Research on Gas Welding for Nano-Precision Instruments

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Advancements

Gas welding technology has undergone significant advancements in recent years, particularly in the field of nano-precision instruments. The evolution of gas welding techniques has been driven by the increasing demand for high-precision manufacturing processes in industries such as electronics, aerospace, and medical devices.

One of the key developments in gas welding for nano-precision instruments is the introduction of micro-flame technology. This innovation allows for extremely fine and controlled heat application, enabling welders to join materials at the nanoscale level with unprecedented accuracy. The micro-flame technology utilizes specialized gas mixtures and nozzle designs to produce flames as small as 1 mm in diameter, providing the precision required for nano-scale welding operations.

Another significant advancement is the integration of computer-controlled systems into gas welding equipment. These systems enable precise control over gas flow rates, flame temperature, and welding duration, ensuring consistent and repeatable results. Advanced sensors and real-time monitoring capabilities have been incorporated to maintain optimal welding conditions throughout the process, compensating for any variations in environmental factors or material properties.

The development of specialized gas mixtures has also played a crucial role in enhancing the capabilities of gas welding for nano-precision instruments. These custom blends are tailored to specific materials and applications, offering improved heat distribution, reduced oxidation, and enhanced weld quality. For instance, the use of hydrogen-enriched gas mixtures has shown promising results in achieving cleaner and stronger welds at the nanoscale.

Advancements in shielding gas technology have further contributed to the improvement of gas welding processes for nano-precision instruments. Innovative shielding gas delivery systems and nozzle designs have been developed to create inert atmospheres around the welding area, preventing contamination and oxidation of sensitive nano-components. This has significantly enhanced the quality and reliability of welds in nano-scale applications.

The integration of laser technology with gas welding has opened up new possibilities for nano-precision welding. Hybrid laser-gas welding systems combine the benefits of both technologies, offering enhanced control over heat input and weld penetration. This approach has proven particularly effective in joining dissimilar materials and creating complex nano-structures with high precision.

Furthermore, the development of advanced cooling techniques has addressed the challenges associated with heat-sensitive nano-components. Innovative cooling systems, such as cryogenic cooling and pulsed gas cooling, have been implemented to minimize thermal distortion and maintain the structural integrity of nano-scale materials during the welding process.

One of the key developments in gas welding for nano-precision instruments is the introduction of micro-flame technology. This innovation allows for extremely fine and controlled heat application, enabling welders to join materials at the nanoscale level with unprecedented accuracy. The micro-flame technology utilizes specialized gas mixtures and nozzle designs to produce flames as small as 1 mm in diameter, providing the precision required for nano-scale welding operations.

Another significant advancement is the integration of computer-controlled systems into gas welding equipment. These systems enable precise control over gas flow rates, flame temperature, and welding duration, ensuring consistent and repeatable results. Advanced sensors and real-time monitoring capabilities have been incorporated to maintain optimal welding conditions throughout the process, compensating for any variations in environmental factors or material properties.

The development of specialized gas mixtures has also played a crucial role in enhancing the capabilities of gas welding for nano-precision instruments. These custom blends are tailored to specific materials and applications, offering improved heat distribution, reduced oxidation, and enhanced weld quality. For instance, the use of hydrogen-enriched gas mixtures has shown promising results in achieving cleaner and stronger welds at the nanoscale.

Advancements in shielding gas technology have further contributed to the improvement of gas welding processes for nano-precision instruments. Innovative shielding gas delivery systems and nozzle designs have been developed to create inert atmospheres around the welding area, preventing contamination and oxidation of sensitive nano-components. This has significantly enhanced the quality and reliability of welds in nano-scale applications.

The integration of laser technology with gas welding has opened up new possibilities for nano-precision welding. Hybrid laser-gas welding systems combine the benefits of both technologies, offering enhanced control over heat input and weld penetration. This approach has proven particularly effective in joining dissimilar materials and creating complex nano-structures with high precision.

Furthermore, the development of advanced cooling techniques has addressed the challenges associated with heat-sensitive nano-components. Innovative cooling systems, such as cryogenic cooling and pulsed gas cooling, have been implemented to minimize thermal distortion and maintain the structural integrity of nano-scale materials during the welding process.

Nano-Precision Market Trends

The nano-precision instrument market is experiencing significant growth, driven by advancements in nanotechnology and increasing demand for high-precision measurements across various industries. This market segment encompasses a wide range of devices, including atomic force microscopes, scanning electron microscopes, and nano-positioning systems, all of which require exceptional accuracy and precision in their manufacturing and assembly processes.

The global nano-precision market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily fueled by the rising adoption of nanotechnology in sectors such as semiconductors, healthcare, and materials science. The semiconductor industry, in particular, is a major driver, as the continuous miniaturization of electronic components demands ever-increasing precision in manufacturing processes.

In the healthcare sector, nano-precision instruments are gaining traction in applications such as drug delivery systems, diagnostic tools, and medical imaging. The ability to manipulate and analyze materials at the nanoscale is opening new avenues for targeted therapies and personalized medicine, further boosting market growth.

The materials science field is another key contributor to the expanding nano-precision market. Researchers and manufacturers are leveraging nano-precision instruments to develop and characterize advanced materials with unique properties, such as graphene and other two-dimensional materials. These innovations are expected to drive demand for high-precision measurement and manufacturing tools in the coming years.

Geographically, North America and Europe currently dominate the nano-precision instrument market, owing to their strong research and development infrastructure and early adoption of nanotechnology. However, the Asia-Pacific region is emerging as a rapidly growing market, with countries like China, Japan, and South Korea investing heavily in nanotechnology research and manufacturing capabilities.

The trend towards Industry 4.0 and smart manufacturing is also influencing the nano-precision market. Integration of advanced technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) into nano-precision instruments is enhancing their capabilities and opening up new applications. This convergence of technologies is expected to drive further innovation and market growth in the coming years.

As the demand for nano-precision instruments continues to rise, manufacturers are focusing on developing more compact, user-friendly, and cost-effective solutions. This trend is likely to expand the market by making nano-precision technology more accessible to a broader range of industries and research institutions, further accelerating market growth and technological advancements in the field.

The global nano-precision market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is primarily fueled by the rising adoption of nanotechnology in sectors such as semiconductors, healthcare, and materials science. The semiconductor industry, in particular, is a major driver, as the continuous miniaturization of electronic components demands ever-increasing precision in manufacturing processes.

In the healthcare sector, nano-precision instruments are gaining traction in applications such as drug delivery systems, diagnostic tools, and medical imaging. The ability to manipulate and analyze materials at the nanoscale is opening new avenues for targeted therapies and personalized medicine, further boosting market growth.

The materials science field is another key contributor to the expanding nano-precision market. Researchers and manufacturers are leveraging nano-precision instruments to develop and characterize advanced materials with unique properties, such as graphene and other two-dimensional materials. These innovations are expected to drive demand for high-precision measurement and manufacturing tools in the coming years.

Geographically, North America and Europe currently dominate the nano-precision instrument market, owing to their strong research and development infrastructure and early adoption of nanotechnology. However, the Asia-Pacific region is emerging as a rapidly growing market, with countries like China, Japan, and South Korea investing heavily in nanotechnology research and manufacturing capabilities.

The trend towards Industry 4.0 and smart manufacturing is also influencing the nano-precision market. Integration of advanced technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) into nano-precision instruments is enhancing their capabilities and opening up new applications. This convergence of technologies is expected to drive further innovation and market growth in the coming years.

As the demand for nano-precision instruments continues to rise, manufacturers are focusing on developing more compact, user-friendly, and cost-effective solutions. This trend is likely to expand the market by making nano-precision technology more accessible to a broader range of industries and research institutions, further accelerating market growth and technological advancements in the field.

Technical Hurdles in Nano-Welding

Gas welding for nano-precision instruments faces several significant technical hurdles that challenge researchers and engineers in the field. One of the primary obstacles is achieving precise control over the welding process at the nanoscale level. The extremely small dimensions involved require unprecedented accuracy in positioning, heat distribution, and material flow.

The heat-affected zone (HAZ) poses a major challenge in nano-welding. Even minimal thermal expansion or contraction can lead to significant distortions and misalignments at the nanoscale. Controlling the HAZ becomes crucial to maintain the structural integrity and functionality of nano-precision instruments. Researchers are exploring advanced cooling techniques and ultra-short pulse lasers to minimize the HAZ, but these methods are still in their infancy.

Material selection and compatibility present another hurdle. Many nano-precision instruments utilize exotic materials or complex composites that may react unpredictably under welding conditions. Finding suitable filler materials that can bond effectively without compromising the properties of the base materials is an ongoing challenge. Additionally, the behavior of materials at the nanoscale often differs from their bulk properties, necessitating a deeper understanding of nano-material science.

The formation and control of intermetallic compounds during the welding process is a critical issue. These compounds can significantly affect the mechanical and electrical properties of the welded joint. At the nanoscale, even slight variations in composition can lead to dramatic changes in performance. Researchers are investigating ways to predict and control intermetallic formation, but this remains a complex problem.

Contamination and oxidation are heightened concerns in nano-welding. Even minute amounts of impurities or oxidation can have outsized effects on the weld quality and instrument performance. Developing ultra-clean welding environments and processes that can operate at the nanoscale is a significant technical challenge. This often requires specialized equipment and facilities, adding to the complexity and cost of nano-welding operations.

Monitoring and quality control present unique difficulties in nano-welding. Traditional inspection methods are often inadequate at this scale, necessitating the development of new techniques. Real-time monitoring of the welding process at the nanoscale is particularly challenging, limiting the ability to make in-process adjustments. Advanced imaging and sensing technologies are being adapted for nano-welding, but their integration into practical welding systems remains a hurdle.

The heat-affected zone (HAZ) poses a major challenge in nano-welding. Even minimal thermal expansion or contraction can lead to significant distortions and misalignments at the nanoscale. Controlling the HAZ becomes crucial to maintain the structural integrity and functionality of nano-precision instruments. Researchers are exploring advanced cooling techniques and ultra-short pulse lasers to minimize the HAZ, but these methods are still in their infancy.

Material selection and compatibility present another hurdle. Many nano-precision instruments utilize exotic materials or complex composites that may react unpredictably under welding conditions. Finding suitable filler materials that can bond effectively without compromising the properties of the base materials is an ongoing challenge. Additionally, the behavior of materials at the nanoscale often differs from their bulk properties, necessitating a deeper understanding of nano-material science.

The formation and control of intermetallic compounds during the welding process is a critical issue. These compounds can significantly affect the mechanical and electrical properties of the welded joint. At the nanoscale, even slight variations in composition can lead to dramatic changes in performance. Researchers are investigating ways to predict and control intermetallic formation, but this remains a complex problem.

Contamination and oxidation are heightened concerns in nano-welding. Even minute amounts of impurities or oxidation can have outsized effects on the weld quality and instrument performance. Developing ultra-clean welding environments and processes that can operate at the nanoscale is a significant technical challenge. This often requires specialized equipment and facilities, adding to the complexity and cost of nano-welding operations.

Monitoring and quality control present unique difficulties in nano-welding. Traditional inspection methods are often inadequate at this scale, necessitating the development of new techniques. Real-time monitoring of the welding process at the nanoscale is particularly challenging, limiting the ability to make in-process adjustments. Advanced imaging and sensing technologies are being adapted for nano-welding, but their integration into practical welding systems remains a hurdle.

Current Gas Welding Techniques

01 Precision control systems for gas welding

Advanced control systems are implemented to enhance the precision of gas welding processes. These systems may include computerized controls, sensors, and feedback mechanisms to regulate gas flow, temperature, and torch positioning. Such precision control allows for more accurate and consistent welds, particularly in applications requiring high precision.- Precision control systems for gas welding: Advanced control systems are implemented to enhance the precision of gas welding processes. These systems may include computerized controls, sensors, and feedback mechanisms to regulate gas flow, temperature, and torch positioning. Such precision control allows for more accurate and consistent welds, particularly in applications requiring high precision.

- Specialized gas welding torches for precision work: Innovative torch designs are developed specifically for precision gas welding. These torches may feature fine-tip nozzles, adjustable flame settings, and ergonomic designs to improve control and accuracy. Some designs incorporate cooling systems or heat shields to maintain stability during prolonged use in precision applications.

- Automated and robotic gas welding systems: Automation and robotics are integrated into gas welding processes to achieve higher levels of precision. These systems can perform repetitive welding tasks with consistent accuracy, minimizing human error. They often include advanced vision systems and motion control to ensure precise positioning and movement during welding operations.

- Gas mixture optimization for precision welding: Research focuses on optimizing gas mixtures to enhance welding precision. This involves developing specific gas blends tailored to different materials and welding conditions. Precise control of gas composition can lead to improved arc stability, reduced spatter, and more consistent weld quality in precision applications.

- Micro-welding techniques using gas welding: Advancements in micro-welding techniques using gas welding are developed for applications requiring extreme precision. These techniques may involve specialized equipment for handling very small workpieces, ultra-fine flame control, and magnification systems to aid in precise positioning. Such methods are particularly useful in industries like electronics and medical device manufacturing.

02 Specialized gas welding torches for precision work

Innovative torch designs are developed specifically for precision gas welding. These torches may feature fine-tip nozzles, adjustable flame settings, and ergonomic designs to allow welders greater control and accuracy. Some designs may incorporate cooling systems or heat shields to maintain stability during delicate operations.Expand Specific Solutions03 Automated gas welding systems for high-precision applications

Robotic and automated gas welding systems are employed to achieve high levels of precision in welding operations. These systems can be programmed to perform complex welding patterns with consistent accuracy, minimizing human error and increasing repeatability. They often incorporate advanced vision systems and real-time monitoring to ensure weld quality.Expand Specific Solutions04 Precision gas mixing and flow control techniques

Advanced gas mixing and flow control methods are developed to improve welding precision. These techniques may involve precise blending of gases, digital flow meters, and pressure regulators to maintain optimal gas composition and flow rates throughout the welding process. Such control contributes to more stable arcs and consistent weld quality.Expand Specific Solutions05 Micro-welding techniques for gas welding

Specialized micro-welding techniques are adapted for gas welding processes to achieve extremely high precision in small-scale applications. These methods may involve the use of microscopes or magnification systems, ultra-fine flame adjustments, and specialized fixturing to enable precise welding of miniature components or delicate materials.Expand Specific Solutions

Key Nano-Welding Innovators

The research on gas welding for nano-precision instruments is in an emerging stage, with a growing market driven by increasing demand for high-precision manufacturing. The technology is still evolving, with varying levels of maturity among key players. Companies like Fronius International GmbH and Praxair Technology, Inc. are leading in welding technology, while research institutions such as Osaka University and Georgia Tech Research Corp. are advancing nano-precision applications. The market is characterized by collaborations between industry and academia, with players like BOC Ltd. and JFE Steel Corp. contributing to the development of specialized gases and materials. As the field progresses, we can expect further innovations in gas composition, welding techniques, and precision control mechanisms.

Fronius International GmbH

Technical Solution: Fronius has developed advanced gas welding technologies for nano-precision instruments, focusing on their Cold Metal Transfer (CMT) process. This innovative approach utilizes a digital process control and modified arc ignition to achieve precise, spatter-free welds at the nanoscale level. The CMT process involves a forward and backward movement of the wire electrode, allowing for controlled heat input and minimal thermal distortion[1][3]. For nano-precision instruments, Fronius has further refined this technology to incorporate shielding gas mixtures optimized for ultra-thin materials, ensuring stable arc characteristics and minimizing oxidation[2]. The company has also integrated real-time monitoring systems that use high-speed cameras and sensors to detect and correct weld imperfections at the nanometer scale, ensuring consistent quality in nano-precision welding applications[4].

Strengths: Highly precise welding control, minimal heat input, and advanced process monitoring. Weaknesses: Potentially higher equipment costs and complexity compared to traditional welding methods.

Praxair Technology, Inc.

Technical Solution: Praxair has developed specialized gas mixtures and delivery systems tailored for nano-precision gas welding. Their approach focuses on ultra-high purity gases and precise flow control to maintain consistent weld quality at the nanoscale. The company's proprietary gas blending technology allows for custom shielding gas compositions that can be adjusted in real-time based on feedback from welding sensors[1]. Praxair has also introduced a nano-scale gas filtration system that removes impurities down to the parts-per-trillion level, ensuring the highest possible weld integrity for sensitive nano-instruments[2]. Additionally, they have developed a cryogenic gas delivery system that maintains gas stability and prevents molecular agglomeration, which is critical for consistent performance in nano-welding applications[3].

Strengths: Ultra-high purity gas solutions, advanced gas delivery systems, and customizable gas compositions. Weaknesses: May require significant infrastructure investment for implementation.

Breakthrough Nano-Welding Patents

Shielding gas, welding method by using the same and weldment thereof

PatentInactiveUS20070034610A1

Innovation

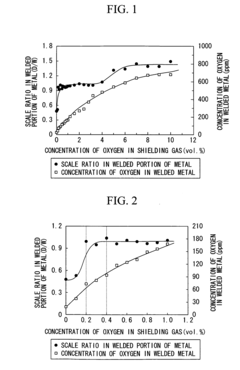

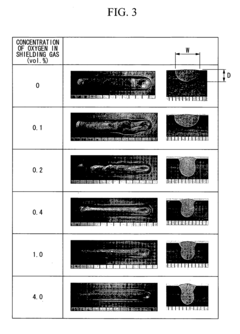

- A shielding gas composition of 0.2% or more oxidative gas, preferably 0.4% or more, with helium as the balance, is used to suppress the dragging force in the molten pool and enhance inward convection, allowing for deeper weld penetration with a D/W ratio of 0.8 or more, achieved through specific welding conditions such as current, speed, and arc length.

Welding method using a shielding gas comprising bewtween 0.2 % and 10 % of an oxidative gas, the rest being helium

PatentInactiveEP1752249B1

Innovation

- A welding method using a shielding gas comprising 0.2% or more by volume of an oxidative gas, such as oxygen, mixed with helium, which suppresses the dragging force in the molten pool and enhances inward convection, allowing for deeper penetration and a higher D/W ratio, thereby improving weld quality and reducing the number of passes required.

Material Compatibility Analysis

Material compatibility is a critical factor in gas welding for nano-precision instruments. The selection of appropriate materials for both the welding process and the final product is essential to ensure the integrity, functionality, and longevity of these delicate devices. In the context of nano-precision instruments, even minor incompatibilities can lead to significant performance issues or device failure.

When considering material compatibility for gas welding in this field, it is crucial to evaluate the thermal properties of the materials involved. Nano-precision instruments often incorporate a variety of materials with different thermal expansion coefficients. During the welding process, these materials may expand and contract at different rates, potentially leading to internal stresses, deformations, or even fractures in the final product. Therefore, careful selection of materials with similar thermal expansion properties is necessary to minimize these risks.

Another important aspect of material compatibility is the chemical reactivity between the welding gas, filler material, and the base materials of the nano-precision instruments. Some materials may be susceptible to oxidation or other chemical reactions when exposed to certain welding gases or at elevated temperatures. This can result in the formation of unwanted compounds, weakening of the weld joint, or alteration of the material properties. Consequently, it is essential to choose welding gases and filler materials that are chemically compatible with the base materials to prevent such adverse reactions.

The mechanical properties of the materials must also be taken into account when assessing compatibility for gas welding. Nano-precision instruments often require materials with specific strength, hardness, and ductility characteristics. The welding process should not compromise these properties, and the resulting weld joint should maintain or enhance the mechanical integrity of the device. This necessitates a thorough understanding of how different materials behave when subjected to the heat and pressure of gas welding, and how their properties may change as a result.

Furthermore, the surface properties of the materials play a crucial role in the success of gas welding for nano-precision instruments. Factors such as surface roughness, wettability, and cleanliness can significantly impact the quality of the weld joint. Materials with incompatible surface properties may result in poor adhesion, incomplete fusion, or the formation of voids or inclusions in the weld. Therefore, careful surface preparation and selection of materials with compatible surface characteristics are essential for achieving high-quality welds in nano-precision applications.

In conclusion, material compatibility analysis for gas welding in nano-precision instruments requires a multifaceted approach. It involves considering thermal, chemical, mechanical, and surface properties of all materials involved in the welding process. By thoroughly evaluating these factors and selecting compatible materials, manufacturers can ensure the production of reliable, high-performance nano-precision instruments that meet the exacting standards required in this field.

When considering material compatibility for gas welding in this field, it is crucial to evaluate the thermal properties of the materials involved. Nano-precision instruments often incorporate a variety of materials with different thermal expansion coefficients. During the welding process, these materials may expand and contract at different rates, potentially leading to internal stresses, deformations, or even fractures in the final product. Therefore, careful selection of materials with similar thermal expansion properties is necessary to minimize these risks.

Another important aspect of material compatibility is the chemical reactivity between the welding gas, filler material, and the base materials of the nano-precision instruments. Some materials may be susceptible to oxidation or other chemical reactions when exposed to certain welding gases or at elevated temperatures. This can result in the formation of unwanted compounds, weakening of the weld joint, or alteration of the material properties. Consequently, it is essential to choose welding gases and filler materials that are chemically compatible with the base materials to prevent such adverse reactions.

The mechanical properties of the materials must also be taken into account when assessing compatibility for gas welding. Nano-precision instruments often require materials with specific strength, hardness, and ductility characteristics. The welding process should not compromise these properties, and the resulting weld joint should maintain or enhance the mechanical integrity of the device. This necessitates a thorough understanding of how different materials behave when subjected to the heat and pressure of gas welding, and how their properties may change as a result.

Furthermore, the surface properties of the materials play a crucial role in the success of gas welding for nano-precision instruments. Factors such as surface roughness, wettability, and cleanliness can significantly impact the quality of the weld joint. Materials with incompatible surface properties may result in poor adhesion, incomplete fusion, or the formation of voids or inclusions in the weld. Therefore, careful surface preparation and selection of materials with compatible surface characteristics are essential for achieving high-quality welds in nano-precision applications.

In conclusion, material compatibility analysis for gas welding in nano-precision instruments requires a multifaceted approach. It involves considering thermal, chemical, mechanical, and surface properties of all materials involved in the welding process. By thoroughly evaluating these factors and selecting compatible materials, manufacturers can ensure the production of reliable, high-performance nano-precision instruments that meet the exacting standards required in this field.

Quality Control in Nano-Welding

Quality control in nano-welding is a critical aspect of gas welding for nano-precision instruments. The miniature scale of these operations demands unprecedented levels of precision and consistency, making quality control measures essential for ensuring the reliability and performance of the final product.

One of the primary challenges in nano-welding quality control is the development and implementation of advanced inspection techniques. Traditional visual inspection methods are inadequate for detecting defects at the nanoscale. Instead, high-resolution imaging technologies such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) are employed to examine weld quality at the molecular level. These techniques allow for the identification of minute imperfections, ensuring that each weld meets the stringent standards required for nano-precision instruments.

In addition to visual inspection, real-time monitoring systems play a crucial role in maintaining quality during the nano-welding process. Advanced sensors and data analytics are utilized to track key parameters such as temperature, pressure, and gas flow rates with extreme accuracy. Any deviations from the optimal range can be detected and corrected instantaneously, minimizing the risk of defects and ensuring consistent weld quality throughout the production process.

Material purity is another critical factor in nano-welding quality control. Even trace amounts of contaminants can significantly impact the integrity of the weld at the nanoscale. Stringent protocols for material handling and storage are implemented to prevent contamination, and advanced purification techniques are employed to ensure that only the highest-grade materials are used in the welding process.

The development of standardized procedures and protocols is essential for maintaining consistent quality in nano-welding operations. These guidelines cover every aspect of the welding process, from equipment calibration and maintenance to operator training and certification. Regular audits and compliance checks are conducted to ensure that these standards are consistently met across all production facilities.

Statistical process control (SPC) techniques are adapted for use in nano-welding quality control. By collecting and analyzing data from multiple welds, manufacturers can identify trends and patterns that may indicate potential quality issues before they become critical. This proactive approach allows for continuous improvement of the welding process and helps maintain high standards of quality over time.

As the field of nano-precision instruments continues to evolve, quality control measures in nano-welding must adapt accordingly. Ongoing research and development efforts focus on creating even more sensitive detection methods and refining process control techniques to meet the ever-increasing demands of this cutting-edge industry.

One of the primary challenges in nano-welding quality control is the development and implementation of advanced inspection techniques. Traditional visual inspection methods are inadequate for detecting defects at the nanoscale. Instead, high-resolution imaging technologies such as scanning electron microscopy (SEM) and atomic force microscopy (AFM) are employed to examine weld quality at the molecular level. These techniques allow for the identification of minute imperfections, ensuring that each weld meets the stringent standards required for nano-precision instruments.

In addition to visual inspection, real-time monitoring systems play a crucial role in maintaining quality during the nano-welding process. Advanced sensors and data analytics are utilized to track key parameters such as temperature, pressure, and gas flow rates with extreme accuracy. Any deviations from the optimal range can be detected and corrected instantaneously, minimizing the risk of defects and ensuring consistent weld quality throughout the production process.

Material purity is another critical factor in nano-welding quality control. Even trace amounts of contaminants can significantly impact the integrity of the weld at the nanoscale. Stringent protocols for material handling and storage are implemented to prevent contamination, and advanced purification techniques are employed to ensure that only the highest-grade materials are used in the welding process.

The development of standardized procedures and protocols is essential for maintaining consistent quality in nano-welding operations. These guidelines cover every aspect of the welding process, from equipment calibration and maintenance to operator training and certification. Regular audits and compliance checks are conducted to ensure that these standards are consistently met across all production facilities.

Statistical process control (SPC) techniques are adapted for use in nano-welding quality control. By collecting and analyzing data from multiple welds, manufacturers can identify trends and patterns that may indicate potential quality issues before they become critical. This proactive approach allows for continuous improvement of the welding process and helps maintain high standards of quality over time.

As the field of nano-precision instruments continues to evolve, quality control measures in nano-welding must adapt accordingly. Ongoing research and development efforts focus on creating even more sensitive detection methods and refining process control techniques to meet the ever-increasing demands of this cutting-edge industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!