Dynamic Temperature Mapping in Gas Weld Formation

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Thermal Dynamics

Gas welding thermal dynamics plays a crucial role in understanding and optimizing the dynamic temperature mapping in gas weld formation. The thermal behavior during gas welding is governed by complex heat transfer mechanisms, including conduction, convection, and radiation. These processes significantly influence the quality and properties of the resulting weld.

The heat source in gas welding, typically an oxy-fuel flame, generates a localized high-temperature zone. This heat is then distributed through the workpiece, creating a temperature gradient that extends from the weld pool to the surrounding material. The dynamic nature of this temperature distribution is influenced by various factors, including the welding speed, gas flow rates, and the thermal properties of the materials involved.

One of the key aspects of gas welding thermal dynamics is the formation and evolution of the weld pool. As the heat source moves along the weld path, the molten pool undergoes continuous changes in size, shape, and temperature distribution. This dynamic behavior affects the solidification process and, consequently, the microstructure and mechanical properties of the weld.

The heat-affected zone (HAZ) surrounding the weld is another critical area influenced by thermal dynamics. The temperature gradients in this region can lead to microstructural changes, residual stresses, and potential defects if not properly controlled. Understanding the thermal dynamics in the HAZ is essential for predicting and mitigating issues such as distortion, cracking, and reduced mechanical performance.

Heat dissipation mechanisms play a significant role in gas welding thermal dynamics. The rate at which heat is conducted away from the weld area affects the cooling rate and, subsequently, the final weld properties. Factors such as material thickness, thermal conductivity, and ambient conditions all contribute to the overall heat dissipation behavior.

Advanced modeling techniques, such as finite element analysis (FEA) and computational fluid dynamics (CFD), have become invaluable tools in studying gas welding thermal dynamics. These methods allow for detailed simulations of heat flow, fluid motion in the weld pool, and temperature distributions, providing insights that are difficult to obtain through experimental methods alone.

Real-time temperature measurement and mapping techniques have also advanced significantly, enabling more accurate monitoring of thermal dynamics during the welding process. Infrared thermography and embedded thermocouple arrays are among the methods used to capture dynamic temperature data, which can be used for process control and quality assurance.

Understanding gas welding thermal dynamics is crucial for optimizing welding parameters, predicting weld quality, and developing new welding techniques. By leveraging this knowledge, engineers can improve weld strength, reduce defects, and enhance overall welding efficiency in various industrial applications.

The heat source in gas welding, typically an oxy-fuel flame, generates a localized high-temperature zone. This heat is then distributed through the workpiece, creating a temperature gradient that extends from the weld pool to the surrounding material. The dynamic nature of this temperature distribution is influenced by various factors, including the welding speed, gas flow rates, and the thermal properties of the materials involved.

One of the key aspects of gas welding thermal dynamics is the formation and evolution of the weld pool. As the heat source moves along the weld path, the molten pool undergoes continuous changes in size, shape, and temperature distribution. This dynamic behavior affects the solidification process and, consequently, the microstructure and mechanical properties of the weld.

The heat-affected zone (HAZ) surrounding the weld is another critical area influenced by thermal dynamics. The temperature gradients in this region can lead to microstructural changes, residual stresses, and potential defects if not properly controlled. Understanding the thermal dynamics in the HAZ is essential for predicting and mitigating issues such as distortion, cracking, and reduced mechanical performance.

Heat dissipation mechanisms play a significant role in gas welding thermal dynamics. The rate at which heat is conducted away from the weld area affects the cooling rate and, subsequently, the final weld properties. Factors such as material thickness, thermal conductivity, and ambient conditions all contribute to the overall heat dissipation behavior.

Advanced modeling techniques, such as finite element analysis (FEA) and computational fluid dynamics (CFD), have become invaluable tools in studying gas welding thermal dynamics. These methods allow for detailed simulations of heat flow, fluid motion in the weld pool, and temperature distributions, providing insights that are difficult to obtain through experimental methods alone.

Real-time temperature measurement and mapping techniques have also advanced significantly, enabling more accurate monitoring of thermal dynamics during the welding process. Infrared thermography and embedded thermocouple arrays are among the methods used to capture dynamic temperature data, which can be used for process control and quality assurance.

Understanding gas welding thermal dynamics is crucial for optimizing welding parameters, predicting weld quality, and developing new welding techniques. By leveraging this knowledge, engineers can improve weld strength, reduce defects, and enhance overall welding efficiency in various industrial applications.

Industrial Demand Analysis

The demand for dynamic temperature mapping in gas weld formation has been steadily increasing across various industrial sectors. This technology plays a crucial role in ensuring the quality and reliability of welded joints, particularly in high-precision manufacturing and critical infrastructure projects.

In the automotive industry, there is a growing need for advanced welding techniques to support the production of lightweight vehicles and electric vehicle components. Dynamic temperature mapping allows manufacturers to optimize welding processes, reduce defects, and improve overall product quality. The aerospace sector also demonstrates a significant demand for this technology, as it enables the production of complex, high-performance components with stringent safety requirements.

The oil and gas industry represents another major market for dynamic temperature mapping in welding. As exploration and production activities expand into more challenging environments, the need for reliable and durable welded structures becomes paramount. This technology helps ensure the integrity of pipelines, offshore platforms, and other critical infrastructure, reducing the risk of failures and associated environmental hazards.

In the power generation sector, particularly in nuclear and renewable energy installations, the demand for precise welding techniques is driven by safety concerns and the need for long-term reliability. Dynamic temperature mapping allows for better control of the welding process, ensuring the structural integrity of critical components such as pressure vessels and turbine housings.

The construction industry, especially in the fabrication of large-scale structures like bridges and skyscrapers, is increasingly adopting advanced welding technologies. Dynamic temperature mapping helps improve the quality of structural welds, enhancing the overall safety and longevity of these projects.

Market analysis indicates that the global welding equipment and consumables market, which includes advanced technologies like dynamic temperature mapping, is expected to grow significantly in the coming years. This growth is driven by increasing industrialization in emerging economies, the ongoing need for infrastructure development, and the adoption of automation in manufacturing processes.

The demand for this technology is also influenced by evolving regulatory standards and quality control requirements across industries. As safety and performance standards become more stringent, manufacturers are compelled to invest in advanced welding technologies to meet these requirements and maintain their competitive edge in the global market.

In the automotive industry, there is a growing need for advanced welding techniques to support the production of lightweight vehicles and electric vehicle components. Dynamic temperature mapping allows manufacturers to optimize welding processes, reduce defects, and improve overall product quality. The aerospace sector also demonstrates a significant demand for this technology, as it enables the production of complex, high-performance components with stringent safety requirements.

The oil and gas industry represents another major market for dynamic temperature mapping in welding. As exploration and production activities expand into more challenging environments, the need for reliable and durable welded structures becomes paramount. This technology helps ensure the integrity of pipelines, offshore platforms, and other critical infrastructure, reducing the risk of failures and associated environmental hazards.

In the power generation sector, particularly in nuclear and renewable energy installations, the demand for precise welding techniques is driven by safety concerns and the need for long-term reliability. Dynamic temperature mapping allows for better control of the welding process, ensuring the structural integrity of critical components such as pressure vessels and turbine housings.

The construction industry, especially in the fabrication of large-scale structures like bridges and skyscrapers, is increasingly adopting advanced welding technologies. Dynamic temperature mapping helps improve the quality of structural welds, enhancing the overall safety and longevity of these projects.

Market analysis indicates that the global welding equipment and consumables market, which includes advanced technologies like dynamic temperature mapping, is expected to grow significantly in the coming years. This growth is driven by increasing industrialization in emerging economies, the ongoing need for infrastructure development, and the adoption of automation in manufacturing processes.

The demand for this technology is also influenced by evolving regulatory standards and quality control requirements across industries. As safety and performance standards become more stringent, manufacturers are compelled to invest in advanced welding technologies to meet these requirements and maintain their competitive edge in the global market.

Temperature Mapping Challenges

Dynamic temperature mapping in gas weld formation presents several significant challenges that researchers and engineers must overcome to achieve accurate and reliable results. One of the primary difficulties lies in the rapid and extreme temperature fluctuations inherent in the welding process. The intense heat generated during welding can cause temperatures to change dramatically within milliseconds, making it challenging to capture these variations with conventional sensing technologies.

The harsh welding environment poses another substantial obstacle to effective temperature mapping. The presence of intense light, electromagnetic interference, and molten metal splatter can interfere with sensor readings and potentially damage sensitive equipment. This necessitates the development of robust and resilient sensing systems capable of withstanding these extreme conditions while maintaining accuracy.

Spatial resolution is a critical factor in temperature mapping that presents its own set of challenges. The welding process often involves small, localized areas of intense heat, requiring high-resolution mapping to capture the fine details of temperature distribution. However, achieving high spatial resolution often comes at the cost of reduced temporal resolution or increased system complexity, creating a trade-off that must be carefully balanced.

The dynamic nature of the weld pool and surrounding areas further complicates temperature mapping efforts. As the weld progresses, the geometry of the workpiece changes, and heat dissipation patterns evolve. This constant flux demands adaptive mapping techniques that can adjust in real-time to changing conditions, a requirement that pushes the boundaries of current sensing and data processing capabilities.

Another significant challenge is the need for non-contact measurement methods. Traditional contact-based temperature sensors are often impractical or impossible to use in welding applications due to the extreme temperatures and the potential for interference with the weld formation. This limitation has driven the development of various optical and infrared sensing technologies, each with its own set of limitations and calibration challenges.

Data processing and interpretation present additional hurdles in dynamic temperature mapping. The vast amount of data generated during high-speed, high-resolution mapping requires sophisticated algorithms and computational power to process and analyze in real-time. Developing methods to extract meaningful insights from this data deluge while filtering out noise and artifacts is an ongoing area of research.

Lastly, the integration of temperature mapping systems into existing welding processes and equipment poses practical challenges. The need for seamless integration without disrupting production workflows or compromising weld quality necessitates careful design considerations and often requires collaboration between sensor developers, welding equipment manufacturers, and end-users.

The harsh welding environment poses another substantial obstacle to effective temperature mapping. The presence of intense light, electromagnetic interference, and molten metal splatter can interfere with sensor readings and potentially damage sensitive equipment. This necessitates the development of robust and resilient sensing systems capable of withstanding these extreme conditions while maintaining accuracy.

Spatial resolution is a critical factor in temperature mapping that presents its own set of challenges. The welding process often involves small, localized areas of intense heat, requiring high-resolution mapping to capture the fine details of temperature distribution. However, achieving high spatial resolution often comes at the cost of reduced temporal resolution or increased system complexity, creating a trade-off that must be carefully balanced.

The dynamic nature of the weld pool and surrounding areas further complicates temperature mapping efforts. As the weld progresses, the geometry of the workpiece changes, and heat dissipation patterns evolve. This constant flux demands adaptive mapping techniques that can adjust in real-time to changing conditions, a requirement that pushes the boundaries of current sensing and data processing capabilities.

Another significant challenge is the need for non-contact measurement methods. Traditional contact-based temperature sensors are often impractical or impossible to use in welding applications due to the extreme temperatures and the potential for interference with the weld formation. This limitation has driven the development of various optical and infrared sensing technologies, each with its own set of limitations and calibration challenges.

Data processing and interpretation present additional hurdles in dynamic temperature mapping. The vast amount of data generated during high-speed, high-resolution mapping requires sophisticated algorithms and computational power to process and analyze in real-time. Developing methods to extract meaningful insights from this data deluge while filtering out noise and artifacts is an ongoing area of research.

Lastly, the integration of temperature mapping systems into existing welding processes and equipment poses practical challenges. The need for seamless integration without disrupting production workflows or compromising weld quality necessitates careful design considerations and often requires collaboration between sensor developers, welding equipment manufacturers, and end-users.

Current Thermal Imaging Solutions

01 Temperature control in gas welding processes

Gas welding processes require precise temperature control to ensure proper weld formation. This involves managing the heat input from the gas flame to achieve the desired melting and fusion of materials. Techniques may include adjusting gas flow rates, flame composition, and torch distance to maintain optimal welding temperatures.- Temperature control in gas welding processes: Gas welding processes require precise temperature control to ensure proper weld formation. This involves managing the heat input from the gas flame to achieve the desired melting and fusion of materials. Techniques may include adjusting gas flow rates, flame composition, and torch distance to maintain optimal welding temperatures.

- Monitoring and measurement of weld temperature: Accurate monitoring and measurement of weld temperature are crucial for quality control in gas welding. Various methods and devices are employed to measure and record temperature data during the welding process. This information helps operators maintain consistent weld quality and adjust parameters as needed.

- Material-specific temperature considerations: Different materials require specific temperature ranges for optimal gas welding. Understanding the melting points and thermal properties of various metals and alloys is essential for achieving strong, defect-free welds. Welding procedures often specify temperature requirements based on the materials being joined.

- Preheating and post-weld heat treatment: Preheating and post-weld heat treatment are important temperature-related processes in gas welding. Preheating can help reduce thermal stress and prevent cracking, while post-weld heat treatment can improve the mechanical properties of the welded joint. These processes involve carefully controlled heating and cooling cycles.

- Advanced temperature control technologies: Emerging technologies are enhancing temperature control in gas welding. These may include computer-controlled systems, real-time feedback mechanisms, and automated temperature adjustment features. Such advancements aim to improve weld quality, consistency, and efficiency in gas welding operations.

02 Monitoring and measurement of weld temperature

Accurate monitoring and measurement of weld temperature are crucial for quality control in gas welding. This may involve the use of thermocouples, infrared sensors, or other temperature measurement devices to ensure that the weld pool and surrounding areas maintain the correct temperature range for proper fusion and material properties.Expand Specific Solutions03 Preheating and post-weld heat treatment

Preheating the base materials and applying post-weld heat treatment can significantly affect the quality of gas welds. These processes help control the cooling rate, reduce thermal stresses, and improve the mechanical properties of the welded joint. Proper temperature management during these stages is essential for achieving desired weld characteristics.Expand Specific Solutions04 Material-specific temperature considerations

Different materials require specific temperature ranges for optimal gas welding results. Factors such as melting point, thermal conductivity, and phase transformations must be considered when determining the appropriate welding temperature for various metals and alloys. This knowledge is crucial for achieving strong, defect-free welds across different material combinations.Expand Specific Solutions05 Innovative temperature control techniques

Advanced techniques for temperature control in gas welding are being developed to improve weld quality and efficiency. These may include pulsed heating methods, computer-controlled temperature regulation, or the use of auxiliary heating sources to maintain precise temperature profiles throughout the welding process.Expand Specific Solutions

Key Players in Welding Industry

The dynamic temperature mapping in gas weld formation market is in a growth phase, driven by increasing demand for precision welding in industries such as automotive, aerospace, and manufacturing. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with key players like Daihen Corp., NIPPON STEEL CORP., and Fronius International GmbH leading innovation. These companies are developing advanced sensors, real-time monitoring systems, and AI-driven analytics to enhance weld quality and process efficiency. While the technology is maturing, there's still room for significant improvements in accuracy, speed, and integration with automated welding systems.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered an innovative approach to dynamic temperature mapping in gas weld formation using their expertise in process control and automation. Their system integrates advanced thermal sensors with their Experion PKS process control platform, allowing for seamless integration of temperature mapping data into overall welding process control[10]. Honeywell's solution uses a combination of contact and non-contact temperature measurement techniques, providing redundancy and increased accuracy. The system also incorporates predictive analytics to anticipate temperature changes based on historical data and current welding parameters. This predictive capability allows for proactive adjustments to maintain optimal weld quality. Honeywell has reported that their system can reduce energy consumption in welding processes by up to 15% while improving weld consistency[11].

Strengths: Seamless integration with process control systems, predictive analytics capabilities, energy efficiency improvements. Weaknesses: May require significant changes to existing welding infrastructure, potential for high implementation costs.

Robert Bosch GmbH

Technical Solution: Bosch has innovated in dynamic temperature mapping for gas weld formation through their advanced sensor technology and IoT integration. Their system employs a network of miniaturized temperature sensors placed strategically around the weld area, combined with machine learning algorithms to predict and map temperature distributions[4]. This approach allows for a more comprehensive temperature profile, including areas that may be obscured from direct visual observation. Bosch's system can interface with robotic welding systems, enabling automated adjustments to welding parameters based on the real-time temperature data. Additionally, their cloud-based analytics platform allows for long-term data storage and analysis, facilitating continuous improvement of welding processes[5].

Strengths: Comprehensive temperature profiling, integration with robotic systems, data analytics capabilities. Weaknesses: Potential complexity in sensor placement, may require significant initial setup.

Innovative Sensing Technologies

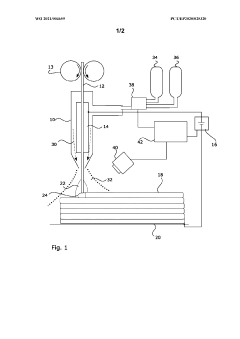

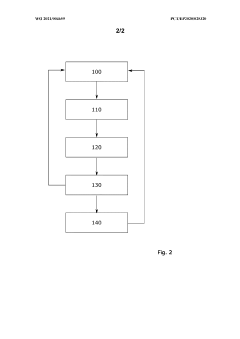

Dynamic mixture of shielding gases

PatentWO2021004659A1

Innovation

- A method for dynamic mixing of protective gases, where the composition is adjusted based on temperature readings to control thermal conductivity and ionization energy, using a control unit and gas mixing system to supply a mixture of gases such as argon and helium, allowing for real-time adjustment of gas proportions to manage heat input effectively.

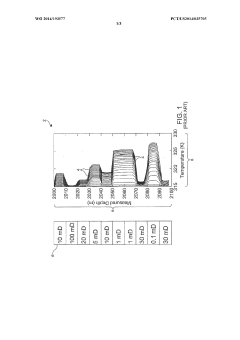

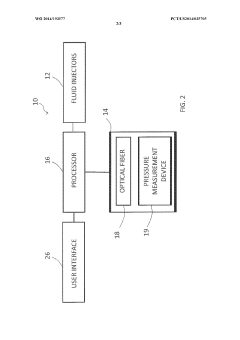

Method of hydraulic fracture identification using temperature

PatentWO2014193577A1

Innovation

- A method utilizing Distributed Temperature Sensing (DTS) technology with a sensor and processor to generate simulated temperature and pressure models before and after fluid injection, allowing for the identification of fractures by analyzing temperature characteristics during a shut-in period.

Welding Process Optimization

Welding process optimization plays a crucial role in achieving dynamic temperature mapping in gas weld formation. This optimization involves a systematic approach to enhance the quality, efficiency, and consistency of welding operations. By leveraging advanced technologies and data-driven methodologies, manufacturers can significantly improve their welding processes.

One of the key aspects of welding process optimization is the implementation of real-time monitoring systems. These systems utilize sensors and advanced imaging technologies to capture and analyze temperature distributions across the weld pool and surrounding areas. By continuously tracking temperature variations, welders can make informed decisions and adjustments on-the-fly, ensuring optimal heat input and distribution throughout the welding process.

Machine learning algorithms and artificial intelligence have revolutionized welding process optimization. These technologies enable the development of predictive models that can anticipate potential defects or inconsistencies in the weld formation. By analyzing historical data and real-time inputs, these models can suggest optimal welding parameters, such as travel speed, arc voltage, and gas flow rates, to achieve the desired temperature profile and weld quality.

Automation and robotics have also significantly contributed to welding process optimization. Robotic welding systems, equipped with advanced sensors and control mechanisms, can execute precise and repeatable welding operations. These systems can maintain consistent travel speeds and torch angles, ensuring uniform heat distribution and minimizing the risk of defects caused by human error or fatigue.

The integration of digital twin technology has further enhanced welding process optimization. By creating virtual replicas of the welding process, engineers can simulate various scenarios and optimize parameters before actual production. This approach allows for the identification of potential issues and the development of mitigation strategies, ultimately leading to improved weld quality and reduced production costs.

Adaptive control systems have emerged as a powerful tool in welding process optimization. These systems can automatically adjust welding parameters based on real-time feedback from sensors and monitoring devices. By continuously fine-tuning variables such as current, voltage, and wire feed speed, adaptive control systems can maintain optimal welding conditions even in the face of changing environmental factors or material variations.

In conclusion, welding process optimization is a multifaceted approach that combines advanced technologies, data analytics, and intelligent control systems to achieve dynamic temperature mapping in gas weld formation. By embracing these innovations, manufacturers can enhance weld quality, increase productivity, and reduce costs associated with rework and material waste.

One of the key aspects of welding process optimization is the implementation of real-time monitoring systems. These systems utilize sensors and advanced imaging technologies to capture and analyze temperature distributions across the weld pool and surrounding areas. By continuously tracking temperature variations, welders can make informed decisions and adjustments on-the-fly, ensuring optimal heat input and distribution throughout the welding process.

Machine learning algorithms and artificial intelligence have revolutionized welding process optimization. These technologies enable the development of predictive models that can anticipate potential defects or inconsistencies in the weld formation. By analyzing historical data and real-time inputs, these models can suggest optimal welding parameters, such as travel speed, arc voltage, and gas flow rates, to achieve the desired temperature profile and weld quality.

Automation and robotics have also significantly contributed to welding process optimization. Robotic welding systems, equipped with advanced sensors and control mechanisms, can execute precise and repeatable welding operations. These systems can maintain consistent travel speeds and torch angles, ensuring uniform heat distribution and minimizing the risk of defects caused by human error or fatigue.

The integration of digital twin technology has further enhanced welding process optimization. By creating virtual replicas of the welding process, engineers can simulate various scenarios and optimize parameters before actual production. This approach allows for the identification of potential issues and the development of mitigation strategies, ultimately leading to improved weld quality and reduced production costs.

Adaptive control systems have emerged as a powerful tool in welding process optimization. These systems can automatically adjust welding parameters based on real-time feedback from sensors and monitoring devices. By continuously fine-tuning variables such as current, voltage, and wire feed speed, adaptive control systems can maintain optimal welding conditions even in the face of changing environmental factors or material variations.

In conclusion, welding process optimization is a multifaceted approach that combines advanced technologies, data analytics, and intelligent control systems to achieve dynamic temperature mapping in gas weld formation. By embracing these innovations, manufacturers can enhance weld quality, increase productivity, and reduce costs associated with rework and material waste.

Safety and Quality Standards

Safety and quality standards play a crucial role in the implementation of dynamic temperature mapping in gas weld formation. These standards ensure the integrity of the welding process, protect workers, and maintain the quality of the final product. The American Welding Society (AWS) and the International Organization for Standardization (ISO) have established comprehensive guidelines for welding safety and quality control.

One of the primary safety concerns in gas welding is the management of heat and temperature. Dynamic temperature mapping systems must comply with OSHA regulations for heat exposure and personal protective equipment (PPE). These systems should be designed to provide real-time alerts when temperature thresholds are exceeded, allowing operators to take immediate corrective action.

Quality standards for dynamic temperature mapping focus on accuracy, precision, and reliability of temperature measurements. The ISO 17025 standard for testing and calibration laboratories provides a framework for ensuring the accuracy of temperature sensing equipment. Regular calibration and maintenance of these systems are essential to maintain compliance with this standard.

The AWS D1.1 Structural Welding Code - Steel includes provisions for temperature control during welding processes. Dynamic temperature mapping systems must be capable of meeting or exceeding these requirements to ensure weld quality. This includes maintaining interpass temperatures within specified ranges and documenting temperature profiles throughout the welding process.

Non-destructive testing (NDT) methods, such as thermography, are often used in conjunction with dynamic temperature mapping to verify weld quality. These methods must comply with standards such as ASNT SNT-TC-1A for personnel qualification and certification in NDT. Integration of NDT techniques with dynamic temperature mapping can enhance overall quality assurance in gas weld formation.

Data management and traceability are critical aspects of quality control in welding processes. Dynamic temperature mapping systems should adhere to ISO 9001 quality management principles, particularly in areas of data recording, analysis, and reporting. This ensures that temperature data can be reliably used for process optimization and quality verification.

As the technology for dynamic temperature mapping advances, standards organizations are working to develop specific guidelines for these systems. The development of new standards will likely focus on the integration of real-time monitoring, data analytics, and automated process control in welding applications. Industry stakeholders should stay informed about emerging standards to ensure compliance and maintain competitive advantage in the market.

One of the primary safety concerns in gas welding is the management of heat and temperature. Dynamic temperature mapping systems must comply with OSHA regulations for heat exposure and personal protective equipment (PPE). These systems should be designed to provide real-time alerts when temperature thresholds are exceeded, allowing operators to take immediate corrective action.

Quality standards for dynamic temperature mapping focus on accuracy, precision, and reliability of temperature measurements. The ISO 17025 standard for testing and calibration laboratories provides a framework for ensuring the accuracy of temperature sensing equipment. Regular calibration and maintenance of these systems are essential to maintain compliance with this standard.

The AWS D1.1 Structural Welding Code - Steel includes provisions for temperature control during welding processes. Dynamic temperature mapping systems must be capable of meeting or exceeding these requirements to ensure weld quality. This includes maintaining interpass temperatures within specified ranges and documenting temperature profiles throughout the welding process.

Non-destructive testing (NDT) methods, such as thermography, are often used in conjunction with dynamic temperature mapping to verify weld quality. These methods must comply with standards such as ASNT SNT-TC-1A for personnel qualification and certification in NDT. Integration of NDT techniques with dynamic temperature mapping can enhance overall quality assurance in gas weld formation.

Data management and traceability are critical aspects of quality control in welding processes. Dynamic temperature mapping systems should adhere to ISO 9001 quality management principles, particularly in areas of data recording, analysis, and reporting. This ensures that temperature data can be reliably used for process optimization and quality verification.

As the technology for dynamic temperature mapping advances, standards organizations are working to develop specific guidelines for these systems. The development of new standards will likely focus on the integration of real-time monitoring, data analytics, and automated process control in welding applications. Industry stakeholders should stay informed about emerging standards to ensure compliance and maintain competitive advantage in the market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!