Understanding the Mechanics of Gas Welding Pulse Methods

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Pulse Evolution

Gas welding pulse methods have undergone significant evolution since their inception, marking key milestones in the advancement of welding technology. The journey began in the early 20th century with the introduction of basic gas welding techniques, which laid the foundation for more sophisticated approaches.

In the 1950s, the concept of pulsed gas welding emerged as a revolutionary technique. This method introduced controlled intervals of high and low heat input, allowing for better control over the weld pool and reduced heat-affected zones. The initial pulse systems were mechanical, relying on manual adjustments to regulate gas flow and achieve the desired pulsing effect.

The 1970s saw a leap forward with the integration of electronic controls into gas welding systems. This advancement enabled more precise and repeatable pulsing patterns, significantly improving weld quality and consistency. The electronic systems allowed for finer control over pulse frequency, duration, and amplitude, opening new possibilities for welding thin materials and heat-sensitive components.

The 1980s and 1990s marked the era of computerization in welding technology. Microprocessor-controlled gas welding systems emerged, offering programmable pulse sequences and adaptive control algorithms. These systems could automatically adjust pulse parameters based on real-time feedback from the welding process, ensuring optimal weld characteristics across varying conditions.

As we entered the 21st century, the focus shifted towards integrating gas welding pulse methods with advanced sensing and monitoring technologies. The introduction of high-speed cameras and spectral analysis tools allowed for real-time observation and control of the weld pool dynamics. This led to the development of intelligent pulse welding systems capable of self-adjusting to maintain consistent weld quality.

Recent years have seen the incorporation of artificial intelligence and machine learning algorithms into gas welding pulse systems. These advanced systems can analyze vast amounts of welding data to optimize pulse parameters for specific materials and joint configurations. The result is a new generation of adaptive pulse welding technologies that can learn from experience and continuously improve their performance.

The latest frontier in gas welding pulse evolution is the integration with Industry 4.0 concepts. Internet of Things (IoT) enabled welding systems now allow for remote monitoring, data collection, and analysis on a global scale. This connectivity facilitates predictive maintenance, quality assurance, and continuous process improvement across entire manufacturing operations.

In the 1950s, the concept of pulsed gas welding emerged as a revolutionary technique. This method introduced controlled intervals of high and low heat input, allowing for better control over the weld pool and reduced heat-affected zones. The initial pulse systems were mechanical, relying on manual adjustments to regulate gas flow and achieve the desired pulsing effect.

The 1970s saw a leap forward with the integration of electronic controls into gas welding systems. This advancement enabled more precise and repeatable pulsing patterns, significantly improving weld quality and consistency. The electronic systems allowed for finer control over pulse frequency, duration, and amplitude, opening new possibilities for welding thin materials and heat-sensitive components.

The 1980s and 1990s marked the era of computerization in welding technology. Microprocessor-controlled gas welding systems emerged, offering programmable pulse sequences and adaptive control algorithms. These systems could automatically adjust pulse parameters based on real-time feedback from the welding process, ensuring optimal weld characteristics across varying conditions.

As we entered the 21st century, the focus shifted towards integrating gas welding pulse methods with advanced sensing and monitoring technologies. The introduction of high-speed cameras and spectral analysis tools allowed for real-time observation and control of the weld pool dynamics. This led to the development of intelligent pulse welding systems capable of self-adjusting to maintain consistent weld quality.

Recent years have seen the incorporation of artificial intelligence and machine learning algorithms into gas welding pulse systems. These advanced systems can analyze vast amounts of welding data to optimize pulse parameters for specific materials and joint configurations. The result is a new generation of adaptive pulse welding technologies that can learn from experience and continuously improve their performance.

The latest frontier in gas welding pulse evolution is the integration with Industry 4.0 concepts. Internet of Things (IoT) enabled welding systems now allow for remote monitoring, data collection, and analysis on a global scale. This connectivity facilitates predictive maintenance, quality assurance, and continuous process improvement across entire manufacturing operations.

Market Demand Analysis

The market demand for gas welding pulse methods has been steadily growing in recent years, driven by the increasing need for precision welding in various industries. This technology offers significant advantages over traditional welding techniques, particularly in terms of heat control and weld quality, making it highly sought after in sectors such as aerospace, automotive, and advanced manufacturing.

In the aerospace industry, the demand for gas welding pulse methods is particularly strong. The need for lightweight yet durable materials in aircraft construction necessitates precise welding techniques that can join thin metals without compromising structural integrity. The ability of pulsed gas welding to minimize heat input and reduce distortion makes it an ideal choice for this sector, leading to increased adoption and market growth.

The automotive industry is another major driver of market demand for gas welding pulse methods. As vehicle designs become more complex and incorporate a wider range of materials, including advanced high-strength steels and aluminum alloys, the need for sophisticated welding techniques has intensified. Pulsed gas welding offers the precision and control required to join these materials effectively, contributing to improved vehicle safety and performance.

In the field of advanced manufacturing, the trend towards miniaturization and the production of intricate components has fueled the demand for gas welding pulse methods. Industries such as electronics and medical device manufacturing require welding techniques that can produce high-quality joints on small-scale components. The ability of pulsed gas welding to deliver controlled heat input and minimize thermal distortion makes it well-suited for these applications.

The market for gas welding pulse methods is also benefiting from the growing emphasis on energy efficiency and sustainability in manufacturing processes. Compared to traditional welding techniques, pulsed gas welding often requires less energy and produces less waste, aligning with the increasing focus on environmentally friendly production methods.

Furthermore, the ongoing trend of automation and robotics in manufacturing is expected to drive further growth in the market for gas welding pulse methods. The precise control offered by this technology makes it highly compatible with automated welding systems, allowing for increased productivity and consistency in welding operations.

As industries continue to push the boundaries of material science and product design, the demand for advanced welding techniques like gas welding pulse methods is projected to grow. The technology's ability to address the challenges of joining new materials and creating complex structures positions it as a key enabler for innovation across multiple sectors, ensuring sustained market demand in the foreseeable future.

In the aerospace industry, the demand for gas welding pulse methods is particularly strong. The need for lightweight yet durable materials in aircraft construction necessitates precise welding techniques that can join thin metals without compromising structural integrity. The ability of pulsed gas welding to minimize heat input and reduce distortion makes it an ideal choice for this sector, leading to increased adoption and market growth.

The automotive industry is another major driver of market demand for gas welding pulse methods. As vehicle designs become more complex and incorporate a wider range of materials, including advanced high-strength steels and aluminum alloys, the need for sophisticated welding techniques has intensified. Pulsed gas welding offers the precision and control required to join these materials effectively, contributing to improved vehicle safety and performance.

In the field of advanced manufacturing, the trend towards miniaturization and the production of intricate components has fueled the demand for gas welding pulse methods. Industries such as electronics and medical device manufacturing require welding techniques that can produce high-quality joints on small-scale components. The ability of pulsed gas welding to deliver controlled heat input and minimize thermal distortion makes it well-suited for these applications.

The market for gas welding pulse methods is also benefiting from the growing emphasis on energy efficiency and sustainability in manufacturing processes. Compared to traditional welding techniques, pulsed gas welding often requires less energy and produces less waste, aligning with the increasing focus on environmentally friendly production methods.

Furthermore, the ongoing trend of automation and robotics in manufacturing is expected to drive further growth in the market for gas welding pulse methods. The precise control offered by this technology makes it highly compatible with automated welding systems, allowing for increased productivity and consistency in welding operations.

As industries continue to push the boundaries of material science and product design, the demand for advanced welding techniques like gas welding pulse methods is projected to grow. The technology's ability to address the challenges of joining new materials and creating complex structures positions it as a key enabler for innovation across multiple sectors, ensuring sustained market demand in the foreseeable future.

Current Challenges

Gas welding pulse methods, while offering significant advantages in precision and control, face several challenges in their current implementation and widespread adoption. One of the primary obstacles is the complexity of the pulsing mechanism itself. The intricate interplay between gas flow, pressure regulation, and timing requires sophisticated control systems, which can be costly to implement and maintain. This complexity often leads to a steep learning curve for operators, potentially limiting the technique's accessibility in smaller workshops or less technologically advanced settings.

Another significant challenge lies in the standardization of pulsing parameters across different welding applications. The optimal pulse frequency, duration, and intensity can vary greatly depending on the materials being welded, the joint configuration, and the desired weld characteristics. This variability makes it difficult to establish universal guidelines or presets, necessitating extensive experimentation and fine-tuning for each specific application. The lack of standardization can result in inconsistent weld quality and productivity across different operators or facilities.

The energy efficiency of gas welding pulse methods also presents a current challenge. While pulsing can reduce overall heat input and minimize distortion in some cases, the rapid cycling of gas flow and pressure can lead to increased gas consumption compared to traditional continuous flow methods. This not only impacts the cost-effectiveness of the process but also raises environmental concerns in an era of increasing focus on sustainable manufacturing practices.

Compatibility with existing welding equipment is another hurdle in the widespread adoption of gas welding pulse methods. Many welding setups are designed for continuous gas flow, and retrofitting them with pulsing capabilities can be expensive and technically challenging. This compatibility issue often forces businesses to choose between significant capital investment in new equipment or foregoing the benefits of pulsing technology.

The real-time monitoring and control of the pulsing process pose additional challenges. While advanced sensors and control systems exist, integrating them seamlessly into the welding process without interrupting workflow or compromising weld quality remains a complex task. The need for precise synchronization between the pulsing mechanism and the welder's movements adds another layer of complexity to the process control challenge.

Lastly, the metallurgical effects of gas welding pulse methods are not yet fully understood across all material combinations and welding scenarios. While the technique has shown promise in reducing heat-affected zones and improving weld microstructure in certain applications, comprehensive research is still needed to map out its effects across a broader range of materials and welding conditions. This knowledge gap can lead to hesitation in adopting the technology for critical applications where weld integrity is paramount.

Another significant challenge lies in the standardization of pulsing parameters across different welding applications. The optimal pulse frequency, duration, and intensity can vary greatly depending on the materials being welded, the joint configuration, and the desired weld characteristics. This variability makes it difficult to establish universal guidelines or presets, necessitating extensive experimentation and fine-tuning for each specific application. The lack of standardization can result in inconsistent weld quality and productivity across different operators or facilities.

The energy efficiency of gas welding pulse methods also presents a current challenge. While pulsing can reduce overall heat input and minimize distortion in some cases, the rapid cycling of gas flow and pressure can lead to increased gas consumption compared to traditional continuous flow methods. This not only impacts the cost-effectiveness of the process but also raises environmental concerns in an era of increasing focus on sustainable manufacturing practices.

Compatibility with existing welding equipment is another hurdle in the widespread adoption of gas welding pulse methods. Many welding setups are designed for continuous gas flow, and retrofitting them with pulsing capabilities can be expensive and technically challenging. This compatibility issue often forces businesses to choose between significant capital investment in new equipment or foregoing the benefits of pulsing technology.

The real-time monitoring and control of the pulsing process pose additional challenges. While advanced sensors and control systems exist, integrating them seamlessly into the welding process without interrupting workflow or compromising weld quality remains a complex task. The need for precise synchronization between the pulsing mechanism and the welder's movements adds another layer of complexity to the process control challenge.

Lastly, the metallurgical effects of gas welding pulse methods are not yet fully understood across all material combinations and welding scenarios. While the technique has shown promise in reducing heat-affected zones and improving weld microstructure in certain applications, comprehensive research is still needed to map out its effects across a broader range of materials and welding conditions. This knowledge gap can lead to hesitation in adopting the technology for critical applications where weld integrity is paramount.

Pulse Welding Techniques

01 Pulse control mechanisms in gas welding

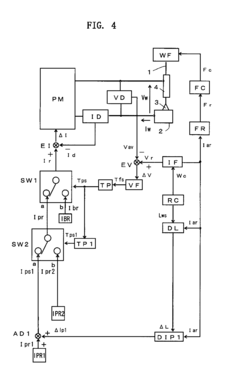

Advanced control systems are employed to regulate gas flow and pressure in welding processes. These mechanisms use pulsed delivery of gases to optimize welding performance, improve arc stability, and enhance weld quality. The pulsed gas flow can be synchronized with other welding parameters to achieve precise control over the welding process.- Pulse control mechanisms in gas welding: Advanced control systems are employed to regulate gas flow and pressure in welding processes. These mechanisms use pulsed gas delivery to optimize welding performance, improve arc stability, and enhance weld quality. The pulsed gas flow can be synchronized with other welding parameters to achieve precise control over the welding process.

- Mechanical design of gas welding equipment: Innovative mechanical designs are implemented in gas welding equipment to improve efficiency and ease of use. These designs may include ergonomic handles, adjustable nozzles, and modular components that allow for quick setup and maintenance. The mechanical aspects of the equipment are engineered to withstand high temperatures and pressures associated with gas welding.

- Integration of sensors and feedback systems: Modern gas welding systems incorporate various sensors and feedback mechanisms to monitor and adjust welding parameters in real-time. These systems can detect changes in gas flow, temperature, and arc characteristics, allowing for automatic adjustments to maintain optimal welding conditions. The integration of sensors enhances the precision and consistency of the welding process.

- Pulsed power supply for gas welding: Pulsed power supply techniques are applied to gas welding to control heat input and improve weld quality. By delivering power in controlled pulses, welders can achieve better penetration, reduced heat-affected zones, and improved control over the weld pool. This method is particularly useful for welding thin materials or heat-sensitive components.

- Gas mixture optimization for pulsed welding: Research focuses on optimizing gas mixtures for pulsed gas welding applications. By carefully selecting and controlling the composition of shielding gases, welders can enhance arc stability, reduce spatter, and improve overall weld quality. The pulsed delivery of these optimized gas mixtures can be synchronized with other welding parameters for superior results.

02 Mechanical design of gas welding equipment

Innovative mechanical designs are implemented in gas welding equipment to improve efficiency and ergonomics. These designs may include adjustable nozzles, lightweight materials, and modular components. The mechanical aspects focus on enhancing maneuverability, reducing operator fatigue, and increasing overall welding productivity.Expand Specific Solutions03 Integration of sensors and feedback systems

Modern gas welding systems incorporate various sensors and feedback mechanisms to monitor and adjust welding parameters in real-time. These systems can detect changes in gas pressure, flow rate, and temperature, allowing for automatic adjustments to maintain optimal welding conditions. The integration of sensors enhances the precision and consistency of the welding process.Expand Specific Solutions04 Pulsed arc techniques in gas welding

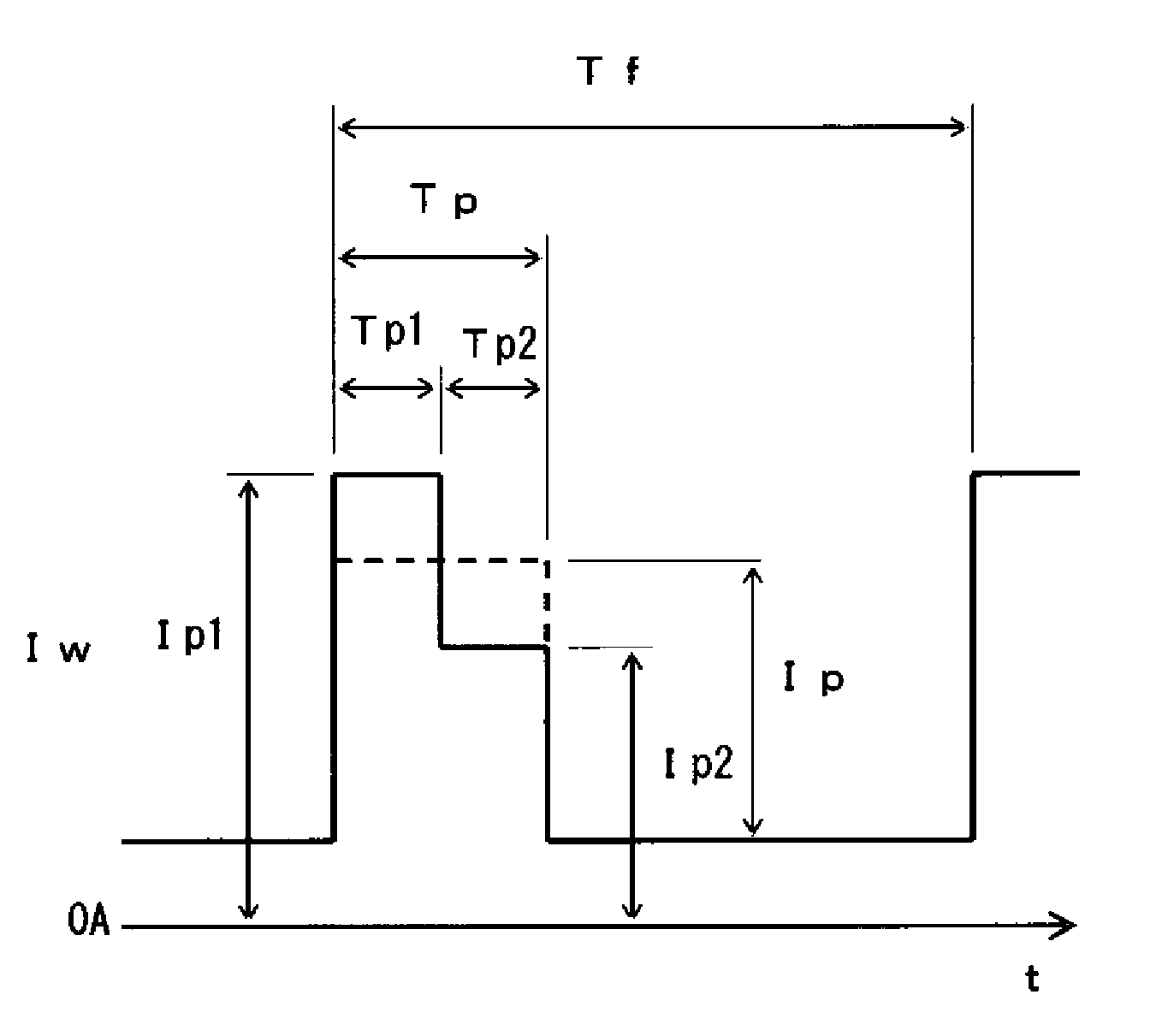

Pulsed arc techniques are applied in gas welding to control heat input and improve weld quality. By alternating between high and low current levels, these methods allow for better control of the weld pool, reduced heat-affected zone, and improved penetration. Pulsed arc welding can be particularly beneficial for welding thin materials or heat-sensitive components.Expand Specific Solutions05 Gas mixture optimization for welding performance

Research focuses on optimizing gas mixtures to enhance welding performance and efficiency. By carefully selecting and combining different gases, welders can achieve improved arc stability, reduced spatter, and better weld quality. The composition of gas mixtures can be tailored to specific materials and welding applications, allowing for customized welding solutions.Expand Specific Solutions

Key Industry Players

The gas welding pulse method market is in a growth phase, driven by increasing demand for precision welding in industries like automotive and aerospace. The global market size is estimated to be over $1 billion, with steady annual growth. Technologically, the field is advancing rapidly, with key players like Illinois Tool Works, Lincoln Global, and ESAB Group leading innovation. These companies are developing sophisticated pulse control systems, improving energy efficiency, and integrating automation features. Emerging players such as Panasonic Welding Systems and Shanghai WTL are also making significant contributions, particularly in Asian markets. The technology's maturity varies across applications, with high-end industrial sectors seeing more advanced implementations.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding pulse methods that utilize precise control of gas flow and pressure to create optimal welding conditions. Their system employs a high-frequency pulsing mechanism that alternates between high and low gas flow rates, allowing for better penetration and reduced heat input[1]. This pulsed gas flow technique is particularly effective in thin material welding, where heat control is crucial. ITW's technology also incorporates adaptive pulse shaping, which adjusts the pulse parameters in real-time based on feedback from sensors monitoring the weld pool dynamics[3]. This results in improved weld quality and consistency across various materials and thicknesses.

Strengths: Precise heat control, improved weld quality on thin materials, adaptive capabilities. Weaknesses: May require more complex equipment, potential for higher initial costs.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has pioneered a gas welding pulse method that integrates advanced digital controls with their proprietary gas delivery system. Their technology utilizes a microprocessor-controlled gas valve that can rapidly modulate gas flow rates up to 1000 times per second[2]. This high-frequency pulsing allows for extremely fine control over the welding arc characteristics. Lincoln's system also incorporates a synergic pulsing mode, which automatically adjusts pulse parameters based on the material type and thickness, simplifying operation for welders[4]. Additionally, they have developed a unique "wave pulse" feature that combines different pulse shapes within a single welding cycle, enabling enhanced control over heat input and weld pool behavior[5].

Strengths: High-frequency pulsing for precise control, user-friendly synergic modes, versatile wave pulse technology. Weaknesses: May require specialized training for operators to fully utilize advanced features.

Core Pulse Innovations

Pulse arc welding method

PatentActiveUS8203100B2

Innovation

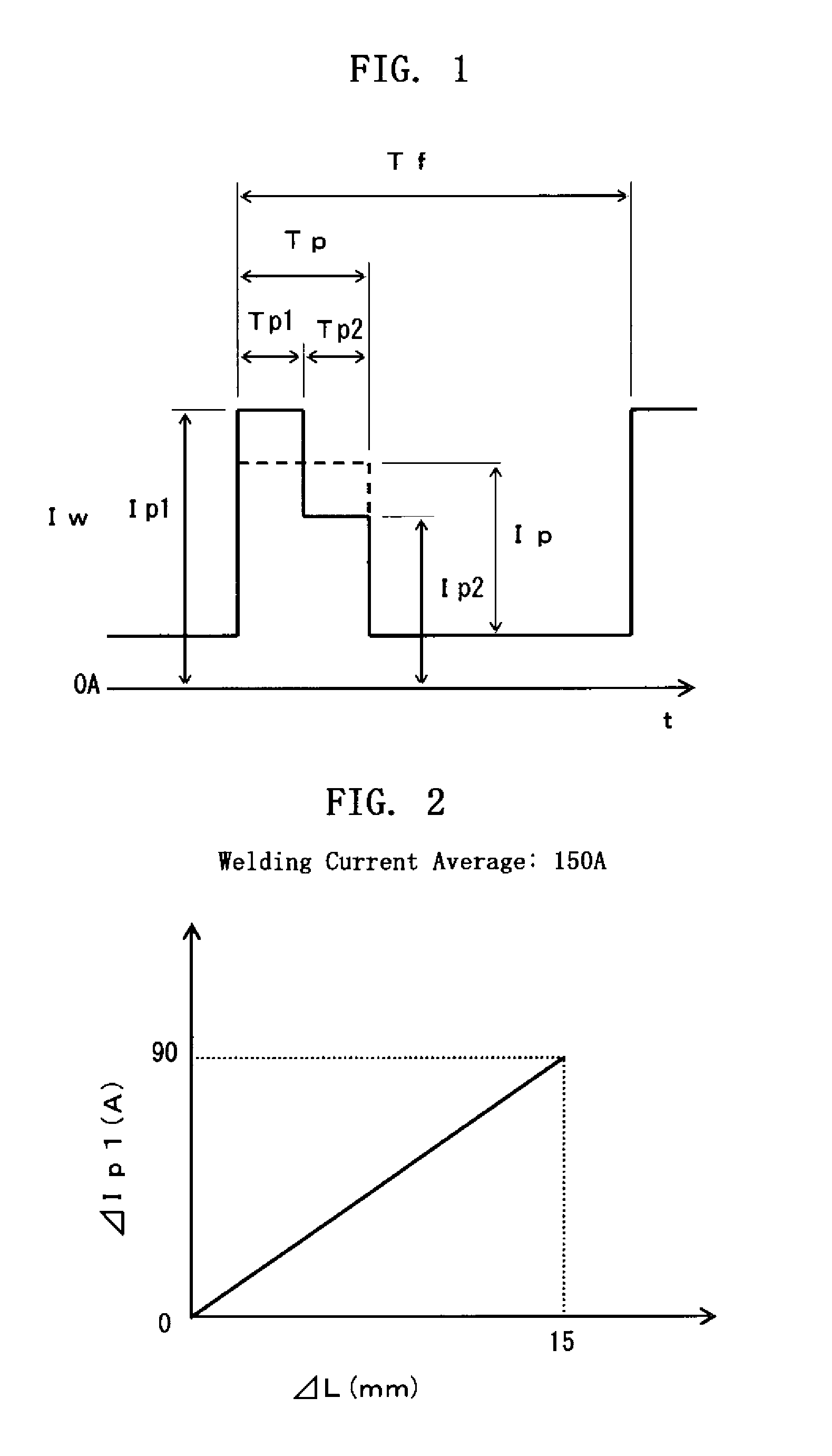

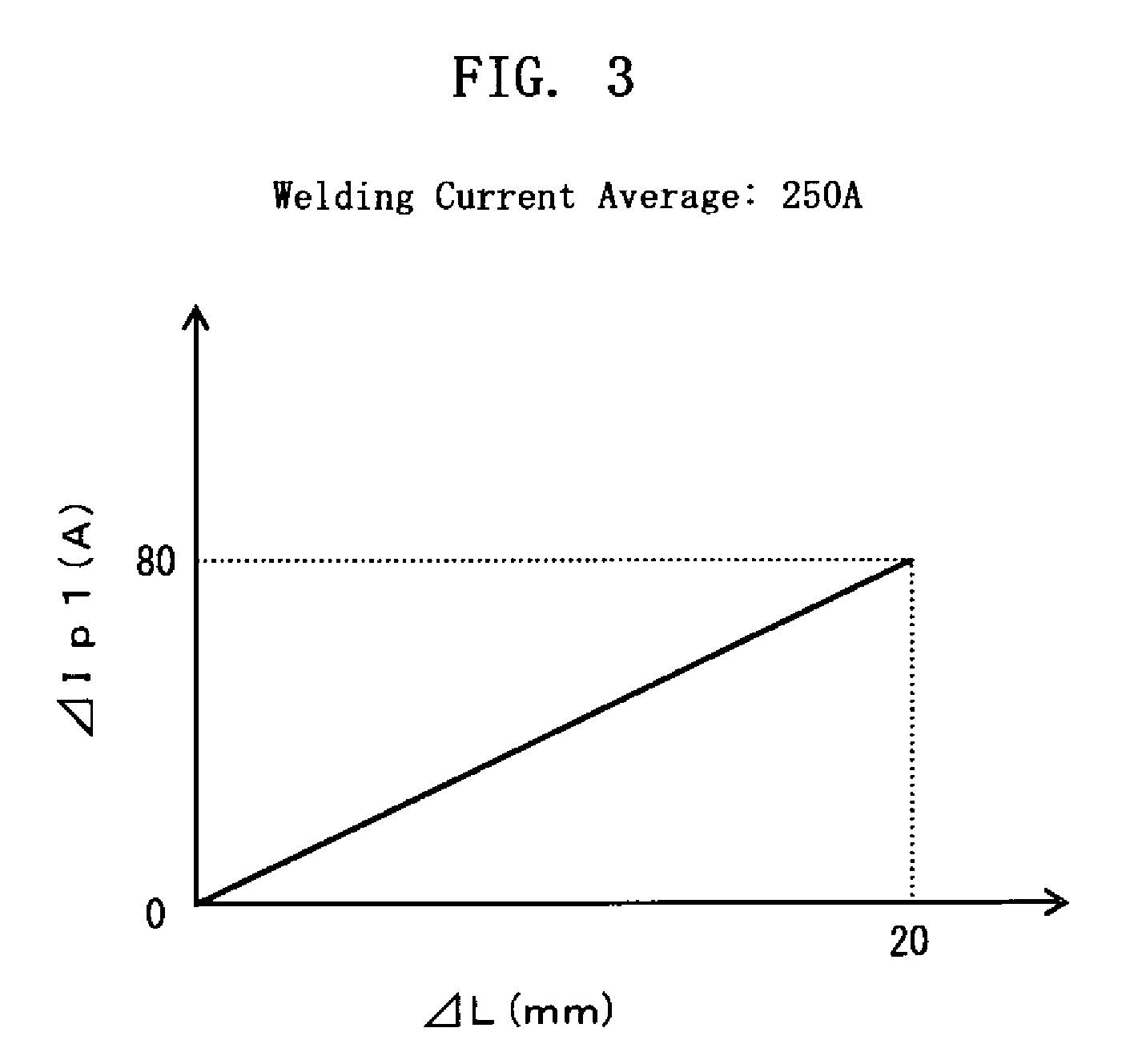

- A pulse arc welding method that adjusts the welding current by incorporating a first and second peak current, with the first peak current increased when the tip-base distance is shorter than the reference value and the second peak current reduced when it is longer, to maintain a stable arc condition.

System and method for pulse welding

PatentInactiveEP1712320A3

Innovation

- A pulse welding system that initiates the transfer pulse based on the energy applied to the electrode, ensuring a uniform molten ball size, allowing for tailored transfer pulse characteristics to avoid short-circuiting and excessive heating, with a controller measuring energy and initiating the transfer pulse when a predetermined energy value is reached, independent of arc current and voltage fluctuations.

Safety Regulations

Safety regulations play a crucial role in gas welding pulse methods, ensuring the protection of workers and the surrounding environment. These regulations encompass various aspects of the welding process, from equipment handling to workplace conditions.

Proper personal protective equipment (PPE) is mandatory for all personnel involved in gas welding operations. This includes flame-resistant clothing, safety glasses or goggles, welding helmets with appropriate shade levels, and leather gloves. Respiratory protection may also be necessary when working with certain materials or in poorly ventilated areas.

Workplace safety measures are essential to prevent accidents and minimize risks. Adequate ventilation systems must be in place to remove harmful fumes and gases produced during welding. Fire prevention protocols should be established, including the availability of fire extinguishers and the removal of flammable materials from the welding area.

Gas cylinder handling and storage regulations are particularly important in gas welding. Cylinders must be secured in an upright position, stored away from heat sources, and equipped with proper valves and regulators. Regular inspection and maintenance of cylinders and associated equipment are mandatory to prevent leaks and potential explosions.

Electrical safety is another critical aspect of gas welding pulse methods. All electrical components, including power sources and control systems, must be properly grounded and insulated. Regular inspection and maintenance of electrical equipment are necessary to prevent electric shock and fire hazards.

Training and certification requirements for welders and supervisors are typically mandated by regulatory bodies. These programs ensure that personnel are knowledgeable about safety procedures, equipment operation, and emergency protocols. Ongoing training and refresher courses are often required to maintain certification and stay updated on new safety standards.

Emergency response plans must be in place and regularly practiced. These plans should cover various scenarios, including fire, gas leaks, and medical emergencies. Clear evacuation routes and assembly points should be established and communicated to all personnel.

Regular safety audits and inspections are necessary to ensure compliance with regulations and identify potential hazards. Documentation of safety procedures, incident reports, and equipment maintenance records should be maintained and readily accessible for review by regulatory authorities.

Adherence to these safety regulations not only protects workers but also contributes to the overall efficiency and quality of gas welding pulse methods. By prioritizing safety, organizations can minimize downtime, reduce accidents, and maintain a productive work environment.

Proper personal protective equipment (PPE) is mandatory for all personnel involved in gas welding operations. This includes flame-resistant clothing, safety glasses or goggles, welding helmets with appropriate shade levels, and leather gloves. Respiratory protection may also be necessary when working with certain materials or in poorly ventilated areas.

Workplace safety measures are essential to prevent accidents and minimize risks. Adequate ventilation systems must be in place to remove harmful fumes and gases produced during welding. Fire prevention protocols should be established, including the availability of fire extinguishers and the removal of flammable materials from the welding area.

Gas cylinder handling and storage regulations are particularly important in gas welding. Cylinders must be secured in an upright position, stored away from heat sources, and equipped with proper valves and regulators. Regular inspection and maintenance of cylinders and associated equipment are mandatory to prevent leaks and potential explosions.

Electrical safety is another critical aspect of gas welding pulse methods. All electrical components, including power sources and control systems, must be properly grounded and insulated. Regular inspection and maintenance of electrical equipment are necessary to prevent electric shock and fire hazards.

Training and certification requirements for welders and supervisors are typically mandated by regulatory bodies. These programs ensure that personnel are knowledgeable about safety procedures, equipment operation, and emergency protocols. Ongoing training and refresher courses are often required to maintain certification and stay updated on new safety standards.

Emergency response plans must be in place and regularly practiced. These plans should cover various scenarios, including fire, gas leaks, and medical emergencies. Clear evacuation routes and assembly points should be established and communicated to all personnel.

Regular safety audits and inspections are necessary to ensure compliance with regulations and identify potential hazards. Documentation of safety procedures, incident reports, and equipment maintenance records should be maintained and readily accessible for review by regulatory authorities.

Adherence to these safety regulations not only protects workers but also contributes to the overall efficiency and quality of gas welding pulse methods. By prioritizing safety, organizations can minimize downtime, reduce accidents, and maintain a productive work environment.

Environmental Impact

Gas welding pulse methods, while efficient in joining metals, have notable environmental impacts that warrant careful consideration. The process inherently involves the combustion of fuel gases, typically acetylene or propane, which results in the emission of greenhouse gases, primarily carbon dioxide. These emissions contribute to the overall carbon footprint of welding operations and, by extension, to global climate change concerns.

The environmental impact extends beyond air pollution. The production of welding gases, particularly acetylene, requires significant energy input and often relies on fossil fuel sources. This upstream environmental cost adds to the overall ecological burden of gas welding pulse methods. Additionally, the extraction and processing of raw materials for welding gases can lead to habitat disruption and resource depletion.

Noise pollution is another environmental factor associated with gas welding pulse methods. The pulsing nature of the process can generate intermittent high-frequency sounds, potentially affecting both human operators and local wildlife. While less severe than some industrial processes, prolonged exposure to welding noise can contribute to broader urban and industrial noise pollution issues.

Water pollution risks are present, albeit minimal, in gas welding pulse operations. Cooling systems used in some welding setups may discharge heated water, and there's potential for contamination from metal particulates or flux residues. Proper management of these discharges is crucial to mitigate impacts on local water bodies and aquatic ecosystems.

The generation of solid waste, including spent welding rods, slag, and metal scraps, presents another environmental challenge. While much of this waste is recyclable, improper disposal can lead to soil contamination and landfill burden. The production of protective equipment and consumables for gas welding also contributes to the overall waste stream associated with this technology.

On a positive note, gas welding pulse methods often result in stronger, more durable welds compared to some alternative techniques. This can lead to longer-lasting products and structures, potentially reducing the need for frequent replacements and the associated environmental impacts of manufacturing new items.

Efforts to mitigate the environmental impact of gas welding pulse methods are ongoing. These include the development of more efficient burners that reduce gas consumption, the use of cleaner fuel alternatives, and improved recycling processes for welding waste. Additionally, the integration of pulse welding with automation and robotics can optimize gas usage and reduce overall environmental impact through increased precision and reduced material waste.

The environmental impact extends beyond air pollution. The production of welding gases, particularly acetylene, requires significant energy input and often relies on fossil fuel sources. This upstream environmental cost adds to the overall ecological burden of gas welding pulse methods. Additionally, the extraction and processing of raw materials for welding gases can lead to habitat disruption and resource depletion.

Noise pollution is another environmental factor associated with gas welding pulse methods. The pulsing nature of the process can generate intermittent high-frequency sounds, potentially affecting both human operators and local wildlife. While less severe than some industrial processes, prolonged exposure to welding noise can contribute to broader urban and industrial noise pollution issues.

Water pollution risks are present, albeit minimal, in gas welding pulse operations. Cooling systems used in some welding setups may discharge heated water, and there's potential for contamination from metal particulates or flux residues. Proper management of these discharges is crucial to mitigate impacts on local water bodies and aquatic ecosystems.

The generation of solid waste, including spent welding rods, slag, and metal scraps, presents another environmental challenge. While much of this waste is recyclable, improper disposal can lead to soil contamination and landfill burden. The production of protective equipment and consumables for gas welding also contributes to the overall waste stream associated with this technology.

On a positive note, gas welding pulse methods often result in stronger, more durable welds compared to some alternative techniques. This can lead to longer-lasting products and structures, potentially reducing the need for frequent replacements and the associated environmental impacts of manufacturing new items.

Efforts to mitigate the environmental impact of gas welding pulse methods are ongoing. These include the development of more efficient burners that reduce gas consumption, the use of cleaner fuel alternatives, and improved recycling processes for welding waste. Additionally, the integration of pulse welding with automation and robotics can optimize gas usage and reduce overall environmental impact through increased precision and reduced material waste.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!