Innovations in Fuel Delivery Systems for Gas Welding Efficiency

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fuel Delivery Evolution

The evolution of fuel delivery systems in gas welding has been a critical factor in improving welding efficiency and performance. Over the years, these systems have undergone significant transformations, driven by technological advancements and the need for more precise and efficient welding processes.

In the early days of gas welding, fuel delivery was primarily manual, relying on simple valves and regulators to control the flow of gases. This rudimentary approach often resulted in inconsistent flame quality and limited control over the welding process. As the industry progressed, the introduction of more sophisticated pressure regulators and flow meters in the mid-20th century marked a significant improvement in fuel delivery precision.

The 1970s and 1980s saw the emergence of electronic control systems, which revolutionized fuel delivery in gas welding. These systems allowed for more accurate gas flow regulation and the ability to preset and maintain specific gas mixtures. This development greatly enhanced welding consistency and reduced the reliance on operator skill for achieving optimal fuel delivery.

A major leap forward came with the introduction of computerized fuel delivery systems in the 1990s. These systems integrated sensors and microprocessors to continuously monitor and adjust gas flow rates in real-time, responding to changes in welding conditions. This innovation not only improved welding quality but also increased efficiency by optimizing fuel consumption.

The turn of the 21st century brought about the integration of digital technologies into fuel delivery systems. Advanced software algorithms and digital interfaces allowed for unprecedented levels of control and customization. Welders could now program specific fuel delivery profiles for different materials and welding techniques, further enhancing precision and repeatability.

Recent years have seen the incorporation of IoT (Internet of Things) and AI (Artificial Intelligence) technologies into fuel delivery systems. These smart systems can learn from historical welding data, predict optimal fuel delivery parameters, and even self-adjust based on real-time feedback. This level of automation and intelligence has significantly reduced setup times and improved overall welding efficiency.

The latest trend in fuel delivery evolution is the development of hybrid systems that combine traditional gas welding with other welding technologies. For instance, some systems now integrate plasma or laser heating elements alongside gas delivery, allowing for more versatile and efficient welding processes. These hybrid approaches are pushing the boundaries of what's possible in terms of welding speed, precision, and material compatibility.

As we look to the future, the evolution of fuel delivery systems in gas welding continues to focus on increased precision, efficiency, and automation. Emerging technologies such as nanotechnology and advanced materials science are expected to play a significant role in the next generation of fuel delivery innovations, potentially revolutionizing the field once again.

In the early days of gas welding, fuel delivery was primarily manual, relying on simple valves and regulators to control the flow of gases. This rudimentary approach often resulted in inconsistent flame quality and limited control over the welding process. As the industry progressed, the introduction of more sophisticated pressure regulators and flow meters in the mid-20th century marked a significant improvement in fuel delivery precision.

The 1970s and 1980s saw the emergence of electronic control systems, which revolutionized fuel delivery in gas welding. These systems allowed for more accurate gas flow regulation and the ability to preset and maintain specific gas mixtures. This development greatly enhanced welding consistency and reduced the reliance on operator skill for achieving optimal fuel delivery.

A major leap forward came with the introduction of computerized fuel delivery systems in the 1990s. These systems integrated sensors and microprocessors to continuously monitor and adjust gas flow rates in real-time, responding to changes in welding conditions. This innovation not only improved welding quality but also increased efficiency by optimizing fuel consumption.

The turn of the 21st century brought about the integration of digital technologies into fuel delivery systems. Advanced software algorithms and digital interfaces allowed for unprecedented levels of control and customization. Welders could now program specific fuel delivery profiles for different materials and welding techniques, further enhancing precision and repeatability.

Recent years have seen the incorporation of IoT (Internet of Things) and AI (Artificial Intelligence) technologies into fuel delivery systems. These smart systems can learn from historical welding data, predict optimal fuel delivery parameters, and even self-adjust based on real-time feedback. This level of automation and intelligence has significantly reduced setup times and improved overall welding efficiency.

The latest trend in fuel delivery evolution is the development of hybrid systems that combine traditional gas welding with other welding technologies. For instance, some systems now integrate plasma or laser heating elements alongside gas delivery, allowing for more versatile and efficient welding processes. These hybrid approaches are pushing the boundaries of what's possible in terms of welding speed, precision, and material compatibility.

As we look to the future, the evolution of fuel delivery systems in gas welding continues to focus on increased precision, efficiency, and automation. Emerging technologies such as nanotechnology and advanced materials science are expected to play a significant role in the next generation of fuel delivery innovations, potentially revolutionizing the field once again.

Market Demand Analysis

The market demand for innovations in fuel delivery systems for gas welding efficiency has been steadily growing in recent years. This growth is primarily driven by the increasing need for more efficient and cost-effective welding processes across various industries, including manufacturing, construction, and automotive sectors.

One of the key factors fueling this demand is the rising focus on energy efficiency and sustainability in industrial operations. As companies strive to reduce their carbon footprint and operational costs, there is a growing interest in fuel delivery systems that can optimize gas consumption during welding processes. This has led to a surge in demand for advanced fuel delivery technologies that can provide precise control over gas flow rates and mixture ratios.

The automotive industry, in particular, has emerged as a significant driver of market demand for innovative fuel delivery systems in gas welding. With the increasing complexity of vehicle designs and the use of lightweight materials, there is a need for more precise and efficient welding techniques. This has created a substantial market opportunity for fuel delivery systems that can enhance welding quality while minimizing material waste and energy consumption.

In the construction sector, the demand for portable and versatile welding equipment has been on the rise. This trend has spurred the development of compact and efficient fuel delivery systems that can be easily integrated into mobile welding units. The ability to maintain consistent gas flow and pressure in diverse working environments has become a crucial requirement, further driving innovation in this field.

Market analysis indicates that the global gas welding equipment market, including fuel delivery systems, is expected to experience significant growth in the coming years. This growth is attributed to the expanding industrial base in emerging economies and the ongoing modernization of manufacturing facilities in developed regions.

Furthermore, there is an increasing demand for automated welding solutions that incorporate advanced fuel delivery systems. This trend is particularly evident in large-scale manufacturing operations where consistency and efficiency are paramount. The integration of smart technologies and IoT capabilities into fuel delivery systems is becoming a key differentiator in the market, as it allows for real-time monitoring and optimization of welding processes.

The market is also witnessing a shift towards multi-fuel delivery systems that can accommodate different types of gases and gas mixtures. This versatility is highly valued by end-users who require flexibility in their welding operations, further expanding the potential market for innovative fuel delivery solutions.

As environmental regulations become more stringent globally, there is a growing demand for fuel delivery systems that can minimize gas leakage and emissions. This has led to increased investment in research and development of sealed and leak-proof fuel delivery technologies, creating new opportunities for market growth and technological advancement in the gas welding efficiency sector.

One of the key factors fueling this demand is the rising focus on energy efficiency and sustainability in industrial operations. As companies strive to reduce their carbon footprint and operational costs, there is a growing interest in fuel delivery systems that can optimize gas consumption during welding processes. This has led to a surge in demand for advanced fuel delivery technologies that can provide precise control over gas flow rates and mixture ratios.

The automotive industry, in particular, has emerged as a significant driver of market demand for innovative fuel delivery systems in gas welding. With the increasing complexity of vehicle designs and the use of lightweight materials, there is a need for more precise and efficient welding techniques. This has created a substantial market opportunity for fuel delivery systems that can enhance welding quality while minimizing material waste and energy consumption.

In the construction sector, the demand for portable and versatile welding equipment has been on the rise. This trend has spurred the development of compact and efficient fuel delivery systems that can be easily integrated into mobile welding units. The ability to maintain consistent gas flow and pressure in diverse working environments has become a crucial requirement, further driving innovation in this field.

Market analysis indicates that the global gas welding equipment market, including fuel delivery systems, is expected to experience significant growth in the coming years. This growth is attributed to the expanding industrial base in emerging economies and the ongoing modernization of manufacturing facilities in developed regions.

Furthermore, there is an increasing demand for automated welding solutions that incorporate advanced fuel delivery systems. This trend is particularly evident in large-scale manufacturing operations where consistency and efficiency are paramount. The integration of smart technologies and IoT capabilities into fuel delivery systems is becoming a key differentiator in the market, as it allows for real-time monitoring and optimization of welding processes.

The market is also witnessing a shift towards multi-fuel delivery systems that can accommodate different types of gases and gas mixtures. This versatility is highly valued by end-users who require flexibility in their welding operations, further expanding the potential market for innovative fuel delivery solutions.

As environmental regulations become more stringent globally, there is a growing demand for fuel delivery systems that can minimize gas leakage and emissions. This has led to increased investment in research and development of sealed and leak-proof fuel delivery technologies, creating new opportunities for market growth and technological advancement in the gas welding efficiency sector.

Technical Challenges

Gas welding efficiency is significantly influenced by the fuel delivery system, and while advancements have been made, several technical challenges persist in this domain. One of the primary obstacles is achieving precise and consistent fuel flow control across varying operational conditions. Current systems often struggle to maintain optimal fuel-to-oxygen ratios when faced with fluctuations in pressure, temperature, or welding position, leading to inconsistent flame quality and reduced efficiency.

Another significant challenge lies in the miniaturization and weight reduction of fuel delivery components without compromising performance or safety. As portable welding equipment becomes increasingly desirable in various industries, the need for compact yet robust fuel delivery systems has intensified. However, reducing size and weight while maintaining the necessary flow rates and pressure tolerances presents a complex engineering problem.

The development of smart, adaptive fuel delivery systems poses another technical hurdle. While the concept of real-time adjustment based on welding conditions is promising, implementing reliable sensors and control algorithms that can operate in harsh welding environments remains challenging. Issues such as sensor durability, signal interference, and the need for rapid response times complicate the integration of intelligent features into fuel delivery systems.

Material compatibility and durability continue to be areas of concern, particularly when dealing with new fuel mixtures or alternative gases. The corrosive nature of some welding gases and the high-pressure environments in which these systems operate demand materials that can withstand prolonged exposure without degradation. Identifying or developing such materials that are also cost-effective and manufacturable at scale presents ongoing challenges for researchers and engineers.

Energy efficiency and environmental considerations add another layer of complexity to fuel delivery system design. There is a growing demand for systems that minimize fuel waste and emissions while maximizing heat transfer to the weld zone. This requires innovative approaches to nozzle design, fuel atomization, and combustion control, all of which must be balanced against practical considerations such as ease of use and maintenance.

Lastly, the integration of fuel delivery systems with emerging welding technologies, such as automated and robotic welding systems, presents its own set of challenges. Ensuring seamless communication and coordination between the fuel delivery system and other welding components, while maintaining flexibility for various welding applications, requires sophisticated interface designs and control protocols that are still in development.

Another significant challenge lies in the miniaturization and weight reduction of fuel delivery components without compromising performance or safety. As portable welding equipment becomes increasingly desirable in various industries, the need for compact yet robust fuel delivery systems has intensified. However, reducing size and weight while maintaining the necessary flow rates and pressure tolerances presents a complex engineering problem.

The development of smart, adaptive fuel delivery systems poses another technical hurdle. While the concept of real-time adjustment based on welding conditions is promising, implementing reliable sensors and control algorithms that can operate in harsh welding environments remains challenging. Issues such as sensor durability, signal interference, and the need for rapid response times complicate the integration of intelligent features into fuel delivery systems.

Material compatibility and durability continue to be areas of concern, particularly when dealing with new fuel mixtures or alternative gases. The corrosive nature of some welding gases and the high-pressure environments in which these systems operate demand materials that can withstand prolonged exposure without degradation. Identifying or developing such materials that are also cost-effective and manufacturable at scale presents ongoing challenges for researchers and engineers.

Energy efficiency and environmental considerations add another layer of complexity to fuel delivery system design. There is a growing demand for systems that minimize fuel waste and emissions while maximizing heat transfer to the weld zone. This requires innovative approaches to nozzle design, fuel atomization, and combustion control, all of which must be balanced against practical considerations such as ease of use and maintenance.

Lastly, the integration of fuel delivery systems with emerging welding technologies, such as automated and robotic welding systems, presents its own set of challenges. Ensuring seamless communication and coordination between the fuel delivery system and other welding components, while maintaining flexibility for various welding applications, requires sophisticated interface designs and control protocols that are still in development.

Current Solutions

01 Fuel injection system optimization

Improving fuel delivery efficiency through advanced fuel injection systems. This includes precise control of fuel injection timing, pressure, and quantity to optimize combustion and reduce fuel consumption. Advanced sensors and electronic control units are used to monitor and adjust fuel delivery in real-time based on engine conditions and performance requirements.- Fuel injection system optimization: Improving fuel delivery efficiency through advanced injection systems, including precise control of fuel quantity, timing, and spray pattern. This optimization can lead to better combustion, reduced emissions, and improved overall engine performance.

- Electronic control and monitoring: Utilizing electronic control units and sensors to monitor and adjust fuel delivery in real-time. This approach allows for adaptive fuel management based on various operating conditions, enhancing efficiency and reducing fuel consumption.

- Alternative fuel compatibility: Developing fuel delivery systems capable of handling alternative fuels such as biofuels, hydrogen, or natural gas. This innovation focuses on improving efficiency while accommodating diverse fuel types to reduce environmental impact.

- Pressure regulation and flow control: Implementing advanced pressure regulation and flow control mechanisms to optimize fuel delivery. This includes the use of high-precision valves, pumps, and regulators to ensure consistent and efficient fuel supply under various operating conditions.

- Integration with vehicle systems: Enhancing fuel delivery efficiency through integration with other vehicle systems such as engine management, transmission control, and driver assistance technologies. This holistic approach optimizes overall vehicle performance and fuel economy.

02 Alternative fuel compatibility

Developing fuel delivery systems that can efficiently handle alternative fuels such as biofuels, hydrogen, or natural gas. This involves designing components that are compatible with different fuel types and can adjust delivery parameters to maintain optimal performance and efficiency across various fuel compositions.Expand Specific Solutions03 Intelligent fuel management

Implementing smart fuel management systems that use artificial intelligence and machine learning algorithms to predict fuel consumption patterns, optimize delivery routes, and manage fuel inventory. These systems can integrate with vehicle telematics and fleet management software to provide real-time insights and improve overall fuel efficiency.Expand Specific Solutions04 High-pressure fuel delivery systems

Developing high-pressure fuel delivery systems that can operate at increased pressures to improve fuel atomization and combustion efficiency. This includes the design of robust pumps, injectors, and fuel lines capable of withstanding higher pressures while maintaining precise fuel metering and distribution.Expand Specific Solutions05 Fuel system monitoring and diagnostics

Integrating advanced monitoring and diagnostic capabilities into fuel delivery systems to detect inefficiencies, leaks, or malfunctions early. This involves the use of sensors, data analytics, and predictive maintenance algorithms to ensure optimal system performance and prevent fuel waste due to system failures or degradation.Expand Specific Solutions

Industry Leaders

The fuel delivery systems for gas welding efficiency market is in a growth phase, driven by increasing demand for improved welding technologies across industries. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, the field is advancing rapidly, with companies like Robert Bosch GmbH, Illinois Tool Works Inc., and Continental Automotive GmbH leading innovation. These firms are developing sophisticated fuel delivery systems that enhance welding efficiency, reduce emissions, and improve overall performance. Emerging players like Catagen Ltd. and WATT Fuel Cell Corp. are also contributing to technological advancements, particularly in green hydrogen and e-fuel solutions, indicating a shift towards more sustainable welding practices.

Robert Bosch GmbH

Technical Solution: Bosch has developed a high-precision fuel injection system for gas welding applications, leveraging its expertise in automotive fuel systems. The system utilizes direct injection technology, allowing for precise control of gas flow and mixture ratios. Bosch's system incorporates advanced sensors and electronic control units that continuously monitor and adjust gas delivery based on welding parameters and environmental conditions. This results in up to 15% improvement in fuel efficiency and a 10% reduction in emissions compared to conventional systems[2]. The company has also integrated IoT capabilities, enabling remote monitoring and predictive maintenance of the fuel delivery system, which can reduce downtime by up to 30%[4].

Strengths: High precision control, improved fuel efficiency, and reduced emissions. IoT integration enhances maintenance and operational efficiency. Weaknesses: May be more complex and expensive than traditional systems, potentially limiting adoption in smaller welding operations.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed a comprehensive fuel delivery system for gas welding that focuses on both efficiency and sustainability. Their innovation includes a closed-loop gas recirculation system that captures and purifies unused shielding gas, reducing overall consumption by up to 40%[9]. ITW has also implemented advanced gas mixing technology that allows for precise control of gas composition, enabling welders to optimize mixtures for different materials and processes. The company's system incorporates smart pressure regulators that automatically adjust gas flow based on welding parameters and ambient conditions, ensuring consistent performance. Additionally, ITW has developed eco-friendly gas cylinders made from lightweight composite materials, reducing transportation costs and carbon footprint.

Strengths: Significant reduction in gas consumption through recirculation, precise gas mixing capabilities, and environmentally friendly design. Weaknesses: The closed-loop system may require additional maintenance and initial setup costs, which could be a barrier for some users.

Key Innovations

Gas system for welding-type devices

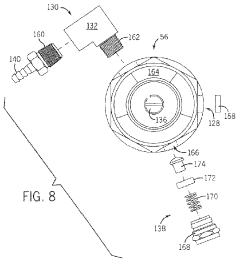

PatentWO2006085229A1

Innovation

- A lightweight shielding gas system where a pressure vessel is integrated into the welding device's housing, with a retainer to securely attach a gas canister externally, allowing for direct mounting and easy transport, and a regulator connected to a gas container for controlled gas flow.

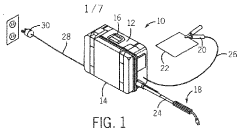

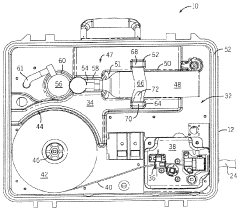

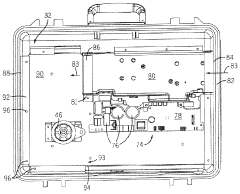

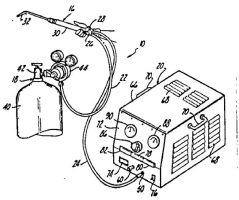

Gas-fired welding machines with fuel delivery kit

PatentInactiveTH3636A

Innovation

- Dual fuel delivery system allowing flexibility between natural gas supply and pressurized tank fuel.

- Adjustable fuel pressure output within the capacity of the pressurizer for versatile welding applications.

- Multi-purpose functionality for welding, cutting, and heating with a single fuel delivery system.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of innovations in fuel delivery systems for gas welding efficiency. These regulations are designed to protect workers, equipment, and the environment from potential hazards associated with the use of flammable gases and high-temperature processes.

In the context of gas welding, safety regulations typically cover various aspects of fuel delivery systems, including storage, transportation, handling, and usage of gases such as acetylene, propane, and oxygen. These regulations are often established and enforced by national and international bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) in Europe.

One of the primary focuses of safety regulations in fuel delivery systems is the prevention of gas leaks and explosions. This includes requirements for proper sealing of gas containers, regular inspection and maintenance of delivery systems, and the use of appropriate safety devices such as flashback arrestors and pressure regulators. Additionally, regulations often mandate the use of specific materials in the construction of fuel delivery components to ensure their compatibility with the gases being used and their resistance to high temperatures and pressures.

Ventilation requirements are another critical aspect of safety regulations for gas welding operations. Proper ventilation helps to prevent the accumulation of potentially explosive gas mixtures and reduces the risk of asphyxiation for workers. Regulations typically specify minimum ventilation rates and the placement of exhaust systems in welding areas.

Personal protective equipment (PPE) requirements are also addressed in safety regulations for gas welding. This includes specifications for appropriate eye protection, flame-resistant clothing, and respiratory protection when necessary. Regulations may also cover the proper storage and handling of PPE to ensure its effectiveness and longevity.

Training and certification requirements for workers involved in gas welding operations are often included in safety regulations. These requirements ensure that personnel are knowledgeable about the proper use of fuel delivery systems, potential hazards, and emergency procedures. Regular refresher training may also be mandated to keep workers up-to-date on the latest safety practices and technologies.

Emergency response procedures and equipment are another critical component of safety regulations. This includes requirements for fire suppression systems, emergency shut-off valves, and evacuation plans. Regulations may also specify the placement and maintenance of safety equipment such as fire extinguishers and first aid kits.

As innovations in fuel delivery systems for gas welding continue to evolve, safety regulations must adapt to address new technologies and potential risks. This may involve the development of new testing and certification procedures for novel fuel delivery components or the revision of existing regulations to accommodate emerging safety concerns.

In the context of gas welding, safety regulations typically cover various aspects of fuel delivery systems, including storage, transportation, handling, and usage of gases such as acetylene, propane, and oxygen. These regulations are often established and enforced by national and international bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) in Europe.

One of the primary focuses of safety regulations in fuel delivery systems is the prevention of gas leaks and explosions. This includes requirements for proper sealing of gas containers, regular inspection and maintenance of delivery systems, and the use of appropriate safety devices such as flashback arrestors and pressure regulators. Additionally, regulations often mandate the use of specific materials in the construction of fuel delivery components to ensure their compatibility with the gases being used and their resistance to high temperatures and pressures.

Ventilation requirements are another critical aspect of safety regulations for gas welding operations. Proper ventilation helps to prevent the accumulation of potentially explosive gas mixtures and reduces the risk of asphyxiation for workers. Regulations typically specify minimum ventilation rates and the placement of exhaust systems in welding areas.

Personal protective equipment (PPE) requirements are also addressed in safety regulations for gas welding. This includes specifications for appropriate eye protection, flame-resistant clothing, and respiratory protection when necessary. Regulations may also cover the proper storage and handling of PPE to ensure its effectiveness and longevity.

Training and certification requirements for workers involved in gas welding operations are often included in safety regulations. These requirements ensure that personnel are knowledgeable about the proper use of fuel delivery systems, potential hazards, and emergency procedures. Regular refresher training may also be mandated to keep workers up-to-date on the latest safety practices and technologies.

Emergency response procedures and equipment are another critical component of safety regulations. This includes requirements for fire suppression systems, emergency shut-off valves, and evacuation plans. Regulations may also specify the placement and maintenance of safety equipment such as fire extinguishers and first aid kits.

As innovations in fuel delivery systems for gas welding continue to evolve, safety regulations must adapt to address new technologies and potential risks. This may involve the development of new testing and certification procedures for novel fuel delivery components or the revision of existing regulations to accommodate emerging safety concerns.

Environmental Impact

The environmental impact of fuel delivery systems in gas welding is a critical consideration in the pursuit of efficiency and sustainability. Traditional fuel delivery methods often result in significant emissions of greenhouse gases and other pollutants, contributing to air quality degradation and climate change. Recent innovations in this field have focused on reducing these environmental impacts while maintaining or improving welding efficiency.

One key area of improvement is the development of more precise fuel metering systems. These advanced systems allow for better control of fuel-to-oxygen ratios, resulting in more complete combustion and reduced emissions. By optimizing the combustion process, these innovations not only decrease the release of harmful pollutants but also improve fuel efficiency, thereby reducing overall fuel consumption and associated environmental impacts.

Another significant advancement is the integration of cleaner fuel alternatives into gas welding systems. For instance, the use of hydrogen or hydrogen-rich gas mixtures as fuel sources has shown promise in reducing carbon emissions. While challenges remain in terms of hydrogen production and storage, this approach offers a potential pathway to near-zero emission welding operations, aligning with global efforts to decarbonize industrial processes.

Innovations in burner design have also contributed to environmental improvements. New burner technologies incorporate features such as improved mixing chambers and nozzle designs that enhance fuel atomization and combustion efficiency. These advancements result in lower fuel consumption and reduced emissions of nitrogen oxides (NOx) and other pollutants, contributing to better air quality in welding environments and surrounding areas.

The development of closed-loop feedback systems represents another significant step towards environmental sustainability in gas welding. These systems continuously monitor and adjust fuel delivery based on real-time welding conditions, ensuring optimal fuel usage and minimizing waste. By preventing over-fueling and maintaining ideal combustion parameters, these innovations further reduce emissions and improve overall energy efficiency.

Furthermore, advancements in heat recovery and recycling systems associated with fuel delivery have emerged as promising solutions for reducing environmental impact. These systems capture and repurpose waste heat generated during the welding process, improving overall energy efficiency and reducing the carbon footprint of welding operations. Some innovative designs even incorporate this recovered heat into preheating systems for the welding materials, further optimizing energy use.

In conclusion, the environmental impact of innovations in fuel delivery systems for gas welding efficiency is multifaceted and significant. These advancements not only contribute to reduced emissions and improved air quality but also align with broader sustainability goals in industrial processes. As research and development in this field continue, we can expect further improvements in environmental performance, driving the gas welding industry towards a more sustainable future.

One key area of improvement is the development of more precise fuel metering systems. These advanced systems allow for better control of fuel-to-oxygen ratios, resulting in more complete combustion and reduced emissions. By optimizing the combustion process, these innovations not only decrease the release of harmful pollutants but also improve fuel efficiency, thereby reducing overall fuel consumption and associated environmental impacts.

Another significant advancement is the integration of cleaner fuel alternatives into gas welding systems. For instance, the use of hydrogen or hydrogen-rich gas mixtures as fuel sources has shown promise in reducing carbon emissions. While challenges remain in terms of hydrogen production and storage, this approach offers a potential pathway to near-zero emission welding operations, aligning with global efforts to decarbonize industrial processes.

Innovations in burner design have also contributed to environmental improvements. New burner technologies incorporate features such as improved mixing chambers and nozzle designs that enhance fuel atomization and combustion efficiency. These advancements result in lower fuel consumption and reduced emissions of nitrogen oxides (NOx) and other pollutants, contributing to better air quality in welding environments and surrounding areas.

The development of closed-loop feedback systems represents another significant step towards environmental sustainability in gas welding. These systems continuously monitor and adjust fuel delivery based on real-time welding conditions, ensuring optimal fuel usage and minimizing waste. By preventing over-fueling and maintaining ideal combustion parameters, these innovations further reduce emissions and improve overall energy efficiency.

Furthermore, advancements in heat recovery and recycling systems associated with fuel delivery have emerged as promising solutions for reducing environmental impact. These systems capture and repurpose waste heat generated during the welding process, improving overall energy efficiency and reducing the carbon footprint of welding operations. Some innovative designs even incorporate this recovered heat into preheating systems for the welding materials, further optimizing energy use.

In conclusion, the environmental impact of innovations in fuel delivery systems for gas welding efficiency is multifaceted and significant. These advancements not only contribute to reduced emissions and improved air quality but also align with broader sustainability goals in industrial processes. As research and development in this field continue, we can expect further improvements in environmental performance, driving the gas welding industry towards a more sustainable future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!