High-Frequency Monitoring Technologies in Gas Welding

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding HF Monitoring Background and Objectives

Gas welding, a traditional joining technique, has been a cornerstone in manufacturing and construction for over a century. As industries evolve and demand higher precision and efficiency, the need for advanced monitoring technologies in gas welding processes has become increasingly apparent. High-frequency monitoring technologies represent a significant leap forward in ensuring weld quality, safety, and productivity.

The evolution of gas welding monitoring has been driven by the growing complexity of manufacturing processes and the increasing emphasis on quality control. Early monitoring methods relied heavily on visual inspection and post-weld testing, which were time-consuming and often failed to detect defects in real-time. The advent of sensor technologies and data analytics has paved the way for more sophisticated monitoring approaches.

High-frequency monitoring in gas welding aims to provide real-time, accurate data on various welding parameters. These include temperature, gas flow rates, torch position, and weld pool dynamics. By continuously tracking these factors, manufacturers can ensure consistent weld quality, reduce defects, and optimize resource utilization. The ultimate goal is to enhance overall welding performance while minimizing human error and material waste.

The development of high-frequency monitoring technologies aligns with broader industry trends towards automation and smart manufacturing. Industry 4.0 principles, emphasizing data-driven decision-making and interconnected systems, have accelerated the adoption of advanced monitoring solutions in welding processes. This shift is not only improving product quality but also contributing to safer work environments and more sustainable manufacturing practices.

Recent technological advancements have expanded the capabilities of high-frequency monitoring systems. Machine learning algorithms can now analyze vast amounts of welding data to predict potential issues before they occur. Additionally, the integration of Internet of Things (IoT) devices allows for remote monitoring and control of welding operations, enabling greater flexibility and efficiency in production processes.

As the field progresses, researchers and industry professionals are focusing on several key objectives. These include developing more robust sensors capable of withstanding harsh welding environments, improving data processing speeds to enable real-time adjustments, and creating user-friendly interfaces that allow welders to interpret complex data easily. There is also a growing emphasis on developing adaptive control systems that can automatically adjust welding parameters based on monitored data, further enhancing the precision and consistency of gas welding processes.

The future of high-frequency monitoring in gas welding looks promising, with potential applications extending beyond traditional manufacturing. Emerging areas such as additive manufacturing and robotic welding are likely to benefit significantly from these advanced monitoring technologies, driving further innovation and research in the field.

The evolution of gas welding monitoring has been driven by the growing complexity of manufacturing processes and the increasing emphasis on quality control. Early monitoring methods relied heavily on visual inspection and post-weld testing, which were time-consuming and often failed to detect defects in real-time. The advent of sensor technologies and data analytics has paved the way for more sophisticated monitoring approaches.

High-frequency monitoring in gas welding aims to provide real-time, accurate data on various welding parameters. These include temperature, gas flow rates, torch position, and weld pool dynamics. By continuously tracking these factors, manufacturers can ensure consistent weld quality, reduce defects, and optimize resource utilization. The ultimate goal is to enhance overall welding performance while minimizing human error and material waste.

The development of high-frequency monitoring technologies aligns with broader industry trends towards automation and smart manufacturing. Industry 4.0 principles, emphasizing data-driven decision-making and interconnected systems, have accelerated the adoption of advanced monitoring solutions in welding processes. This shift is not only improving product quality but also contributing to safer work environments and more sustainable manufacturing practices.

Recent technological advancements have expanded the capabilities of high-frequency monitoring systems. Machine learning algorithms can now analyze vast amounts of welding data to predict potential issues before they occur. Additionally, the integration of Internet of Things (IoT) devices allows for remote monitoring and control of welding operations, enabling greater flexibility and efficiency in production processes.

As the field progresses, researchers and industry professionals are focusing on several key objectives. These include developing more robust sensors capable of withstanding harsh welding environments, improving data processing speeds to enable real-time adjustments, and creating user-friendly interfaces that allow welders to interpret complex data easily. There is also a growing emphasis on developing adaptive control systems that can automatically adjust welding parameters based on monitored data, further enhancing the precision and consistency of gas welding processes.

The future of high-frequency monitoring in gas welding looks promising, with potential applications extending beyond traditional manufacturing. Emerging areas such as additive manufacturing and robotic welding are likely to benefit significantly from these advanced monitoring technologies, driving further innovation and research in the field.

Market Analysis for HF Monitoring in Gas Welding

The market for high-frequency monitoring technologies in gas welding is experiencing significant growth, driven by the increasing demand for precision and quality control in welding processes across various industries. This technology offers real-time monitoring of welding parameters, enabling immediate detection of defects and ensuring consistent weld quality.

The global gas welding market, which forms the foundation for this technology, is projected to expand steadily over the next five years. Key industries driving this growth include automotive manufacturing, construction, aerospace, and shipbuilding. These sectors are increasingly adopting advanced welding technologies to improve productivity and meet stringent quality standards.

High-frequency monitoring systems in gas welding are gaining traction due to their ability to enhance weld quality, reduce rework, and minimize material waste. The automotive industry, in particular, is a major adopter of this technology, as it strives to meet strict safety regulations and lightweight vehicle requirements. The aerospace sector also shows strong demand, given the critical nature of welding in aircraft construction.

The market for HF monitoring in gas welding is segmented by technology type, including acoustic emission monitoring, thermal imaging, and laser-based systems. Each of these technologies caters to specific industry needs and applications. Acoustic emission monitoring is gaining popularity for its non-invasive nature and ability to detect defects in real-time.

Geographically, North America and Europe lead the market adoption of HF monitoring technologies in gas welding, owing to their advanced manufacturing sectors and stringent quality control regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization in countries like China and India.

The market is characterized by a mix of established players and innovative startups. Major welding equipment manufacturers are investing in R&D to integrate HF monitoring capabilities into their existing product lines. Simultaneously, specialized technology firms are entering the market with advanced monitoring solutions, creating a competitive and dynamic landscape.

Key market trends include the integration of artificial intelligence and machine learning algorithms to enhance defect detection and predictive maintenance capabilities. There is also a growing focus on developing user-friendly interfaces and cloud-based data analytics platforms to make the technology more accessible to a broader range of users.

Despite the promising outlook, challenges such as high initial investment costs and the need for skilled operators may hinder market growth, particularly among small and medium-sized enterprises. However, the long-term benefits of improved quality control and reduced operational costs are expected to drive continued adoption of HF monitoring technologies in gas welding across various industries.

The global gas welding market, which forms the foundation for this technology, is projected to expand steadily over the next five years. Key industries driving this growth include automotive manufacturing, construction, aerospace, and shipbuilding. These sectors are increasingly adopting advanced welding technologies to improve productivity and meet stringent quality standards.

High-frequency monitoring systems in gas welding are gaining traction due to their ability to enhance weld quality, reduce rework, and minimize material waste. The automotive industry, in particular, is a major adopter of this technology, as it strives to meet strict safety regulations and lightweight vehicle requirements. The aerospace sector also shows strong demand, given the critical nature of welding in aircraft construction.

The market for HF monitoring in gas welding is segmented by technology type, including acoustic emission monitoring, thermal imaging, and laser-based systems. Each of these technologies caters to specific industry needs and applications. Acoustic emission monitoring is gaining popularity for its non-invasive nature and ability to detect defects in real-time.

Geographically, North America and Europe lead the market adoption of HF monitoring technologies in gas welding, owing to their advanced manufacturing sectors and stringent quality control regulations. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization in countries like China and India.

The market is characterized by a mix of established players and innovative startups. Major welding equipment manufacturers are investing in R&D to integrate HF monitoring capabilities into their existing product lines. Simultaneously, specialized technology firms are entering the market with advanced monitoring solutions, creating a competitive and dynamic landscape.

Key market trends include the integration of artificial intelligence and machine learning algorithms to enhance defect detection and predictive maintenance capabilities. There is also a growing focus on developing user-friendly interfaces and cloud-based data analytics platforms to make the technology more accessible to a broader range of users.

Despite the promising outlook, challenges such as high initial investment costs and the need for skilled operators may hinder market growth, particularly among small and medium-sized enterprises. However, the long-term benefits of improved quality control and reduced operational costs are expected to drive continued adoption of HF monitoring technologies in gas welding across various industries.

Current Challenges in Gas Welding HF Monitoring

Gas welding high-frequency monitoring faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complexity of the welding environment, which is characterized by intense heat, electromagnetic interference, and rapid changes in material properties. These factors make it difficult to obtain accurate and reliable measurements in real-time.

The high temperatures involved in gas welding pose a particular challenge for sensor technologies. Many conventional sensors are unable to withstand the extreme heat generated during the welding process, leading to rapid degradation or failure. This necessitates the development of specialized, heat-resistant sensors capable of operating in such harsh conditions without compromising measurement accuracy.

Another major challenge is the need for high-speed data acquisition and processing. Gas welding processes occur at rapid rates, with critical changes happening in milliseconds. Current monitoring systems often struggle to capture and analyze data at the required speeds, resulting in missed defects or quality issues. This limitation is particularly problematic when attempting to detect and respond to welding anomalies in real-time.

The integration of high-frequency monitoring systems into existing welding equipment and processes presents additional difficulties. Many welding setups are not designed with advanced monitoring in mind, making it challenging to retrofit them with sophisticated sensors and data collection systems. This integration challenge extends to the software side as well, where compatibility issues between monitoring systems and existing welding control software can arise.

Data interpretation and analysis represent another significant hurdle. The vast amount of data generated by high-frequency monitoring systems can be overwhelming, and extracting meaningful insights from this data requires advanced algorithms and expertise. Many current systems lack the sophisticated analytics capabilities needed to translate raw data into actionable information for welders and quality control personnel.

Electromagnetic interference (EMI) from the welding process itself poses a substantial challenge to accurate monitoring. The high currents and voltages involved in gas welding can create significant electromagnetic noise, which can interfere with sensor readings and data transmission. Developing effective EMI shielding and filtering techniques is crucial for ensuring the reliability of high-frequency monitoring systems.

Cost considerations also present a barrier to widespread adoption. High-frequency monitoring technologies often require significant investment in hardware, software, and training. Many smaller welding operations may find it difficult to justify these costs, particularly if the benefits are not immediately apparent or quantifiable.

Lastly, there is a notable skills gap in the industry when it comes to implementing and utilizing advanced monitoring technologies. Many welders and technicians lack the necessary training to effectively operate and interpret data from high-frequency monitoring systems. Bridging this knowledge gap requires comprehensive training programs and a shift in industry practices, which can be slow to implement across the sector.

The high temperatures involved in gas welding pose a particular challenge for sensor technologies. Many conventional sensors are unable to withstand the extreme heat generated during the welding process, leading to rapid degradation or failure. This necessitates the development of specialized, heat-resistant sensors capable of operating in such harsh conditions without compromising measurement accuracy.

Another major challenge is the need for high-speed data acquisition and processing. Gas welding processes occur at rapid rates, with critical changes happening in milliseconds. Current monitoring systems often struggle to capture and analyze data at the required speeds, resulting in missed defects or quality issues. This limitation is particularly problematic when attempting to detect and respond to welding anomalies in real-time.

The integration of high-frequency monitoring systems into existing welding equipment and processes presents additional difficulties. Many welding setups are not designed with advanced monitoring in mind, making it challenging to retrofit them with sophisticated sensors and data collection systems. This integration challenge extends to the software side as well, where compatibility issues between monitoring systems and existing welding control software can arise.

Data interpretation and analysis represent another significant hurdle. The vast amount of data generated by high-frequency monitoring systems can be overwhelming, and extracting meaningful insights from this data requires advanced algorithms and expertise. Many current systems lack the sophisticated analytics capabilities needed to translate raw data into actionable information for welders and quality control personnel.

Electromagnetic interference (EMI) from the welding process itself poses a substantial challenge to accurate monitoring. The high currents and voltages involved in gas welding can create significant electromagnetic noise, which can interfere with sensor readings and data transmission. Developing effective EMI shielding and filtering techniques is crucial for ensuring the reliability of high-frequency monitoring systems.

Cost considerations also present a barrier to widespread adoption. High-frequency monitoring technologies often require significant investment in hardware, software, and training. Many smaller welding operations may find it difficult to justify these costs, particularly if the benefits are not immediately apparent or quantifiable.

Lastly, there is a notable skills gap in the industry when it comes to implementing and utilizing advanced monitoring technologies. Many welders and technicians lack the necessary training to effectively operate and interpret data from high-frequency monitoring systems. Bridging this knowledge gap requires comprehensive training programs and a shift in industry practices, which can be slow to implement across the sector.

Existing HF Monitoring Solutions for Gas Welding

01 High-frequency electromagnetic field monitoring

This technology involves the use of sensors and devices to monitor high-frequency electromagnetic fields. It allows for real-time detection and measurement of electromagnetic radiation in various environments, which is crucial for safety and compliance in industries such as telecommunications and power generation.- High-frequency electromagnetic field monitoring: This technology involves the use of sensors and devices to monitor high-frequency electromagnetic fields in various environments. It allows for real-time detection and measurement of electromagnetic radiation, which is crucial for safety and compliance in industries such as telecommunications, power generation, and medical equipment manufacturing.

- Frequency monitoring in electronic circuits: This approach focuses on monitoring and analyzing frequency characteristics in electronic circuits. It includes techniques for measuring oscillation frequencies, detecting frequency shifts, and ensuring stability in high-frequency circuits. These methods are essential for optimizing performance in applications such as communication systems and signal processing.

- High-frequency monitoring in medical applications: High-frequency monitoring technologies are utilized in medical settings for various purposes, including tissue analysis, surgical precision, and patient monitoring. These technologies enable real-time feedback during procedures, enhance diagnostic capabilities, and improve overall patient care through continuous high-frequency data collection and analysis.

- Wireless high-frequency monitoring systems: This category encompasses wireless technologies designed for high-frequency monitoring applications. These systems utilize advanced communication protocols and sensor networks to collect and transmit high-frequency data wirelessly. They offer flexibility in deployment and are particularly useful in remote or hard-to-reach locations for environmental, industrial, or security monitoring.

- High-frequency monitoring for power systems: This technology focuses on monitoring high-frequency phenomena in power systems and electrical grids. It includes methods for detecting and analyzing transients, harmonics, and other high-frequency disturbances that can affect power quality and system stability. These monitoring techniques are crucial for maintaining reliable and efficient power distribution networks.

02 Frequency monitoring in electronic circuits

This approach focuses on monitoring and analyzing frequency characteristics in electronic circuits. It includes techniques for measuring oscillation frequencies, detecting frequency shifts, and ensuring stability in high-frequency circuits, which are essential for applications in communications and signal processing.Expand Specific Solutions03 High-frequency monitoring in medical applications

High-frequency monitoring technologies are applied in medical devices and procedures. This includes real-time monitoring during surgeries, high-frequency ablation treatments, and diagnostic imaging, enhancing precision and safety in medical interventions.Expand Specific Solutions04 Wireless high-frequency monitoring systems

These systems utilize wireless technologies for high-frequency monitoring applications. They enable remote and continuous monitoring of various parameters, offering advantages in terms of flexibility, scalability, and data transmission in industrial, environmental, and IoT applications.Expand Specific Solutions05 High-frequency monitoring for power systems

This technology focuses on monitoring high-frequency phenomena in power systems. It includes techniques for detecting and analyzing transients, harmonics, and other high-frequency disturbances in electrical grids, which is crucial for maintaining power quality and system stability.Expand Specific Solutions

Key Players in Gas Welding Monitoring Industry

The research on high-frequency monitoring technologies in gas welding is in a growth phase, with increasing market demand driven by the need for improved safety and efficiency in industrial processes. The global market size for welding monitoring systems is expanding, expected to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with key players like Fronius International, Illinois Tool Works, and Lincoln Global leading innovation. These companies are developing sophisticated sensors, data analytics, and AI-driven solutions to enhance real-time monitoring capabilities. Emerging players such as UDMTEK and Kanary Alert Systems are also contributing to technological advancements, particularly in machine learning and gas detection applications for welding processes.

Fronius International GmbH

Technical Solution: Fronius has developed advanced high-frequency monitoring technologies for gas welding, including their WeldCube data management system. This system utilizes sensors to collect real-time data on welding parameters such as current, voltage, and gas flow rates. The data is processed using machine learning algorithms to detect anomalies and predict weld quality[1]. Fronius has also implemented vision-based monitoring systems that use high-speed cameras and image processing to analyze the weld pool and detect defects in real-time[2]. Their TPS/i welding platform incorporates these monitoring technologies with adaptive control systems to automatically adjust welding parameters for optimal results[3].

Strengths: Comprehensive data collection and analysis, integration with welding systems for real-time adjustments. Weaknesses: May require significant investment in hardware and software infrastructure.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed the Miller WeldScore system for high-frequency monitoring in gas welding. This technology uses advanced sensors to capture welding data at rates up to 120,000 times per second[4]. The system analyzes factors such as arc stability, wire feed speed, and shielding gas flow to provide a numerical score indicating weld quality. ITW has also implemented acoustic monitoring technologies that use sound signatures to detect welding defects and inconsistencies in real-time[5]. Their IntelliWeld system combines these monitoring capabilities with adaptive control algorithms to maintain consistent weld quality across varying conditions[6].

Strengths: High-frequency data capture, multi-factor analysis for comprehensive quality assessment. Weaknesses: May be complex to implement and interpret results for less experienced operators.

Core Innovations in Gas Welding HF Monitoring

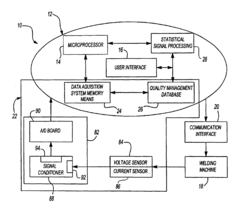

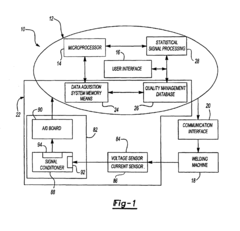

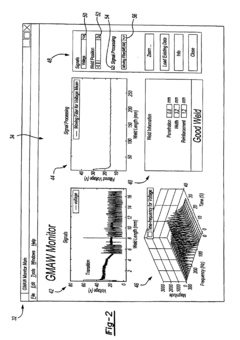

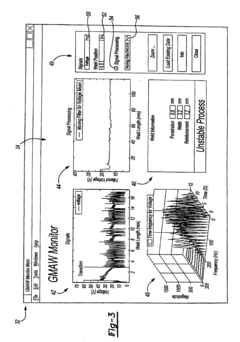

Online monitoring system and method for a short-circuiting gas metal arc welding process

PatentInactiveUS6744011B1

Innovation

- An online monitoring system using a computer with a microprocessor and graphical user interface, communicating with welding machines to acquire and process current and voltage signals, providing real-time feedback for adjusting welding parameters and storing data for statistical analysis, without requiring additional hardware.

procedure for process monitoring in gas metal arc welding

PatentInactiveDE102021002047A1

Innovation

- A method utilizing time-series data of welding current and voltage, scaled and used to train a neural network, predicts welding voltage through a process model, allowing for real-time quality assessment and anomaly detection without explicit cause modeling, applicable to modern welding processes.

Safety Standards and Regulations in Gas Welding

Gas welding safety standards and regulations play a crucial role in ensuring the well-being of workers and maintaining a secure work environment. These standards are developed and enforced by various national and international organizations, such as the Occupational Safety and Health Administration (OSHA) in the United States and the International Organization for Standardization (ISO) globally.

One of the primary focuses of safety standards in gas welding is the proper handling and storage of compressed gases. Regulations typically mandate that gas cylinders must be secured in an upright position, stored in well-ventilated areas, and kept away from heat sources. Additionally, specific guidelines are in place for the transportation of gas cylinders, including the use of appropriate valve protection caps and securing methods during transit.

Personal protective equipment (PPE) requirements are another critical aspect of gas welding safety regulations. Standards often specify the use of flame-resistant clothing, appropriate eye protection with the correct shade of filter lenses, and respiratory protection when working in confined spaces or with certain materials. These PPE requirements are designed to protect welders from potential hazards such as burns, eye damage from intense light and UV radiation, and inhalation of harmful fumes.

Ventilation standards are also a key component of gas welding safety regulations. Adequate ventilation is essential to prevent the accumulation of toxic fumes and gases produced during the welding process. Regulations may specify minimum air flow rates, the use of local exhaust ventilation systems, or the implementation of general ventilation strategies to maintain safe air quality in the work area.

Fire prevention measures are heavily emphasized in gas welding safety standards. Regulations typically require the removal or protection of flammable materials within a specified radius of the welding area. Fire watch procedures, including monitoring the area for a specified period after welding operations have ceased, are often mandated to prevent delayed ignition of smoldering materials.

Training and certification requirements for gas welding operators are also outlined in safety standards. These regulations ensure that workers have the necessary knowledge and skills to perform welding tasks safely and effectively. Training programs typically cover topics such as proper equipment use, hazard recognition, emergency procedures, and first aid.

Regular equipment inspection and maintenance procedures are prescribed by safety standards to ensure the integrity and safe operation of gas welding equipment. This includes routine checks of hoses, regulators, torches, and cylinders for signs of wear, damage, or leaks. Compliance with these inspection protocols is essential for preventing accidents and equipment failures.

One of the primary focuses of safety standards in gas welding is the proper handling and storage of compressed gases. Regulations typically mandate that gas cylinders must be secured in an upright position, stored in well-ventilated areas, and kept away from heat sources. Additionally, specific guidelines are in place for the transportation of gas cylinders, including the use of appropriate valve protection caps and securing methods during transit.

Personal protective equipment (PPE) requirements are another critical aspect of gas welding safety regulations. Standards often specify the use of flame-resistant clothing, appropriate eye protection with the correct shade of filter lenses, and respiratory protection when working in confined spaces or with certain materials. These PPE requirements are designed to protect welders from potential hazards such as burns, eye damage from intense light and UV radiation, and inhalation of harmful fumes.

Ventilation standards are also a key component of gas welding safety regulations. Adequate ventilation is essential to prevent the accumulation of toxic fumes and gases produced during the welding process. Regulations may specify minimum air flow rates, the use of local exhaust ventilation systems, or the implementation of general ventilation strategies to maintain safe air quality in the work area.

Fire prevention measures are heavily emphasized in gas welding safety standards. Regulations typically require the removal or protection of flammable materials within a specified radius of the welding area. Fire watch procedures, including monitoring the area for a specified period after welding operations have ceased, are often mandated to prevent delayed ignition of smoldering materials.

Training and certification requirements for gas welding operators are also outlined in safety standards. These regulations ensure that workers have the necessary knowledge and skills to perform welding tasks safely and effectively. Training programs typically cover topics such as proper equipment use, hazard recognition, emergency procedures, and first aid.

Regular equipment inspection and maintenance procedures are prescribed by safety standards to ensure the integrity and safe operation of gas welding equipment. This includes routine checks of hoses, regulators, torches, and cylinders for signs of wear, damage, or leaks. Compliance with these inspection protocols is essential for preventing accidents and equipment failures.

Environmental Impact of HF Monitoring Technologies

The implementation of high-frequency monitoring technologies in gas welding processes has significant environmental implications that warrant careful consideration. These advanced monitoring systems, while offering improved precision and efficiency in welding operations, also introduce new environmental challenges and opportunities.

One of the primary environmental benefits of high-frequency monitoring technologies is the potential reduction in material waste. By providing real-time feedback on welding parameters, these systems enable more accurate control of the welding process, resulting in fewer defects and less need for rework. This reduction in waste translates to lower consumption of raw materials and energy, thereby minimizing the overall environmental footprint of welding operations.

Furthermore, high-frequency monitoring technologies contribute to improved energy efficiency in gas welding processes. The precise control afforded by these systems allows for optimized gas flow rates and welding currents, reducing unnecessary energy consumption. This enhanced efficiency not only lowers operational costs but also decreases greenhouse gas emissions associated with energy production.

However, the adoption of high-frequency monitoring technologies also raises concerns regarding electronic waste. As these systems rely on sophisticated sensors and electronic components, their widespread implementation could lead to an increase in e-waste generation when equipment reaches end-of-life. Proper disposal and recycling protocols must be established to mitigate the environmental impact of discarded monitoring devices.

Another environmental consideration is the potential for electromagnetic interference (EMI) generated by high-frequency monitoring equipment. While the EMI levels are generally low, cumulative effects in industrial settings with multiple welding stations could impact nearby electronic systems or sensitive wildlife. Shielding and proper installation practices are essential to minimize these effects.

The use of high-frequency monitoring technologies may also indirectly contribute to reduced air pollution. By enabling more precise control of gas flow and arc characteristics, these systems can help minimize the release of welding fumes and particulate matter. This improvement in air quality not only benefits the immediate work environment but also reduces the overall atmospheric pollution associated with welding operations.

In terms of lifecycle assessment, the environmental impact of manufacturing and distributing high-frequency monitoring technologies must be weighed against their long-term benefits. While the production of these systems requires resources and energy, their potential to extend the lifespan of welding equipment and improve overall process efficiency may offset initial environmental costs.

One of the primary environmental benefits of high-frequency monitoring technologies is the potential reduction in material waste. By providing real-time feedback on welding parameters, these systems enable more accurate control of the welding process, resulting in fewer defects and less need for rework. This reduction in waste translates to lower consumption of raw materials and energy, thereby minimizing the overall environmental footprint of welding operations.

Furthermore, high-frequency monitoring technologies contribute to improved energy efficiency in gas welding processes. The precise control afforded by these systems allows for optimized gas flow rates and welding currents, reducing unnecessary energy consumption. This enhanced efficiency not only lowers operational costs but also decreases greenhouse gas emissions associated with energy production.

However, the adoption of high-frequency monitoring technologies also raises concerns regarding electronic waste. As these systems rely on sophisticated sensors and electronic components, their widespread implementation could lead to an increase in e-waste generation when equipment reaches end-of-life. Proper disposal and recycling protocols must be established to mitigate the environmental impact of discarded monitoring devices.

Another environmental consideration is the potential for electromagnetic interference (EMI) generated by high-frequency monitoring equipment. While the EMI levels are generally low, cumulative effects in industrial settings with multiple welding stations could impact nearby electronic systems or sensitive wildlife. Shielding and proper installation practices are essential to minimize these effects.

The use of high-frequency monitoring technologies may also indirectly contribute to reduced air pollution. By enabling more precise control of gas flow and arc characteristics, these systems can help minimize the release of welding fumes and particulate matter. This improvement in air quality not only benefits the immediate work environment but also reduces the overall atmospheric pollution associated with welding operations.

In terms of lifecycle assessment, the environmental impact of manufacturing and distributing high-frequency monitoring technologies must be weighed against their long-term benefits. While the production of these systems requires resources and energy, their potential to extend the lifespan of welding equipment and improve overall process efficiency may offset initial environmental costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!