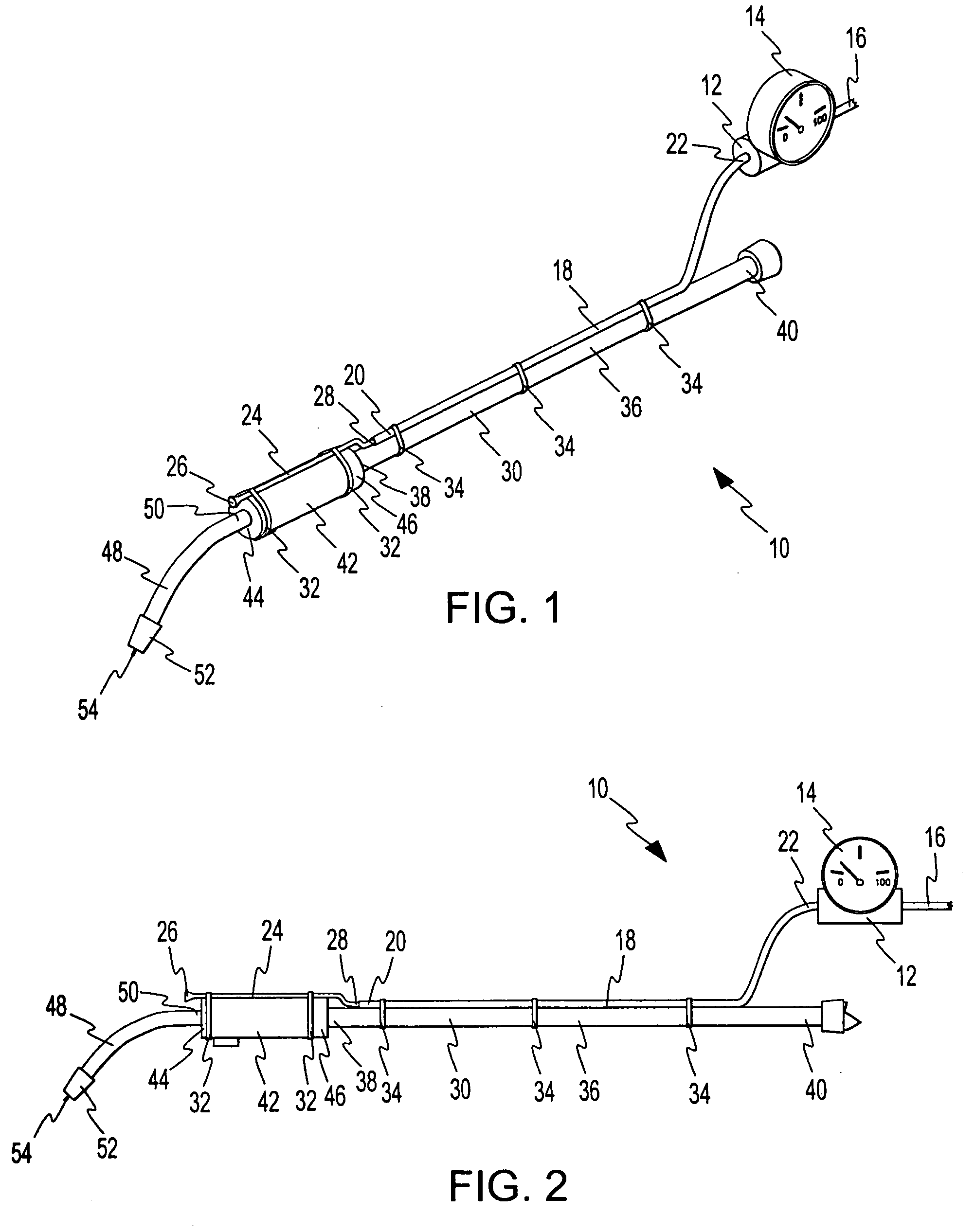

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding technologies specifically for marine engineering applications. Their innovative approach includes the use of specialized gas mixtures and precision flow control systems to optimize weld quality in challenging offshore environments. ITW's gas welding solutions incorporate adaptive pressure regulation to maintain consistent gas flow even in high-wind conditions common in marine settings [1]. The company has also introduced automated gas welding systems that can operate in confined spaces typical of shipbuilding, improving efficiency and worker safety [3]. ITW's gas welding equipment features corrosion-resistant materials and sealed designs to withstand the harsh saltwater environment, ensuring long-term reliability for marine applications [5].

Strengths: Specialized marine-grade equipment, adaptive pressure regulation, automated systems for confined spaces. Weaknesses: Higher initial cost compared to traditional welding methods, requires specialized training for operators.

China National Offshore Oil Corp.

Technical Solution: China National Offshore Oil Corp. (CNOOC) has invested heavily in gas welding technologies for offshore platform construction and maintenance. Their approach focuses on developing high-strength, corrosion-resistant welds suitable for deep-sea environments. CNOOC has pioneered the use of robotic gas welding systems for underwater repairs, capable of operating at depths of up to 500 meters [2]. The company's gas welding techniques incorporate real-time monitoring and adaptive control systems to ensure weld integrity under varying pressure conditions. CNOOC has also developed specialized shielding gas mixtures that minimize porosity in welds exposed to high-pressure underwater environments [4]. Their gas welding solutions include portable systems designed for rapid deployment during emergency repairs on offshore structures.

Strengths: Deep-sea welding capabilities, robotic systems for underwater repairs, specialized gas mixtures for high-pressure environments. Weaknesses: Limited to offshore applications, high operational costs for deep-sea welding.

Innovations in Marine

Less smoke fume-dispersing device for welding operations

PatentInactiveUS20060006160A1

Innovation

- A portable, low-cost fume-dispersing device that uses a stream of air to create flow currents and disperse gases and fumes from the welding area, rather than extracting them, allowing for easy attachment to various welders or workstations, and featuring a flexible design that avoids interference with the welding operation.

Welding method using a shielding gas comprising bewtween 0.2 % and 10 % of an oxidative gas, the rest being helium

PatentInactiveEP1752249B1

Innovation

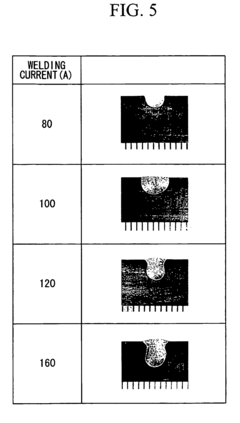

- A welding method using a shielding gas comprising 0.2% or more by volume of an oxidative gas, such as oxygen, mixed with helium, which suppresses the dragging force in the molten pool and enhances inward convection, allowing for deeper penetration and a higher D/W ratio, thereby improving weld quality and reducing the number of passes required.

Safety Regulations

Safety regulations play a crucial role in the application of gas welding techniques in advanced marine engineering. The maritime industry, known for its challenging and hazardous working environments, demands stringent safety measures to protect workers and equipment during welding operations.

International regulatory bodies, such as the International Maritime Organization (IMO) and the International Association of Classification Societies (IACS), have established comprehensive guidelines for gas welding in marine environments. These regulations cover various aspects, including equipment specifications, personnel training, and operational procedures.

One of the primary safety concerns in gas welding for marine applications is the risk of fire and explosion. To mitigate this, regulations mandate the use of flame arrestors on gas cylinders and welding torches. Additionally, strict protocols are in place for the storage and handling of flammable gases, with requirements for proper ventilation and segregation of fuel gases and oxidizers.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Welders must wear appropriate flame-resistant clothing, protective eyewear, and respiratory protection to guard against harmful fumes and radiation. Regular inspection and maintenance of PPE are also mandated to ensure their effectiveness.

The regulations also address the importance of proper training and certification for welders working in marine environments. Specialized courses and certifications are required to ensure that welders are proficient in both the technical aspects of gas welding and the specific safety protocols for maritime applications.

Environmental considerations are increasingly prominent in safety regulations for marine gas welding. Guidelines now include measures to prevent the release of harmful gases and particulates into the marine ecosystem. This includes proper disposal of welding waste and the use of eco-friendly welding techniques where possible.

Emergency response procedures form a significant part of safety regulations. Shipyards and vessels must have clearly defined protocols for handling welding-related accidents, including fire suppression systems, evacuation plans, and first-aid procedures tailored to welding injuries.

Regulations also emphasize the importance of regular safety audits and inspections. These assessments help identify potential hazards, ensure compliance with safety standards, and promote continuous improvement in safety practices.

As technology advances, safety regulations for gas welding in marine engineering continue to evolve. Recent updates have incorporated guidelines for the use of automated welding systems and the integration of digital monitoring tools to enhance safety oversight during welding operations.

International regulatory bodies, such as the International Maritime Organization (IMO) and the International Association of Classification Societies (IACS), have established comprehensive guidelines for gas welding in marine environments. These regulations cover various aspects, including equipment specifications, personnel training, and operational procedures.

One of the primary safety concerns in gas welding for marine applications is the risk of fire and explosion. To mitigate this, regulations mandate the use of flame arrestors on gas cylinders and welding torches. Additionally, strict protocols are in place for the storage and handling of flammable gases, with requirements for proper ventilation and segregation of fuel gases and oxidizers.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Welders must wear appropriate flame-resistant clothing, protective eyewear, and respiratory protection to guard against harmful fumes and radiation. Regular inspection and maintenance of PPE are also mandated to ensure their effectiveness.

The regulations also address the importance of proper training and certification for welders working in marine environments. Specialized courses and certifications are required to ensure that welders are proficient in both the technical aspects of gas welding and the specific safety protocols for maritime applications.

Environmental considerations are increasingly prominent in safety regulations for marine gas welding. Guidelines now include measures to prevent the release of harmful gases and particulates into the marine ecosystem. This includes proper disposal of welding waste and the use of eco-friendly welding techniques where possible.

Emergency response procedures form a significant part of safety regulations. Shipyards and vessels must have clearly defined protocols for handling welding-related accidents, including fire suppression systems, evacuation plans, and first-aid procedures tailored to welding injuries.

Regulations also emphasize the importance of regular safety audits and inspections. These assessments help identify potential hazards, ensure compliance with safety standards, and promote continuous improvement in safety practices.

As technology advances, safety regulations for gas welding in marine engineering continue to evolve. Recent updates have incorporated guidelines for the use of automated welding systems and the integration of digital monitoring tools to enhance safety oversight during welding operations.

Environmental Impact

Gas welding applications in advanced marine engineering have significant environmental implications that warrant careful consideration. The combustion process inherent in gas welding produces emissions that can contribute to air pollution and greenhouse gas effects. These emissions primarily consist of carbon dioxide, nitrogen oxides, and particulate matter, which can have both local and global environmental impacts. In marine environments, these pollutants can affect air quality in coastal areas and contribute to ocean acidification when absorbed by seawater.

The use of shielding gases in gas welding processes also raises environmental concerns. While these gases are essential for protecting the weld area from atmospheric contamination, some commonly used gases, such as argon and helium, are non-renewable resources. Their extraction and production processes contribute to energy consumption and associated environmental impacts. Additionally, the potential release of these gases during welding operations can contribute to the depletion of atmospheric resources.

Waste management is another critical environmental aspect of gas welding in marine engineering. The process generates various waste materials, including metal scraps, used welding rods, and contaminated personal protective equipment. Proper disposal and recycling of these materials are essential to minimize environmental impact and conserve resources. In marine settings, particular attention must be paid to preventing the release of welding-related waste into aquatic ecosystems, as this can harm marine life and disrupt delicate ecological balances.

Energy consumption is a significant factor in the environmental footprint of gas welding applications. The high temperatures required for welding processes demand substantial energy inputs, often derived from fossil fuel sources. This energy use contributes to carbon emissions and resource depletion. In advanced marine engineering, efforts to improve energy efficiency in welding processes can significantly reduce overall environmental impact.

The potential for accidental releases or spills during gas welding operations in marine environments poses additional environmental risks. Fuel gases, such as acetylene or propane, if improperly handled or stored, can lead to leaks that may harm marine ecosystems. Similarly, the use of flux materials and cleaning agents in the welding process can introduce chemical contaminants into the marine environment if not properly managed.

To mitigate these environmental impacts, the marine engineering industry is increasingly focusing on developing and implementing more sustainable welding practices. This includes the adoption of cleaner fuel gases, improved emission control technologies, and more efficient welding equipment. Additionally, there is a growing emphasis on training welders in environmentally responsible practices and implementing strict waste management protocols in marine welding operations.

The use of shielding gases in gas welding processes also raises environmental concerns. While these gases are essential for protecting the weld area from atmospheric contamination, some commonly used gases, such as argon and helium, are non-renewable resources. Their extraction and production processes contribute to energy consumption and associated environmental impacts. Additionally, the potential release of these gases during welding operations can contribute to the depletion of atmospheric resources.

Waste management is another critical environmental aspect of gas welding in marine engineering. The process generates various waste materials, including metal scraps, used welding rods, and contaminated personal protective equipment. Proper disposal and recycling of these materials are essential to minimize environmental impact and conserve resources. In marine settings, particular attention must be paid to preventing the release of welding-related waste into aquatic ecosystems, as this can harm marine life and disrupt delicate ecological balances.

Energy consumption is a significant factor in the environmental footprint of gas welding applications. The high temperatures required for welding processes demand substantial energy inputs, often derived from fossil fuel sources. This energy use contributes to carbon emissions and resource depletion. In advanced marine engineering, efforts to improve energy efficiency in welding processes can significantly reduce overall environmental impact.

The potential for accidental releases or spills during gas welding operations in marine environments poses additional environmental risks. Fuel gases, such as acetylene or propane, if improperly handled or stored, can lead to leaks that may harm marine ecosystems. Similarly, the use of flux materials and cleaning agents in the welding process can introduce chemical contaminants into the marine environment if not properly managed.

To mitigate these environmental impacts, the marine engineering industry is increasingly focusing on developing and implementing more sustainable welding practices. This includes the adoption of cleaner fuel gases, improved emission control technologies, and more efficient welding equipment. Additionally, there is a growing emphasis on training welders in environmentally responsible practices and implementing strict waste management protocols in marine welding operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!