Exploring Gas Welding in the Manufacture of Precision Instruments

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution

Gas welding has undergone significant evolution since its inception in the early 20th century, particularly in its application to the manufacture of precision instruments. The journey of gas welding in this field can be traced through several key developmental stages, each marked by technological advancements and innovative solutions.

In the 1920s and 1930s, gas welding was primarily used for joining larger metal components in industrial settings. However, as the demand for more precise and intricate instruments grew, engineers began to explore its potential for smaller-scale applications. The 1940s saw the first attempts to adapt gas welding techniques for use in precision instrument manufacturing, with a focus on improving flame control and reducing heat-affected zones.

The 1950s and 1960s marked a period of rapid advancement in gas welding technology for precision instruments. This era witnessed the development of specialized torches and nozzles designed specifically for delicate work. Innovations in gas mixture ratios and flow control allowed for finer temperature adjustments, crucial for working with sensitive materials often found in precision instruments.

By the 1970s, gas welding had become an established technique in the precision instrument industry. This decade saw the introduction of automated gas welding systems, which greatly enhanced repeatability and consistency in manufacturing processes. These systems incorporated early computer controls, allowing for more precise regulation of gas flow and welding parameters.

The 1980s and 1990s brought about further refinements in gas welding techniques for precision instruments. This period was characterized by the development of micro-welding techniques, enabling the joining of extremely small components with minimal heat input. Advances in metallurgy also led to the creation of specialized filler materials tailored for specific applications in precision instrument manufacturing.

Entering the 21st century, gas welding in precision instrument manufacturing has continued to evolve, albeit at a slower pace due to competition from newer technologies. Recent developments have focused on enhancing energy efficiency, improving workplace safety, and integrating gas welding processes with digital manufacturing systems. The advent of smart welding equipment, capable of real-time monitoring and adjustment, has further improved the precision and reliability of gas welding in this specialized field.

Throughout its evolution, gas welding has maintained its relevance in precision instrument manufacturing due to its unique advantages, such as its ability to join dissimilar metals and its cost-effectiveness for certain applications. While other welding technologies have emerged, gas welding continues to play a crucial role in specific niches within the precision instrument industry, adapting and evolving to meet the ever-increasing demands for accuracy and quality in modern manufacturing processes.

In the 1920s and 1930s, gas welding was primarily used for joining larger metal components in industrial settings. However, as the demand for more precise and intricate instruments grew, engineers began to explore its potential for smaller-scale applications. The 1940s saw the first attempts to adapt gas welding techniques for use in precision instrument manufacturing, with a focus on improving flame control and reducing heat-affected zones.

The 1950s and 1960s marked a period of rapid advancement in gas welding technology for precision instruments. This era witnessed the development of specialized torches and nozzles designed specifically for delicate work. Innovations in gas mixture ratios and flow control allowed for finer temperature adjustments, crucial for working with sensitive materials often found in precision instruments.

By the 1970s, gas welding had become an established technique in the precision instrument industry. This decade saw the introduction of automated gas welding systems, which greatly enhanced repeatability and consistency in manufacturing processes. These systems incorporated early computer controls, allowing for more precise regulation of gas flow and welding parameters.

The 1980s and 1990s brought about further refinements in gas welding techniques for precision instruments. This period was characterized by the development of micro-welding techniques, enabling the joining of extremely small components with minimal heat input. Advances in metallurgy also led to the creation of specialized filler materials tailored for specific applications in precision instrument manufacturing.

Entering the 21st century, gas welding in precision instrument manufacturing has continued to evolve, albeit at a slower pace due to competition from newer technologies. Recent developments have focused on enhancing energy efficiency, improving workplace safety, and integrating gas welding processes with digital manufacturing systems. The advent of smart welding equipment, capable of real-time monitoring and adjustment, has further improved the precision and reliability of gas welding in this specialized field.

Throughout its evolution, gas welding has maintained its relevance in precision instrument manufacturing due to its unique advantages, such as its ability to join dissimilar metals and its cost-effectiveness for certain applications. While other welding technologies have emerged, gas welding continues to play a crucial role in specific niches within the precision instrument industry, adapting and evolving to meet the ever-increasing demands for accuracy and quality in modern manufacturing processes.

Precision Instrument Market

The precision instrument market has experienced significant growth in recent years, driven by advancements in technology and increasing demand across various industries. This market encompasses a wide range of high-precision devices used in fields such as healthcare, aerospace, defense, and manufacturing. The global precision instrument market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong in the coming years.

One of the key factors contributing to market growth is the rising demand for miniaturization and improved accuracy in various applications. Industries such as electronics, automotive, and medical devices require increasingly precise components and measurements, driving the need for advanced precision instruments. Additionally, the growing adoption of automation and Industry 4.0 technologies has further fueled the demand for high-precision measurement and control devices.

In the context of gas welding in precision instrument manufacturing, there is a specific niche within the broader market. Gas welding techniques are particularly valuable in the production of delicate components and assemblies that require precise, controlled heat application. This method is often preferred for joining small, heat-sensitive parts in instruments such as medical devices, scientific equipment, and specialized sensors.

The market for precision instruments utilizing gas welding techniques is influenced by several trends. There is an increasing focus on developing instruments with higher accuracy and reliability, which necessitates advanced welding processes. Furthermore, the push for more environmentally friendly manufacturing methods has led to innovations in gas welding technologies that reduce emissions and improve energy efficiency.

Geographically, the precision instrument market is well-established in North America, Europe, and Asia-Pacific regions. These areas have strong industrial bases and significant investments in research and development. However, emerging economies in Asia and Latin America are showing rapid growth in this sector, driven by increasing industrialization and technological adoption.

The competitive landscape of the precision instrument market is characterized by a mix of large, established players and innovative start-ups. Major companies often have diverse product portfolios spanning multiple precision instrument categories, while smaller firms tend to specialize in niche applications or cutting-edge technologies. Collaboration between instrument manufacturers and end-users is becoming increasingly common, leading to more customized and application-specific solutions.

As the precision instrument market continues to evolve, there is a growing emphasis on integrating digital technologies. This includes the incorporation of IoT capabilities, data analytics, and cloud connectivity in precision instruments, enabling real-time monitoring, predictive maintenance, and enhanced performance optimization. These advancements are expected to open new opportunities and reshape the market landscape in the coming years.

One of the key factors contributing to market growth is the rising demand for miniaturization and improved accuracy in various applications. Industries such as electronics, automotive, and medical devices require increasingly precise components and measurements, driving the need for advanced precision instruments. Additionally, the growing adoption of automation and Industry 4.0 technologies has further fueled the demand for high-precision measurement and control devices.

In the context of gas welding in precision instrument manufacturing, there is a specific niche within the broader market. Gas welding techniques are particularly valuable in the production of delicate components and assemblies that require precise, controlled heat application. This method is often preferred for joining small, heat-sensitive parts in instruments such as medical devices, scientific equipment, and specialized sensors.

The market for precision instruments utilizing gas welding techniques is influenced by several trends. There is an increasing focus on developing instruments with higher accuracy and reliability, which necessitates advanced welding processes. Furthermore, the push for more environmentally friendly manufacturing methods has led to innovations in gas welding technologies that reduce emissions and improve energy efficiency.

Geographically, the precision instrument market is well-established in North America, Europe, and Asia-Pacific regions. These areas have strong industrial bases and significant investments in research and development. However, emerging economies in Asia and Latin America are showing rapid growth in this sector, driven by increasing industrialization and technological adoption.

The competitive landscape of the precision instrument market is characterized by a mix of large, established players and innovative start-ups. Major companies often have diverse product portfolios spanning multiple precision instrument categories, while smaller firms tend to specialize in niche applications or cutting-edge technologies. Collaboration between instrument manufacturers and end-users is becoming increasingly common, leading to more customized and application-specific solutions.

As the precision instrument market continues to evolve, there is a growing emphasis on integrating digital technologies. This includes the incorporation of IoT capabilities, data analytics, and cloud connectivity in precision instruments, enabling real-time monitoring, predictive maintenance, and enhanced performance optimization. These advancements are expected to open new opportunities and reshape the market landscape in the coming years.

Gas Welding Challenges

Gas welding in the manufacture of precision instruments presents several significant challenges that require careful consideration and innovative solutions. One of the primary difficulties lies in controlling the heat input during the welding process. Precision instruments often contain delicate components that can be easily damaged by excessive heat, making it crucial to maintain a precise balance between achieving proper fusion and avoiding thermal distortion.

The small scale of precision instrument components further complicates the welding process. Welders must possess exceptional dexterity and control to manipulate the welding torch and filler material accurately on miniature parts. This level of precision is particularly challenging when working with thin materials or intricate geometries commonly found in precision instruments.

Another major hurdle is the potential for contamination during gas welding. The high temperatures involved can cause oxidation or introduce impurities into the weld joint, compromising the integrity and functionality of the precision instrument. Ensuring a clean and controlled welding environment becomes paramount, often requiring specialized shielding techniques or inert gas atmospheres.

The selection of appropriate filler materials poses an additional challenge. Precision instruments frequently utilize exotic alloys or materials with specific properties, necessitating careful matching of filler metals to maintain the desired characteristics of the final product. This may involve extensive research and testing to identify compatible materials that meet both welding and performance requirements.

Distortion and residual stress management are critical concerns in gas welding of precision instruments. The localized heating and cooling cycles can induce warping or internal stresses, potentially affecting the instrument's accuracy and longevity. Implementing proper fixturing, heat sinking, and post-weld stress relief techniques becomes essential to mitigate these issues.

Quality control and inspection present unique challenges in this context. The small scale and intricate nature of precision instrument welds make visual inspection difficult, often requiring advanced non-destructive testing methods such as X-ray or ultrasonic inspection. Developing reliable and efficient quality assurance protocols is crucial to ensure the integrity of the welded components.

Lastly, the increasing demand for miniaturization and complexity in precision instruments continually pushes the boundaries of gas welding capabilities. Welders and engineers must constantly adapt to new materials, designs, and tolerances, necessitating ongoing research and development of specialized welding techniques and equipment tailored to the evolving needs of precision instrument manufacturing.

The small scale of precision instrument components further complicates the welding process. Welders must possess exceptional dexterity and control to manipulate the welding torch and filler material accurately on miniature parts. This level of precision is particularly challenging when working with thin materials or intricate geometries commonly found in precision instruments.

Another major hurdle is the potential for contamination during gas welding. The high temperatures involved can cause oxidation or introduce impurities into the weld joint, compromising the integrity and functionality of the precision instrument. Ensuring a clean and controlled welding environment becomes paramount, often requiring specialized shielding techniques or inert gas atmospheres.

The selection of appropriate filler materials poses an additional challenge. Precision instruments frequently utilize exotic alloys or materials with specific properties, necessitating careful matching of filler metals to maintain the desired characteristics of the final product. This may involve extensive research and testing to identify compatible materials that meet both welding and performance requirements.

Distortion and residual stress management are critical concerns in gas welding of precision instruments. The localized heating and cooling cycles can induce warping or internal stresses, potentially affecting the instrument's accuracy and longevity. Implementing proper fixturing, heat sinking, and post-weld stress relief techniques becomes essential to mitigate these issues.

Quality control and inspection present unique challenges in this context. The small scale and intricate nature of precision instrument welds make visual inspection difficult, often requiring advanced non-destructive testing methods such as X-ray or ultrasonic inspection. Developing reliable and efficient quality assurance protocols is crucial to ensure the integrity of the welded components.

Lastly, the increasing demand for miniaturization and complexity in precision instruments continually pushes the boundaries of gas welding capabilities. Welders and engineers must constantly adapt to new materials, designs, and tolerances, necessitating ongoing research and development of specialized welding techniques and equipment tailored to the evolving needs of precision instrument manufacturing.

Current Gas Welding Methods

01 Welding equipment and techniques

Gas welding involves specialized equipment and techniques for joining metals using heat generated by combustion of gases. This includes torches, regulators, and various gas mixtures to achieve optimal welding results for different materials and applications.- Welding torch design and improvements: Advancements in gas welding torch design focus on improving efficiency, safety, and ease of use. These improvements include ergonomic handles, adjustable flame controls, and enhanced gas mixing mechanisms. Modern welding torches may incorporate features for better heat distribution and reduced operator fatigue.

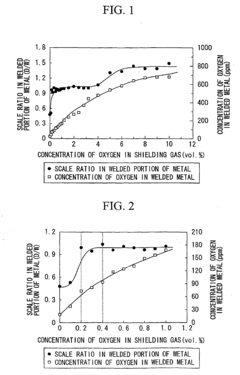

- Gas mixture optimization for welding: Research into optimal gas mixtures for various welding applications aims to enhance weld quality and efficiency. This includes developing precise ratios of fuel gases and oxygen, as well as exploring the use of shielding gases to improve weld characteristics and reduce defects.

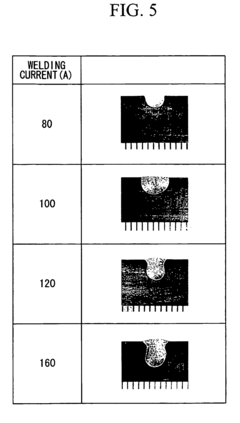

- Automated and robotic gas welding systems: Integration of automation and robotics in gas welding processes improves precision, consistency, and productivity. These systems may include computer-controlled welding parameters, automated torch positioning, and real-time monitoring of weld quality.

- Safety features and protective equipment: Development of advanced safety features and personal protective equipment for gas welding operations. This includes improved flame arrestors, gas leak detection systems, and specialized welding helmets with enhanced visibility and protection against harmful radiation.

- Portable and compact gas welding solutions: Innovations in portable gas welding equipment focus on creating compact, lightweight systems for field use and small-scale applications. These solutions may include integrated gas storage, quick-connect fittings, and multi-functional tools to enhance mobility and versatility.

02 Safety measures in gas welding

Safety is crucial in gas welding operations. This includes proper handling of gas cylinders, use of personal protective equipment, and implementation of safety protocols to prevent accidents and ensure worker protection during welding processes.Expand Specific Solutions03 Automation and robotics in gas welding

Advancements in automation and robotics have been applied to gas welding processes. This includes the development of automated welding systems, robotic welders, and computer-controlled welding equipment to improve precision, efficiency, and consistency in welding operations.Expand Specific Solutions04 Gas mixture optimization

Research into optimal gas mixtures for different welding applications has led to improvements in weld quality and efficiency. This includes the development of specialized gas blends for specific materials and welding conditions to enhance weld strength and appearance.Expand Specific Solutions05 Innovations in welding torch design

Advancements in welding torch design have improved gas welding performance and user experience. This includes ergonomic designs, improved gas flow control, and integration of advanced materials to enhance torch durability and efficiency.Expand Specific Solutions

Key Industry Players

The gas welding market for precision instruments is in a mature stage, with a stable global market size estimated in the billions of dollars. The technology is well-established, with key players like Illinois Tool Works Inc. and Fronius International GmbH leading innovation. These companies, along with others such as BOC Ltd. and Messer SE & Co. KGaA, have developed advanced welding techniques and equipment specifically tailored for precision manufacturing. The competitive landscape is characterized by a focus on improving efficiency, reducing environmental impact, and enhancing weld quality for increasingly complex precision instruments. As the industry evolves, there's a growing emphasis on automation and integration with Industry 4.0 technologies.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding technologies for precision instrument manufacturing. Their approach involves using micro-flame torches with precise gas mixture control, allowing for highly accurate and controlled welding of small components. ITW's system incorporates real-time monitoring of gas flow and temperature, ensuring consistent weld quality. They have also implemented automated gas welding processes for repetitive tasks in instrument assembly, improving efficiency and reducing human error [1][3]. ITW's gas welding solutions include specialized fixtures and positioning systems designed to hold delicate instrument parts securely during the welding process.

Strengths: Precise control over welding parameters, suitable for delicate components. Automated processes improve consistency. Weaknesses: May be less versatile than some newer welding technologies for certain applications.

Fronius International GmbH

Technical Solution: Fronius has developed a hybrid gas welding system specifically for precision instrument manufacturing. Their technology combines traditional gas welding with advanced electronic controls and sensors. The system uses a computer-controlled gas mixing unit to achieve optimal flame characteristics for different materials and thicknesses. Fronius' approach includes a vision system that guides the welding torch along complex paths with high accuracy, essential for intricate instrument components. They have also integrated thermal imaging to monitor weld quality in real-time, allowing for immediate adjustments to prevent defects [2][5]. The system is designed to be flexible, accommodating a wide range of precision instruments from medical devices to scientific equipment.

Strengths: High precision and flexibility, real-time quality monitoring, suitable for a wide range of precision instruments. Weaknesses: Higher initial investment compared to traditional gas welding setups, may require specialized training for operators.

Innovative Welding Patents

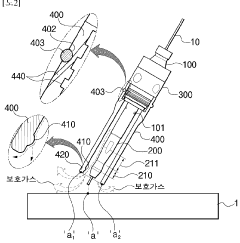

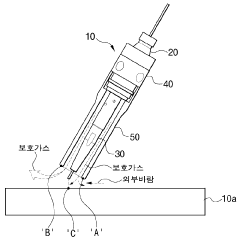

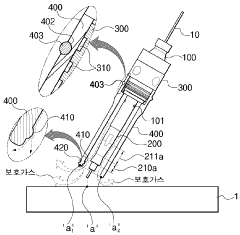

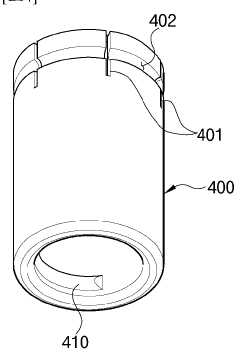

Torch head for gas welding

PatentWO2023128175A1

Innovation

- The torch head incorporates a gas spreading guide on the welding tip and a protective gas concentration guide on the nozzle, directing shielding gas flow towards the welding area and increasing its velocity vector, even when the nozzle is inclined, to effectively block external air and reduce gas consumption.

Welding method using a shielding gas comprising bewtween 0.2 % and 10 % of an oxidative gas, the rest being helium

PatentInactiveEP1752249B1

Innovation

- A welding method using a shielding gas comprising 0.2% or more by volume of an oxidative gas, such as oxygen, mixed with helium, which suppresses the dragging force in the molten pool and enhances inward convection, allowing for deeper penetration and a higher D/W ratio, thereby improving weld quality and reducing the number of passes required.

Quality Control Measures

Quality control measures are paramount in gas welding processes for precision instrument manufacturing. The implementation of stringent quality control protocols ensures the production of high-quality, reliable, and consistent welded components. These measures typically encompass various aspects of the welding process, from material selection to final inspection.

One crucial quality control measure is the careful selection and testing of welding gases and materials. Precision instruments require high-purity gases to minimize contamination and ensure optimal weld quality. Regular gas composition analysis and purity checks are essential to maintain consistent welding performance. Similarly, the quality of filler materials and base metals must be rigorously controlled to meet the exacting standards of precision instrument manufacturing.

Welding equipment calibration and maintenance form another critical aspect of quality control. Regular calibration of gas flow meters, pressure regulators, and welding torches ensures accurate gas mixtures and consistent heat input. Preventive maintenance schedules help identify and address potential equipment issues before they impact weld quality.

Process parameter control is vital for maintaining weld consistency. This includes monitoring and adjusting factors such as gas flow rates, torch angle, travel speed, and flame characteristics. Advanced welding systems may incorporate automated parameter control and data logging to ensure repeatability and traceability of welding operations.

Operator training and certification play a significant role in quality control. Welders working on precision instruments must possess specialized skills and knowledge. Ongoing training programs and regular skill assessments help maintain a high level of expertise among welding personnel.

In-process inspection techniques are employed to detect and correct welding defects in real-time. These may include visual inspection, penetrant testing, or advanced methods like radiographic or ultrasonic testing for critical components. Implementing statistical process control (SPC) techniques allows for continuous monitoring of weld quality trends and early detection of process deviations.

Post-weld inspection and testing are crucial final steps in the quality control process. This may involve dimensional checks, leak testing, strength testing, and microscopic examination of weld structures. Non-destructive testing methods are often preferred to ensure the integrity of precision components without compromising their functionality.

Documentation and traceability are essential components of a robust quality control system. Detailed records of welding parameters, material certifications, inspection results, and any corrective actions taken must be maintained. This documentation not only aids in quality assurance but also supports continuous improvement efforts and regulatory compliance.

One crucial quality control measure is the careful selection and testing of welding gases and materials. Precision instruments require high-purity gases to minimize contamination and ensure optimal weld quality. Regular gas composition analysis and purity checks are essential to maintain consistent welding performance. Similarly, the quality of filler materials and base metals must be rigorously controlled to meet the exacting standards of precision instrument manufacturing.

Welding equipment calibration and maintenance form another critical aspect of quality control. Regular calibration of gas flow meters, pressure regulators, and welding torches ensures accurate gas mixtures and consistent heat input. Preventive maintenance schedules help identify and address potential equipment issues before they impact weld quality.

Process parameter control is vital for maintaining weld consistency. This includes monitoring and adjusting factors such as gas flow rates, torch angle, travel speed, and flame characteristics. Advanced welding systems may incorporate automated parameter control and data logging to ensure repeatability and traceability of welding operations.

Operator training and certification play a significant role in quality control. Welders working on precision instruments must possess specialized skills and knowledge. Ongoing training programs and regular skill assessments help maintain a high level of expertise among welding personnel.

In-process inspection techniques are employed to detect and correct welding defects in real-time. These may include visual inspection, penetrant testing, or advanced methods like radiographic or ultrasonic testing for critical components. Implementing statistical process control (SPC) techniques allows for continuous monitoring of weld quality trends and early detection of process deviations.

Post-weld inspection and testing are crucial final steps in the quality control process. This may involve dimensional checks, leak testing, strength testing, and microscopic examination of weld structures. Non-destructive testing methods are often preferred to ensure the integrity of precision components without compromising their functionality.

Documentation and traceability are essential components of a robust quality control system. Detailed records of welding parameters, material certifications, inspection results, and any corrective actions taken must be maintained. This documentation not only aids in quality assurance but also supports continuous improvement efforts and regulatory compliance.

Environmental Impact

Gas welding in the manufacture of precision instruments, while offering certain advantages, raises significant environmental concerns that warrant careful consideration. The process inherently involves the combustion of gases, primarily acetylene and oxygen, which leads to the emission of greenhouse gases, particularly carbon dioxide. These emissions contribute to global warming and climate change, aligning with broader industrial environmental impacts. Additionally, the welding process can release various pollutants, including nitrogen oxides and particulate matter, which can have detrimental effects on local air quality.

The environmental impact extends beyond air pollution. The production and transportation of welding gases require energy-intensive processes, further increasing the carbon footprint associated with this manufacturing technique. Moreover, the disposal of welding consumables and waste materials, such as used gas cylinders and welding rods, presents challenges in terms of waste management and potential soil contamination if not handled properly.

Water resources may also be affected by gas welding operations. Cooling systems used in some welding setups can consume significant amounts of water, and there is a risk of contaminating water sources with metal particles and other pollutants if proper filtration and treatment systems are not in place. This aspect is particularly crucial in regions facing water scarcity or with sensitive aquatic ecosystems.

The use of gas welding in precision instrument manufacturing also raises concerns about resource depletion. The gases used in the process, particularly rare or non-renewable resources, contribute to the overall environmental impact through their extraction and processing. Furthermore, the energy consumption associated with gas welding can be substantial, especially in large-scale manufacturing operations, leading to increased demand for electricity or fossil fuels.

However, it's important to note that the environmental impact of gas welding can be mitigated through various strategies. Implementing more efficient welding techniques, optimizing gas usage, and adopting cleaner energy sources for power supply can significantly reduce the carbon footprint. Additionally, investing in advanced filtration systems and proper waste management practices can minimize air and water pollution. The development of recycling programs for welding consumables and the adoption of circular economy principles in manufacturing processes can further alleviate the environmental burden.

As environmental regulations become more stringent globally, manufacturers using gas welding techniques in precision instrument production must proactively address these environmental concerns. This may involve exploring alternative welding methods with lower environmental impacts, such as laser welding or electron beam welding, where applicable. Ultimately, balancing the technical requirements of precision instrument manufacturing with environmental sustainability will be crucial for the long-term viability of gas welding in this industry.

The environmental impact extends beyond air pollution. The production and transportation of welding gases require energy-intensive processes, further increasing the carbon footprint associated with this manufacturing technique. Moreover, the disposal of welding consumables and waste materials, such as used gas cylinders and welding rods, presents challenges in terms of waste management and potential soil contamination if not handled properly.

Water resources may also be affected by gas welding operations. Cooling systems used in some welding setups can consume significant amounts of water, and there is a risk of contaminating water sources with metal particles and other pollutants if proper filtration and treatment systems are not in place. This aspect is particularly crucial in regions facing water scarcity or with sensitive aquatic ecosystems.

The use of gas welding in precision instrument manufacturing also raises concerns about resource depletion. The gases used in the process, particularly rare or non-renewable resources, contribute to the overall environmental impact through their extraction and processing. Furthermore, the energy consumption associated with gas welding can be substantial, especially in large-scale manufacturing operations, leading to increased demand for electricity or fossil fuels.

However, it's important to note that the environmental impact of gas welding can be mitigated through various strategies. Implementing more efficient welding techniques, optimizing gas usage, and adopting cleaner energy sources for power supply can significantly reduce the carbon footprint. Additionally, investing in advanced filtration systems and proper waste management practices can minimize air and water pollution. The development of recycling programs for welding consumables and the adoption of circular economy principles in manufacturing processes can further alleviate the environmental burden.

As environmental regulations become more stringent globally, manufacturers using gas welding techniques in precision instrument production must proactively address these environmental concerns. This may involve exploring alternative welding methods with lower environmental impacts, such as laser welding or electron beam welding, where applicable. Ultimately, balancing the technical requirements of precision instrument manufacturing with environmental sustainability will be crucial for the long-term viability of gas welding in this industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!