Gas Welding Applications in Emergency Engineering Projects

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution

Gas welding has undergone significant evolution since its inception in the late 19th century. The technology's development can be traced through several key stages, each marked by important advancements that have shaped its applications in emergency engineering projects.

In the early 1900s, gas welding primarily utilized acetylene and oxygen gases. This combination provided a high-temperature flame suitable for melting and joining metals. The portability of gas welding equipment made it particularly valuable for emergency repairs and on-site construction projects.

The 1920s and 1930s saw improvements in gas regulators and torch designs, enhancing control over the welding flame. These advancements allowed for more precise welding operations, crucial in emergency situations where accuracy and speed are paramount.

During World War II, gas welding played a vital role in rapid repair and construction of military equipment and infrastructure. This period accelerated the development of more efficient and reliable gas welding techniques, particularly for field operations under challenging conditions.

The post-war era brought about the introduction of new fuel gases, such as propane and MAPP (methylacetylene-propadiene), offering alternatives to acetylene. These gases provided different flame characteristics and improved safety profiles, expanding the versatility of gas welding in emergency applications.

In the 1960s and 1970s, advancements in metallurgy led to the development of specialized filler materials and fluxes for gas welding. These innovations improved the quality of welds on a wider range of materials, enhancing the technique's applicability in diverse emergency engineering scenarios.

The late 20th century saw the integration of electronic controls and sensors into gas welding equipment. These technological additions improved gas flow regulation and monitoring, leading to more consistent weld quality and increased safety – critical factors in high-pressure emergency situations.

Recent developments have focused on enhancing the portability and efficiency of gas welding systems. Lightweight, compact designs have made the technology even more suitable for rapid deployment in emergency engineering projects, particularly in remote or difficult-to-access locations.

The evolution of gas welding has been characterized by continuous improvements in safety, efficiency, and versatility. These advancements have solidified its position as a valuable tool in emergency engineering, capable of providing quick, reliable solutions in challenging environments where other welding methods may be impractical or unavailable.

In the early 1900s, gas welding primarily utilized acetylene and oxygen gases. This combination provided a high-temperature flame suitable for melting and joining metals. The portability of gas welding equipment made it particularly valuable for emergency repairs and on-site construction projects.

The 1920s and 1930s saw improvements in gas regulators and torch designs, enhancing control over the welding flame. These advancements allowed for more precise welding operations, crucial in emergency situations where accuracy and speed are paramount.

During World War II, gas welding played a vital role in rapid repair and construction of military equipment and infrastructure. This period accelerated the development of more efficient and reliable gas welding techniques, particularly for field operations under challenging conditions.

The post-war era brought about the introduction of new fuel gases, such as propane and MAPP (methylacetylene-propadiene), offering alternatives to acetylene. These gases provided different flame characteristics and improved safety profiles, expanding the versatility of gas welding in emergency applications.

In the 1960s and 1970s, advancements in metallurgy led to the development of specialized filler materials and fluxes for gas welding. These innovations improved the quality of welds on a wider range of materials, enhancing the technique's applicability in diverse emergency engineering scenarios.

The late 20th century saw the integration of electronic controls and sensors into gas welding equipment. These technological additions improved gas flow regulation and monitoring, leading to more consistent weld quality and increased safety – critical factors in high-pressure emergency situations.

Recent developments have focused on enhancing the portability and efficiency of gas welding systems. Lightweight, compact designs have made the technology even more suitable for rapid deployment in emergency engineering projects, particularly in remote or difficult-to-access locations.

The evolution of gas welding has been characterized by continuous improvements in safety, efficiency, and versatility. These advancements have solidified its position as a valuable tool in emergency engineering, capable of providing quick, reliable solutions in challenging environments where other welding methods may be impractical or unavailable.

Emergency Project Demands

Emergency engineering projects often arise in response to natural disasters, industrial accidents, or critical infrastructure failures. These situations demand rapid and effective solutions, making gas welding a crucial technology due to its versatility and portability. The market for emergency engineering services is driven by the increasing frequency and severity of natural disasters, aging infrastructure in many developed countries, and the growing complexity of industrial facilities.

In disaster response scenarios, gas welding plays a vital role in repairing damaged structures, pipelines, and equipment. For instance, after hurricanes or earthquakes, gas welding is essential for quickly restoring water and gas supply lines, reinforcing damaged buildings, and repairing critical machinery. The demand for these services is particularly high in coastal regions prone to hurricanes and areas along seismic fault lines.

Industrial accidents, such as chemical spills or refinery fires, also create significant demand for emergency gas welding applications. These incidents require immediate containment and repair of damaged equipment to prevent further environmental damage and ensure worker safety. The petrochemical and manufacturing sectors are key drivers of this demand, especially in regions with high concentrations of industrial facilities.

Critical infrastructure failures, including bridge collapses, power plant malfunctions, or railway accidents, necessitate rapid welding solutions to restore essential services and transportation networks. Governments and infrastructure management companies are increasingly investing in emergency response capabilities, including mobile welding units equipped for gas welding, to address these challenges promptly.

The global market for emergency engineering services, including gas welding applications, is experiencing steady growth. Factors contributing to this trend include climate change-induced extreme weather events, urbanization leading to more complex infrastructure networks, and stricter safety regulations in industrial sectors. Additionally, the expansion of offshore oil and gas operations has created new demands for emergency welding services in remote and challenging environments.

Emerging technologies and smart city initiatives are also influencing the demand for emergency gas welding applications. As cities integrate more sensors and interconnected systems, the need for rapid repair and maintenance of these networks during emergencies is increasing. This trend is particularly evident in developing countries experiencing rapid urbanization and infrastructure development.

To meet these diverse emergency project demands, gas welding equipment manufacturers are focusing on developing more portable, efficient, and versatile welding systems. There is a growing emphasis on multi-fuel capabilities, allowing welders to operate in various conditions and with different available fuel sources. Additionally, the integration of digital technologies for remote diagnostics and guidance is becoming increasingly important in emergency response scenarios.

In disaster response scenarios, gas welding plays a vital role in repairing damaged structures, pipelines, and equipment. For instance, after hurricanes or earthquakes, gas welding is essential for quickly restoring water and gas supply lines, reinforcing damaged buildings, and repairing critical machinery. The demand for these services is particularly high in coastal regions prone to hurricanes and areas along seismic fault lines.

Industrial accidents, such as chemical spills or refinery fires, also create significant demand for emergency gas welding applications. These incidents require immediate containment and repair of damaged equipment to prevent further environmental damage and ensure worker safety. The petrochemical and manufacturing sectors are key drivers of this demand, especially in regions with high concentrations of industrial facilities.

Critical infrastructure failures, including bridge collapses, power plant malfunctions, or railway accidents, necessitate rapid welding solutions to restore essential services and transportation networks. Governments and infrastructure management companies are increasingly investing in emergency response capabilities, including mobile welding units equipped for gas welding, to address these challenges promptly.

The global market for emergency engineering services, including gas welding applications, is experiencing steady growth. Factors contributing to this trend include climate change-induced extreme weather events, urbanization leading to more complex infrastructure networks, and stricter safety regulations in industrial sectors. Additionally, the expansion of offshore oil and gas operations has created new demands for emergency welding services in remote and challenging environments.

Emerging technologies and smart city initiatives are also influencing the demand for emergency gas welding applications. As cities integrate more sensors and interconnected systems, the need for rapid repair and maintenance of these networks during emergencies is increasing. This trend is particularly evident in developing countries experiencing rapid urbanization and infrastructure development.

To meet these diverse emergency project demands, gas welding equipment manufacturers are focusing on developing more portable, efficient, and versatile welding systems. There is a growing emphasis on multi-fuel capabilities, allowing welders to operate in various conditions and with different available fuel sources. Additionally, the integration of digital technologies for remote diagnostics and guidance is becoming increasingly important in emergency response scenarios.

Technical Challenges

Gas welding applications in emergency engineering projects face several significant technical challenges that require innovative solutions and careful consideration. One of the primary obstacles is the need for rapid deployment and setup in unpredictable environments. Emergency situations often demand immediate action, leaving little time for extensive preparation or equipment calibration. This necessitates the development of portable and easily transportable gas welding systems that can be quickly assembled and operational in diverse settings.

The variability of working conditions presents another substantial challenge. Emergency projects may require welding operations in extreme weather conditions, confined spaces, or hazardous environments. These circumstances can affect the stability of the gas flame, the quality of the weld, and the safety of the operators. Engineers must devise adaptive techniques and specialized equipment to maintain consistent welding performance across a wide range of environmental factors.

Material compatibility is a critical concern in emergency welding applications. The diverse nature of emergency projects means that welders may encounter a variety of metals and alloys, some of which may be unfamiliar or challenging to work with using standard gas welding techniques. This requires a comprehensive understanding of metallurgy and the ability to quickly assess and adapt welding parameters to suit different materials.

Safety considerations pose significant technical challenges in emergency gas welding operations. The inherent risks associated with high-temperature flames and pressurized gas cylinders are amplified in urgent situations where standard safety protocols may be difficult to implement fully. Developing fail-safe mechanisms, improved personal protective equipment, and enhanced training protocols are essential to mitigate these risks.

The need for precision and quality control in emergency welding projects presents another technical hurdle. Time constraints and challenging working conditions can compromise weld integrity, potentially leading to structural failures or safety hazards. Implementing real-time quality assessment tools and non-destructive testing methods that can be applied quickly and effectively in the field is crucial for ensuring the reliability of emergency welds.

Energy efficiency and resource management are also significant challenges in emergency gas welding applications. The limited availability of gas supplies and the need for extended operation periods require the development of more efficient burner designs and gas management systems. This includes exploring alternative fuel mixtures and optimizing gas flow rates to maximize welding performance while minimizing resource consumption.

Lastly, the integration of digital technologies and automation into emergency gas welding processes presents both opportunities and challenges. While these advancements can enhance precision and efficiency, they must be robust enough to function reliably in unpredictable and harsh environments. Developing ruggedized control systems and user-friendly interfaces that can be operated by welders with varying levels of technical expertise is a key area for innovation in this field.

The variability of working conditions presents another substantial challenge. Emergency projects may require welding operations in extreme weather conditions, confined spaces, or hazardous environments. These circumstances can affect the stability of the gas flame, the quality of the weld, and the safety of the operators. Engineers must devise adaptive techniques and specialized equipment to maintain consistent welding performance across a wide range of environmental factors.

Material compatibility is a critical concern in emergency welding applications. The diverse nature of emergency projects means that welders may encounter a variety of metals and alloys, some of which may be unfamiliar or challenging to work with using standard gas welding techniques. This requires a comprehensive understanding of metallurgy and the ability to quickly assess and adapt welding parameters to suit different materials.

Safety considerations pose significant technical challenges in emergency gas welding operations. The inherent risks associated with high-temperature flames and pressurized gas cylinders are amplified in urgent situations where standard safety protocols may be difficult to implement fully. Developing fail-safe mechanisms, improved personal protective equipment, and enhanced training protocols are essential to mitigate these risks.

The need for precision and quality control in emergency welding projects presents another technical hurdle. Time constraints and challenging working conditions can compromise weld integrity, potentially leading to structural failures or safety hazards. Implementing real-time quality assessment tools and non-destructive testing methods that can be applied quickly and effectively in the field is crucial for ensuring the reliability of emergency welds.

Energy efficiency and resource management are also significant challenges in emergency gas welding applications. The limited availability of gas supplies and the need for extended operation periods require the development of more efficient burner designs and gas management systems. This includes exploring alternative fuel mixtures and optimizing gas flow rates to maximize welding performance while minimizing resource consumption.

Lastly, the integration of digital technologies and automation into emergency gas welding processes presents both opportunities and challenges. While these advancements can enhance precision and efficiency, they must be robust enough to function reliably in unpredictable and harsh environments. Developing ruggedized control systems and user-friendly interfaces that can be operated by welders with varying levels of technical expertise is a key area for innovation in this field.

Current Gas Welding Methods

01 Welding equipment and techniques

Gas welding involves specialized equipment and techniques for joining metals using heat from burning gases. This includes torches, regulators, and various types of flames for different welding applications. Proper setup and control of gas flow and flame characteristics are crucial for achieving high-quality welds.- Welding equipment and techniques: Gas welding involves specialized equipment and techniques for joining metals using heat generated by combustion of gases. This includes torches, regulators, and various gas mixtures to achieve optimal welding results for different materials and applications.

- Safety measures in gas welding: Implementing safety measures is crucial in gas welding operations. This includes proper handling of gas cylinders, use of personal protective equipment, and adherence to safety protocols to prevent accidents and ensure worker protection.

- Automation and robotics in gas welding: Advancements in automation and robotics have been applied to gas welding processes. This includes the development of automated welding systems, robotic welders, and computer-controlled equipment to improve precision, efficiency, and consistency in welding operations.

- Gas mixture optimization: Optimizing gas mixtures for specific welding applications is essential for achieving desired weld quality. This involves selecting appropriate combinations of fuel gases and oxidizers to control flame characteristics, heat input, and weld properties for various materials and joint configurations.

- Innovations in gas welding torches: Advancements in gas welding torch design focus on improving ergonomics, heat control, and gas flow. These innovations aim to enhance welding precision, reduce operator fatigue, and increase overall efficiency in gas welding processes.

02 Gas mixture optimization

The composition and ratio of gases used in welding significantly impact weld quality and efficiency. Research focuses on optimizing gas mixtures for specific materials and applications, considering factors such as heat input, penetration, and weld bead characteristics. This includes the use of shielding gases to protect the weld pool from atmospheric contamination.Expand Specific Solutions03 Automation and robotics in gas welding

Advancements in automation and robotics are being applied to gas welding processes to improve precision, consistency, and productivity. This includes the development of automated welding systems, robotic welding arms, and computer-controlled gas flow management for complex welding operations.Expand Specific Solutions04 Safety innovations

Safety is a critical aspect of gas welding. Innovations in this area include improved personal protective equipment, gas leak detection systems, and flame arrestors. These advancements aim to minimize risks associated with gas handling, high temperatures, and potential explosions in welding environments.Expand Specific Solutions05 Specialized gas welding applications

Gas welding techniques are being adapted for specialized applications in various industries. This includes underwater welding, high-pressure vessel welding, and joining of advanced materials. Research focuses on developing specific gas mixtures, equipment modifications, and welding procedures for these unique applications.Expand Specific Solutions

Key Industry Players

The gas welding applications market in emergency engineering projects is in a growth phase, driven by increasing demand for rapid infrastructure repairs and disaster response. The market size is expanding, particularly in developing regions prone to natural disasters. Technologically, gas welding remains a mature and reliable solution, with ongoing innovations in portability and efficiency. Key players like Illinois Tool Works Inc., Lincoln Global, Inc., and Hobart Brothers LLC dominate the market, leveraging their extensive experience and global presence. These companies are focusing on developing advanced welding equipment and consumables tailored for emergency applications, emphasizing speed, durability, and ease of use in challenging environments.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding solutions for emergency engineering projects. Their technology focuses on portable and rapid deployment systems, utilizing a mix of acetylene and oxygen for high-temperature welding. ITW's gas welding equipment features innovative torch designs that allow for precise flame control and reduced gas consumption. They have also implemented safety enhancements, such as flashback arrestors and ergonomic handles, to improve operator safety in high-pressure emergency situations[1]. ITW's gas welding systems are designed for quick setup and operation, crucial for time-sensitive emergency repairs[2].

Strengths: Rapid deployment, high-temperature capability, and enhanced safety features. Weaknesses: Reliance on gas supplies in emergency situations and potential for gas leaks in damaged infrastructure.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has pioneered gas welding technologies specifically tailored for emergency engineering applications. Their systems incorporate advanced gas mixing technologies that allow for optimal flame characteristics across various welding scenarios. Lincoln's emergency gas welding kits are designed for portability and durability, featuring reinforced casing and shock-resistant components to withstand harsh emergency environments[3]. The company has also developed specialized alloys for filler rods that enhance weld strength and corrosion resistance in emergency repairs. Lincoln's gas welding equipment includes smart pressure regulators that automatically adjust gas flow based on environmental conditions, ensuring consistent weld quality even in challenging situations[4].

Strengths: Portable and durable equipment, specialized alloys for emergency repairs, and smart pressure regulation. Weaknesses: Higher initial cost compared to basic systems and potential complexity for less experienced operators.

Innovative Welding Techniques

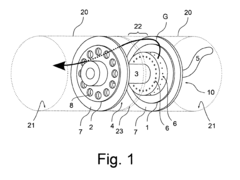

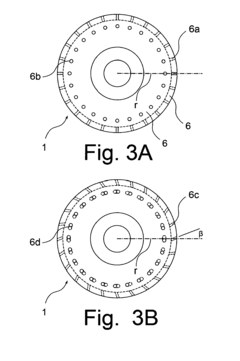

Gas emitting device for internal pipe sections with at least one gas nozzle arrangement ; welding method using such gas emitting device

PatentInactiveEP2647468A1

Innovation

- A gas application device with a nozzle arrangement that generates a defined, laminar gas flow by directed bores, allowing for focused gas delivery to the pipe interior, and can be adapted for use in bent pipes through adjustable design and sealing features, ensuring effective particle removal and preventing temper color formation.

Method,welding flux and device for electroslag welding

PatentWO1982000016A1

Innovation

- Incorporating internal gas channels in the welding device that allow for gas removal and exhaust, enabling precise control of the gas composition and flow, which enhances the welding process stability and efficiency by removing gases and maintaining a stable weld bath.

Safety Regulations

Safety regulations play a crucial role in gas welding applications for emergency engineering projects. These regulations are designed to protect workers, the public, and the environment from potential hazards associated with gas welding operations in high-pressure situations.

One of the primary safety concerns in gas welding is the handling and storage of compressed gases. Proper storage facilities must be provided for gas cylinders, ensuring they are secured upright and protected from physical damage. Cylinders should be stored in well-ventilated areas away from heat sources and flammable materials. Regular inspections of cylinders, valves, and regulators are mandatory to prevent leaks and equipment failures.

Personal protective equipment (PPE) is essential for workers engaged in gas welding activities during emergency projects. This includes flame-resistant clothing, safety glasses or goggles, welding helmets with appropriate shade lenses, and leather gloves. Respiratory protection may also be necessary when working in confined spaces or areas with poor ventilation.

Fire prevention measures are paramount in gas welding operations. A designated fire watch should be assigned to monitor the work area for potential fire hazards. Fire extinguishers must be readily available, and workers should be trained in their proper use. Hot work permits are typically required for gas welding in emergency situations, ensuring that all necessary precautions are taken before work begins.

Ventilation is another critical aspect of safety regulations for gas welding. Adequate ventilation must be provided to prevent the accumulation of toxic fumes and gases. In emergency projects, portable ventilation systems may be necessary to ensure proper air circulation in confined or poorly ventilated areas.

Electrical safety is also a concern, particularly when using electric arc welding equipment in conjunction with gas welding. Proper grounding and insulation of electrical equipment are essential to prevent electric shock and fires. Regular maintenance and inspection of electrical components are required to ensure their safe operation.

Training and certification requirements for workers involved in gas welding operations are typically mandated by safety regulations. This includes proper handling of equipment, recognition of potential hazards, and emergency response procedures. In emergency engineering projects, workers may need additional training to address unique challenges and risks associated with the specific situation.

Safety regulations also address the proper disposal of welding waste materials, including spent gas cylinders and contaminated materials. Proper labeling and segregation of hazardous waste are essential to prevent environmental contamination and ensure worker safety during disposal processes.

Emergency response plans are a critical component of safety regulations for gas welding in emergency projects. These plans should outline procedures for dealing with gas leaks, fires, explosions, and other potential emergencies. Regular drills and training exercises should be conducted to ensure all workers are familiar with emergency protocols.

One of the primary safety concerns in gas welding is the handling and storage of compressed gases. Proper storage facilities must be provided for gas cylinders, ensuring they are secured upright and protected from physical damage. Cylinders should be stored in well-ventilated areas away from heat sources and flammable materials. Regular inspections of cylinders, valves, and regulators are mandatory to prevent leaks and equipment failures.

Personal protective equipment (PPE) is essential for workers engaged in gas welding activities during emergency projects. This includes flame-resistant clothing, safety glasses or goggles, welding helmets with appropriate shade lenses, and leather gloves. Respiratory protection may also be necessary when working in confined spaces or areas with poor ventilation.

Fire prevention measures are paramount in gas welding operations. A designated fire watch should be assigned to monitor the work area for potential fire hazards. Fire extinguishers must be readily available, and workers should be trained in their proper use. Hot work permits are typically required for gas welding in emergency situations, ensuring that all necessary precautions are taken before work begins.

Ventilation is another critical aspect of safety regulations for gas welding. Adequate ventilation must be provided to prevent the accumulation of toxic fumes and gases. In emergency projects, portable ventilation systems may be necessary to ensure proper air circulation in confined or poorly ventilated areas.

Electrical safety is also a concern, particularly when using electric arc welding equipment in conjunction with gas welding. Proper grounding and insulation of electrical equipment are essential to prevent electric shock and fires. Regular maintenance and inspection of electrical components are required to ensure their safe operation.

Training and certification requirements for workers involved in gas welding operations are typically mandated by safety regulations. This includes proper handling of equipment, recognition of potential hazards, and emergency response procedures. In emergency engineering projects, workers may need additional training to address unique challenges and risks associated with the specific situation.

Safety regulations also address the proper disposal of welding waste materials, including spent gas cylinders and contaminated materials. Proper labeling and segregation of hazardous waste are essential to prevent environmental contamination and ensure worker safety during disposal processes.

Emergency response plans are a critical component of safety regulations for gas welding in emergency projects. These plans should outline procedures for dealing with gas leaks, fires, explosions, and other potential emergencies. Regular drills and training exercises should be conducted to ensure all workers are familiar with emergency protocols.

Environmental Impact

Gas welding applications in emergency engineering projects can have significant environmental impacts that need to be carefully considered and mitigated. The combustion process inherent in gas welding releases various pollutants into the atmosphere, including carbon dioxide, nitrogen oxides, and particulate matter. These emissions contribute to air pollution and can have adverse effects on local air quality, especially in confined spaces or areas with poor ventilation.

The use of shielding gases in gas welding processes, such as argon or helium, may also have environmental implications. While these gases are generally inert, their production and transportation contribute to the overall carbon footprint of the welding operation. Additionally, the potential for gas leaks during storage or use poses risks to both human health and the environment.

Waste generation is another environmental concern associated with gas welding in emergency projects. Welding operations produce slag, spatter, and used welding rods, which require proper disposal to prevent soil and water contamination. The improper handling of these waste materials can lead to long-term environmental degradation in the project area.

Energy consumption is a significant factor in the environmental impact of gas welding. The high temperatures required for welding consume substantial amounts of fuel, contributing to overall energy usage and associated greenhouse gas emissions. In emergency situations, where power sources may be limited, the reliance on gas welding can strain available resources and increase the project's environmental footprint.

Noise pollution is an often-overlooked environmental impact of gas welding operations. The loud sounds produced during welding can disturb local wildlife and affect nearby communities, particularly in sensitive ecological areas or densely populated urban environments where emergency engineering projects may take place.

The potential for accidental fires or explosions associated with gas welding poses risks not only to human safety but also to the surrounding environment. Such incidents can lead to habitat destruction, soil contamination, and the release of harmful substances into ecosystems.

To mitigate these environmental impacts, emergency engineering projects employing gas welding should implement best practices such as using efficient welding equipment, proper ventilation systems, and appropriate waste management protocols. Additionally, considering alternative welding technologies or methods that have lower environmental impacts may be beneficial in certain emergency scenarios, balancing the need for rapid response with environmental stewardship.

The use of shielding gases in gas welding processes, such as argon or helium, may also have environmental implications. While these gases are generally inert, their production and transportation contribute to the overall carbon footprint of the welding operation. Additionally, the potential for gas leaks during storage or use poses risks to both human health and the environment.

Waste generation is another environmental concern associated with gas welding in emergency projects. Welding operations produce slag, spatter, and used welding rods, which require proper disposal to prevent soil and water contamination. The improper handling of these waste materials can lead to long-term environmental degradation in the project area.

Energy consumption is a significant factor in the environmental impact of gas welding. The high temperatures required for welding consume substantial amounts of fuel, contributing to overall energy usage and associated greenhouse gas emissions. In emergency situations, where power sources may be limited, the reliance on gas welding can strain available resources and increase the project's environmental footprint.

Noise pollution is an often-overlooked environmental impact of gas welding operations. The loud sounds produced during welding can disturb local wildlife and affect nearby communities, particularly in sensitive ecological areas or densely populated urban environments where emergency engineering projects may take place.

The potential for accidental fires or explosions associated with gas welding poses risks not only to human safety but also to the surrounding environment. Such incidents can lead to habitat destruction, soil contamination, and the release of harmful substances into ecosystems.

To mitigate these environmental impacts, emergency engineering projects employing gas welding should implement best practices such as using efficient welding equipment, proper ventilation systems, and appropriate waste management protocols. Additionally, considering alternative welding technologies or methods that have lower environmental impacts may be beneficial in certain emergency scenarios, balancing the need for rapid response with environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!