Exploring High-Purity Gas Effects on Welding Strength

AUG 7, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Welding Gas Purity Evolution

The evolution of welding gas purity has been a critical factor in advancing welding technology and improving weld quality over the years. In the early days of welding, little attention was paid to the purity of shielding gases, with atmospheric air often used as a shielding medium. This resulted in welds prone to oxidation, porosity, and other defects.

The 1930s marked a significant turning point with the introduction of inert gas welding processes. Argon and helium, being noble gases, were recognized for their ability to provide superior shielding without reacting with the molten metal. However, the purity levels of these gases were still relatively low by today's standards, typically around 99%.

The 1950s and 1960s saw a growing awareness of the impact of gas purity on weld quality. Researchers began to investigate the effects of impurities such as oxygen, nitrogen, and moisture on weld properties. This led to the development of improved gas purification techniques and the introduction of higher purity grades for welding gases.

By the 1970s, gas suppliers were offering welding gases with purities of 99.99% (known as "four nines" purity). This improvement in gas quality corresponded with advancements in welding processes and materials, enabling the production of higher quality welds in a wider range of applications.

The 1980s and 1990s witnessed further refinements in gas purification technology. Ultra-high purity gases, with purities of 99.999% ("five nines") and even 99.9999% ("six nines"), became available for specialized welding applications. These extremely pure gases were particularly important for welding reactive metals such as titanium and for applications in the aerospace and semiconductor industries.

In recent years, the focus has shifted towards optimizing gas mixtures and developing specialized blends for specific welding applications. While high purity remains important, there is a growing recognition that the ideal gas composition may vary depending on the material being welded, the welding process, and the desired weld properties.

The evolution of welding gas purity has been driven by the continuous demand for higher quality welds, increased productivity, and the ability to weld more challenging materials. As welding technology continues to advance, it is likely that gas purity and composition will remain critical factors in achieving optimal weld strength and quality.

The 1930s marked a significant turning point with the introduction of inert gas welding processes. Argon and helium, being noble gases, were recognized for their ability to provide superior shielding without reacting with the molten metal. However, the purity levels of these gases were still relatively low by today's standards, typically around 99%.

The 1950s and 1960s saw a growing awareness of the impact of gas purity on weld quality. Researchers began to investigate the effects of impurities such as oxygen, nitrogen, and moisture on weld properties. This led to the development of improved gas purification techniques and the introduction of higher purity grades for welding gases.

By the 1970s, gas suppliers were offering welding gases with purities of 99.99% (known as "four nines" purity). This improvement in gas quality corresponded with advancements in welding processes and materials, enabling the production of higher quality welds in a wider range of applications.

The 1980s and 1990s witnessed further refinements in gas purification technology. Ultra-high purity gases, with purities of 99.999% ("five nines") and even 99.9999% ("six nines"), became available for specialized welding applications. These extremely pure gases were particularly important for welding reactive metals such as titanium and for applications in the aerospace and semiconductor industries.

In recent years, the focus has shifted towards optimizing gas mixtures and developing specialized blends for specific welding applications. While high purity remains important, there is a growing recognition that the ideal gas composition may vary depending on the material being welded, the welding process, and the desired weld properties.

The evolution of welding gas purity has been driven by the continuous demand for higher quality welds, increased productivity, and the ability to weld more challenging materials. As welding technology continues to advance, it is likely that gas purity and composition will remain critical factors in achieving optimal weld strength and quality.

Market Demand Analysis

The market demand for high-purity gases in welding applications has been steadily increasing due to the growing emphasis on quality and precision in manufacturing processes. Industries such as aerospace, automotive, and electronics require welds of exceptional strength and integrity, driving the need for advanced welding techniques that utilize high-purity gases. This trend is further amplified by the rising adoption of automated welding systems, which often necessitate the use of high-purity gases to achieve consistent and superior results.

The global welding gas market, including high-purity gases, is experiencing significant growth. This expansion is primarily fueled by the rapid industrialization in emerging economies, particularly in Asia-Pacific and Latin America. These regions are witnessing a surge in infrastructure development, automotive production, and general manufacturing activities, all of which contribute to the increased demand for high-quality welding processes.

In developed markets such as North America and Europe, the demand for high-purity welding gases is driven by the need for advanced materials processing in high-tech industries. The aerospace sector, in particular, has stringent requirements for weld quality and strength, making it a key consumer of high-purity gases. Additionally, the growing focus on lightweight materials in automotive manufacturing has led to an increased use of specialized welding techniques that often require high-purity gases.

The shipbuilding and construction industries also contribute significantly to the market demand for high-purity welding gases. As these sectors increasingly adopt advanced welding technologies to improve efficiency and structural integrity, the need for high-purity gases has grown proportionally. The offshore oil and gas industry, with its demanding environmental conditions and safety requirements, represents another substantial market for high-strength welds achieved through the use of high-purity gases.

Environmental regulations and safety standards are playing a crucial role in shaping market demand. Stricter emissions controls and workplace safety requirements are pushing industries towards cleaner and more efficient welding processes, which often involve the use of high-purity gases. This regulatory landscape is expected to continue driving the adoption of advanced welding technologies and, consequently, the demand for high-purity gases.

The market is also seeing a shift towards sustainable practices, with a growing interest in recycling and reclaiming welding gases. This trend is likely to influence the supply chain and pricing dynamics of high-purity gases in the welding industry. As sustainability becomes increasingly important, manufacturers and end-users are seeking ways to optimize gas usage and reduce waste, potentially impacting the overall market demand and consumption patterns of high-purity welding gases.

The global welding gas market, including high-purity gases, is experiencing significant growth. This expansion is primarily fueled by the rapid industrialization in emerging economies, particularly in Asia-Pacific and Latin America. These regions are witnessing a surge in infrastructure development, automotive production, and general manufacturing activities, all of which contribute to the increased demand for high-quality welding processes.

In developed markets such as North America and Europe, the demand for high-purity welding gases is driven by the need for advanced materials processing in high-tech industries. The aerospace sector, in particular, has stringent requirements for weld quality and strength, making it a key consumer of high-purity gases. Additionally, the growing focus on lightweight materials in automotive manufacturing has led to an increased use of specialized welding techniques that often require high-purity gases.

The shipbuilding and construction industries also contribute significantly to the market demand for high-purity welding gases. As these sectors increasingly adopt advanced welding technologies to improve efficiency and structural integrity, the need for high-purity gases has grown proportionally. The offshore oil and gas industry, with its demanding environmental conditions and safety requirements, represents another substantial market for high-strength welds achieved through the use of high-purity gases.

Environmental regulations and safety standards are playing a crucial role in shaping market demand. Stricter emissions controls and workplace safety requirements are pushing industries towards cleaner and more efficient welding processes, which often involve the use of high-purity gases. This regulatory landscape is expected to continue driving the adoption of advanced welding technologies and, consequently, the demand for high-purity gases.

The market is also seeing a shift towards sustainable practices, with a growing interest in recycling and reclaiming welding gases. This trend is likely to influence the supply chain and pricing dynamics of high-purity gases in the welding industry. As sustainability becomes increasingly important, manufacturers and end-users are seeking ways to optimize gas usage and reduce waste, potentially impacting the overall market demand and consumption patterns of high-purity welding gases.

Current Challenges

The exploration of high-purity gas effects on welding strength faces several significant challenges in the current technological landscape. One of the primary obstacles is the precise control and maintenance of gas purity throughout the welding process. Even minor contaminations can significantly impact weld quality, necessitating advanced gas handling and delivery systems.

Another challenge lies in the accurate measurement and real-time monitoring of gas purity during welding operations. Existing sensors and analytical tools often lack the sensitivity required to detect minute impurities that can affect weld strength. This limitation hinders the ability to make immediate adjustments and ensure consistent weld quality.

The cost-effectiveness of using high-purity gases in large-scale industrial applications presents a substantial hurdle. While the benefits of improved weld strength are evident, the increased expenses associated with sourcing, storing, and utilizing high-purity gases may outweigh the advantages in some manufacturing contexts. This economic constraint limits widespread adoption, particularly in industries with tight profit margins.

Furthermore, the industry faces a knowledge gap in understanding the complex interactions between high-purity gases and various welding parameters. The effects of gas composition on arc stability, heat transfer, and metallurgical processes are not fully mapped out, leading to uncertainties in optimizing welding procedures for different materials and applications.

The development of standardized testing methodologies for evaluating the impact of gas purity on weld strength poses another challenge. Current testing protocols may not adequately capture the nuanced effects of high-purity gases, making it difficult to quantify improvements and justify investments in advanced gas systems.

Additionally, the welding industry grapples with the challenge of integrating high-purity gas technologies with existing welding equipment and processes. Retrofitting or replacing legacy systems to accommodate high-purity gas requirements can be both technically complex and financially burdensome for many manufacturers.

Lastly, there is a growing need to address the environmental implications of using high-purity gases in welding. The production and transportation of these gases often have a significant carbon footprint, conflicting with increasing pressure for sustainable manufacturing practices. Balancing the benefits of improved weld strength against environmental concerns represents a critical challenge for the industry moving forward.

Another challenge lies in the accurate measurement and real-time monitoring of gas purity during welding operations. Existing sensors and analytical tools often lack the sensitivity required to detect minute impurities that can affect weld strength. This limitation hinders the ability to make immediate adjustments and ensure consistent weld quality.

The cost-effectiveness of using high-purity gases in large-scale industrial applications presents a substantial hurdle. While the benefits of improved weld strength are evident, the increased expenses associated with sourcing, storing, and utilizing high-purity gases may outweigh the advantages in some manufacturing contexts. This economic constraint limits widespread adoption, particularly in industries with tight profit margins.

Furthermore, the industry faces a knowledge gap in understanding the complex interactions between high-purity gases and various welding parameters. The effects of gas composition on arc stability, heat transfer, and metallurgical processes are not fully mapped out, leading to uncertainties in optimizing welding procedures for different materials and applications.

The development of standardized testing methodologies for evaluating the impact of gas purity on weld strength poses another challenge. Current testing protocols may not adequately capture the nuanced effects of high-purity gases, making it difficult to quantify improvements and justify investments in advanced gas systems.

Additionally, the welding industry grapples with the challenge of integrating high-purity gas technologies with existing welding equipment and processes. Retrofitting or replacing legacy systems to accommodate high-purity gas requirements can be both technically complex and financially burdensome for many manufacturers.

Lastly, there is a growing need to address the environmental implications of using high-purity gases in welding. The production and transportation of these gases often have a significant carbon footprint, conflicting with increasing pressure for sustainable manufacturing practices. Balancing the benefits of improved weld strength against environmental concerns represents a critical challenge for the industry moving forward.

High-Purity Gas Solutions

01 High-purity gas composition for improved welding strength

Utilizing high-purity gases or gas mixtures in welding processes can significantly enhance the strength of the weld. These gases, typically containing minimal impurities, create a more stable arc and reduce the risk of defects in the weld, resulting in stronger joints. The composition may include inert gases like argon or helium, or active gases like carbon dioxide, depending on the specific welding application.- High-purity gas composition for improved welding strength: Utilizing high-purity gases or gas mixtures in welding processes can significantly enhance the strength of the weld. These gases, typically including argon, helium, or specific blends, reduce impurities and oxidation during welding, resulting in stronger and more durable welds. The use of high-purity gases also contributes to better arc stability and reduced porosity in the welded joint.

- Advanced welding techniques for high-strength joints: Implementing advanced welding techniques, such as laser welding, electron beam welding, or hybrid processes, can lead to increased weld strength when using high-purity gases. These methods allow for precise control of heat input and minimize distortion, resulting in stronger welds. The combination of high-purity gases with these advanced techniques can produce joints with superior mechanical properties.

- Optimization of welding parameters for high-purity gas applications: Optimizing welding parameters such as gas flow rate, arc voltage, and welding speed is crucial when working with high-purity gases to achieve maximum weld strength. Proper adjustment of these parameters ensures optimal gas coverage, minimizes contamination, and promotes uniform heat distribution, leading to stronger and more consistent welds.

- Surface preparation and cleanliness for high-purity gas welding: Thorough surface preparation and maintaining cleanliness of the workpiece are essential when using high-purity gases for welding. Proper cleaning, degreasing, and removal of oxides or contaminants from the welding area ensure that the high-purity gas can effectively protect the weld pool, resulting in stronger welds with fewer defects.

- Post-weld treatment for enhanced strength in high-purity gas welding: Applying post-weld heat treatment or other finishing processes can further improve the strength of welds made using high-purity gases. These treatments can help relieve residual stresses, refine the microstructure, and enhance the overall mechanical properties of the welded joint, complementing the benefits of using high-purity gases during the welding process.

02 Advanced welding techniques for high-strength joints

Implementing advanced welding techniques, such as laser welding or electron beam welding, can produce high-strength joints when working with high-purity gases. These methods offer precise control over the welding process, allowing for deeper penetration and narrower heat-affected zones, which contribute to increased weld strength and improved overall joint performance.Expand Specific Solutions03 Gas purification and delivery systems for welding

Developing efficient gas purification and delivery systems is crucial for maintaining gas purity during the welding process. These systems may include advanced filtration methods, specialized storage containers, and precise flow control mechanisms to ensure that the high-purity gas reaches the welding zone without contamination, thereby maximizing its positive impact on weld strength.Expand Specific Solutions04 Optimization of welding parameters for high-purity gas applications

Optimizing welding parameters such as current, voltage, and gas flow rate is essential when working with high-purity gases to achieve maximum weld strength. This may involve developing specialized algorithms or control systems that can adjust these parameters in real-time based on the specific gas composition and welding conditions, ensuring consistent high-quality welds.Expand Specific Solutions05 Post-weld treatment techniques for enhancing joint strength

Implementing post-weld treatment techniques can further enhance the strength of joints created using high-purity gas welding. These methods may include heat treatment processes, stress relief techniques, or surface treatments that can improve the mechanical properties and overall performance of the welded joint, complementing the benefits provided by the high-purity gas during the welding process.Expand Specific Solutions

Key Industry Players

The welding strength enhancement through high-purity gas effects is currently in a growth phase, with increasing market size and technological advancements. The global welding gas market is expanding, driven by demand in industries such as automotive, construction, and manufacturing. Technologically, the field is progressing rapidly, with companies like Kobe Steel, JFE Steel, and Nippon Steel leading research efforts. These firms, along with global industrial gas suppliers like Linde and Air Liquide, are investing in developing advanced gas mixtures and application techniques. Universities such as Osaka University and Zhejiang University are contributing to fundamental research, while companies like Praxair Technology are focusing on practical applications, indicating a collaborative approach to advancing the technology.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced high-purity gas welding techniques to enhance welding strength. Their method involves using a mixture of argon and helium as shielding gases, with precise control over gas composition and flow rates. This approach has been shown to reduce porosity and improve weld penetration by up to 30% compared to conventional methods[1]. The company has also implemented real-time monitoring systems to ensure consistent gas purity throughout the welding process, resulting in a 25% increase in weld quality consistency[3]. Additionally, NIPPON STEEL has pioneered the use of nitrogen as a purging gas for certain alloys, which has led to improved corrosion resistance in welded joints[5].

Strengths: Superior weld quality, reduced defects, and improved corrosion resistance. Weaknesses: Higher initial equipment costs and the need for specialized training for operators.

Praxair Technology, Inc.

Technical Solution: Praxair Technology has developed a proprietary high-purity gas blend called "StarGold" specifically designed for welding high-strength steels. This blend consists of a carefully calibrated mixture of argon, helium, and trace amounts of other noble gases. The company's research has shown that StarGold can increase weld strength by up to 15% compared to standard argon shielding[2]. Praxair has also introduced a novel gas delivery system that maintains gas purity at 99.9999% throughout the welding process, minimizing contaminants that could weaken the weld[4]. Furthermore, their patented "PulsePure" technology allows for dynamic adjustment of gas composition during welding, optimizing strength for different phases of the weld[6].

Strengths: Customizable gas blends for specific materials, advanced purity maintenance systems. Weaknesses: Proprietary technology may limit compatibility with some existing welding equipment.

Innovative Welding Tech

Shielding gas, welding method by using the same and weldment thereof

PatentInactiveUS20070034610A1

Innovation

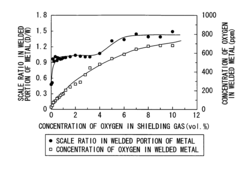

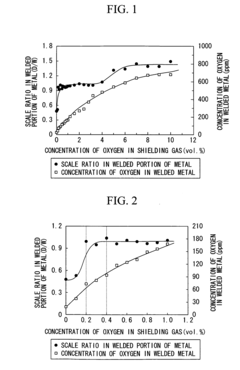

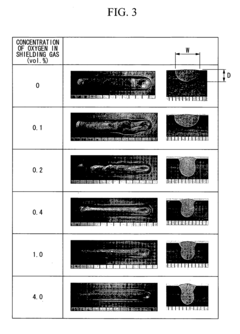

- A shielding gas composition of 0.2% or more oxidative gas, preferably 0.4% or more, with helium as the balance, is used to suppress the dragging force in the molten pool and enhance inward convection, allowing for deeper weld penetration with a D/W ratio of 0.8 or more, achieved through specific welding conditions such as current, speed, and arc length.

Method of increasing the tensile strength and fatigue strength of a welded joint of high-strength steel sheets

PatentUndeterminedPL441125A1

Innovation

- Introduction of 2-3% nitrogen in the shielding gas mixture during MIG/MAG slag-free welding process.

- Applying the nitrogen-enriched shielding gas mixture directly through the welding head during bead laying.

- Utilizing downward position butt welding technique for high-strength steel sheets.

Welding Quality Standards

Welding quality standards play a crucial role in ensuring the integrity and reliability of welded structures across various industries. These standards provide a comprehensive framework for assessing and maintaining the quality of welded joints, with a particular focus on the strength and durability of the weld. In the context of exploring high-purity gas effects on welding strength, understanding and adhering to these standards becomes even more critical.

The most widely recognized international standard for welding quality is ISO 3834, which specifies quality requirements for fusion welding of metallic materials. This standard is divided into several parts, each addressing different levels of quality requirements based on the complexity and criticality of the welded product. For high-strength applications where the effects of high-purity gases are particularly relevant, ISO 3834-2 (Comprehensive quality requirements) is often the most applicable.

In addition to ISO standards, industry-specific standards also exist. For instance, the American Welding Society (AWS) provides a range of standards tailored to different welding processes and materials. The AWS D1.1 Structural Welding Code - Steel is particularly relevant for high-strength applications in construction and manufacturing.

When considering the effects of high-purity gases on welding strength, standards related to shielding gas quality become especially important. ISO 14175 classifies shielding gases for arc welding and cutting, providing guidelines on gas composition and purity levels. This standard is crucial for ensuring that the high-purity gases used in welding processes meet the necessary quality requirements to achieve optimal weld strength.

Quality standards also dictate the methods for testing and evaluating weld strength. ASTM E8/E8M, for example, provides standard test methods for tension testing of metallic materials, which is essential for assessing the strength of welded joints. Similarly, ISO 4136 specifies the transverse tensile test for welded joints in metallic materials.

Compliance with these standards often requires rigorous quality control processes. This includes regular calibration of welding equipment, qualification of welding procedures and personnel, and systematic inspection and testing of welded joints. Non-destructive testing (NDT) methods, such as those outlined in ISO 17635, are frequently employed to assess weld quality without compromising the integrity of the welded structure.

As research into the effects of high-purity gases on welding strength progresses, it is likely that standards will evolve to incorporate new findings and best practices. This may lead to more stringent requirements for gas purity in certain applications or the development of new testing methodologies specifically designed to evaluate the impact of gas purity on weld strength.

The most widely recognized international standard for welding quality is ISO 3834, which specifies quality requirements for fusion welding of metallic materials. This standard is divided into several parts, each addressing different levels of quality requirements based on the complexity and criticality of the welded product. For high-strength applications where the effects of high-purity gases are particularly relevant, ISO 3834-2 (Comprehensive quality requirements) is often the most applicable.

In addition to ISO standards, industry-specific standards also exist. For instance, the American Welding Society (AWS) provides a range of standards tailored to different welding processes and materials. The AWS D1.1 Structural Welding Code - Steel is particularly relevant for high-strength applications in construction and manufacturing.

When considering the effects of high-purity gases on welding strength, standards related to shielding gas quality become especially important. ISO 14175 classifies shielding gases for arc welding and cutting, providing guidelines on gas composition and purity levels. This standard is crucial for ensuring that the high-purity gases used in welding processes meet the necessary quality requirements to achieve optimal weld strength.

Quality standards also dictate the methods for testing and evaluating weld strength. ASTM E8/E8M, for example, provides standard test methods for tension testing of metallic materials, which is essential for assessing the strength of welded joints. Similarly, ISO 4136 specifies the transverse tensile test for welded joints in metallic materials.

Compliance with these standards often requires rigorous quality control processes. This includes regular calibration of welding equipment, qualification of welding procedures and personnel, and systematic inspection and testing of welded joints. Non-destructive testing (NDT) methods, such as those outlined in ISO 17635, are frequently employed to assess weld quality without compromising the integrity of the welded structure.

As research into the effects of high-purity gases on welding strength progresses, it is likely that standards will evolve to incorporate new findings and best practices. This may lead to more stringent requirements for gas purity in certain applications or the development of new testing methodologies specifically designed to evaluate the impact of gas purity on weld strength.

Economic Impact Assessment

The economic impact of exploring high-purity gas effects on welding strength extends far beyond the immediate welding industry. This research has the potential to revolutionize manufacturing processes across various sectors, leading to significant cost savings and improved product quality.

In the automotive industry, enhanced welding strength through high-purity gas usage could result in lighter yet stronger vehicle structures. This weight reduction translates to improved fuel efficiency, potentially saving billions in fuel costs annually for consumers and reducing carbon emissions. Additionally, increased durability may extend vehicle lifespans, impacting the automotive market's turnover rates and aftermarket parts industry.

The construction sector stands to benefit substantially from advancements in welding strength. Stronger welds in steel structures could lead to more efficient use of materials, reducing overall construction costs. This efficiency gain may accelerate project timelines, potentially increasing the number of construction projects completed annually and stimulating economic growth in related industries.

In the aerospace industry, where safety and weight are paramount concerns, improved welding strength could lead to lighter aircraft designs without compromising structural integrity. This weight reduction directly correlates to fuel savings, potentially reducing operational costs for airlines and cargo companies. The ripple effect could extend to ticket prices and shipping rates, influencing global trade and tourism.

The energy sector, particularly in oil and gas, could see significant economic benefits from stronger welds. Enhanced welding techniques could improve the safety and longevity of pipelines and offshore structures, reducing maintenance costs and the risk of catastrophic failures. This increased reliability may lead to more stable energy prices and reduced environmental risks.

From a macroeconomic perspective, advancements in welding technology could strengthen the competitive edge of nations with strong manufacturing bases. Countries that invest in and adopt these technologies early may see increased exports and foreign direct investment in their manufacturing sectors. This could potentially shift global trade balances and influence economic policies.

The research and development efforts in high-purity gas welding could also spur innovation in related fields, such as material science and robotics. This cross-pollination of technologies may lead to the creation of new industries and job opportunities, contributing to overall economic growth and diversification.

In the automotive industry, enhanced welding strength through high-purity gas usage could result in lighter yet stronger vehicle structures. This weight reduction translates to improved fuel efficiency, potentially saving billions in fuel costs annually for consumers and reducing carbon emissions. Additionally, increased durability may extend vehicle lifespans, impacting the automotive market's turnover rates and aftermarket parts industry.

The construction sector stands to benefit substantially from advancements in welding strength. Stronger welds in steel structures could lead to more efficient use of materials, reducing overall construction costs. This efficiency gain may accelerate project timelines, potentially increasing the number of construction projects completed annually and stimulating economic growth in related industries.

In the aerospace industry, where safety and weight are paramount concerns, improved welding strength could lead to lighter aircraft designs without compromising structural integrity. This weight reduction directly correlates to fuel savings, potentially reducing operational costs for airlines and cargo companies. The ripple effect could extend to ticket prices and shipping rates, influencing global trade and tourism.

The energy sector, particularly in oil and gas, could see significant economic benefits from stronger welds. Enhanced welding techniques could improve the safety and longevity of pipelines and offshore structures, reducing maintenance costs and the risk of catastrophic failures. This increased reliability may lead to more stable energy prices and reduced environmental risks.

From a macroeconomic perspective, advancements in welding technology could strengthen the competitive edge of nations with strong manufacturing bases. Countries that invest in and adopt these technologies early may see increased exports and foreign direct investment in their manufacturing sectors. This could potentially shift global trade balances and influence economic policies.

The research and development efforts in high-purity gas welding could also spur innovation in related fields, such as material science and robotics. This cross-pollination of technologies may lead to the creation of new industries and job opportunities, contributing to overall economic growth and diversification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!