Exploring Gas Welding Applications in Offshore Engineering

AUG 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding in Offshore: Background and Objectives

Gas welding has been a cornerstone of offshore engineering for decades, playing a crucial role in the construction, maintenance, and repair of offshore structures. The technology's evolution has been closely tied to the growth of the offshore industry, particularly in oil and gas exploration and production. As offshore operations have expanded into deeper waters and more challenging environments, the demands on welding technologies have intensified, driving continuous innovation in gas welding techniques.

The primary objective of exploring gas welding applications in offshore engineering is to enhance the safety, efficiency, and durability of offshore structures. This exploration aims to address the unique challenges posed by the marine environment, including high-pressure conditions, corrosive saltwater exposure, and dynamic loads from waves and currents. By improving gas welding techniques, offshore engineers seek to extend the lifespan of offshore installations, reduce maintenance costs, and minimize downtime.

Historically, gas welding in offshore applications has undergone significant transformations. Early offshore structures relied heavily on manual gas welding techniques, which were time-consuming and often limited by weather conditions. As the industry progressed, automated and semi-automated gas welding systems were introduced, allowing for more precise and consistent welds even in challenging offshore conditions.

The development of specialized gas mixtures for offshore welding has been a key focus area. These mixtures are designed to provide optimal arc stability and weld quality while minimizing the risk of defects such as porosity and hydrogen embrittlement, which are particularly problematic in marine environments. Additionally, advancements in shielding gas technologies have improved the protection of the weld pool from atmospheric contamination, a critical factor in ensuring weld integrity in offshore applications.

Recent technological trends in offshore gas welding include the integration of digital monitoring and control systems. These innovations allow for real-time adjustment of welding parameters based on environmental conditions and material properties, ensuring consistent weld quality across diverse offshore scenarios. Furthermore, the development of portable and lightweight gas welding equipment has expanded the range of applications, enabling repairs and modifications in previously inaccessible areas of offshore structures.

As the offshore industry continues to push boundaries, exploring new frontiers such as ultra-deepwater installations and renewable energy structures, the role of gas welding in offshore engineering is evolving. Current research focuses on developing gas welding techniques that can operate effectively at extreme depths, withstand higher pressures, and accommodate new materials being introduced in offshore construction, such as high-strength steels and composite materials.

The primary objective of exploring gas welding applications in offshore engineering is to enhance the safety, efficiency, and durability of offshore structures. This exploration aims to address the unique challenges posed by the marine environment, including high-pressure conditions, corrosive saltwater exposure, and dynamic loads from waves and currents. By improving gas welding techniques, offshore engineers seek to extend the lifespan of offshore installations, reduce maintenance costs, and minimize downtime.

Historically, gas welding in offshore applications has undergone significant transformations. Early offshore structures relied heavily on manual gas welding techniques, which were time-consuming and often limited by weather conditions. As the industry progressed, automated and semi-automated gas welding systems were introduced, allowing for more precise and consistent welds even in challenging offshore conditions.

The development of specialized gas mixtures for offshore welding has been a key focus area. These mixtures are designed to provide optimal arc stability and weld quality while minimizing the risk of defects such as porosity and hydrogen embrittlement, which are particularly problematic in marine environments. Additionally, advancements in shielding gas technologies have improved the protection of the weld pool from atmospheric contamination, a critical factor in ensuring weld integrity in offshore applications.

Recent technological trends in offshore gas welding include the integration of digital monitoring and control systems. These innovations allow for real-time adjustment of welding parameters based on environmental conditions and material properties, ensuring consistent weld quality across diverse offshore scenarios. Furthermore, the development of portable and lightweight gas welding equipment has expanded the range of applications, enabling repairs and modifications in previously inaccessible areas of offshore structures.

As the offshore industry continues to push boundaries, exploring new frontiers such as ultra-deepwater installations and renewable energy structures, the role of gas welding in offshore engineering is evolving. Current research focuses on developing gas welding techniques that can operate effectively at extreme depths, withstand higher pressures, and accommodate new materials being introduced in offshore construction, such as high-strength steels and composite materials.

Offshore Industry Demand for Gas Welding

The offshore industry's demand for gas welding has been steadily increasing due to the unique challenges and requirements of marine environments. As offshore structures become more complex and expansive, the need for reliable and efficient welding techniques has grown significantly. Gas welding, particularly in its advanced forms, offers several advantages that make it particularly suitable for offshore applications.

One of the primary drivers for gas welding demand in offshore engineering is its versatility in handling various materials commonly used in marine structures. Steel, aluminum, and other alloys used in offshore platforms, pipelines, and vessels require specialized welding techniques to ensure structural integrity in harsh marine conditions. Gas welding provides the flexibility to work with these diverse materials, often in challenging positions and confined spaces typical of offshore installations.

The ability of gas welding to operate independently of electrical power sources is another crucial factor driving its demand in offshore environments. In remote offshore locations or during power outages, gas welding equipment can continue to function, ensuring critical repairs and maintenance can be carried out without interruption. This reliability is essential for maintaining the safety and operational continuity of offshore facilities.

Furthermore, the offshore industry's increasing focus on environmental sustainability has led to a growing interest in gas welding techniques that minimize emissions and reduce the carbon footprint of welding operations. Advanced gas welding methods that optimize fuel efficiency and reduce waste are becoming increasingly sought after by offshore operators looking to meet stringent environmental regulations.

The expansion of deep-water offshore projects has also contributed to the rising demand for specialized gas welding applications. As exploration and production activities move into deeper waters, welding techniques must adapt to more extreme pressure conditions and corrosive environments. Gas welding technologies that can maintain weld quality and integrity under these challenging conditions are in high demand.

Maintenance and repair operations in the offshore industry represent another significant area driving the demand for gas welding. The corrosive nature of the marine environment necessitates frequent maintenance of offshore structures. Gas welding's portability and ability to perform quick, high-quality repairs on-site make it an invaluable tool for extending the lifespan of offshore assets and minimizing downtime.

As the offshore industry continues to evolve, with new technologies and materials being introduced, the demand for advanced gas welding techniques is expected to grow further. Research and development efforts are focusing on improving the efficiency, precision, and automation capabilities of gas welding processes to meet the increasingly complex needs of offshore engineering projects.

One of the primary drivers for gas welding demand in offshore engineering is its versatility in handling various materials commonly used in marine structures. Steel, aluminum, and other alloys used in offshore platforms, pipelines, and vessels require specialized welding techniques to ensure structural integrity in harsh marine conditions. Gas welding provides the flexibility to work with these diverse materials, often in challenging positions and confined spaces typical of offshore installations.

The ability of gas welding to operate independently of electrical power sources is another crucial factor driving its demand in offshore environments. In remote offshore locations or during power outages, gas welding equipment can continue to function, ensuring critical repairs and maintenance can be carried out without interruption. This reliability is essential for maintaining the safety and operational continuity of offshore facilities.

Furthermore, the offshore industry's increasing focus on environmental sustainability has led to a growing interest in gas welding techniques that minimize emissions and reduce the carbon footprint of welding operations. Advanced gas welding methods that optimize fuel efficiency and reduce waste are becoming increasingly sought after by offshore operators looking to meet stringent environmental regulations.

The expansion of deep-water offshore projects has also contributed to the rising demand for specialized gas welding applications. As exploration and production activities move into deeper waters, welding techniques must adapt to more extreme pressure conditions and corrosive environments. Gas welding technologies that can maintain weld quality and integrity under these challenging conditions are in high demand.

Maintenance and repair operations in the offshore industry represent another significant area driving the demand for gas welding. The corrosive nature of the marine environment necessitates frequent maintenance of offshore structures. Gas welding's portability and ability to perform quick, high-quality repairs on-site make it an invaluable tool for extending the lifespan of offshore assets and minimizing downtime.

As the offshore industry continues to evolve, with new technologies and materials being introduced, the demand for advanced gas welding techniques is expected to grow further. Research and development efforts are focusing on improving the efficiency, precision, and automation capabilities of gas welding processes to meet the increasingly complex needs of offshore engineering projects.

Current Challenges in Offshore Gas Welding

Gas welding in offshore engineering faces numerous challenges due to the harsh marine environment and complex operational conditions. One of the primary obstacles is the corrosive nature of seawater, which can significantly impact the integrity of welded joints. The constant exposure to salt spray and high humidity accelerates corrosion processes, potentially leading to premature failure of welded structures.

The dynamic nature of offshore platforms presents another significant challenge. Constant movement and vibrations caused by waves and wind can affect the stability of the welding process, making it difficult to maintain consistent weld quality. This is particularly problematic for precision welding tasks that require high accuracy and reliability.

Environmental factors such as strong winds and extreme temperatures also pose substantial difficulties for offshore gas welding operations. Wind can disrupt the shielding gas flow, compromising weld quality and increasing the risk of defects. Temperature fluctuations can affect the properties of welding materials and the behavior of molten metal, necessitating careful control of welding parameters.

Safety concerns are paramount in offshore environments, where the risks associated with gas welding are amplified. The presence of flammable materials and confined spaces on offshore platforms requires stringent safety protocols and specialized equipment. Ensuring proper ventilation and managing the risks of fire and explosion are critical challenges that must be addressed.

The logistics of gas welding in offshore settings present additional hurdles. Transporting and storing welding gases safely on offshore platforms can be complex and costly. Limited space and weight restrictions may constrain the types and quantities of equipment that can be used, potentially limiting welding capabilities.

Underwater welding, a specialized application in offshore engineering, introduces its own set of challenges. The high pressure and low visibility underwater environment make it extremely difficult to perform gas welding operations. Special techniques and equipment are required, and the safety risks for divers performing underwater welding are significant.

The need for highly skilled welders trained in offshore operations is another critical challenge. The unique demands of offshore welding require specialized expertise that is often in short supply. Training and retaining qualified personnel for these challenging roles can be difficult and expensive for offshore engineering companies.

Regulatory compliance adds another layer of complexity to offshore gas welding. Strict industry standards and environmental regulations govern offshore operations, requiring careful adherence to specific welding procedures and quality control measures. Meeting these standards while maintaining operational efficiency is an ongoing challenge for offshore engineering projects.

The dynamic nature of offshore platforms presents another significant challenge. Constant movement and vibrations caused by waves and wind can affect the stability of the welding process, making it difficult to maintain consistent weld quality. This is particularly problematic for precision welding tasks that require high accuracy and reliability.

Environmental factors such as strong winds and extreme temperatures also pose substantial difficulties for offshore gas welding operations. Wind can disrupt the shielding gas flow, compromising weld quality and increasing the risk of defects. Temperature fluctuations can affect the properties of welding materials and the behavior of molten metal, necessitating careful control of welding parameters.

Safety concerns are paramount in offshore environments, where the risks associated with gas welding are amplified. The presence of flammable materials and confined spaces on offshore platforms requires stringent safety protocols and specialized equipment. Ensuring proper ventilation and managing the risks of fire and explosion are critical challenges that must be addressed.

The logistics of gas welding in offshore settings present additional hurdles. Transporting and storing welding gases safely on offshore platforms can be complex and costly. Limited space and weight restrictions may constrain the types and quantities of equipment that can be used, potentially limiting welding capabilities.

Underwater welding, a specialized application in offshore engineering, introduces its own set of challenges. The high pressure and low visibility underwater environment make it extremely difficult to perform gas welding operations. Special techniques and equipment are required, and the safety risks for divers performing underwater welding are significant.

The need for highly skilled welders trained in offshore operations is another critical challenge. The unique demands of offshore welding require specialized expertise that is often in short supply. Training and retaining qualified personnel for these challenging roles can be difficult and expensive for offshore engineering companies.

Regulatory compliance adds another layer of complexity to offshore gas welding. Strict industry standards and environmental regulations govern offshore operations, requiring careful adherence to specific welding procedures and quality control measures. Meeting these standards while maintaining operational efficiency is an ongoing challenge for offshore engineering projects.

Existing Gas Welding Solutions for Offshore Use

01 Welding torch improvements

Advancements in gas welding torch design focus on enhancing efficiency, safety, and precision. These improvements include optimized nozzle configurations, ergonomic handle designs, and integrated cooling systems. Such enhancements contribute to better flame control, reduced operator fatigue, and increased welding quality across various applications.- Welding torch design and improvements: Various innovations in gas welding torch design focus on improving efficiency, safety, and ease of use. These improvements include enhanced gas flow control, ergonomic handle designs, and integrated cooling systems. Such advancements aim to provide better control over the welding process and reduce operator fatigue during prolonged use.

- Gas mixture control and regulation: Precise control and regulation of gas mixtures are crucial for optimal welding performance. Innovations in this area include advanced gas flow meters, automated mixing systems, and digital control interfaces. These technologies allow for more accurate gas ratios, resulting in improved weld quality and consistency across different materials and thicknesses.

- Safety features in gas welding equipment: Enhanced safety features are being incorporated into gas welding equipment to prevent accidents and protect operators. These include automatic shut-off valves, flame arrestors, and improved pressure regulators. Some designs also integrate sensors to detect gas leaks or abnormal operating conditions, further improving workplace safety.

- Portable and compact gas welding systems: Development of portable and compact gas welding systems caters to the need for on-site welding and repairs. These systems often feature integrated gas cylinders, lightweight materials, and modular designs. Such innovations make gas welding more accessible for field work and small-scale operations.

- Automation and robotics in gas welding: Integration of automation and robotics in gas welding processes aims to improve precision, consistency, and productivity. These systems may include computer-controlled torch movements, automated gas flow adjustments, and real-time monitoring of weld quality. Such advancements are particularly beneficial for large-scale manufacturing and repetitive welding tasks.

02 Gas mixture control systems

Innovative gas mixture control systems for welding applications enable precise regulation of fuel gas and oxygen ratios. These systems incorporate advanced sensors, flow meters, and digital controls to maintain optimal flame characteristics. By ensuring consistent gas mixtures, these technologies improve weld quality, reduce material waste, and enhance overall process efficiency.Expand Specific Solutions03 Safety mechanisms in gas welding equipment

Enhanced safety features in gas welding equipment include improved flashback arrestors, automatic shut-off valves, and pressure regulators. These mechanisms help prevent accidents, minimize the risk of gas leaks, and protect operators from potential hazards. Implementation of these safety features contributes to a safer working environment and compliance with industry standards.Expand Specific Solutions04 Portable gas welding systems

Development of compact and portable gas welding systems caters to on-site welding needs and improves mobility. These systems integrate lightweight materials, modular designs, and efficient gas storage solutions. Portable gas welding equipment enables versatile applications in various industries, including construction, maintenance, and repair services.Expand Specific Solutions05 Automated gas welding processes

Automation in gas welding processes incorporates robotics, computer-controlled systems, and sensor technologies. These advancements enable precise control of welding parameters, consistent weld quality, and increased productivity. Automated gas welding systems find applications in manufacturing, pipeline construction, and other industries requiring high-volume welding operations.Expand Specific Solutions

Key Players in Offshore Gas Welding Technology

The gas welding market in offshore engineering is in a mature stage, with a global market size estimated to be in the billions of dollars. The technology is well-established, with major players like Illinois Tool Works Inc., China National Offshore Oil Corp., and Offshore Oil Engineering Co., Ltd. leading the industry. These companies have developed advanced welding techniques and equipment specifically tailored for offshore applications. The competitive landscape is characterized by ongoing innovation in welding materials, automation, and safety features to meet the demanding requirements of offshore environments. While the market is relatively consolidated among large corporations, there is still room for specialized niche players and technological advancements to improve efficiency and reliability in extreme offshore conditions.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding technologies specifically tailored for offshore engineering applications. Their innovative approach combines traditional gas welding techniques with modern materials and control systems. ITW's gas welding solutions for offshore use feature precision gas flow control, allowing for optimal flame characteristics in challenging marine environments [1]. The company has also introduced specialized filler materials designed to withstand corrosive saltwater conditions, enhancing weld durability in offshore structures [3]. ITW's gas welding equipment incorporates advanced safety features, such as automatic shut-off valves and flame failure detection, crucial for offshore operations where safety is paramount [5].

Strengths: Specialized offshore-grade materials, advanced safety features, and precision control systems. Weaknesses: May be less suitable for very deep underwater applications compared to some alternative welding methods.

China National Offshore Oil Corp.

Technical Solution: China National Offshore Oil Corp. (CNOOC) has implemented gas welding techniques in its offshore engineering projects, focusing on adaptability to various marine conditions. CNOOC's approach integrates gas welding with other joining methods to optimize offshore structure fabrication. The company has developed specialized gas welding procedures for different zones of offshore platforms, considering factors such as water depth and environmental exposure [2]. CNOOC's gas welding applications include the use of flux-cored wires designed for offshore environments, improving weld quality and corrosion resistance in seawater [4]. The corporation has also invested in training programs to enhance the skills of welders in offshore gas welding techniques, ensuring high-quality welds in challenging marine conditions [6].

Strengths: Comprehensive approach integrating multiple welding techniques, specialized procedures for different offshore zones. Weaknesses: May face challenges in very deep water applications where gas welding has limitations.

Innovations in Offshore Gas Welding Techniques

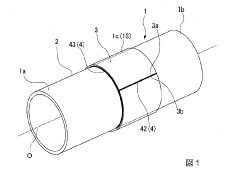

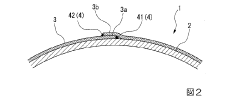

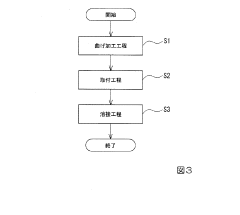

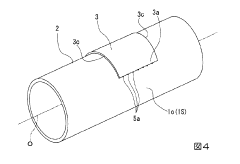

Method of manufacturing component for offshore structure, component for offshore structure

PatentInactiveJP2020044563A

Innovation

- Employing MIG or MAG welding to fix a plate-shaped austenitic stainless steel coating onto steel materials, using temporary attachment and TIG welding at spaced locations to facilitate easy and cost-effective welding without large-scale equipment, and compensating for chromium and nickel loss with additional deposition during welding.

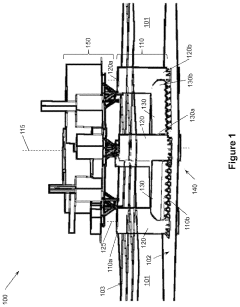

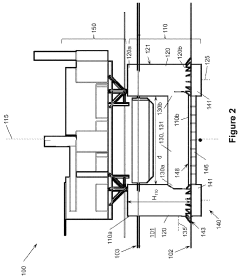

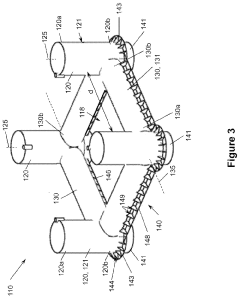

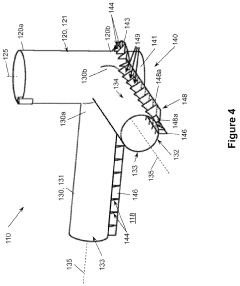

Offshore Steel Structure with Integral Anti-Scour and Foundation Skirts

PatentActiveUS20210032827A1

Innovation

- The design incorporates an adjustably buoyant hull with integral anti-scour plates and foundation skirts that increase contact area with the seafloor, allowing self-weighting and self-flotation for easier installation and scour prevention, eliminating the need for specialized vessels.

Environmental Impact of Offshore Gas Welding

Gas welding in offshore engineering presents significant environmental challenges that require careful consideration and mitigation strategies. The process releases various pollutants into the marine environment, including metal fumes, particulate matter, and greenhouse gases. These emissions can have detrimental effects on marine ecosystems, air quality, and contribute to climate change.

The release of metal fumes during offshore gas welding is a primary concern. These fumes contain toxic metals such as manganese, chromium, and nickel, which can accumulate in marine organisms and potentially enter the food chain. This bioaccumulation poses risks to marine life and may ultimately affect human health through seafood consumption. Additionally, the dispersion of these fumes can impact air quality in the surrounding areas, potentially affecting workers on offshore platforms and nearby coastal communities.

Particulate matter generated during welding operations can also have adverse effects on marine environments. These particles can settle on the ocean surface or be suspended in the water column, reducing light penetration and potentially affecting photosynthetic organisms. Furthermore, the deposition of particulate matter on the seafloor can alter benthic habitats and disrupt local ecosystems.

The combustion of gases used in welding processes contributes to greenhouse gas emissions, primarily carbon dioxide and nitrous oxides. While the scale of emissions from individual welding operations may be relatively small, the cumulative impact of numerous offshore projects can be significant. These emissions contribute to global climate change, which has far-reaching consequences for marine ecosystems, including ocean acidification, sea-level rise, and changes in water temperature and circulation patterns.

To mitigate these environmental impacts, the offshore industry has been developing and implementing various strategies. Advanced filtration systems and fume extraction technologies are being employed to reduce the release of metal fumes and particulate matter into the environment. Some companies are exploring the use of alternative welding techniques, such as friction stir welding or laser welding, which produce fewer emissions and pollutants.

Improved waste management practices are also being implemented to minimize the discharge of welding-related materials into the marine environment. This includes proper disposal of welding rods, flux, and other consumables, as well as the collection and treatment of contaminated water used in cooling processes.

Regulatory bodies are increasingly focusing on the environmental aspects of offshore operations, including welding activities. Stricter emission standards and monitoring requirements are being implemented in many jurisdictions, pushing the industry towards more environmentally friendly practices. Environmental impact assessments are now commonly required before the commencement of offshore projects, ensuring that potential risks are identified and mitigated.

Research and development efforts are ongoing to further reduce the environmental footprint of offshore gas welding. This includes the development of cleaner welding gases, more efficient welding equipment, and improved welding techniques that minimize emissions and waste. Additionally, there is growing interest in the use of renewable energy sources to power welding equipment on offshore platforms, further reducing the overall environmental impact of these operations.

The release of metal fumes during offshore gas welding is a primary concern. These fumes contain toxic metals such as manganese, chromium, and nickel, which can accumulate in marine organisms and potentially enter the food chain. This bioaccumulation poses risks to marine life and may ultimately affect human health through seafood consumption. Additionally, the dispersion of these fumes can impact air quality in the surrounding areas, potentially affecting workers on offshore platforms and nearby coastal communities.

Particulate matter generated during welding operations can also have adverse effects on marine environments. These particles can settle on the ocean surface or be suspended in the water column, reducing light penetration and potentially affecting photosynthetic organisms. Furthermore, the deposition of particulate matter on the seafloor can alter benthic habitats and disrupt local ecosystems.

The combustion of gases used in welding processes contributes to greenhouse gas emissions, primarily carbon dioxide and nitrous oxides. While the scale of emissions from individual welding operations may be relatively small, the cumulative impact of numerous offshore projects can be significant. These emissions contribute to global climate change, which has far-reaching consequences for marine ecosystems, including ocean acidification, sea-level rise, and changes in water temperature and circulation patterns.

To mitigate these environmental impacts, the offshore industry has been developing and implementing various strategies. Advanced filtration systems and fume extraction technologies are being employed to reduce the release of metal fumes and particulate matter into the environment. Some companies are exploring the use of alternative welding techniques, such as friction stir welding or laser welding, which produce fewer emissions and pollutants.

Improved waste management practices are also being implemented to minimize the discharge of welding-related materials into the marine environment. This includes proper disposal of welding rods, flux, and other consumables, as well as the collection and treatment of contaminated water used in cooling processes.

Regulatory bodies are increasingly focusing on the environmental aspects of offshore operations, including welding activities. Stricter emission standards and monitoring requirements are being implemented in many jurisdictions, pushing the industry towards more environmentally friendly practices. Environmental impact assessments are now commonly required before the commencement of offshore projects, ensuring that potential risks are identified and mitigated.

Research and development efforts are ongoing to further reduce the environmental footprint of offshore gas welding. This includes the development of cleaner welding gases, more efficient welding equipment, and improved welding techniques that minimize emissions and waste. Additionally, there is growing interest in the use of renewable energy sources to power welding equipment on offshore platforms, further reducing the overall environmental impact of these operations.

Safety Regulations in Offshore Gas Welding

Safety regulations in offshore gas welding are of paramount importance due to the high-risk nature of offshore operations. These regulations are designed to protect workers, equipment, and the environment from potential hazards associated with gas welding in marine settings. The offshore industry adheres to stringent safety standards set by international organizations and national regulatory bodies.

One of the primary safety concerns in offshore gas welding is the risk of fire and explosion. To mitigate this risk, regulations mandate the use of intrinsically safe equipment and the implementation of strict fire prevention measures. This includes the proper storage and handling of gas cylinders, regular maintenance of welding equipment, and the establishment of designated welding areas with appropriate fire suppression systems.

Personal protective equipment (PPE) requirements are another crucial aspect of safety regulations. Welders must wear flame-resistant clothing, protective eyewear, and respiratory protection to guard against harmful fumes and radiation. Additionally, regulations often specify the need for proper ventilation systems to remove welding fumes and maintain air quality in confined spaces typical of offshore structures.

The unique challenges of the offshore environment necessitate specific safety protocols. Regulations address issues such as working at heights, marine weather conditions, and the potential for gas leaks in enclosed spaces. Emergency response plans and evacuation procedures are mandatory, with regular drills conducted to ensure preparedness.

Certification and training requirements for offshore welders are typically more rigorous than those for onshore operations. Welders must demonstrate proficiency in specialized techniques and safety procedures specific to offshore environments. Regular recertification and ongoing training are often mandated to maintain compliance with evolving safety standards.

Environmental protection is another key focus of offshore welding regulations. Measures to prevent contamination of marine ecosystems, such as proper disposal of welding waste and the use of environmentally friendly materials, are often stipulated. Regulations may also address the potential impact of welding activities on marine life, including noise pollution and light emissions.

Compliance with these safety regulations is typically monitored through regular inspections and audits. Offshore operators are required to maintain detailed records of safety procedures, incident reports, and equipment maintenance. Penalties for non-compliance can be severe, reflecting the high stakes involved in offshore operations.

As technology advances, safety regulations in offshore gas welding continue to evolve. The integration of automated welding systems and remote monitoring technologies is beginning to reshape safety protocols, potentially reducing human exposure to hazardous conditions while maintaining or improving weld quality and consistency.

One of the primary safety concerns in offshore gas welding is the risk of fire and explosion. To mitigate this risk, regulations mandate the use of intrinsically safe equipment and the implementation of strict fire prevention measures. This includes the proper storage and handling of gas cylinders, regular maintenance of welding equipment, and the establishment of designated welding areas with appropriate fire suppression systems.

Personal protective equipment (PPE) requirements are another crucial aspect of safety regulations. Welders must wear flame-resistant clothing, protective eyewear, and respiratory protection to guard against harmful fumes and radiation. Additionally, regulations often specify the need for proper ventilation systems to remove welding fumes and maintain air quality in confined spaces typical of offshore structures.

The unique challenges of the offshore environment necessitate specific safety protocols. Regulations address issues such as working at heights, marine weather conditions, and the potential for gas leaks in enclosed spaces. Emergency response plans and evacuation procedures are mandatory, with regular drills conducted to ensure preparedness.

Certification and training requirements for offshore welders are typically more rigorous than those for onshore operations. Welders must demonstrate proficiency in specialized techniques and safety procedures specific to offshore environments. Regular recertification and ongoing training are often mandated to maintain compliance with evolving safety standards.

Environmental protection is another key focus of offshore welding regulations. Measures to prevent contamination of marine ecosystems, such as proper disposal of welding waste and the use of environmentally friendly materials, are often stipulated. Regulations may also address the potential impact of welding activities on marine life, including noise pollution and light emissions.

Compliance with these safety regulations is typically monitored through regular inspections and audits. Offshore operators are required to maintain detailed records of safety procedures, incident reports, and equipment maintenance. Penalties for non-compliance can be severe, reflecting the high stakes involved in offshore operations.

As technology advances, safety regulations in offshore gas welding continue to evolve. The integration of automated welding systems and remote monitoring technologies is beginning to reshape safety protocols, potentially reducing human exposure to hazardous conditions while maintaining or improving weld quality and consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!