Analysis of Gas Welding Impact on Material Wear Reduction

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Background and Objectives

Gas welding, a time-honored joining technique, has been a cornerstone in the manufacturing and repair industries for over a century. This process, which utilizes the combustion of gases to generate heat for melting and fusing metals, has evolved significantly since its inception in the late 19th century. The technology has progressed from simple oxy-hydrogen setups to more sophisticated oxy-acetylene systems, enhancing efficiency and expanding its applications across various sectors.

The primary objective of this technical research report is to comprehensively analyze the impact of gas welding on material wear reduction. This focus stems from the growing demand for sustainable manufacturing processes and the need to extend the lifespan of industrial components. By examining the effects of gas welding on material properties and wear resistance, we aim to uncover potential innovations that could revolutionize maintenance practices and material longevity in industrial settings.

Throughout its history, gas welding has demonstrated remarkable versatility, finding applications in automotive repair, plumbing, jewelry making, and even aerospace manufacturing. Its ability to join a wide range of metals, including steel, aluminum, and copper, has contributed to its enduring relevance in the face of newer welding technologies. However, the relationship between gas welding processes and material wear characteristics has not been fully explored, presenting an opportunity for groundbreaking research and development.

Recent advancements in metallurgy and materials science have opened new avenues for understanding the microstructural changes induced by gas welding. These insights are crucial for predicting and potentially enhancing the wear resistance of welded components. By leveraging this knowledge, we aim to develop innovative welding techniques and post-weld treatments that could significantly reduce material wear in high-stress applications.

The global push towards more efficient and environmentally friendly manufacturing processes has also placed gas welding under scrutiny. While it remains a relatively low-tech solution compared to laser or electron beam welding, gas welding's potential for reducing material waste through improved wear resistance aligns well with sustainable manufacturing goals. This research seeks to bridge the gap between traditional welding practices and modern sustainability requirements, potentially breathing new life into this classic technique.

As we embark on this technical exploration, we will examine the fundamental principles of gas welding, its current applications in wear-resistant coatings, and the latest research on how welding parameters affect material properties. By synthesizing this information, we aim to identify promising directions for future research and development, ultimately contributing to the advancement of material science and manufacturing technology.

The primary objective of this technical research report is to comprehensively analyze the impact of gas welding on material wear reduction. This focus stems from the growing demand for sustainable manufacturing processes and the need to extend the lifespan of industrial components. By examining the effects of gas welding on material properties and wear resistance, we aim to uncover potential innovations that could revolutionize maintenance practices and material longevity in industrial settings.

Throughout its history, gas welding has demonstrated remarkable versatility, finding applications in automotive repair, plumbing, jewelry making, and even aerospace manufacturing. Its ability to join a wide range of metals, including steel, aluminum, and copper, has contributed to its enduring relevance in the face of newer welding technologies. However, the relationship between gas welding processes and material wear characteristics has not been fully explored, presenting an opportunity for groundbreaking research and development.

Recent advancements in metallurgy and materials science have opened new avenues for understanding the microstructural changes induced by gas welding. These insights are crucial for predicting and potentially enhancing the wear resistance of welded components. By leveraging this knowledge, we aim to develop innovative welding techniques and post-weld treatments that could significantly reduce material wear in high-stress applications.

The global push towards more efficient and environmentally friendly manufacturing processes has also placed gas welding under scrutiny. While it remains a relatively low-tech solution compared to laser or electron beam welding, gas welding's potential for reducing material waste through improved wear resistance aligns well with sustainable manufacturing goals. This research seeks to bridge the gap between traditional welding practices and modern sustainability requirements, potentially breathing new life into this classic technique.

As we embark on this technical exploration, we will examine the fundamental principles of gas welding, its current applications in wear-resistant coatings, and the latest research on how welding parameters affect material properties. By synthesizing this information, we aim to identify promising directions for future research and development, ultimately contributing to the advancement of material science and manufacturing technology.

Market Demand Analysis for Wear-Resistant Materials

The market demand for wear-resistant materials in the context of gas welding has been steadily increasing due to the growing emphasis on efficiency and longevity in industrial processes. Industries such as manufacturing, construction, and automotive are particularly driving this demand as they seek to reduce maintenance costs and improve overall productivity.

In the manufacturing sector, wear-resistant materials are crucial for extending the lifespan of machinery components subjected to high temperatures and abrasive conditions during gas welding processes. The automotive industry, in particular, has shown a significant uptick in demand for these materials, as vehicle manufacturers strive to produce lighter yet more durable parts to meet stringent fuel efficiency standards.

The construction industry also contributes substantially to the market demand for wear-resistant materials. Gas welding is extensively used in structural steel fabrication, and the need for materials that can withstand the intense heat and pressure of the welding process while maintaining structural integrity is paramount.

Market analysis indicates that the global wear-resistant materials market is expected to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is largely attributed to the increasing adoption of advanced manufacturing techniques and the push for longer-lasting, more reliable industrial equipment.

The oil and gas industry represents another significant driver of demand for wear-resistant materials in gas welding applications. As exploration and extraction activities expand into more challenging environments, the need for materials that can withstand extreme conditions while maintaining weld integrity becomes critical.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing rapid growth in industrialization, which is fueling the demand for wear-resistant materials. These regions are investing heavily in infrastructure development and manufacturing capabilities, creating new opportunities for the wear-resistant materials market.

Environmental regulations and sustainability concerns are also shaping market demand. There is a growing preference for materials that not only offer superior wear resistance but also contribute to reduced energy consumption and emissions during the welding process. This trend is pushing manufacturers to innovate and develop eco-friendly wear-resistant solutions.

The market is also witnessing a shift towards customized wear-resistant materials tailored for specific gas welding applications. This trend is driven by the need for optimized performance in diverse industrial settings, leading to increased research and development activities in the field of materials science.

In the manufacturing sector, wear-resistant materials are crucial for extending the lifespan of machinery components subjected to high temperatures and abrasive conditions during gas welding processes. The automotive industry, in particular, has shown a significant uptick in demand for these materials, as vehicle manufacturers strive to produce lighter yet more durable parts to meet stringent fuel efficiency standards.

The construction industry also contributes substantially to the market demand for wear-resistant materials. Gas welding is extensively used in structural steel fabrication, and the need for materials that can withstand the intense heat and pressure of the welding process while maintaining structural integrity is paramount.

Market analysis indicates that the global wear-resistant materials market is expected to grow at a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is largely attributed to the increasing adoption of advanced manufacturing techniques and the push for longer-lasting, more reliable industrial equipment.

The oil and gas industry represents another significant driver of demand for wear-resistant materials in gas welding applications. As exploration and extraction activities expand into more challenging environments, the need for materials that can withstand extreme conditions while maintaining weld integrity becomes critical.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing rapid growth in industrialization, which is fueling the demand for wear-resistant materials. These regions are investing heavily in infrastructure development and manufacturing capabilities, creating new opportunities for the wear-resistant materials market.

Environmental regulations and sustainability concerns are also shaping market demand. There is a growing preference for materials that not only offer superior wear resistance but also contribute to reduced energy consumption and emissions during the welding process. This trend is pushing manufacturers to innovate and develop eco-friendly wear-resistant solutions.

The market is also witnessing a shift towards customized wear-resistant materials tailored for specific gas welding applications. This trend is driven by the need for optimized performance in diverse industrial settings, leading to increased research and development activities in the field of materials science.

Current State and Challenges in Gas Welding

Gas welding has been a cornerstone in material joining processes for decades, yet its impact on material wear reduction remains a complex and evolving field of study. The current state of gas welding technology showcases both significant advancements and persistent challenges in achieving optimal wear resistance in welded materials.

Recent developments in gas welding techniques have led to improved control over heat input and weld pool dynamics, resulting in more precise and consistent welds. Advanced gas mixtures and flow control systems have enabled welders to tailor the welding atmosphere to specific material requirements, enhancing the overall quality of the weld and potentially reducing wear-related issues.

However, the industry still grapples with several key challenges. One of the primary concerns is the formation of heat-affected zones (HAZ) during the welding process. These zones often exhibit altered microstructures that can be more susceptible to wear compared to the base material. Researchers and engineers are actively working on methods to minimize the extent and impact of HAZs, including the development of post-weld heat treatment protocols and the use of specialized filler materials.

Another significant challenge lies in the control of residual stresses induced by the welding process. These stresses can lead to distortion and premature wear in welded components, particularly in applications subject to cyclic loading or extreme environmental conditions. Advanced simulation tools and real-time monitoring systems are being employed to predict and mitigate these stress-related issues, but further refinement is needed to address complex geometries and material combinations.

The variability in weld quality due to operator skill remains a persistent issue in gas welding. While automation and robotic systems have made significant inroads in many welding applications, gas welding still relies heavily on manual techniques for certain specialized tasks. This human factor introduces inconsistencies that can affect the wear resistance of welded joints. Efforts to standardize procedures and implement more sophisticated training programs are ongoing, but bridging the gap between manual skill and automated precision remains a challenge.

Material compatibility and selection present another hurdle in optimizing wear resistance through gas welding. The diverse range of alloys and composites used in modern engineering applications requires a nuanced understanding of how different materials interact during the welding process and how these interactions influence long-term wear behavior. Ongoing research focuses on developing comprehensive databases and predictive models to guide material selection and welding parameter optimization for enhanced wear resistance.

Environmental concerns and regulatory pressures also shape the current landscape of gas welding technology. The industry is tasked with developing more environmentally friendly welding processes that maintain or improve wear resistance while reducing emissions and energy consumption. This has led to innovations in gas mixture compositions and the exploration of hybrid welding techniques that combine the benefits of gas welding with other joining methods.

Recent developments in gas welding techniques have led to improved control over heat input and weld pool dynamics, resulting in more precise and consistent welds. Advanced gas mixtures and flow control systems have enabled welders to tailor the welding atmosphere to specific material requirements, enhancing the overall quality of the weld and potentially reducing wear-related issues.

However, the industry still grapples with several key challenges. One of the primary concerns is the formation of heat-affected zones (HAZ) during the welding process. These zones often exhibit altered microstructures that can be more susceptible to wear compared to the base material. Researchers and engineers are actively working on methods to minimize the extent and impact of HAZs, including the development of post-weld heat treatment protocols and the use of specialized filler materials.

Another significant challenge lies in the control of residual stresses induced by the welding process. These stresses can lead to distortion and premature wear in welded components, particularly in applications subject to cyclic loading or extreme environmental conditions. Advanced simulation tools and real-time monitoring systems are being employed to predict and mitigate these stress-related issues, but further refinement is needed to address complex geometries and material combinations.

The variability in weld quality due to operator skill remains a persistent issue in gas welding. While automation and robotic systems have made significant inroads in many welding applications, gas welding still relies heavily on manual techniques for certain specialized tasks. This human factor introduces inconsistencies that can affect the wear resistance of welded joints. Efforts to standardize procedures and implement more sophisticated training programs are ongoing, but bridging the gap between manual skill and automated precision remains a challenge.

Material compatibility and selection present another hurdle in optimizing wear resistance through gas welding. The diverse range of alloys and composites used in modern engineering applications requires a nuanced understanding of how different materials interact during the welding process and how these interactions influence long-term wear behavior. Ongoing research focuses on developing comprehensive databases and predictive models to guide material selection and welding parameter optimization for enhanced wear resistance.

Environmental concerns and regulatory pressures also shape the current landscape of gas welding technology. The industry is tasked with developing more environmentally friendly welding processes that maintain or improve wear resistance while reducing emissions and energy consumption. This has led to innovations in gas mixture compositions and the exploration of hybrid welding techniques that combine the benefits of gas welding with other joining methods.

Existing Gas Welding Solutions for Wear Reduction

01 Wear-resistant materials for gas welding equipment

Development of specialized materials to enhance the durability of gas welding equipment components. These materials are designed to withstand high temperatures and resist wear caused by friction and chemical reactions during the welding process. The use of such materials can significantly extend the lifespan of welding tools and improve overall performance.- Wear-resistant materials for gas welding equipment: Development of specialized materials to enhance the durability of gas welding equipment components. These materials are designed to withstand high temperatures and corrosive environments, reducing wear and extending the lifespan of welding tools.

- Protective coatings for gas welding surfaces: Application of protective coatings on gas welding surfaces to minimize material wear. These coatings provide a barrier against heat, abrasion, and chemical reactions, thereby improving the longevity of welding equipment and maintaining performance over time.

- Advanced alloy compositions for gas welding nozzles: Development of specialized alloy compositions tailored for gas welding nozzles. These alloys offer improved resistance to high-temperature oxidation, erosion, and thermal fatigue, resulting in reduced material wear and increased nozzle lifespan.

- Cooling systems for gas welding equipment: Integration of advanced cooling systems in gas welding equipment to mitigate material wear caused by excessive heat. These systems help maintain optimal operating temperatures, reducing thermal stress on components and extending their service life.

- Surface treatment techniques for gas welding components: Implementation of various surface treatment techniques to enhance the wear resistance of gas welding components. These methods include hardening, nitriding, and laser surface modification, which improve the mechanical properties and durability of the treated surfaces.

02 Protective coatings for gas welding surfaces

Application of protective coatings on gas welding surfaces to minimize wear and corrosion. These coatings are formulated to provide a barrier against heat, abrasion, and chemical reactions. They can be applied to various components of welding equipment, including nozzles, tips, and regulators, to extend their service life and maintain optimal performance.Expand Specific Solutions03 Advanced alloy compositions for gas welding tools

Development of specialized alloy compositions tailored for gas welding applications. These alloys are engineered to possess superior wear resistance, thermal stability, and mechanical properties. The use of such advanced alloys in the manufacturing of welding tools and equipment components can significantly improve their durability and performance under harsh welding conditions.Expand Specific Solutions04 Innovative design features to reduce material wear

Implementation of novel design features in gas welding equipment to minimize material wear. These design innovations may include improved gas flow patterns, optimized heat distribution, and enhanced cooling mechanisms. By addressing wear-prone areas through intelligent design, the overall lifespan and efficiency of welding equipment can be significantly improved.Expand Specific Solutions05 Surface treatment techniques for wear reduction

Application of various surface treatment techniques to enhance the wear resistance of gas welding components. These techniques may include heat treatment, surface hardening, and micro-texturing. By modifying the surface properties of welding equipment, their resistance to wear, corrosion, and thermal degradation can be significantly improved, leading to extended service life and reduced maintenance requirements.Expand Specific Solutions

Key Players in Gas Welding Industry

The gas welding impact on material wear reduction market is in a growth phase, driven by increasing demand for efficient welding processes across industries. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like Illinois Tool Works, Kobe Steel, and POSCO Holdings leading innovation in welding materials and techniques. These firms are developing advanced alloys and automated welding systems to enhance wear resistance. Emerging players such as Lufthansa Technik and MTU Aero Engines are focusing on specialized applications in aerospace, while established giants like Air Liquide and Linde GmbH are improving gas mixtures for optimal welding performance.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding technologies to reduce material wear. Their approach includes precise gas mixture control and optimized torch designs. ITW's gas welding systems utilize a proprietary gas flow regulation mechanism that ensures consistent gas delivery, resulting in more stable arcs and reduced spatter[1]. They have also implemented advanced cooling techniques in their torches, which help maintain optimal welding temperatures and reduce thermal stress on materials[3]. ITW's gas welding solutions incorporate real-time monitoring and adaptive control systems, allowing for automatic adjustments to welding parameters based on material properties and environmental conditions[5].

Strengths: Precise gas control, advanced cooling systems, and adaptive welding parameters. Weaknesses: May require specialized training for operators and higher initial equipment costs.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed innovative gas welding techniques focused on reducing material wear in high-stress applications. Their approach combines specialized filler materials with optimized gas mixtures. Kobe Steel's proprietary filler metals are designed to create weld deposits with enhanced wear resistance properties, particularly effective in applications involving abrasive or high-temperature environments[2]. They have also developed a pulsed gas flow system that alternates between high and low gas flow rates during welding, which helps to control heat input and minimize distortion in thin materials[4]. Additionally, Kobe Steel has implemented advanced shielding gas compositions that include small amounts of reactive elements, which promote the formation of hard, wear-resistant phases in the weld metal[6].

Strengths: Specialized filler materials, pulsed gas flow system, and advanced shielding gas compositions. Weaknesses: May be more expensive than conventional welding methods and require specific gas mixtures.

Core Innovations in Gas Welding Techniques

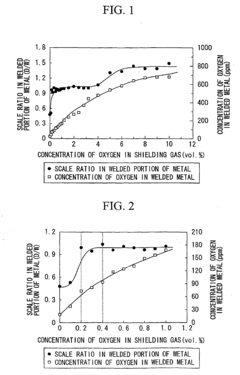

Welding method using a shielding gas comprising bewtween 0.2 % and 10 % of an oxidative gas, the rest being helium

PatentInactiveEP1752249B1

Innovation

- A welding method using a shielding gas comprising 0.2% or more by volume of an oxidative gas, such as oxygen, mixed with helium, which suppresses the dragging force in the molten pool and enhances inward convection, allowing for deeper penetration and a higher D/W ratio, thereby improving weld quality and reducing the number of passes required.

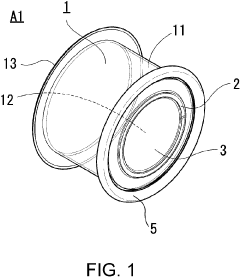

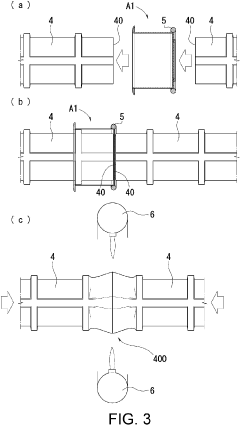

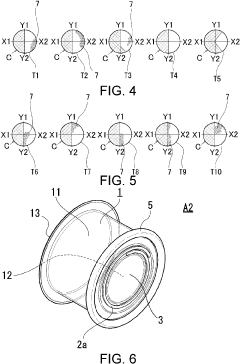

Polymeric reduction material for gas pressure welding and gas pressure welding method

PatentInactiveUS20230339041A1

Innovation

- A polymeric reduction material comprising an air blocking ring made of thermosetting resin, a reduction sheet made of thermoplastic resin, and a string-shaped or band-shaped reduction ring made of thermosetting resin, which creates a reducing atmosphere and blocks oxygen ingress, preventing oxide film formation and ensuring sufficient strength during pressure welding.

Environmental Impact of Gas Welding Processes

Gas welding processes, while effective for joining metals, have significant environmental implications that warrant careful consideration. The primary environmental concern stems from the emission of various gases and particulate matter during the welding process. These emissions can contribute to air pollution, potentially affecting both local air quality and broader atmospheric conditions.

The combustion of fuel gases, such as acetylene or propane, in combination with oxygen, produces carbon dioxide (CO2) as a byproduct. CO2 is a well-known greenhouse gas that contributes to global warming and climate change. The scale of CO2 emissions from gas welding operations can be substantial, especially in large-scale industrial applications or when considering cumulative effects across multiple welding sites.

In addition to CO2, gas welding processes can release other harmful substances into the environment. These may include nitrogen oxides (NOx), carbon monoxide (CO), and volatile organic compounds (VOCs). NOx emissions can contribute to the formation of smog and acid rain, while CO is a toxic gas that can have detrimental effects on human health and the environment. VOCs can react with other pollutants in the atmosphere, forming ground-level ozone and contributing to photochemical smog.

Particulate matter emissions from gas welding are another significant environmental concern. These fine particles can remain suspended in the air for extended periods and may contain various metal oxides and other potentially hazardous substances. Inhalation of these particles can pose health risks to welders and nearby workers, as well as contribute to broader air quality issues in the surrounding area.

The environmental impact of gas welding processes extends beyond air pollution. The production and transportation of fuel gases and oxygen cylinders used in gas welding also have associated environmental costs, including energy consumption and greenhouse gas emissions from manufacturing and logistics operations. Furthermore, the disposal of welding consumables and waste materials can contribute to solid waste management challenges if not properly handled.

To mitigate the environmental impact of gas welding processes, various strategies can be employed. These include optimizing welding parameters to reduce fuel consumption and emissions, implementing proper ventilation and filtration systems to capture and treat welding fumes, and exploring alternative welding technologies with lower environmental footprints. Additionally, proper maintenance of welding equipment and the use of more environmentally friendly fuel gases can help minimize the overall environmental impact of gas welding operations.

The combustion of fuel gases, such as acetylene or propane, in combination with oxygen, produces carbon dioxide (CO2) as a byproduct. CO2 is a well-known greenhouse gas that contributes to global warming and climate change. The scale of CO2 emissions from gas welding operations can be substantial, especially in large-scale industrial applications or when considering cumulative effects across multiple welding sites.

In addition to CO2, gas welding processes can release other harmful substances into the environment. These may include nitrogen oxides (NOx), carbon monoxide (CO), and volatile organic compounds (VOCs). NOx emissions can contribute to the formation of smog and acid rain, while CO is a toxic gas that can have detrimental effects on human health and the environment. VOCs can react with other pollutants in the atmosphere, forming ground-level ozone and contributing to photochemical smog.

Particulate matter emissions from gas welding are another significant environmental concern. These fine particles can remain suspended in the air for extended periods and may contain various metal oxides and other potentially hazardous substances. Inhalation of these particles can pose health risks to welders and nearby workers, as well as contribute to broader air quality issues in the surrounding area.

The environmental impact of gas welding processes extends beyond air pollution. The production and transportation of fuel gases and oxygen cylinders used in gas welding also have associated environmental costs, including energy consumption and greenhouse gas emissions from manufacturing and logistics operations. Furthermore, the disposal of welding consumables and waste materials can contribute to solid waste management challenges if not properly handled.

To mitigate the environmental impact of gas welding processes, various strategies can be employed. These include optimizing welding parameters to reduce fuel consumption and emissions, implementing proper ventilation and filtration systems to capture and treat welding fumes, and exploring alternative welding technologies with lower environmental footprints. Additionally, proper maintenance of welding equipment and the use of more environmentally friendly fuel gases can help minimize the overall environmental impact of gas welding operations.

Safety Regulations in Gas Welding Applications

Safety regulations in gas welding applications are crucial for ensuring the well-being of workers and maintaining a secure work environment. These regulations encompass a wide range of aspects, from personal protective equipment to proper handling of gases and equipment maintenance. One of the primary safety concerns in gas welding is the prevention of fire and explosions. Strict guidelines are in place for the storage and handling of flammable gases, such as acetylene and oxygen, to minimize the risk of accidental ignition.

Personal protective equipment (PPE) is a fundamental component of safety regulations in gas welding. Workers are required to wear appropriate eye protection, such as welding goggles or face shields, to guard against harmful radiation and flying debris. Heat-resistant gloves, flame-resistant clothing, and safety shoes are also mandatory to protect against burns and other injuries. Proper ventilation is another critical aspect of safety regulations, as gas welding can produce harmful fumes and gases. Adequate ventilation systems must be in place to remove these contaminants and maintain air quality in the work area.

Equipment maintenance and inspection are integral parts of safety regulations in gas welding applications. Regular checks of welding torches, hoses, and regulators are required to ensure they are in good working condition and free from leaks or damage. Proper storage of gas cylinders is also regulated, with specific guidelines for securing cylinders, keeping them away from heat sources, and separating different types of gases.

Training and certification requirements form another crucial aspect of safety regulations. Workers involved in gas welding operations must undergo comprehensive training on proper techniques, equipment usage, and emergency procedures. Many jurisdictions require welders to obtain certification to demonstrate their competence and knowledge of safety protocols.

Emergency preparedness is an essential component of safety regulations in gas welding. This includes the development of emergency response plans, installation of fire suppression systems, and provision of easily accessible first aid equipment. Workers must be trained in emergency procedures, including the proper use of fire extinguishers and evacuation protocols.

Workplace organization and housekeeping are also addressed in safety regulations for gas welding. This includes maintaining clear work areas, proper storage of materials and equipment, and the implementation of hot work permit systems to control welding activities in potentially hazardous areas. Regular safety audits and inspections are typically required to ensure ongoing compliance with these regulations and to identify potential hazards before they lead to accidents.

In the context of material wear reduction, safety regulations play a significant role in ensuring that any new techniques or processes implemented to improve wear resistance do not compromise worker safety. As research continues into the impact of gas welding on material wear reduction, it is essential that safety considerations remain at the forefront of any technological advancements or changes in welding practices.

Personal protective equipment (PPE) is a fundamental component of safety regulations in gas welding. Workers are required to wear appropriate eye protection, such as welding goggles or face shields, to guard against harmful radiation and flying debris. Heat-resistant gloves, flame-resistant clothing, and safety shoes are also mandatory to protect against burns and other injuries. Proper ventilation is another critical aspect of safety regulations, as gas welding can produce harmful fumes and gases. Adequate ventilation systems must be in place to remove these contaminants and maintain air quality in the work area.

Equipment maintenance and inspection are integral parts of safety regulations in gas welding applications. Regular checks of welding torches, hoses, and regulators are required to ensure they are in good working condition and free from leaks or damage. Proper storage of gas cylinders is also regulated, with specific guidelines for securing cylinders, keeping them away from heat sources, and separating different types of gases.

Training and certification requirements form another crucial aspect of safety regulations. Workers involved in gas welding operations must undergo comprehensive training on proper techniques, equipment usage, and emergency procedures. Many jurisdictions require welders to obtain certification to demonstrate their competence and knowledge of safety protocols.

Emergency preparedness is an essential component of safety regulations in gas welding. This includes the development of emergency response plans, installation of fire suppression systems, and provision of easily accessible first aid equipment. Workers must be trained in emergency procedures, including the proper use of fire extinguishers and evacuation protocols.

Workplace organization and housekeeping are also addressed in safety regulations for gas welding. This includes maintaining clear work areas, proper storage of materials and equipment, and the implementation of hot work permit systems to control welding activities in potentially hazardous areas. Regular safety audits and inspections are typically required to ensure ongoing compliance with these regulations and to identify potential hazards before they lead to accidents.

In the context of material wear reduction, safety regulations play a significant role in ensuring that any new techniques or processes implemented to improve wear resistance do not compromise worker safety. As research continues into the impact of gas welding on material wear reduction, it is essential that safety considerations remain at the forefront of any technological advancements or changes in welding practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!