How Gas Welding Enhances Overall Manufacturing Resilience

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution and Objectives

Gas welding has played a pivotal role in manufacturing since its inception in the late 19th century. The evolution of this technology has been marked by significant advancements, contributing to enhanced manufacturing resilience over time. Initially developed as a method for joining metals, gas welding quickly became a cornerstone of industrial production due to its versatility and effectiveness.

The primary objective of gas welding in manufacturing has been to provide a reliable and efficient means of joining materials, particularly metals. As industries evolved, so did the demands placed on welding technologies. Gas welding's ability to adapt to these changing needs has been crucial in maintaining and improving manufacturing resilience.

Throughout its history, gas welding has undergone several key developments. The introduction of various fuel gases, such as acetylene and propane, expanded the technique's applicability across different materials and thicknesses. Improvements in torch design and gas control mechanisms enhanced precision and safety, making the process more reliable and easier to use in diverse manufacturing environments.

One of the most significant objectives in the evolution of gas welding has been to increase productivity while maintaining or improving weld quality. This goal has driven innovations in equipment design, welding techniques, and the development of specialized filler materials. These advancements have allowed manufacturers to produce stronger, more durable welds in less time, directly contributing to overall manufacturing resilience.

Another critical objective has been to improve the adaptability of gas welding to various manufacturing scenarios. This has led to the development of portable welding equipment, enabling on-site repairs and maintenance, which is crucial for minimizing downtime in manufacturing operations. The ability to perform welding tasks in diverse locations and conditions has significantly enhanced the flexibility and responsiveness of manufacturing processes.

Safety and environmental considerations have also been key drivers in the evolution of gas welding. Objectives in this area have included reducing harmful emissions, improving energy efficiency, and enhancing operator safety. These goals have resulted in the development of cleaner-burning fuel mixtures, more efficient torch designs, and improved personal protective equipment, all contributing to a more sustainable and resilient manufacturing ecosystem.

In recent years, the integration of gas welding with advanced manufacturing technologies has become a primary objective. This includes the development of automated and robotic gas welding systems, as well as the incorporation of digital control and monitoring technologies. These advancements aim to further enhance precision, consistency, and efficiency in welding operations, thereby strengthening manufacturing resilience in an increasingly competitive global market.

The primary objective of gas welding in manufacturing has been to provide a reliable and efficient means of joining materials, particularly metals. As industries evolved, so did the demands placed on welding technologies. Gas welding's ability to adapt to these changing needs has been crucial in maintaining and improving manufacturing resilience.

Throughout its history, gas welding has undergone several key developments. The introduction of various fuel gases, such as acetylene and propane, expanded the technique's applicability across different materials and thicknesses. Improvements in torch design and gas control mechanisms enhanced precision and safety, making the process more reliable and easier to use in diverse manufacturing environments.

One of the most significant objectives in the evolution of gas welding has been to increase productivity while maintaining or improving weld quality. This goal has driven innovations in equipment design, welding techniques, and the development of specialized filler materials. These advancements have allowed manufacturers to produce stronger, more durable welds in less time, directly contributing to overall manufacturing resilience.

Another critical objective has been to improve the adaptability of gas welding to various manufacturing scenarios. This has led to the development of portable welding equipment, enabling on-site repairs and maintenance, which is crucial for minimizing downtime in manufacturing operations. The ability to perform welding tasks in diverse locations and conditions has significantly enhanced the flexibility and responsiveness of manufacturing processes.

Safety and environmental considerations have also been key drivers in the evolution of gas welding. Objectives in this area have included reducing harmful emissions, improving energy efficiency, and enhancing operator safety. These goals have resulted in the development of cleaner-burning fuel mixtures, more efficient torch designs, and improved personal protective equipment, all contributing to a more sustainable and resilient manufacturing ecosystem.

In recent years, the integration of gas welding with advanced manufacturing technologies has become a primary objective. This includes the development of automated and robotic gas welding systems, as well as the incorporation of digital control and monitoring technologies. These advancements aim to further enhance precision, consistency, and efficiency in welding operations, thereby strengthening manufacturing resilience in an increasingly competitive global market.

Market Demand Analysis for Gas Welding

The market demand for gas welding in manufacturing has shown resilience and steady growth in recent years, driven by several key factors. The construction and infrastructure sectors continue to be major consumers of gas welding technologies, particularly in developing economies where large-scale projects are underway. The automotive industry, despite the shift towards electric vehicles, still relies heavily on gas welding for various components and repair work.

In the aerospace sector, gas welding remains a critical process for manufacturing and maintaining aircraft components, contributing to the overall market demand. The shipbuilding industry, experiencing a resurgence in some regions, also fuels the demand for gas welding equipment and consumables. Additionally, the repair and maintenance sector across various industries consistently requires gas welding solutions, ensuring a stable market base.

The global gas welding market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth is attributed to the increasing adoption of automation in welding processes, which has led to the development of advanced gas welding equipment that offers higher precision and efficiency. The market is also benefiting from the rising demand for lightweight materials in industries such as automotive and aerospace, where gas welding plays a crucial role in joining these materials.

Emerging trends in the gas welding market include the integration of IoT and AI technologies to enhance welding processes, improve quality control, and reduce downtime. This technological advancement is particularly appealing to industries seeking to improve their manufacturing resilience and efficiency. The market is also seeing a growing demand for eco-friendly welding solutions, with manufacturers developing gas welding equipment that produces lower emissions and consumes less energy.

Geographically, Asia-Pacific remains the largest market for gas welding, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe follow, with steady demand from established manufacturing sectors and ongoing technological advancements. The Middle East and Africa region is showing promising growth potential, particularly in the oil and gas and construction sectors.

Despite the growing popularity of alternative welding methods such as laser and electron beam welding, gas welding continues to hold a significant market share due to its versatility, cost-effectiveness, and suitability for a wide range of materials and applications. The ongoing focus on enhancing manufacturing resilience across industries is expected to further bolster the demand for gas welding technologies, as companies seek reliable and adaptable welding solutions to meet evolving production challenges.

In the aerospace sector, gas welding remains a critical process for manufacturing and maintaining aircraft components, contributing to the overall market demand. The shipbuilding industry, experiencing a resurgence in some regions, also fuels the demand for gas welding equipment and consumables. Additionally, the repair and maintenance sector across various industries consistently requires gas welding solutions, ensuring a stable market base.

The global gas welding market is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth is attributed to the increasing adoption of automation in welding processes, which has led to the development of advanced gas welding equipment that offers higher precision and efficiency. The market is also benefiting from the rising demand for lightweight materials in industries such as automotive and aerospace, where gas welding plays a crucial role in joining these materials.

Emerging trends in the gas welding market include the integration of IoT and AI technologies to enhance welding processes, improve quality control, and reduce downtime. This technological advancement is particularly appealing to industries seeking to improve their manufacturing resilience and efficiency. The market is also seeing a growing demand for eco-friendly welding solutions, with manufacturers developing gas welding equipment that produces lower emissions and consumes less energy.

Geographically, Asia-Pacific remains the largest market for gas welding, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe follow, with steady demand from established manufacturing sectors and ongoing technological advancements. The Middle East and Africa region is showing promising growth potential, particularly in the oil and gas and construction sectors.

Despite the growing popularity of alternative welding methods such as laser and electron beam welding, gas welding continues to hold a significant market share due to its versatility, cost-effectiveness, and suitability for a wide range of materials and applications. The ongoing focus on enhancing manufacturing resilience across industries is expected to further bolster the demand for gas welding technologies, as companies seek reliable and adaptable welding solutions to meet evolving production challenges.

Current Gas Welding Challenges

Gas welding, despite its long history in manufacturing, continues to face several challenges that impact its effectiveness and widespread adoption in modern industrial settings. One of the primary concerns is the inherent safety risks associated with the use of flammable gases. The handling and storage of acetylene and oxygen cylinders require strict safety protocols, which can be complex to implement and maintain across large manufacturing facilities.

The precision and consistency of gas welding processes also present ongoing challenges. Unlike more advanced welding techniques, gas welding relies heavily on the skill and experience of the operator. This human factor introduces variability in weld quality, which can be problematic in industries requiring high-precision components. The difficulty in automating gas welding processes further compounds this issue, limiting its application in high-volume production environments.

Environmental concerns pose another significant challenge to gas welding. The process produces fumes and gases that can be harmful to both workers and the environment. Implementing effective ventilation systems and personal protective equipment adds to the operational costs and complexity of using gas welding in manufacturing settings.

The speed of gas welding is another limitation, particularly when compared to more modern welding techniques. In an era where production efficiency is paramount, the relatively slow pace of gas welding can be a significant drawback. This speed limitation affects not only production rates but also overall manufacturing flexibility and responsiveness to market demands.

Energy efficiency is an additional concern in gas welding. The process consumes significant amounts of fuel gases, which can be costly and contribute to a manufacturer's carbon footprint. As industries increasingly focus on sustainability and energy conservation, the energy-intensive nature of gas welding becomes a more prominent issue.

Lastly, the availability and cost of gases used in welding can fluctuate, impacting the stability and predictability of manufacturing operations. Supply chain disruptions or price volatility in gas supplies can have ripple effects throughout the production process, potentially leading to delays or increased costs.

These challenges collectively impact the resilience of manufacturing processes that rely on gas welding. Addressing these issues requires ongoing innovation in safety protocols, skill development, environmental management, and process optimization. While gas welding continues to have its place in certain manufacturing applications, overcoming these challenges is crucial for enhancing its role in building more resilient and efficient manufacturing systems.

The precision and consistency of gas welding processes also present ongoing challenges. Unlike more advanced welding techniques, gas welding relies heavily on the skill and experience of the operator. This human factor introduces variability in weld quality, which can be problematic in industries requiring high-precision components. The difficulty in automating gas welding processes further compounds this issue, limiting its application in high-volume production environments.

Environmental concerns pose another significant challenge to gas welding. The process produces fumes and gases that can be harmful to both workers and the environment. Implementing effective ventilation systems and personal protective equipment adds to the operational costs and complexity of using gas welding in manufacturing settings.

The speed of gas welding is another limitation, particularly when compared to more modern welding techniques. In an era where production efficiency is paramount, the relatively slow pace of gas welding can be a significant drawback. This speed limitation affects not only production rates but also overall manufacturing flexibility and responsiveness to market demands.

Energy efficiency is an additional concern in gas welding. The process consumes significant amounts of fuel gases, which can be costly and contribute to a manufacturer's carbon footprint. As industries increasingly focus on sustainability and energy conservation, the energy-intensive nature of gas welding becomes a more prominent issue.

Lastly, the availability and cost of gases used in welding can fluctuate, impacting the stability and predictability of manufacturing operations. Supply chain disruptions or price volatility in gas supplies can have ripple effects throughout the production process, potentially leading to delays or increased costs.

These challenges collectively impact the resilience of manufacturing processes that rely on gas welding. Addressing these issues requires ongoing innovation in safety protocols, skill development, environmental management, and process optimization. While gas welding continues to have its place in certain manufacturing applications, overcoming these challenges is crucial for enhancing its role in building more resilient and efficient manufacturing systems.

Current Gas Welding Solutions

01 Improved welding techniques for enhanced resilience

Advanced gas welding techniques are developed to improve the resilience of manufactured components. These methods focus on optimizing heat input, controlling cooling rates, and enhancing the microstructure of welded joints. By implementing these techniques, manufacturers can produce more durable and resilient welded products that can withstand various environmental and mechanical stresses.- Improved welding techniques for enhanced resilience: Advanced gas welding techniques are developed to improve the resilience of manufactured components. These methods focus on optimizing heat input, controlling cooling rates, and minimizing distortion to enhance the structural integrity and longevity of welded parts. Such techniques contribute to increased manufacturing resilience by producing more durable and reliable products.

- Automation and robotics in gas welding: Integration of automation and robotics in gas welding processes enhances manufacturing resilience by improving consistency, precision, and efficiency. Automated systems can adapt to various welding parameters, reduce human error, and operate in challenging environments, thereby increasing production reliability and flexibility.

- Advanced materials for gas welding applications: Development of specialized materials and alloys for gas welding applications contributes to manufacturing resilience. These materials are designed to withstand high temperatures, resist corrosion, and maintain structural integrity under various operating conditions, resulting in more durable and reliable welded components.

- Monitoring and quality control systems: Implementation of advanced monitoring and quality control systems in gas welding processes enhances manufacturing resilience. These systems utilize sensors, real-time data analysis, and machine learning algorithms to detect defects, optimize welding parameters, and ensure consistent weld quality, thereby reducing rework and improving overall production reliability.

- Sustainable and eco-friendly gas welding practices: Development of sustainable and eco-friendly gas welding practices contributes to long-term manufacturing resilience. These practices focus on reducing energy consumption, minimizing waste, and utilizing environmentally friendly gases and materials. By adopting such practices, manufacturers can ensure compliance with regulations, reduce environmental impact, and improve overall operational sustainability.

02 Automation and robotics in gas welding processes

Integration of automation and robotics in gas welding processes enhances manufacturing resilience by improving consistency, precision, and efficiency. Automated systems can adapt to various welding parameters, reduce human error, and maintain high-quality standards across production runs. This approach contributes to increased productivity and reliability in manufacturing operations.Expand Specific Solutions03 Advanced materials for resilient welded structures

Development and utilization of advanced materials in gas welding applications contribute to manufacturing resilience. These materials are designed to have superior mechanical properties, corrosion resistance, and thermal stability. By incorporating these materials into welded structures, manufacturers can produce more durable and long-lasting products that can withstand harsh operating conditions.Expand Specific Solutions04 Monitoring and quality control systems for welding processes

Implementation of advanced monitoring and quality control systems in gas welding processes enhances manufacturing resilience. These systems utilize sensors, data analytics, and real-time feedback mechanisms to ensure consistent weld quality, detect defects, and optimize process parameters. By maintaining high-quality standards, manufacturers can reduce rework and improve overall product reliability.Expand Specific Solutions05 Sustainable and eco-friendly gas welding practices

Adoption of sustainable and eco-friendly gas welding practices contributes to manufacturing resilience by reducing environmental impact and improving resource efficiency. These practices include the use of cleaner fuel gases, optimized gas mixtures, and improved waste management techniques. By implementing these approaches, manufacturers can enhance their long-term sustainability and adaptability to changing environmental regulations.Expand Specific Solutions

Key Gas Welding Industry Players

The gas welding industry is in a mature phase, characterized by established technologies and a stable market. The global market size for welding equipment and consumables is estimated to be around $20 billion, with steady growth projected. Technologically, gas welding is well-developed, but innovations continue to enhance efficiency and safety. Key players like Illinois Tool Works, Kobe Steel, and Lincoln Global dominate the market, offering advanced solutions. Emerging companies such as Chengdu Xindayang Welding Material and Shanghai Atlantic Welding Consumables are also contributing to the industry's resilience. The sector's maturity is evident in the diverse applications across manufacturing, construction, and automotive industries, underlining its crucial role in enhancing overall manufacturing resilience.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding technologies that enhance manufacturing resilience. Their innovative approach includes the use of specialized gas mixtures and precision flow control systems to optimize welding performance. ITW's gas welding solutions incorporate real-time monitoring and adaptive control mechanisms, allowing for consistent weld quality across varying environmental conditions. The company has also introduced portable gas welding units that increase flexibility in manufacturing processes, enabling quick reconfigurations of production lines[1]. Additionally, ITW has implemented IoT-enabled gas management systems that ensure uninterrupted supply and efficient utilization of welding gases, contributing to overall manufacturing resilience[2].

Strengths: Advanced gas mixture technology, precision control systems, and IoT integration enhance weld quality and process efficiency. Weaknesses: May require significant initial investment and specialized training for operators.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed a high-efficiency gas welding system that significantly contributes to manufacturing resilience. Their technology utilizes a proprietary gas mixture composition that enhances heat distribution and penetration, resulting in stronger welds and reduced material waste. Kobe Steel's system incorporates advanced sensors and real-time feedback mechanisms to maintain optimal gas flow and pressure, ensuring consistent weld quality even under varying environmental conditions[3]. The company has also introduced a modular gas welding setup that allows for quick adaptation to different materials and thicknesses, improving manufacturing flexibility. Furthermore, Kobe Steel's gas welding technology includes an innovative heat recovery system that captures and recycles excess heat, improving energy efficiency and reducing operational costs[4].

Strengths: Proprietary gas mixture for enhanced weld strength, modular design for flexibility, and energy-efficient heat recovery system. Weaknesses: May have higher initial costs compared to traditional welding methods.

Gas Welding Innovation Analysis

Gas system for welding-type devices

PatentInactiveEP1848566A1

Innovation

- A lightweight shielding gas system where a pressure vessel is integrated into the welding device's housing, with a regulator and canister design that allows for direct mounting and easy replacement, eliminating the need for large external gas cylinders.

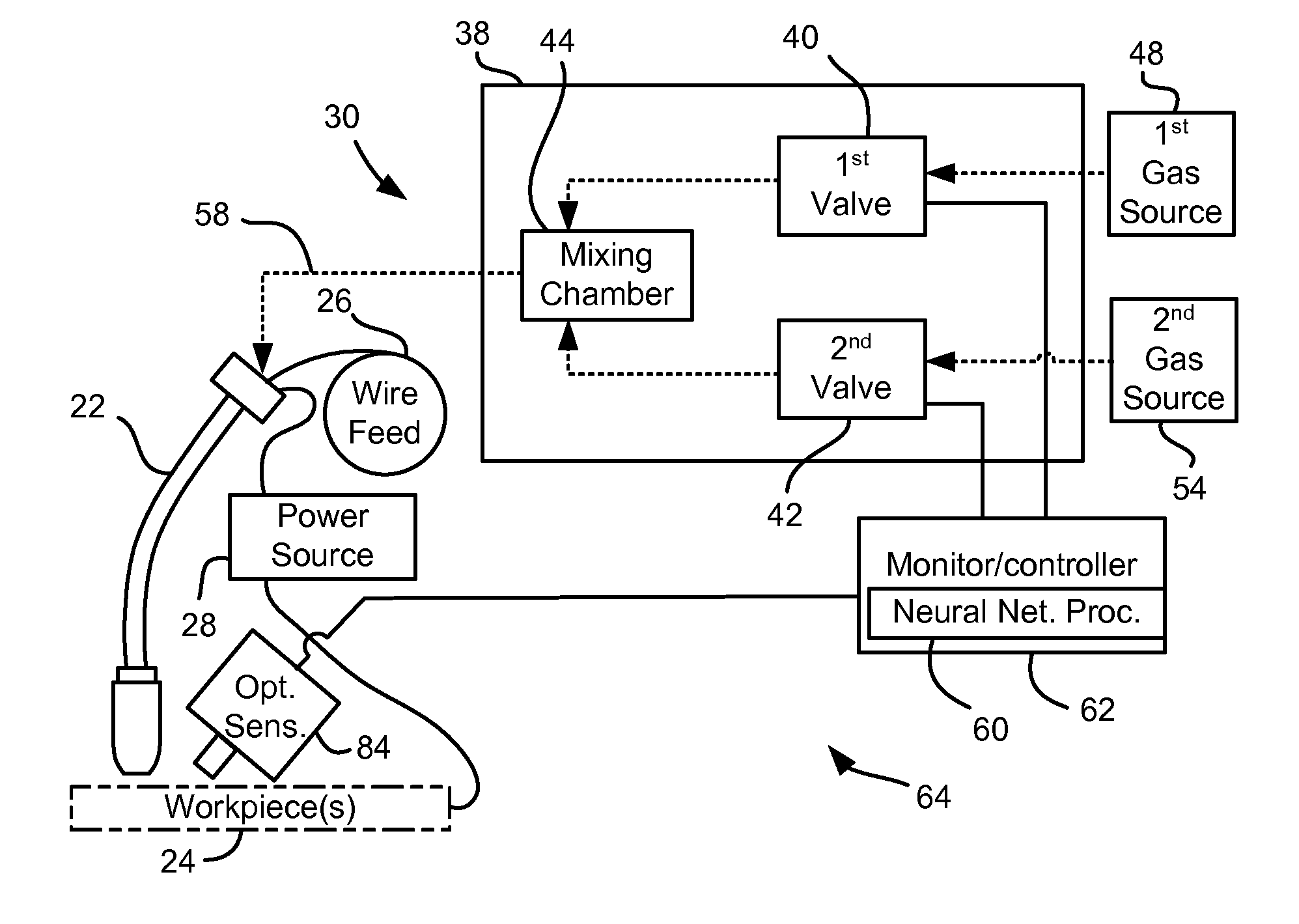

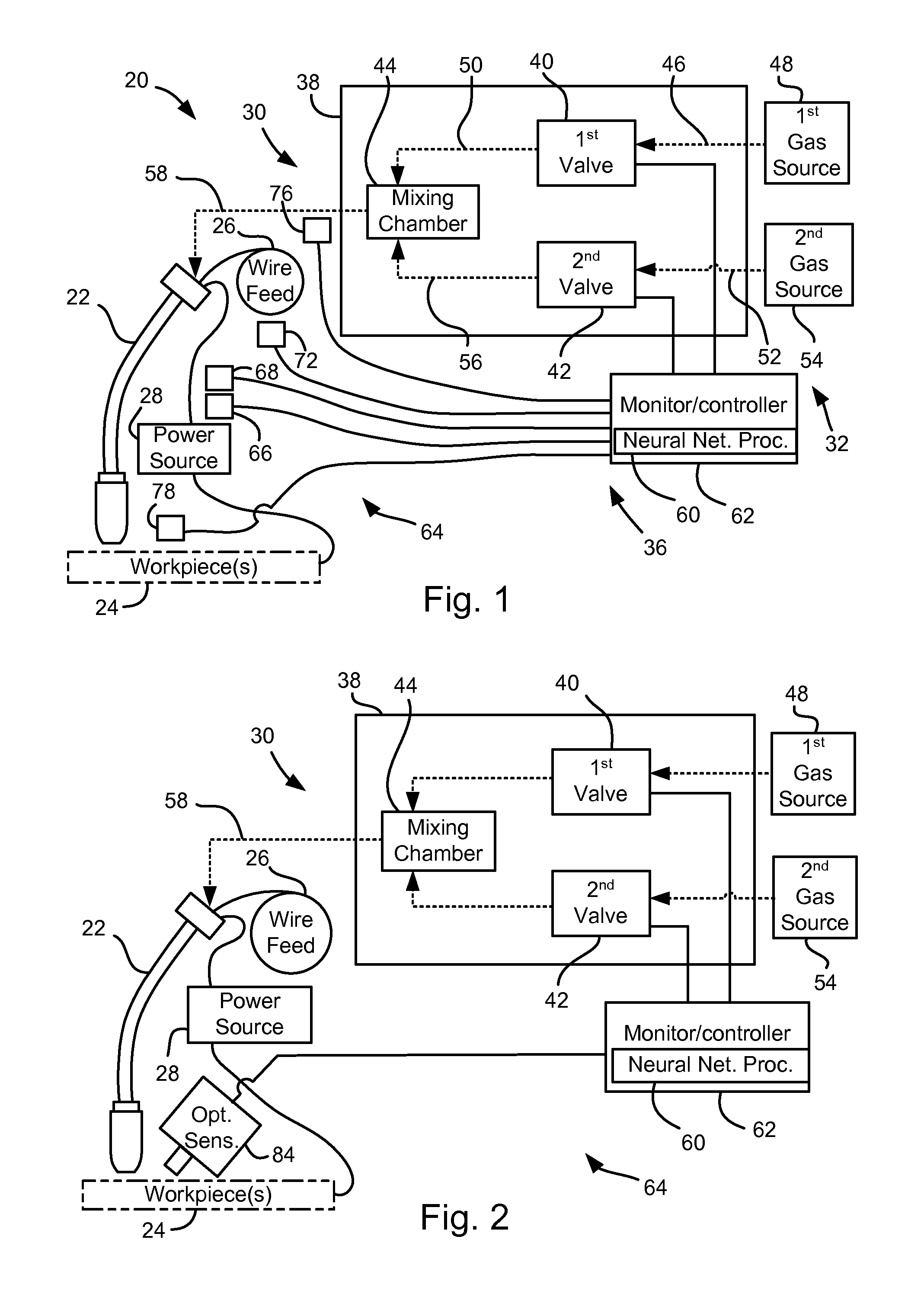

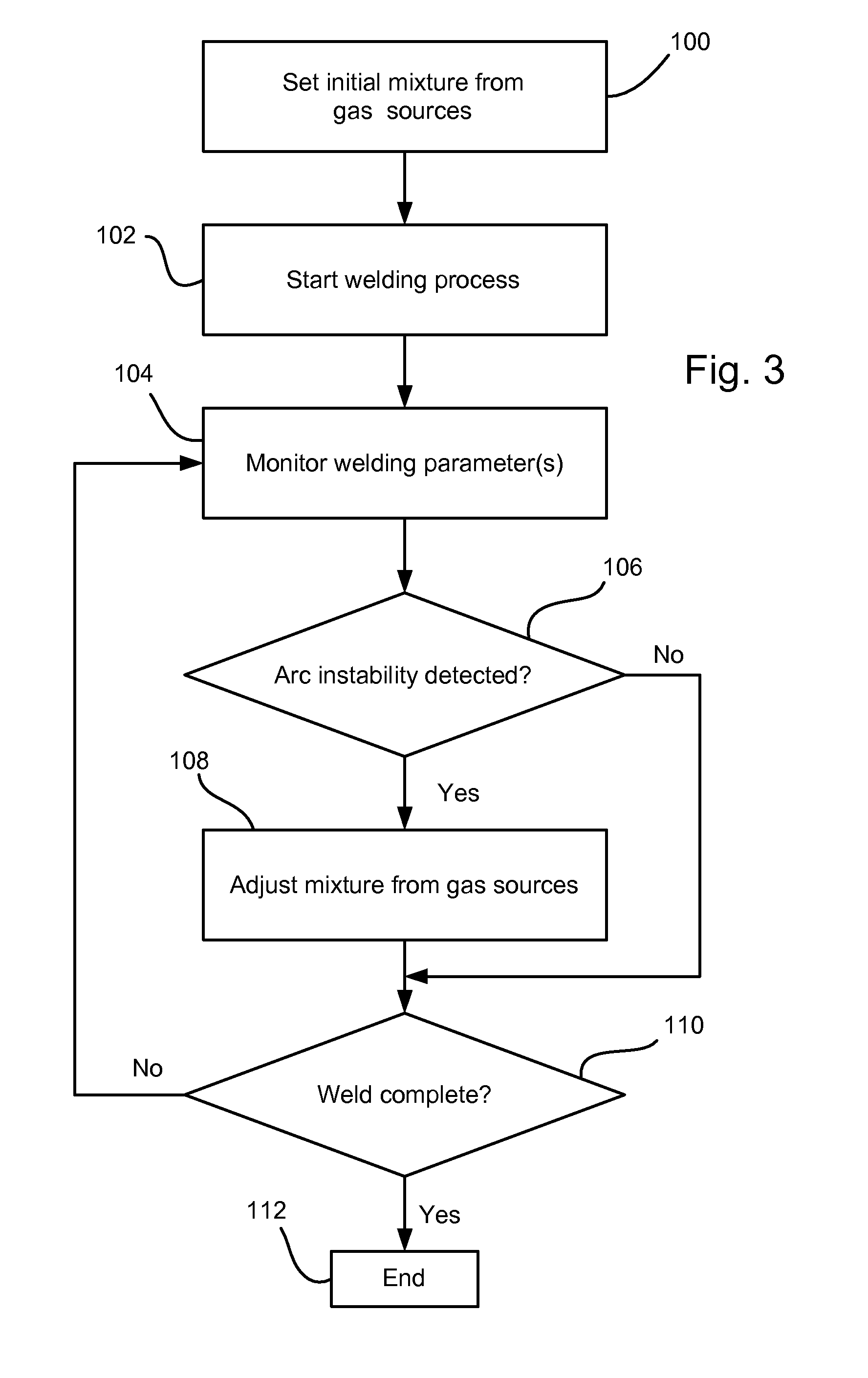

Welding stability system and method

PatentActiveUS8129652B2

Innovation

- A weld stability system that includes a shielding gas supply with multiple sources of different gas mixtures and a control assembly with automatically controllable valves and sensors to monitor and adjust the gas mixture in real-time during the welding process, using a controller to actuate the valves based on detected arc instability.

Safety Regulations in Gas Welding

Safety regulations in gas welding play a crucial role in ensuring the resilience of manufacturing processes. These regulations are designed to protect workers, equipment, and the environment from potential hazards associated with gas welding operations. The Occupational Safety and Health Administration (OSHA) in the United States, along with similar regulatory bodies worldwide, have established comprehensive guidelines for gas welding safety.

One of the primary focuses of safety regulations is the proper handling and storage of compressed gas cylinders. These regulations mandate that cylinders must be secured in an upright position, stored away from heat sources, and equipped with protective valve caps when not in use. Additionally, specific color-coding systems are required to identify the contents of each cylinder, reducing the risk of accidental misuse.

Personal protective equipment (PPE) is another critical aspect of gas welding safety regulations. Workers are required to wear appropriate eye protection, such as welding helmets with the correct shade of filter lens, to prevent eye damage from intense light and UV radiation. Heat-resistant gloves, flame-resistant clothing, and safety shoes are also mandated to protect against burns and other injuries.

Ventilation requirements form a significant part of safety regulations in gas welding. Adequate ventilation systems must be in place to remove harmful fumes and gases produced during the welding process. This may include local exhaust ventilation or general workplace ventilation, depending on the specific welding application and workspace configuration.

Fire prevention measures are heavily emphasized in gas welding safety regulations. These include maintaining a clear area free of flammable materials within a specified radius of the welding operation, having appropriate fire extinguishing equipment readily available, and implementing hot work permit systems for welding in areas with potential fire hazards.

Regular inspection and maintenance of welding equipment are mandated by safety regulations to ensure their proper functioning and prevent accidents. This includes checking for gas leaks, inspecting hoses and connections, and verifying the integrity of welding torches and regulators.

Training and certification requirements for gas welding operators are also stipulated in safety regulations. Workers must receive comprehensive training on proper welding techniques, equipment operation, hazard recognition, and emergency procedures. Many jurisdictions require welders to obtain and maintain certifications to demonstrate their competence in safe welding practices.

By adhering to these comprehensive safety regulations, manufacturers can significantly enhance their operational resilience. These measures not only protect workers and assets but also contribute to improved productivity, reduced downtime due to accidents, and enhanced overall manufacturing efficiency. Moreover, compliance with safety regulations helps companies maintain their reputation, avoid legal liabilities, and foster a culture of safety that extends beyond gas welding to all aspects of manufacturing operations.

One of the primary focuses of safety regulations is the proper handling and storage of compressed gas cylinders. These regulations mandate that cylinders must be secured in an upright position, stored away from heat sources, and equipped with protective valve caps when not in use. Additionally, specific color-coding systems are required to identify the contents of each cylinder, reducing the risk of accidental misuse.

Personal protective equipment (PPE) is another critical aspect of gas welding safety regulations. Workers are required to wear appropriate eye protection, such as welding helmets with the correct shade of filter lens, to prevent eye damage from intense light and UV radiation. Heat-resistant gloves, flame-resistant clothing, and safety shoes are also mandated to protect against burns and other injuries.

Ventilation requirements form a significant part of safety regulations in gas welding. Adequate ventilation systems must be in place to remove harmful fumes and gases produced during the welding process. This may include local exhaust ventilation or general workplace ventilation, depending on the specific welding application and workspace configuration.

Fire prevention measures are heavily emphasized in gas welding safety regulations. These include maintaining a clear area free of flammable materials within a specified radius of the welding operation, having appropriate fire extinguishing equipment readily available, and implementing hot work permit systems for welding in areas with potential fire hazards.

Regular inspection and maintenance of welding equipment are mandated by safety regulations to ensure their proper functioning and prevent accidents. This includes checking for gas leaks, inspecting hoses and connections, and verifying the integrity of welding torches and regulators.

Training and certification requirements for gas welding operators are also stipulated in safety regulations. Workers must receive comprehensive training on proper welding techniques, equipment operation, hazard recognition, and emergency procedures. Many jurisdictions require welders to obtain and maintain certifications to demonstrate their competence in safe welding practices.

By adhering to these comprehensive safety regulations, manufacturers can significantly enhance their operational resilience. These measures not only protect workers and assets but also contribute to improved productivity, reduced downtime due to accidents, and enhanced overall manufacturing efficiency. Moreover, compliance with safety regulations helps companies maintain their reputation, avoid legal liabilities, and foster a culture of safety that extends beyond gas welding to all aspects of manufacturing operations.

Environmental Impact of Gas Welding

Gas welding, while an essential process in manufacturing, has significant environmental implications that must be carefully considered. The primary environmental concern associated with gas welding is the emission of harmful gases and particulate matter. These emissions include carbon dioxide, nitrogen oxides, and various metal fumes, which can contribute to air pollution and pose health risks to workers and surrounding communities.

The combustion of fuel gases used in gas welding, such as acetylene or propane, releases greenhouse gases that contribute to climate change. Additionally, the production and transportation of these fuel gases have their own environmental footprint, further increasing the overall impact of gas welding processes.

Particulate matter released during gas welding can contain heavy metals and other toxic substances, which may settle in soil and water bodies, potentially contaminating ecosystems and entering the food chain. This can lead to long-term environmental degradation and health issues for both humans and wildlife.

Water pollution is another concern, as cooling water used in some gas welding applications may become contaminated with metal particles and chemicals. If not properly treated, this wastewater can harm aquatic ecosystems when discharged into water bodies.

Noise pollution is an often-overlooked environmental impact of gas welding. The high-decibel levels produced during welding operations can disturb local communities and wildlife, potentially affecting biodiversity in surrounding areas.

However, it's important to note that the environmental impact of gas welding can be mitigated through various measures. The implementation of advanced filtration systems and fume extractors can significantly reduce air emissions. Proper waste management practices, including the recycling of metal scraps and responsible disposal of hazardous materials, can minimize the environmental footprint of welding operations.

Furthermore, the adoption of more efficient welding techniques and equipment can reduce energy consumption and emissions. Training welders in best practices for environmental protection and providing them with appropriate personal protective equipment can also help minimize the ecological impact of gas welding processes.

As manufacturing industries strive for greater sustainability, the environmental impact of gas welding is receiving increased attention. Research and development efforts are focused on developing cleaner welding technologies and improving existing processes to reduce their environmental footprint. This includes exploring alternative fuel gases with lower emissions and investigating the potential of renewable energy sources to power welding operations.

The combustion of fuel gases used in gas welding, such as acetylene or propane, releases greenhouse gases that contribute to climate change. Additionally, the production and transportation of these fuel gases have their own environmental footprint, further increasing the overall impact of gas welding processes.

Particulate matter released during gas welding can contain heavy metals and other toxic substances, which may settle in soil and water bodies, potentially contaminating ecosystems and entering the food chain. This can lead to long-term environmental degradation and health issues for both humans and wildlife.

Water pollution is another concern, as cooling water used in some gas welding applications may become contaminated with metal particles and chemicals. If not properly treated, this wastewater can harm aquatic ecosystems when discharged into water bodies.

Noise pollution is an often-overlooked environmental impact of gas welding. The high-decibel levels produced during welding operations can disturb local communities and wildlife, potentially affecting biodiversity in surrounding areas.

However, it's important to note that the environmental impact of gas welding can be mitigated through various measures. The implementation of advanced filtration systems and fume extractors can significantly reduce air emissions. Proper waste management practices, including the recycling of metal scraps and responsible disposal of hazardous materials, can minimize the environmental footprint of welding operations.

Furthermore, the adoption of more efficient welding techniques and equipment can reduce energy consumption and emissions. Training welders in best practices for environmental protection and providing them with appropriate personal protective equipment can also help minimize the ecological impact of gas welding processes.

As manufacturing industries strive for greater sustainability, the environmental impact of gas welding is receiving increased attention. Research and development efforts are focused on developing cleaner welding technologies and improving existing processes to reduce their environmental footprint. This includes exploring alternative fuel gases with lower emissions and investigating the potential of renewable energy sources to power welding operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!