How Gas Welding Techniques Influence Quantum Computing Devices

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Computing and Gas Welding Synergy

The synergy between quantum computing and gas welding techniques represents an intriguing intersection of cutting-edge technology and traditional manufacturing processes. Quantum computing, a field at the forefront of computational advancement, relies on the precise manipulation of quantum states to perform complex calculations. Gas welding, on the other hand, is a well-established technique in materials joining and fabrication.

The influence of gas welding techniques on quantum computing devices primarily stems from the need for precise material manipulation and assembly in the construction of quantum hardware. Quantum bits, or qubits, the fundamental units of quantum information, are extremely sensitive to their environment and require meticulous fabrication processes to maintain coherence and minimize errors.

Gas welding techniques, when adapted for use in quantum device manufacturing, offer several potential benefits. The controlled heat application and precise flame characteristics of gas welding can be utilized for the delicate joining of materials used in quantum circuits. This includes the creation of superconducting connections and the bonding of specialized components that form the core of quantum processors.

Furthermore, the ability to manipulate small-scale structures with gas welding techniques aligns well with the miniaturization requirements of quantum computing devices. As quantum processors continue to scale up in complexity, the need for precise, localized joining methods becomes increasingly critical. Gas welding, with its adaptability and fine control, presents an opportunity to address these challenges.

The synergy extends to the materials science aspect of quantum computing. Many quantum devices rely on exotic materials and alloys that exhibit specific quantum properties. Gas welding techniques can be adapted to work with these materials, potentially enabling new fabrication methods that preserve or even enhance their quantum characteristics.

Additionally, the controlled atmosphere capabilities often associated with gas welding setups can be leveraged to create the ultra-clean environments necessary for quantum device assembly. This synergy between welding technology and quantum computing requirements opens up new avenues for innovation in both fields.

As quantum computing continues to evolve, the integration of traditional manufacturing techniques like gas welding with advanced quantum engineering principles may lead to breakthroughs in device fabrication and performance. This collaboration between seemingly disparate fields exemplifies the interdisciplinary nature of cutting-edge technology development and highlights the potential for unexpected synergies in pushing the boundaries of computational capabilities.

The influence of gas welding techniques on quantum computing devices primarily stems from the need for precise material manipulation and assembly in the construction of quantum hardware. Quantum bits, or qubits, the fundamental units of quantum information, are extremely sensitive to their environment and require meticulous fabrication processes to maintain coherence and minimize errors.

Gas welding techniques, when adapted for use in quantum device manufacturing, offer several potential benefits. The controlled heat application and precise flame characteristics of gas welding can be utilized for the delicate joining of materials used in quantum circuits. This includes the creation of superconducting connections and the bonding of specialized components that form the core of quantum processors.

Furthermore, the ability to manipulate small-scale structures with gas welding techniques aligns well with the miniaturization requirements of quantum computing devices. As quantum processors continue to scale up in complexity, the need for precise, localized joining methods becomes increasingly critical. Gas welding, with its adaptability and fine control, presents an opportunity to address these challenges.

The synergy extends to the materials science aspect of quantum computing. Many quantum devices rely on exotic materials and alloys that exhibit specific quantum properties. Gas welding techniques can be adapted to work with these materials, potentially enabling new fabrication methods that preserve or even enhance their quantum characteristics.

Additionally, the controlled atmosphere capabilities often associated with gas welding setups can be leveraged to create the ultra-clean environments necessary for quantum device assembly. This synergy between welding technology and quantum computing requirements opens up new avenues for innovation in both fields.

As quantum computing continues to evolve, the integration of traditional manufacturing techniques like gas welding with advanced quantum engineering principles may lead to breakthroughs in device fabrication and performance. This collaboration between seemingly disparate fields exemplifies the interdisciplinary nature of cutting-edge technology development and highlights the potential for unexpected synergies in pushing the boundaries of computational capabilities.

Market Demand Analysis

The market demand for quantum computing devices has been steadily growing, driven by the increasing need for advanced computational capabilities in various sectors. As quantum computing technology matures, industries such as finance, pharmaceuticals, and cybersecurity are showing keen interest in its potential applications. The global quantum computing market is projected to expand significantly over the next decade, with some estimates suggesting a compound annual growth rate of over 30%.

Gas welding techniques, traditionally associated with metalworking, have found an unexpected niche in the quantum computing industry. The precision and control offered by gas welding processes have become crucial in the fabrication of certain quantum computing components. This intersection has created a unique market demand for specialized gas welding equipment and expertise tailored to quantum device manufacturing.

The influence of gas welding on quantum computing devices has led to a surge in demand for highly skilled technicians who can apply these techniques in cleanroom environments. Universities and technical institutes are beginning to offer specialized courses to meet this growing need, indicating a long-term market trend for skilled labor in this niche area.

Furthermore, there is an emerging market for ultra-high purity gases and precision gas delivery systems specifically designed for quantum device fabrication. Companies that can provide these specialized materials and equipment are experiencing increased demand from quantum computing research laboratories and manufacturers.

The market for quantum computing devices is also seeing a shift towards more robust and scalable architectures. Gas welding techniques have played a role in enabling the development of larger and more complex quantum systems, potentially accelerating the timeline for practical quantum computers. This has sparked interest from major tech companies and government agencies, further driving market growth.

As quantum computing moves closer to practical applications, there is a growing demand for integration services that can bridge the gap between quantum and classical computing systems. This has created opportunities for companies specializing in hybrid quantum-classical architectures, where gas welding techniques may play a role in creating interfaces between different types of computing hardware.

The market demand analysis also reveals a trend towards miniaturization and increased efficiency in quantum computing devices. Gas welding techniques that can achieve precise, nanoscale modifications are becoming increasingly valuable. This has led to collaborations between quantum computing researchers and materials science experts, fostering innovation in both fields and expanding the market for advanced materials and fabrication techniques.

Gas welding techniques, traditionally associated with metalworking, have found an unexpected niche in the quantum computing industry. The precision and control offered by gas welding processes have become crucial in the fabrication of certain quantum computing components. This intersection has created a unique market demand for specialized gas welding equipment and expertise tailored to quantum device manufacturing.

The influence of gas welding on quantum computing devices has led to a surge in demand for highly skilled technicians who can apply these techniques in cleanroom environments. Universities and technical institutes are beginning to offer specialized courses to meet this growing need, indicating a long-term market trend for skilled labor in this niche area.

Furthermore, there is an emerging market for ultra-high purity gases and precision gas delivery systems specifically designed for quantum device fabrication. Companies that can provide these specialized materials and equipment are experiencing increased demand from quantum computing research laboratories and manufacturers.

The market for quantum computing devices is also seeing a shift towards more robust and scalable architectures. Gas welding techniques have played a role in enabling the development of larger and more complex quantum systems, potentially accelerating the timeline for practical quantum computers. This has sparked interest from major tech companies and government agencies, further driving market growth.

As quantum computing moves closer to practical applications, there is a growing demand for integration services that can bridge the gap between quantum and classical computing systems. This has created opportunities for companies specializing in hybrid quantum-classical architectures, where gas welding techniques may play a role in creating interfaces between different types of computing hardware.

The market demand analysis also reveals a trend towards miniaturization and increased efficiency in quantum computing devices. Gas welding techniques that can achieve precise, nanoscale modifications are becoming increasingly valuable. This has led to collaborations between quantum computing researchers and materials science experts, fostering innovation in both fields and expanding the market for advanced materials and fabrication techniques.

Current Challenges

The integration of gas welding techniques into quantum computing device fabrication presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is maintaining the delicate quantum states required for quantum computing operations while applying high-temperature welding processes. The extreme heat generated during gas welding can potentially disrupt the coherence of quantum bits (qubits), leading to decoherence and loss of quantum information.

Another major challenge lies in the precision and control required for welding quantum computing components. Quantum devices often operate at nanoscale levels, demanding unprecedented accuracy in material joining processes. Traditional gas welding techniques may lack the fine-tuned control necessary to achieve the required precision, potentially leading to structural defects or misalignments that could compromise the functionality of quantum circuits.

Material compatibility poses a significant hurdle in the application of gas welding to quantum computing devices. Many quantum systems rely on exotic materials or superconducting elements that may react unfavorably to the high temperatures and chemical processes involved in gas welding. This incompatibility could result in altered material properties, compromised performance, or even complete failure of quantum components.

The issue of contamination during the welding process is another critical concern. Quantum computing devices are extremely sensitive to impurities and environmental factors. Gas welding introduces the risk of introducing foreign particles or gases into the quantum system, potentially degrading qubit performance or causing unintended interactions within the quantum circuit.

Thermal management presents a significant challenge when applying gas welding techniques to quantum computing devices. Many quantum systems operate at extremely low temperatures, often near absolute zero. The heat generated during welding processes can disrupt the carefully controlled thermal environment, potentially causing thermal expansion, stress, or damage to sensitive components.

Scalability remains a formidable obstacle in adapting gas welding for quantum computing manufacturing. As quantum systems grow in complexity and size, the ability to consistently and reliably apply welding techniques across larger scales becomes increasingly difficult. Ensuring uniform quality and maintaining quantum coherence across multiple welded components poses a substantial engineering challenge.

Lastly, the integration of gas welding processes into clean room environments, often required for quantum device fabrication, presents logistical and practical challenges. The introduction of welding equipment and associated gases into these controlled environments may compromise cleanliness standards and introduce potential sources of contamination, necessitating novel approaches to maintain the stringent conditions required for quantum computing device production.

Another major challenge lies in the precision and control required for welding quantum computing components. Quantum devices often operate at nanoscale levels, demanding unprecedented accuracy in material joining processes. Traditional gas welding techniques may lack the fine-tuned control necessary to achieve the required precision, potentially leading to structural defects or misalignments that could compromise the functionality of quantum circuits.

Material compatibility poses a significant hurdle in the application of gas welding to quantum computing devices. Many quantum systems rely on exotic materials or superconducting elements that may react unfavorably to the high temperatures and chemical processes involved in gas welding. This incompatibility could result in altered material properties, compromised performance, or even complete failure of quantum components.

The issue of contamination during the welding process is another critical concern. Quantum computing devices are extremely sensitive to impurities and environmental factors. Gas welding introduces the risk of introducing foreign particles or gases into the quantum system, potentially degrading qubit performance or causing unintended interactions within the quantum circuit.

Thermal management presents a significant challenge when applying gas welding techniques to quantum computing devices. Many quantum systems operate at extremely low temperatures, often near absolute zero. The heat generated during welding processes can disrupt the carefully controlled thermal environment, potentially causing thermal expansion, stress, or damage to sensitive components.

Scalability remains a formidable obstacle in adapting gas welding for quantum computing manufacturing. As quantum systems grow in complexity and size, the ability to consistently and reliably apply welding techniques across larger scales becomes increasingly difficult. Ensuring uniform quality and maintaining quantum coherence across multiple welded components poses a substantial engineering challenge.

Lastly, the integration of gas welding processes into clean room environments, often required for quantum device fabrication, presents logistical and practical challenges. The introduction of welding equipment and associated gases into these controlled environments may compromise cleanliness standards and introduce potential sources of contamination, necessitating novel approaches to maintain the stringent conditions required for quantum computing device production.

Existing Welding Solutions

01 Welding torch design improvements

Advancements in gas welding torch designs focus on enhancing efficiency, safety, and precision. These improvements include optimized gas flow control, ergonomic handle designs, and integrated cooling systems. Such innovations contribute to better flame control, reduced operator fatigue, and increased welding quality.- Welding torch design and improvements: Advancements in gas welding torch design focus on improving efficiency, safety, and ease of use. These innovations include ergonomic handles, adjustable flame controls, and integrated safety features to prevent gas leaks and backfires. Some designs incorporate multiple gas inputs for versatility in different welding applications.

- Gas mixture optimization: Research into optimal gas mixtures for various welding applications aims to enhance weld quality and efficiency. This includes developing precise ratios of fuel gases and oxygen for different materials and thicknesses, as well as exploring the use of shielding gases to improve weld characteristics and reduce oxidation.

- Automated gas welding systems: Integration of automation and robotics in gas welding processes improves precision and consistency. These systems often include computerized control of gas flow, torch movement, and welding parameters. Automated systems can be programmed for complex welding patterns and are particularly useful in high-volume production environments.

- Safety mechanisms and protocols: Development of advanced safety features for gas welding equipment, including automatic shut-off valves, flame arrestors, and pressure regulators. These innovations aim to prevent accidents such as flashbacks and gas leaks. Additionally, improved personal protective equipment and ventilation systems are designed to enhance welder safety.

- Specialized gas welding techniques: Exploration of specialized gas welding techniques for specific materials or applications. This includes methods for welding thin materials, dissimilar metals, or creating precise joints in challenging environments. Some techniques focus on minimizing heat-affected zones or improving the aesthetic quality of welds.

02 Gas mixture optimization

Research into optimal gas mixtures for various welding applications aims to improve weld quality and efficiency. This includes developing precise ratios of fuel gases and oxygen, as well as exploring the use of shielding gases to protect the weld pool. These advancements result in stronger welds, reduced porosity, and improved overall welding performance.Expand Specific Solutions03 Automated gas welding systems

Integration of automation and robotics in gas welding processes enhances precision and consistency. These systems incorporate sensors for real-time monitoring and adjustment of welding parameters, as well as programmable welding paths. Automated gas welding systems improve productivity, reduce human error, and enable complex welding operations.Expand Specific Solutions04 Safety enhancements in gas welding

Innovations in gas welding safety focus on preventing accidents and protecting welders. These include improved gas leak detection systems, flame arrestors, and personal protective equipment designed specifically for gas welding. Enhanced safety features contribute to a safer working environment and reduced risk of injuries or accidents.Expand Specific Solutions05 Specialized gas welding techniques

Development of specialized gas welding techniques for specific materials or applications enhances the versatility of the process. These techniques may include methods for welding thin materials, joining dissimilar metals, or achieving specific surface finishes. Such advancements expand the range of applications for gas welding in various industries.Expand Specific Solutions

Key Industry Players

The competitive landscape for gas welding techniques in quantum computing devices is in its early stages, with the market size still relatively small but growing rapidly. The technology is not yet fully mature, with companies like Intel, Origin Quantum, and Silicon Quantum Computing leading research and development efforts. While traditional welding companies such as Illinois Tool Works and Fronius International have expertise in gas welding, they are not yet major players in the quantum computing space. The intersection of these fields presents opportunities for collaboration between welding specialists and quantum technology firms to advance device fabrication techniques.

Intel Corp.

Technical Solution: Intel is exploring the intersection of gas welding techniques and quantum computing through their cryogenic control chips. These chips, designed to operate at extremely low temperatures, are crucial for controlling qubits in quantum systems. Intel's approach involves using precision gas welding techniques to create hermetic seals for these cryogenic packages, ensuring the integrity of the quantum environment. The company has developed a proprietary gas welding process that minimizes thermal stress on the delicate quantum components while maintaining the necessary vacuum conditions[1]. This technique allows for the creation of robust interconnects between the quantum processor and the control electronics, which is essential for scaling up quantum systems[2].

Strengths: Intel's expertise in semiconductor manufacturing provides a solid foundation for developing quantum-compatible welding techniques. Their approach potentially offers better scalability for large-scale quantum systems. Weaknesses: The specialized nature of the welding process may limit its applicability outside of Intel's specific quantum architecture.

Origin Quantum Computing Technology (Hefei) Co., Ltd.

Technical Solution: Origin Quantum is focusing on developing superconducting quantum chips, where precise gas welding techniques play a crucial role in fabrication. The company has pioneered a novel gas-assisted electron beam welding method for creating superconducting joints in their quantum circuits. This technique allows for the creation of high-quality, low-loss connections between superconducting elements, which is critical for maintaining quantum coherence[3]. Origin Quantum's process involves carefully controlled gas flow during the welding process to prevent oxidation and maintain the superconducting properties of materials like aluminum and niobium, which are commonly used in quantum circuits[4].

Strengths: The gas-assisted welding technique potentially offers higher fidelity quantum operations due to improved superconducting joints. Weaknesses: The process may be more complex and time-consuming compared to traditional fabrication methods, potentially impacting production scalability.

Innovative Welding Techniques

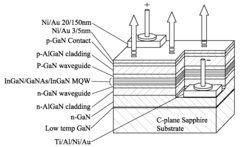

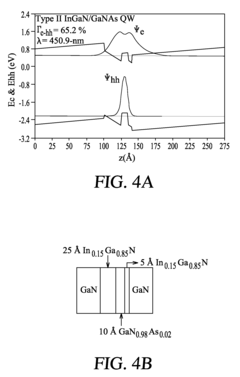

Gallium nitride-based device and method

PatentInactiveUS20090162963A1

Innovation

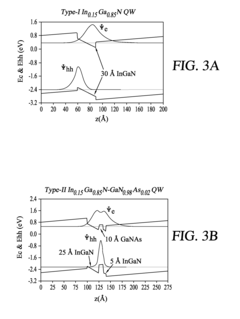

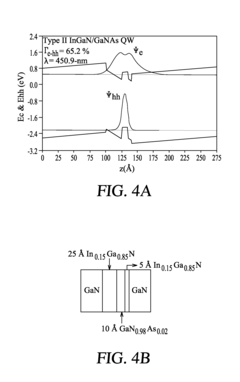

- A gallium nitride-based device with a type II quantum well active region comprising InGaN and GaNAs layers, where the GaNAs layer is sandwiched between InGaN layers, reducing polarization effects and enhancing electron-hole wavefunction overlap for efficient emission from 420-nm to 650-nm.

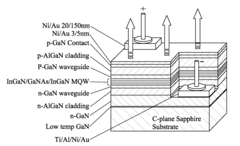

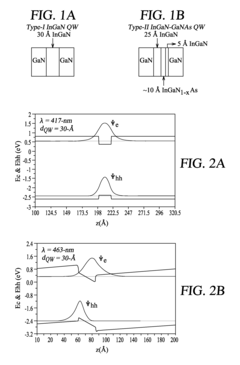

Graded in content gallium nitride-based device and method

PatentInactiveUS20080144685A1

Innovation

- A gallium nitride-based device with a graded In-content InGaN quantum well structure and GaNAs layers is developed, featuring a type-II quantum well active region with multiple InGaN layers and GaNAs layers, where the In concentration is graded to optimize electron-hole wavefunction overlap and reduce charge separation.

Material Science Implications

Gas welding techniques have significant implications for material science in the context of quantum computing devices. The precise control of material properties at the atomic level is crucial for the development and performance of quantum computing components. Gas welding, traditionally used in metalworking, has found unexpected applications in the fabrication of quantum computing devices due to its ability to manipulate materials at high temperatures with exceptional precision.

The use of gas welding in quantum computing device fabrication has led to advancements in the creation of superconducting qubits. These qubits require materials with specific electromagnetic properties, which can be achieved through carefully controlled heating and cooling processes. Gas welding techniques allow for the precise manipulation of material composition and structure, enabling the creation of superconducting materials with the desired characteristics for quantum computing applications.

Furthermore, gas welding has proven valuable in the development of quantum sensing devices. The ability to create nanoscale structures with high precision is essential for these sensors, and gas welding techniques have demonstrated the capability to produce such structures with remarkable accuracy. This has led to improvements in the sensitivity and reliability of quantum sensors, which are critical components in various quantum computing applications.

The influence of gas welding on material science extends to the creation of novel quantum materials. By utilizing the high-temperature capabilities of gas welding, researchers have been able to synthesize materials with unique quantum properties. These materials exhibit behaviors such as topological insulation or unconventional superconductivity, which are of great interest in the field of quantum computing.

Gas welding techniques have also contributed to advancements in the fabrication of quantum dots. These nanoscale structures are fundamental to certain quantum computing architectures, and their properties are highly dependent on the precise control of material composition and structure. The ability to manipulate materials at high temperatures with gas welding has enabled the creation of quantum dots with improved coherence times and reduced decoherence, which are critical factors in quantum computing performance.

In addition, gas welding has played a role in the development of materials for quantum memory devices. The ability to create materials with long coherence times and high fidelity is essential for quantum memory applications. Gas welding techniques have facilitated the creation of materials with improved spin coherence properties, leading to advancements in quantum memory storage and retrieval capabilities.

The use of gas welding in quantum computing device fabrication has led to advancements in the creation of superconducting qubits. These qubits require materials with specific electromagnetic properties, which can be achieved through carefully controlled heating and cooling processes. Gas welding techniques allow for the precise manipulation of material composition and structure, enabling the creation of superconducting materials with the desired characteristics for quantum computing applications.

Furthermore, gas welding has proven valuable in the development of quantum sensing devices. The ability to create nanoscale structures with high precision is essential for these sensors, and gas welding techniques have demonstrated the capability to produce such structures with remarkable accuracy. This has led to improvements in the sensitivity and reliability of quantum sensors, which are critical components in various quantum computing applications.

The influence of gas welding on material science extends to the creation of novel quantum materials. By utilizing the high-temperature capabilities of gas welding, researchers have been able to synthesize materials with unique quantum properties. These materials exhibit behaviors such as topological insulation or unconventional superconductivity, which are of great interest in the field of quantum computing.

Gas welding techniques have also contributed to advancements in the fabrication of quantum dots. These nanoscale structures are fundamental to certain quantum computing architectures, and their properties are highly dependent on the precise control of material composition and structure. The ability to manipulate materials at high temperatures with gas welding has enabled the creation of quantum dots with improved coherence times and reduced decoherence, which are critical factors in quantum computing performance.

In addition, gas welding has played a role in the development of materials for quantum memory devices. The ability to create materials with long coherence times and high fidelity is essential for quantum memory applications. Gas welding techniques have facilitated the creation of materials with improved spin coherence properties, leading to advancements in quantum memory storage and retrieval capabilities.

Quantum Device Fabrication

Quantum device fabrication plays a crucial role in the development of quantum computing systems. The process involves intricate techniques to create and manipulate quantum bits (qubits) with high precision and reliability. Gas welding techniques have emerged as a potential method to influence the fabrication of quantum computing devices, offering unique advantages in certain aspects of the manufacturing process.

The application of gas welding in quantum device fabrication primarily focuses on the creation of superconducting circuits and interconnects. These components are essential for maintaining quantum coherence and facilitating the flow of information within the quantum processor. Gas welding techniques allow for precise control of heat distribution and material deposition, which is critical when working with the delicate materials used in quantum devices.

One of the key advantages of gas welding in this context is its ability to create high-quality, low-resistance joints between superconducting materials. This is particularly important for maintaining the integrity of quantum circuits and minimizing decoherence effects. The controlled heat input of gas welding can be fine-tuned to achieve optimal bonding without compromising the superconducting properties of the materials involved.

Furthermore, gas welding techniques can be adapted for the fabrication of specialized components in quantum devices, such as Josephson junctions. These junctions are fundamental building blocks in many superconducting qubit designs. The precise control offered by gas welding allows for the creation of ultra-thin insulating barriers between superconducting layers, which is crucial for the proper functioning of Josephson junctions.

Another area where gas welding techniques show promise is in the creation of hermetic seals for quantum device packaging. Maintaining a controlled environment is essential for preserving the delicate quantum states of qubits. Gas welding can produce high-quality, leak-tight seals that protect the quantum components from external interference and environmental factors that could lead to decoherence.

However, the integration of gas welding techniques in quantum device fabrication also presents challenges. The extreme sensitivity of quantum systems to thermal fluctuations and impurities necessitates stringent control over the welding process. Researchers and engineers must develop specialized protocols and equipment to ensure that the heat and gases involved in the welding process do not introduce unwanted defects or contaminants into the quantum devices.

As the field of quantum computing continues to advance, the role of gas welding techniques in device fabrication is likely to evolve. Ongoing research focuses on optimizing these techniques to meet the increasingly demanding requirements of next-generation quantum processors. This includes exploring novel gas mixtures, refining temperature control methods, and developing automated welding systems tailored specifically for quantum device manufacturing.

The application of gas welding in quantum device fabrication primarily focuses on the creation of superconducting circuits and interconnects. These components are essential for maintaining quantum coherence and facilitating the flow of information within the quantum processor. Gas welding techniques allow for precise control of heat distribution and material deposition, which is critical when working with the delicate materials used in quantum devices.

One of the key advantages of gas welding in this context is its ability to create high-quality, low-resistance joints between superconducting materials. This is particularly important for maintaining the integrity of quantum circuits and minimizing decoherence effects. The controlled heat input of gas welding can be fine-tuned to achieve optimal bonding without compromising the superconducting properties of the materials involved.

Furthermore, gas welding techniques can be adapted for the fabrication of specialized components in quantum devices, such as Josephson junctions. These junctions are fundamental building blocks in many superconducting qubit designs. The precise control offered by gas welding allows for the creation of ultra-thin insulating barriers between superconducting layers, which is crucial for the proper functioning of Josephson junctions.

Another area where gas welding techniques show promise is in the creation of hermetic seals for quantum device packaging. Maintaining a controlled environment is essential for preserving the delicate quantum states of qubits. Gas welding can produce high-quality, leak-tight seals that protect the quantum components from external interference and environmental factors that could lead to decoherence.

However, the integration of gas welding techniques in quantum device fabrication also presents challenges. The extreme sensitivity of quantum systems to thermal fluctuations and impurities necessitates stringent control over the welding process. Researchers and engineers must develop specialized protocols and equipment to ensure that the heat and gases involved in the welding process do not introduce unwanted defects or contaminants into the quantum devices.

As the field of quantum computing continues to advance, the role of gas welding techniques in device fabrication is likely to evolve. Ongoing research focuses on optimizing these techniques to meet the increasingly demanding requirements of next-generation quantum processors. This includes exploring novel gas mixtures, refining temperature control methods, and developing automated welding systems tailored specifically for quantum device manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!