Impact of Gas Welding on the Manufacture of Heat Exchangers

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution

Gas welding has played a significant role in the evolution of heat exchanger manufacturing, marking several key milestones in the industry's development. The technique, which utilizes a mixture of oxygen and acetylene to produce a high-temperature flame, was first introduced in the early 20th century and quickly became a staple in metal fabrication processes.

In the 1920s and 1930s, gas welding emerged as the primary method for joining metal components in heat exchangers. This period saw the first widespread application of gas welding in the production of shell and tube heat exchangers, which remain a common design to this day. The ability to create strong, leak-tight joints between tubes and tube sheets significantly improved the reliability and efficiency of these devices.

The 1940s and 1950s witnessed further refinements in gas welding techniques specific to heat exchanger manufacturing. Specialized torches and filler materials were developed to address the unique challenges posed by different heat exchanger materials, such as copper, brass, and various grades of steel. These advancements allowed for more precise control over the welding process, resulting in higher quality joints and reduced rejection rates.

During the 1960s and 1970s, gas welding continued to dominate the heat exchanger manufacturing landscape, despite the introduction of newer welding technologies. Its versatility and relatively low equipment costs made it particularly attractive for small to medium-sized manufacturers. This period also saw the development of automated gas welding systems, which improved consistency and productivity in large-scale production environments.

The 1980s marked a turning point in the use of gas welding for heat exchangers. While still widely used, it began to face competition from more advanced welding methods, such as TIG (Tungsten Inert Gas) welding and resistance welding. These newer techniques offered advantages in terms of precision and speed, particularly for thin-walled materials commonly used in compact heat exchangers.

In recent decades, gas welding has seen a decline in its application for heat exchanger manufacturing, particularly in high-volume production settings. However, it remains relevant in certain niche applications, such as repair work and custom fabrication of specialized heat exchangers. The technique's simplicity and flexibility continue to make it valuable in situations where more advanced welding equipment may not be available or practical.

Today, while no longer the dominant welding method in heat exchanger production, gas welding's legacy is evident in many aspects of modern manufacturing processes. The principles and skills developed through decades of gas welding application have informed the development of newer welding technologies and continue to influence best practices in heat exchanger fabrication.

In the 1920s and 1930s, gas welding emerged as the primary method for joining metal components in heat exchangers. This period saw the first widespread application of gas welding in the production of shell and tube heat exchangers, which remain a common design to this day. The ability to create strong, leak-tight joints between tubes and tube sheets significantly improved the reliability and efficiency of these devices.

The 1940s and 1950s witnessed further refinements in gas welding techniques specific to heat exchanger manufacturing. Specialized torches and filler materials were developed to address the unique challenges posed by different heat exchanger materials, such as copper, brass, and various grades of steel. These advancements allowed for more precise control over the welding process, resulting in higher quality joints and reduced rejection rates.

During the 1960s and 1970s, gas welding continued to dominate the heat exchanger manufacturing landscape, despite the introduction of newer welding technologies. Its versatility and relatively low equipment costs made it particularly attractive for small to medium-sized manufacturers. This period also saw the development of automated gas welding systems, which improved consistency and productivity in large-scale production environments.

The 1980s marked a turning point in the use of gas welding for heat exchangers. While still widely used, it began to face competition from more advanced welding methods, such as TIG (Tungsten Inert Gas) welding and resistance welding. These newer techniques offered advantages in terms of precision and speed, particularly for thin-walled materials commonly used in compact heat exchangers.

In recent decades, gas welding has seen a decline in its application for heat exchanger manufacturing, particularly in high-volume production settings. However, it remains relevant in certain niche applications, such as repair work and custom fabrication of specialized heat exchangers. The technique's simplicity and flexibility continue to make it valuable in situations where more advanced welding equipment may not be available or practical.

Today, while no longer the dominant welding method in heat exchanger production, gas welding's legacy is evident in many aspects of modern manufacturing processes. The principles and skills developed through decades of gas welding application have informed the development of newer welding technologies and continue to influence best practices in heat exchanger fabrication.

Heat Exchanger Market

The heat exchanger market has experienced significant growth in recent years, driven by increasing demand across various industries such as chemical processing, oil and gas, power generation, and HVAC systems. This market expansion is closely tied to the rising need for energy-efficient solutions and the growing emphasis on sustainable industrial practices.

Global market trends indicate a steady increase in heat exchanger adoption, with a particular focus on plate heat exchangers and shell and tube heat exchangers. These types are favored for their efficiency and versatility in handling diverse fluid types and temperature ranges. The market is also witnessing a shift towards compact and modular heat exchanger designs, which offer advantages in terms of space utilization and ease of maintenance.

In the context of gas welding's impact on heat exchanger manufacturing, the market dynamics are influenced by the ongoing evolution of welding technologies. While gas welding has been a traditional method in heat exchanger production, there is a growing trend towards more advanced welding techniques such as TIG (Tungsten Inert Gas) welding and automated welding systems. This shift is driven by the need for higher precision, improved weld quality, and increased production efficiency.

The heat exchanger market is characterized by a strong emphasis on customization, with manufacturers offering tailored solutions to meet specific industry requirements. This trend is particularly evident in sectors such as petrochemicals and food processing, where heat exchangers must comply with stringent regulatory standards and operational specifications.

Geographically, the Asia-Pacific region has emerged as a key growth area for the heat exchanger market, fueled by rapid industrialization and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on technological advancements and energy-efficient solutions.

The market is also influenced by environmental regulations and sustainability initiatives. There is a growing demand for heat exchangers that can operate with lower energy consumption and reduced environmental impact. This has led to innovations in materials and design, including the use of corrosion-resistant alloys and enhanced heat transfer surfaces.

As the manufacturing processes for heat exchangers evolve, including the role of gas welding, the market is expected to see further advancements in product quality, durability, and performance. These developments are likely to shape the competitive landscape and drive further innovation in the heat exchanger industry.

Global market trends indicate a steady increase in heat exchanger adoption, with a particular focus on plate heat exchangers and shell and tube heat exchangers. These types are favored for their efficiency and versatility in handling diverse fluid types and temperature ranges. The market is also witnessing a shift towards compact and modular heat exchanger designs, which offer advantages in terms of space utilization and ease of maintenance.

In the context of gas welding's impact on heat exchanger manufacturing, the market dynamics are influenced by the ongoing evolution of welding technologies. While gas welding has been a traditional method in heat exchanger production, there is a growing trend towards more advanced welding techniques such as TIG (Tungsten Inert Gas) welding and automated welding systems. This shift is driven by the need for higher precision, improved weld quality, and increased production efficiency.

The heat exchanger market is characterized by a strong emphasis on customization, with manufacturers offering tailored solutions to meet specific industry requirements. This trend is particularly evident in sectors such as petrochemicals and food processing, where heat exchangers must comply with stringent regulatory standards and operational specifications.

Geographically, the Asia-Pacific region has emerged as a key growth area for the heat exchanger market, fueled by rapid industrialization and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on technological advancements and energy-efficient solutions.

The market is also influenced by environmental regulations and sustainability initiatives. There is a growing demand for heat exchangers that can operate with lower energy consumption and reduced environmental impact. This has led to innovations in materials and design, including the use of corrosion-resistant alloys and enhanced heat transfer surfaces.

As the manufacturing processes for heat exchangers evolve, including the role of gas welding, the market is expected to see further advancements in product quality, durability, and performance. These developments are likely to shape the competitive landscape and drive further innovation in the heat exchanger industry.

Welding Challenges

Gas welding in the manufacture of heat exchangers presents several significant challenges that impact both the production process and the final product quality. One of the primary concerns is the precise control of heat input during the welding process. Heat exchangers often involve thin-walled tubes and delicate components that can easily warp or distort under excessive heat. The gas welding process, while versatile, can lead to overheating if not carefully managed, potentially compromising the structural integrity of the heat exchanger.

Another challenge lies in achieving consistent weld quality across numerous joints. Heat exchangers typically contain multiple tubes and connections, each requiring precise welding. Maintaining uniformity in weld penetration, bead profile, and strength across all these joints is crucial for ensuring the overall efficiency and reliability of the heat exchanger. The manual nature of gas welding introduces variability, making it difficult to achieve the level of consistency required for high-performance heat exchangers.

Contamination during the welding process poses a significant risk to heat exchanger functionality. Gas welding can introduce impurities into the weld pool, potentially leading to weak joints or corrosion-prone areas. This is particularly problematic for heat exchangers used in industries with stringent cleanliness requirements, such as food processing or pharmaceutical manufacturing. Ensuring a clean welding environment and using appropriate shielding techniques become critical challenges in maintaining the purity of the welds.

The geometry of heat exchangers often includes complex configurations and tight spaces, making access for gas welding torches difficult. Welders must navigate intricate tube arrangements and confined areas, which can lead to awkward welding positions and reduced visibility. This challenge not only affects the quality of the welds but also impacts the overall production efficiency and ergonomics for the welders.

Material compatibility is another significant welding challenge in heat exchanger manufacturing. Heat exchangers often incorporate different metals to optimize heat transfer and corrosion resistance. Welding dissimilar metals requires careful selection of filler materials and precise control of the welding parameters to prevent issues such as galvanic corrosion or brittle intermetallic compounds at the weld interface.

Lastly, the thermal cycling that heat exchangers undergo during operation places additional stress on the welded joints. The repeated expansion and contraction can lead to fatigue and eventual failure if the welds are not properly executed. Ensuring that gas-welded joints can withstand these thermal stresses over the long-term operational life of the heat exchanger is a critical challenge that manufacturers must address through careful welding technique and post-weld heat treatment processes.

Another challenge lies in achieving consistent weld quality across numerous joints. Heat exchangers typically contain multiple tubes and connections, each requiring precise welding. Maintaining uniformity in weld penetration, bead profile, and strength across all these joints is crucial for ensuring the overall efficiency and reliability of the heat exchanger. The manual nature of gas welding introduces variability, making it difficult to achieve the level of consistency required for high-performance heat exchangers.

Contamination during the welding process poses a significant risk to heat exchanger functionality. Gas welding can introduce impurities into the weld pool, potentially leading to weak joints or corrosion-prone areas. This is particularly problematic for heat exchangers used in industries with stringent cleanliness requirements, such as food processing or pharmaceutical manufacturing. Ensuring a clean welding environment and using appropriate shielding techniques become critical challenges in maintaining the purity of the welds.

The geometry of heat exchangers often includes complex configurations and tight spaces, making access for gas welding torches difficult. Welders must navigate intricate tube arrangements and confined areas, which can lead to awkward welding positions and reduced visibility. This challenge not only affects the quality of the welds but also impacts the overall production efficiency and ergonomics for the welders.

Material compatibility is another significant welding challenge in heat exchanger manufacturing. Heat exchangers often incorporate different metals to optimize heat transfer and corrosion resistance. Welding dissimilar metals requires careful selection of filler materials and precise control of the welding parameters to prevent issues such as galvanic corrosion or brittle intermetallic compounds at the weld interface.

Lastly, the thermal cycling that heat exchangers undergo during operation places additional stress on the welded joints. The repeated expansion and contraction can lead to fatigue and eventual failure if the welds are not properly executed. Ensuring that gas-welded joints can withstand these thermal stresses over the long-term operational life of the heat exchanger is a critical challenge that manufacturers must address through careful welding technique and post-weld heat treatment processes.

Current Welding Methods

01 Welding torch improvements

Advancements in gas welding torch design focus on enhancing efficiency, safety, and precision. These improvements include optimized gas flow control, ergonomic handle designs, and integrated cooling systems. Such innovations contribute to better weld quality and increased operator comfort during prolonged use.- Gas welding equipment and techniques: This category covers various aspects of gas welding equipment and techniques, including torch designs, gas mixing systems, and welding process improvements. Innovations in this area focus on enhancing welding efficiency, precision, and safety for operators.

- Welding gas composition and control: This point addresses the development of specialized gas mixtures and control systems for gas welding. It includes innovations in gas composition, flow regulation, and pressure control to optimize welding performance and quality across different materials and applications.

- Automated and robotic gas welding systems: This category focuses on the integration of automation and robotics in gas welding processes. It includes developments in computer-controlled welding systems, robotic welding arms, and sensors for real-time monitoring and adjustment of welding parameters.

- Safety features and protective equipment: This point covers innovations in safety measures and protective equipment for gas welding operations. It includes advancements in flame arrestors, gas leak detection systems, personal protective equipment, and workplace safety protocols specific to gas welding environments.

- Specialized gas welding applications: This category addresses gas welding techniques and equipment designed for specific applications or materials. It includes innovations in underwater gas welding, high-temperature alloy welding, and gas welding processes for non-traditional materials or challenging environments.

02 Gas mixture control systems

Sophisticated gas mixture control systems have been developed to ensure optimal fuel-to-oxygen ratios for different welding applications. These systems often incorporate digital controls, precise flow meters, and automated adjustment mechanisms to maintain consistent flame characteristics and improve overall welding performance.Expand Specific Solutions03 Safety features in gas welding equipment

Enhanced safety features have been integrated into gas welding equipment to prevent accidents and protect operators. These include flame arrestors, automatic shut-off valves, improved pressure regulators, and advanced leak detection systems. Such safety innovations help minimize risks associated with gas leaks and flashbacks.Expand Specific Solutions04 Portable gas welding systems

Compact and portable gas welding systems have been developed to improve mobility and versatility in various work environments. These systems often feature lightweight components, integrated gas cylinders, and quick-connect fittings. Such portability allows for easier use in remote locations or confined spaces.Expand Specific Solutions05 Automation in gas welding processes

Automation technologies have been applied to gas welding processes to enhance precision and consistency. These advancements include robotic welding systems, computer-controlled gas flow, and automated torch positioning. Such automation helps improve weld quality, reduce human error, and increase productivity in industrial applications.Expand Specific Solutions

Key Manufacturers

The gas welding technology in heat exchanger manufacturing is in a mature stage, with a well-established market and proven techniques. The global heat exchanger market size is substantial, estimated to reach $20 billion by 2025, driven by increasing demand in various industries. Companies like Behr GmbH & Co. KG, Valeo Termico SA, and Danfoss A/S are key players in this sector, leveraging advanced welding technologies to produce high-quality heat exchangers. The technology's maturity is evident in the diverse applications across automotive, HVAC, and industrial sectors, with ongoing innovations focusing on improving efficiency and reducing environmental impact. Emerging players like Ningbo Hrale Plate Heat Exchanger Co. Ltd. and Zhejiang Sanhua Intelligent Controls Co., Ltd. are also contributing to the competitive landscape, particularly in the Asian market.

Behr GmbH & Co. KG

Technical Solution: Behr has focused on optimizing gas welding for compact heat exchangers used in automotive climate control systems. Their approach involves a micro-gas welding technique that allows for extremely precise and small-scale welds, crucial for the intricate designs of modern heat exchangers. Behr's process utilizes a specially formulated shielding gas mixture that improves weld pool stability and reduces oxidation in narrow joints. The company has also developed a robotic gas welding system with adaptive torch positioning, capable of navigating complex 3D heat exchanger geometries[6].

Strengths: High precision for compact designs, improved weld quality in narrow joints, and flexibility in complex geometries. Weaknesses: Potentially slower welding speeds compared to some alternative methods and higher equipment costs for the specialized robotic systems.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding techniques for heat exchanger manufacturing, focusing on precision and efficiency. Their approach utilizes a proprietary gas mixture and specialized welding equipment to achieve high-quality joints in various heat exchanger materials, including aluminum and stainless steel. ITW's gas welding process incorporates real-time monitoring and adaptive control systems to ensure consistent weld quality and minimize defects[1]. The company has also implemented automated welding stations that can handle complex geometries and tight tolerances required in modern heat exchanger designs[3].

Strengths: High precision welding, adaptability to various materials, and automated processes for consistency. Weaknesses: Potential higher initial equipment costs and the need for specialized training for operators.

Innovative Techniques

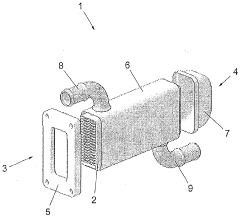

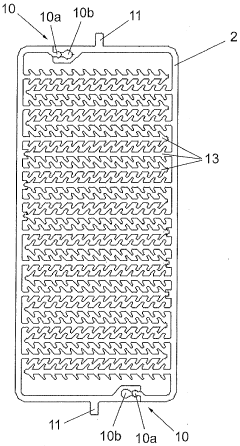

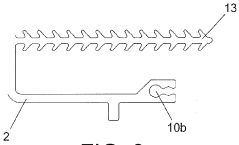

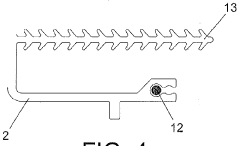

Heat exchanger for gas and corresponding method of manufacture

PatentWO2009021826A1

Innovation

- A gas heat exchanger made from extruded aluminum components brazed in a controlled atmosphere furnace, featuring connection means with clip-type interlocking elements and spaces for low-melting-point filler material, reducing the number of connection points and simplifying assembly.

Heat exchanger for gas and method for making same

PatentActiveEP2137477A1

Innovation

- A gas heat exchanger design featuring a metal core with parallel ducts joined by laser or arc welding to support plates and gas tanks, eliminating the need for a separate carcass and simplifying the manufacturing process, while allowing for efficient cooling and reduced component count.

Material Advancements

Material advancements have played a crucial role in enhancing the efficiency and durability of heat exchangers, particularly in the context of gas welding manufacturing processes. The development of high-performance alloys and composite materials has significantly improved the heat transfer capabilities and corrosion resistance of heat exchanger components.

One of the most notable advancements is the introduction of advanced stainless steel alloys, such as duplex and super duplex grades. These materials offer superior strength and corrosion resistance compared to traditional austenitic stainless steels, making them ideal for use in harsh environments and high-temperature applications. The improved weldability of these alloys has also facilitated more efficient gas welding processes in heat exchanger manufacturing.

Nickel-based alloys have emerged as another key material advancement in heat exchanger technology. Alloys such as Inconel and Hastelloy exhibit exceptional resistance to high-temperature oxidation and corrosion, making them suitable for extreme operating conditions. These materials have enabled the production of heat exchangers capable of withstanding aggressive chemical environments and elevated temperatures, expanding their applicability in various industries.

The development of titanium alloys has revolutionized heat exchanger design for marine and offshore applications. Titanium's excellent corrosion resistance in seawater and its high strength-to-weight ratio have made it an attractive option for compact, lightweight heat exchangers. Gas welding techniques have been adapted to accommodate the unique properties of titanium, ensuring reliable and durable joints in these critical components.

Composite materials, particularly metal matrix composites (MMCs), have gained traction in heat exchanger manufacturing. These materials combine the thermal conductivity of metals with the lightweight properties of ceramics or polymers, resulting in heat exchangers with improved performance and reduced weight. While gas welding of MMCs presents challenges, ongoing research is focused on developing specialized techniques to overcome these limitations.

Advancements in surface engineering have also contributed to the enhancement of heat exchanger performance. Techniques such as thermal spraying and laser cladding allow for the application of wear-resistant and corrosion-resistant coatings on heat exchanger surfaces. These coatings can significantly extend the lifespan of components exposed to harsh operating conditions, reducing maintenance requirements and improving overall efficiency.

The integration of nanomaterials in heat exchanger design represents a promising frontier in material advancements. Nanostructured surfaces and nanofluid coolants have demonstrated potential for enhancing heat transfer rates and reducing fouling. While the application of gas welding to nanomaterial-enhanced components is still in its early stages, it presents an exciting area for future research and development in heat exchanger manufacturing.

One of the most notable advancements is the introduction of advanced stainless steel alloys, such as duplex and super duplex grades. These materials offer superior strength and corrosion resistance compared to traditional austenitic stainless steels, making them ideal for use in harsh environments and high-temperature applications. The improved weldability of these alloys has also facilitated more efficient gas welding processes in heat exchanger manufacturing.

Nickel-based alloys have emerged as another key material advancement in heat exchanger technology. Alloys such as Inconel and Hastelloy exhibit exceptional resistance to high-temperature oxidation and corrosion, making them suitable for extreme operating conditions. These materials have enabled the production of heat exchangers capable of withstanding aggressive chemical environments and elevated temperatures, expanding their applicability in various industries.

The development of titanium alloys has revolutionized heat exchanger design for marine and offshore applications. Titanium's excellent corrosion resistance in seawater and its high strength-to-weight ratio have made it an attractive option for compact, lightweight heat exchangers. Gas welding techniques have been adapted to accommodate the unique properties of titanium, ensuring reliable and durable joints in these critical components.

Composite materials, particularly metal matrix composites (MMCs), have gained traction in heat exchanger manufacturing. These materials combine the thermal conductivity of metals with the lightweight properties of ceramics or polymers, resulting in heat exchangers with improved performance and reduced weight. While gas welding of MMCs presents challenges, ongoing research is focused on developing specialized techniques to overcome these limitations.

Advancements in surface engineering have also contributed to the enhancement of heat exchanger performance. Techniques such as thermal spraying and laser cladding allow for the application of wear-resistant and corrosion-resistant coatings on heat exchanger surfaces. These coatings can significantly extend the lifespan of components exposed to harsh operating conditions, reducing maintenance requirements and improving overall efficiency.

The integration of nanomaterials in heat exchanger design represents a promising frontier in material advancements. Nanostructured surfaces and nanofluid coolants have demonstrated potential for enhancing heat transfer rates and reducing fouling. While the application of gas welding to nanomaterial-enhanced components is still in its early stages, it presents an exciting area for future research and development in heat exchanger manufacturing.

Environmental Impact

Gas welding in the manufacture of heat exchangers has significant environmental implications that warrant careful consideration. The process involves the combustion of fuel gases, typically acetylene or propane, which releases various pollutants into the atmosphere. These emissions primarily consist of carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. The release of these greenhouse gases and air pollutants contributes to global warming and local air quality degradation, potentially impacting both human health and ecosystems in the vicinity of manufacturing facilities.

The energy-intensive nature of gas welding also raises concerns about resource consumption and energy efficiency. The high temperatures required for welding consume substantial amounts of fossil fuels, further exacerbating the carbon footprint of heat exchanger production. This energy consumption not only depletes non-renewable resources but also indirectly contributes to environmental degradation through the extraction and processing of these fuels.

Water pollution is another environmental concern associated with gas welding in heat exchanger manufacturing. Cooling processes and cleaning operations often generate wastewater containing heavy metals, oils, and other contaminants. If not properly treated, this effluent can harm aquatic ecosystems and potentially contaminate groundwater resources.

The production of welding gases and associated equipment also has upstream environmental impacts. The extraction and processing of raw materials for gas cylinders, regulators, and other welding accessories contribute to resource depletion and pollution. Additionally, the transportation of these materials and finished products adds to the overall environmental footprint of heat exchanger manufacturing.

Waste generation is a further environmental consideration. Gas welding processes produce slag, spatter, and other solid waste materials that require proper disposal. Improper management of these wastes can lead to soil contamination and pose risks to local flora and fauna. Moreover, the disposal of used welding equipment and consumables at the end of their lifecycle presents additional environmental challenges.

To mitigate these environmental impacts, manufacturers are increasingly exploring alternative welding technologies and implementing more sustainable practices. These include the adoption of electric welding methods, which can reduce direct emissions and improve energy efficiency when powered by renewable sources. Additionally, the implementation of advanced filtration systems and waste management protocols can help minimize air and water pollution associated with gas welding processes in heat exchanger production.

The energy-intensive nature of gas welding also raises concerns about resource consumption and energy efficiency. The high temperatures required for welding consume substantial amounts of fossil fuels, further exacerbating the carbon footprint of heat exchanger production. This energy consumption not only depletes non-renewable resources but also indirectly contributes to environmental degradation through the extraction and processing of these fuels.

Water pollution is another environmental concern associated with gas welding in heat exchanger manufacturing. Cooling processes and cleaning operations often generate wastewater containing heavy metals, oils, and other contaminants. If not properly treated, this effluent can harm aquatic ecosystems and potentially contaminate groundwater resources.

The production of welding gases and associated equipment also has upstream environmental impacts. The extraction and processing of raw materials for gas cylinders, regulators, and other welding accessories contribute to resource depletion and pollution. Additionally, the transportation of these materials and finished products adds to the overall environmental footprint of heat exchanger manufacturing.

Waste generation is a further environmental consideration. Gas welding processes produce slag, spatter, and other solid waste materials that require proper disposal. Improper management of these wastes can lead to soil contamination and pose risks to local flora and fauna. Moreover, the disposal of used welding equipment and consumables at the end of their lifecycle presents additional environmental challenges.

To mitigate these environmental impacts, manufacturers are increasingly exploring alternative welding technologies and implementing more sustainable practices. These include the adoption of electric welding methods, which can reduce direct emissions and improve energy efficiency when powered by renewable sources. Additionally, the implementation of advanced filtration systems and waste management protocols can help minimize air and water pollution associated with gas welding processes in heat exchanger production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!