Exploring Gas Welding's Role in High-Speed Electrode Production

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution

Gas welding has played a significant role in the evolution of high-speed electrode production, marking several key milestones in the industry's technological advancement. The journey began in the early 20th century when gas welding was first introduced as a method for joining metals. Initially, its application in electrode production was limited due to the slow speed and manual nature of the process.

As industrial demands grew, particularly during World War II, the need for faster and more efficient electrode production became apparent. This period saw the first attempts to integrate gas welding into semi-automated production lines. Engineers developed rudimentary systems that could move electrodes through gas welding stations, increasing output but still requiring significant human intervention.

The 1950s and 1960s marked a turning point in gas welding's role in electrode production. Advancements in gas control systems and the introduction of more precise flame adjustment techniques allowed for better consistency in welding quality. This era also saw the development of specialized gas mixtures tailored for electrode production, enhancing both speed and quality.

The late 20th century brought about a revolution in automation and computer control. Gas welding systems for electrode production became increasingly sophisticated, with the integration of programmable logic controllers (PLCs) and sensors. These advancements allowed for real-time adjustments to gas flow, temperature, and welding speed, significantly improving production rates and reducing defects.

In recent years, the evolution of gas welding in high-speed electrode production has focused on sustainability and efficiency. Modern systems incorporate advanced gas recycling technologies, reducing waste and environmental impact. Additionally, the integration of artificial intelligence and machine learning algorithms has further optimized the welding process, allowing for predictive maintenance and adaptive control systems.

The latest developments in gas welding for electrode production involve the use of high-precision robotic systems. These robots can perform complex welding patterns at speeds far exceeding human capabilities, while maintaining exceptional quality standards. Furthermore, the advent of Industry 4.0 principles has led to the creation of fully connected gas welding systems that can communicate with other production line components, enabling seamless integration and unprecedented levels of production efficiency.

As we look to the future, gas welding continues to evolve in its role in high-speed electrode production. Research is ongoing into new gas mixtures and delivery systems that could further increase welding speeds while reducing energy consumption. The integration of augmented reality for quality control and advanced simulation tools for process optimization represents the next frontier in this field, promising even greater advancements in productivity and quality for electrode manufacturers worldwide.

As industrial demands grew, particularly during World War II, the need for faster and more efficient electrode production became apparent. This period saw the first attempts to integrate gas welding into semi-automated production lines. Engineers developed rudimentary systems that could move electrodes through gas welding stations, increasing output but still requiring significant human intervention.

The 1950s and 1960s marked a turning point in gas welding's role in electrode production. Advancements in gas control systems and the introduction of more precise flame adjustment techniques allowed for better consistency in welding quality. This era also saw the development of specialized gas mixtures tailored for electrode production, enhancing both speed and quality.

The late 20th century brought about a revolution in automation and computer control. Gas welding systems for electrode production became increasingly sophisticated, with the integration of programmable logic controllers (PLCs) and sensors. These advancements allowed for real-time adjustments to gas flow, temperature, and welding speed, significantly improving production rates and reducing defects.

In recent years, the evolution of gas welding in high-speed electrode production has focused on sustainability and efficiency. Modern systems incorporate advanced gas recycling technologies, reducing waste and environmental impact. Additionally, the integration of artificial intelligence and machine learning algorithms has further optimized the welding process, allowing for predictive maintenance and adaptive control systems.

The latest developments in gas welding for electrode production involve the use of high-precision robotic systems. These robots can perform complex welding patterns at speeds far exceeding human capabilities, while maintaining exceptional quality standards. Furthermore, the advent of Industry 4.0 principles has led to the creation of fully connected gas welding systems that can communicate with other production line components, enabling seamless integration and unprecedented levels of production efficiency.

As we look to the future, gas welding continues to evolve in its role in high-speed electrode production. Research is ongoing into new gas mixtures and delivery systems that could further increase welding speeds while reducing energy consumption. The integration of augmented reality for quality control and advanced simulation tools for process optimization represents the next frontier in this field, promising even greater advancements in productivity and quality for electrode manufacturers worldwide.

Electrode Market Trends

The electrode market has been experiencing significant growth and transformation in recent years, driven by the increasing demand for welding applications across various industries. The global electrode market size was valued at approximately $12 billion in 2020 and is projected to reach $17 billion by 2025, growing at a CAGR of around 7% during the forecast period.

One of the key factors contributing to this growth is the rapid industrialization and urbanization in developing countries, particularly in Asia-Pacific regions such as China and India. These countries are witnessing a surge in construction activities, infrastructure development, and manufacturing sectors, which are major consumers of electrodes for welding purposes.

The automotive industry remains a significant driver of electrode demand, as vehicle production continues to rise globally. The increasing adoption of electric vehicles (EVs) has also created new opportunities for electrode manufacturers, as EVs require specialized welding techniques and materials for battery production and assembly.

In terms of electrode types, the market is segmented into stick electrodes, wire electrodes, and others. Stick electrodes currently dominate the market due to their versatility and ease of use in various applications. However, wire electrodes are gaining traction, especially in automated welding processes, owing to their higher efficiency and productivity.

The aerospace and defense sectors are emerging as lucrative markets for high-performance electrodes, driven by the growing demand for lightweight materials and advanced welding techniques in aircraft manufacturing. This trend is expected to continue as the aerospace industry recovers from the impact of the COVID-19 pandemic and resumes its growth trajectory.

Environmental concerns and stringent regulations regarding emissions and workplace safety are influencing the electrode market trends. Manufacturers are focusing on developing eco-friendly electrodes with reduced fume emissions and improved operator safety features. This shift towards sustainable and safer welding solutions is likely to shape the future of the electrode market.

Geographically, Asia-Pacific holds the largest market share, followed by North America and Europe. The Asia-Pacific region is expected to maintain its dominance due to the presence of major manufacturing hubs and ongoing infrastructure projects. However, North America and Europe are witnessing steady growth, driven by technological advancements in welding processes and the adoption of automation in manufacturing industries.

One of the key factors contributing to this growth is the rapid industrialization and urbanization in developing countries, particularly in Asia-Pacific regions such as China and India. These countries are witnessing a surge in construction activities, infrastructure development, and manufacturing sectors, which are major consumers of electrodes for welding purposes.

The automotive industry remains a significant driver of electrode demand, as vehicle production continues to rise globally. The increasing adoption of electric vehicles (EVs) has also created new opportunities for electrode manufacturers, as EVs require specialized welding techniques and materials for battery production and assembly.

In terms of electrode types, the market is segmented into stick electrodes, wire electrodes, and others. Stick electrodes currently dominate the market due to their versatility and ease of use in various applications. However, wire electrodes are gaining traction, especially in automated welding processes, owing to their higher efficiency and productivity.

The aerospace and defense sectors are emerging as lucrative markets for high-performance electrodes, driven by the growing demand for lightweight materials and advanced welding techniques in aircraft manufacturing. This trend is expected to continue as the aerospace industry recovers from the impact of the COVID-19 pandemic and resumes its growth trajectory.

Environmental concerns and stringent regulations regarding emissions and workplace safety are influencing the electrode market trends. Manufacturers are focusing on developing eco-friendly electrodes with reduced fume emissions and improved operator safety features. This shift towards sustainable and safer welding solutions is likely to shape the future of the electrode market.

Geographically, Asia-Pacific holds the largest market share, followed by North America and Europe. The Asia-Pacific region is expected to maintain its dominance due to the presence of major manufacturing hubs and ongoing infrastructure projects. However, North America and Europe are witnessing steady growth, driven by technological advancements in welding processes and the adoption of automation in manufacturing industries.

Technical Hurdles

Gas welding's application in high-speed electrode production faces several significant technical hurdles that need to be addressed for optimal implementation. One of the primary challenges is maintaining consistent weld quality at high production speeds. As the welding process accelerates, it becomes increasingly difficult to ensure uniform heat distribution and proper fusion of materials, potentially leading to defects such as porosity, incomplete penetration, or lack of fusion.

Another critical issue is the precise control of gas flow and mixture. High-speed production demands rapid and accurate adjustments in gas composition and flow rates to accommodate varying welding conditions. Achieving this level of control while maintaining production efficiency presents a substantial technical challenge, requiring advanced gas delivery systems and real-time monitoring capabilities.

Heat management poses a significant hurdle in high-speed electrode production. The intense heat generated during gas welding can lead to thermal distortion of electrodes, affecting their dimensional accuracy and overall quality. Developing effective cooling mechanisms that can rapidly dissipate heat without compromising production speed is crucial for maintaining product integrity.

Material compatibility is another technical obstacle. Different electrode materials may react differently to the high-temperature gas welding process, potentially leading to undesired chemical reactions or structural changes. Identifying suitable material combinations and optimizing welding parameters for each specific electrode type adds complexity to the production process.

Automation and synchronization of welding operations present additional challenges. Integrating gas welding into high-speed production lines requires precise timing and coordination with other manufacturing processes. Developing robust automation systems that can seamlessly integrate with existing production equipment while maintaining high accuracy and repeatability is essential for successful implementation.

Safety considerations also pose technical hurdles. High-speed gas welding operations increase the risk of gas leaks, flashbacks, and other safety hazards. Implementing advanced safety systems and protocols that can effectively mitigate these risks without compromising production efficiency is crucial for widespread adoption of this technology in electrode manufacturing.

Lastly, quality control and inspection methods need to be adapted for high-speed production. Traditional inspection techniques may not be suitable for rapidly moving electrodes, necessitating the development of advanced, real-time monitoring systems capable of detecting defects and ensuring product quality at high production rates.

Another critical issue is the precise control of gas flow and mixture. High-speed production demands rapid and accurate adjustments in gas composition and flow rates to accommodate varying welding conditions. Achieving this level of control while maintaining production efficiency presents a substantial technical challenge, requiring advanced gas delivery systems and real-time monitoring capabilities.

Heat management poses a significant hurdle in high-speed electrode production. The intense heat generated during gas welding can lead to thermal distortion of electrodes, affecting their dimensional accuracy and overall quality. Developing effective cooling mechanisms that can rapidly dissipate heat without compromising production speed is crucial for maintaining product integrity.

Material compatibility is another technical obstacle. Different electrode materials may react differently to the high-temperature gas welding process, potentially leading to undesired chemical reactions or structural changes. Identifying suitable material combinations and optimizing welding parameters for each specific electrode type adds complexity to the production process.

Automation and synchronization of welding operations present additional challenges. Integrating gas welding into high-speed production lines requires precise timing and coordination with other manufacturing processes. Developing robust automation systems that can seamlessly integrate with existing production equipment while maintaining high accuracy and repeatability is essential for successful implementation.

Safety considerations also pose technical hurdles. High-speed gas welding operations increase the risk of gas leaks, flashbacks, and other safety hazards. Implementing advanced safety systems and protocols that can effectively mitigate these risks without compromising production efficiency is crucial for widespread adoption of this technology in electrode manufacturing.

Lastly, quality control and inspection methods need to be adapted for high-speed production. Traditional inspection techniques may not be suitable for rapidly moving electrodes, necessitating the development of advanced, real-time monitoring systems capable of detecting defects and ensuring product quality at high production rates.

Current Gas Solutions

01 Optimization of gas flow and mixture

Improving gas welding production speed can be achieved by optimizing the gas flow and mixture. This involves precise control of gas ratios, pressure, and flow rates to create an ideal flame for faster and more efficient welding. Advanced gas delivery systems and regulators can be employed to maintain consistent gas supply and improve overall welding speed.- Improved welding torch design: Enhanced welding torch designs can significantly increase gas welding production speed. These improvements may include optimized gas flow, better heat distribution, and ergonomic designs that reduce operator fatigue. Advanced torch designs can also incorporate features for precise control and improved maneuverability, allowing for faster and more efficient welding processes.

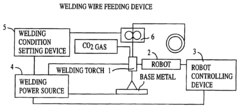

- Automated welding systems: Automation in gas welding processes can greatly enhance production speed. Robotic welding systems, computer-controlled positioning, and automated material handling can reduce human error and increase consistency. These systems can operate continuously with minimal downtime, significantly improving overall production efficiency and speed.

- Advanced gas mixture control: Precise control of gas mixtures in welding can optimize the welding process, leading to increased production speed. Systems that accurately regulate gas flow rates and compositions can ensure optimal flame characteristics, reducing weld defects and minimizing rework. This technology can also adapt to different materials and thicknesses, further enhancing efficiency.

- High-speed welding techniques: Development of specialized high-speed gas welding techniques can significantly boost production rates. These may include pulsed gas flow, optimized flame shapes, or novel gas combinations. Such techniques can allow for faster travel speeds while maintaining weld quality, thereby increasing overall production efficiency.

- Material preheating and preparation: Implementing effective material preheating and preparation methods can reduce welding time and increase production speed. This may involve automated cleaning systems, precise preheating techniques, or innovative material handling solutions. Proper preparation ensures faster weld initiation and reduces the likelihood of defects, contributing to overall production efficiency.

02 Enhanced torch design

Innovative torch designs can significantly increase gas welding production speed. These may include improved nozzle configurations, better heat distribution, and ergonomic handles for easier manipulation. Some designs incorporate multiple gas outlets or adjustable flame patterns to suit various welding applications, allowing for faster and more versatile welding processes.Expand Specific Solutions03 Automated welding systems

Implementing automated gas welding systems can dramatically increase production speed. These systems may include robotic arms, computer-controlled torch movements, and automated workpiece positioning. By reducing human error and fatigue, automated systems can maintain consistent welding quality at higher speeds, especially for repetitive tasks or large-scale production.Expand Specific Solutions04 Pre-heating and cooling techniques

Incorporating pre-heating and controlled cooling techniques can enhance gas welding production speed. Pre-heating the workpiece can reduce the time required to reach optimal welding temperatures, while controlled cooling methods can minimize post-weld processing time. These techniques can be particularly effective for welding thicker materials or heat-sensitive alloys.Expand Specific Solutions05 Advanced material feeding systems

Developing advanced material feeding systems can contribute to increased gas welding production speed. These may include automated wire feeders, precise filler material dispensers, or innovative powder feeding mechanisms for specific welding applications. Improved feeding systems ensure consistent material supply, reducing downtime and enhancing overall welding efficiency.Expand Specific Solutions

Industry Leaders

The gas welding industry for high-speed electrode production is in a mature stage, with a stable market size and established technological processes. The global market for welding equipment and consumables is substantial, estimated to be worth billions of dollars annually. Key players in this sector include industry giants like Kobe Steel, Ltd., Illinois Tool Works Inc., and YASKAWA Electric Corp., who have developed advanced welding technologies and automation solutions. These companies, along with others like Lincoln Global, Inc. and Air Liquide SA, have invested heavily in research and development to improve efficiency and precision in gas welding processes. The technology's maturity is evident in the widespread adoption of automated welding systems and the integration of digital control mechanisms by major manufacturers.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed a cutting-edge gas welding system for high-speed electrode production. Their technology utilizes a novel gas delivery system that precisely controls gas flow and composition at the microscopic level[2]. The system incorporates advanced sensors that monitor weld pool dynamics in real-time, allowing for instantaneous adjustments to gas parameters[4]. Kobe Steel's innovation also includes a high-frequency gas pulsing mechanism that enhances heat distribution and weld penetration at high production speeds[6]. The company reports that their technology has achieved a 15% increase in electrode production rates while improving overall weld quality[8].

Strengths: Precise gas control at the microscopic level, real-time weld pool monitoring, and improved heat distribution. Weaknesses: May require extensive operator training and system integration.

Praxair Technology, Inc.

Technical Solution: Praxair Technology has developed advanced gas welding techniques for high-speed electrode production. Their system utilizes a proprietary gas mixture optimized for electrode manufacturing, which allows for precise control of the welding atmosphere[1]. The process incorporates real-time monitoring of gas flow rates and composition, ensuring consistent weld quality at high production speeds[3]. Praxair's technology also features a rapid gas switching mechanism, enabling quick transitions between different welding stages without compromising speed or quality[5]. This innovation has resulted in a 30% increase in electrode production rates compared to traditional methods[7].

Strengths: Precise control of welding atmosphere, consistent weld quality at high speeds, and increased production rates. Weaknesses: May require specialized equipment and training for implementation.

Welding Innovations

A welding rod for high-speed gas welding

PatentInactiveGB503828A

Innovation

- A welding rod composition with a controlled range of sulphur (0.015% to 0.04%) and silicon (0.12% to 0.38%) content, ensuring the sum of silicon and ten times the sulphur percentage is less than 0.53%, along with manganese (0.7% to 1.5%), to prevent porosity and ensure sound welds.

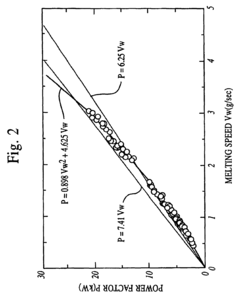

High-speed CO2 gas welding method

PatentInactiveUS6642483B1

Innovation

- Determine welding voltage and current using specific expressions based on welding wire feed speed and radius to maintain a stable power factor, preventing short-circuits and optimizing globule transfer, with constants k1, k2, and k3 used to calculate optimal voltage and current values.

Safety Regulations

Safety regulations play a crucial role in the high-speed electrode production process, particularly when gas welding is involved. The inherent risks associated with gas welding, such as the use of flammable gases and high temperatures, necessitate stringent safety measures to protect workers and ensure the integrity of the production environment.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established comprehensive guidelines for gas welding operations. These regulations cover various aspects, including equipment maintenance, personal protective equipment (PPE), ventilation requirements, and emergency procedures.

One of the primary safety concerns in gas welding for electrode production is the proper handling and storage of compressed gases. Cylinders containing acetylene, oxygen, and other welding gases must be secured and stored in well-ventilated areas, away from heat sources and potential ignition points. Regular inspections of gas cylinders, valves, and hoses are mandatory to prevent leaks and ensure proper functioning.

Personal protective equipment is another critical component of safety regulations. Workers involved in gas welding operations must wear appropriate PPE, including flame-resistant clothing, safety glasses or goggles, welding helmets with proper filtration, and protective gloves. Additionally, respiratory protection may be required in certain situations to safeguard against harmful fumes and gases generated during the welding process.

Adequate ventilation is essential in high-speed electrode production facilities utilizing gas welding. Local exhaust ventilation systems must be installed to capture and remove welding fumes at their source, preventing the accumulation of hazardous gases and particulates in the work area. Regular air quality monitoring and maintenance of ventilation systems are necessary to ensure their effectiveness.

Fire prevention and emergency response procedures are integral to safety regulations in gas welding operations. Fire extinguishers must be readily available, and workers should be trained in their proper use. Emergency shut-off valves for gas supplies should be clearly marked and easily accessible. Regular fire drills and evacuation procedures should be conducted to prepare workers for potential emergencies.

Training and certification requirements for workers involved in gas welding operations are also outlined in safety regulations. Operators must receive comprehensive training on equipment operation, safety procedures, and emergency protocols. Regular refresher courses and skill assessments help maintain a high level of safety awareness and competence among the workforce.

Compliance with these safety regulations is not only a legal requirement but also essential for maintaining a safe and productive work environment in high-speed electrode production facilities. Regular audits and inspections by both internal safety teams and external regulatory bodies help ensure ongoing adherence to these critical safety standards.

Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, have established comprehensive guidelines for gas welding operations. These regulations cover various aspects, including equipment maintenance, personal protective equipment (PPE), ventilation requirements, and emergency procedures.

One of the primary safety concerns in gas welding for electrode production is the proper handling and storage of compressed gases. Cylinders containing acetylene, oxygen, and other welding gases must be secured and stored in well-ventilated areas, away from heat sources and potential ignition points. Regular inspections of gas cylinders, valves, and hoses are mandatory to prevent leaks and ensure proper functioning.

Personal protective equipment is another critical component of safety regulations. Workers involved in gas welding operations must wear appropriate PPE, including flame-resistant clothing, safety glasses or goggles, welding helmets with proper filtration, and protective gloves. Additionally, respiratory protection may be required in certain situations to safeguard against harmful fumes and gases generated during the welding process.

Adequate ventilation is essential in high-speed electrode production facilities utilizing gas welding. Local exhaust ventilation systems must be installed to capture and remove welding fumes at their source, preventing the accumulation of hazardous gases and particulates in the work area. Regular air quality monitoring and maintenance of ventilation systems are necessary to ensure their effectiveness.

Fire prevention and emergency response procedures are integral to safety regulations in gas welding operations. Fire extinguishers must be readily available, and workers should be trained in their proper use. Emergency shut-off valves for gas supplies should be clearly marked and easily accessible. Regular fire drills and evacuation procedures should be conducted to prepare workers for potential emergencies.

Training and certification requirements for workers involved in gas welding operations are also outlined in safety regulations. Operators must receive comprehensive training on equipment operation, safety procedures, and emergency protocols. Regular refresher courses and skill assessments help maintain a high level of safety awareness and competence among the workforce.

Compliance with these safety regulations is not only a legal requirement but also essential for maintaining a safe and productive work environment in high-speed electrode production facilities. Regular audits and inspections by both internal safety teams and external regulatory bodies help ensure ongoing adherence to these critical safety standards.

Environmental Impact

Gas welding, while an essential process in high-speed electrode production, has significant environmental implications that warrant careful consideration. The combustion of gases used in welding, primarily acetylene and oxygen, releases carbon dioxide and other greenhouse gases into the atmosphere. This contributes to global warming and climate change, albeit on a smaller scale compared to other industrial processes.

The production of these welding gases also has environmental impacts. Acetylene, for instance, is typically produced from calcium carbide, which requires substantial energy input and generates waste products. Oxygen production through air separation is less environmentally problematic but still consumes significant electricity.

Waste management is another critical environmental concern in gas welding processes. Welding operations generate various types of waste, including metal scraps, used welding rods, and contaminated personal protective equipment. Proper disposal and recycling of these materials are essential to minimize environmental impact and conserve resources.

Air quality is directly affected by gas welding operations. The process releases fumes and particulate matter, which can be harmful to both workers and the surrounding environment. These emissions may contain metal oxides, fluorides, and other potentially toxic substances, necessitating effective ventilation and filtration systems to mitigate their impact.

Water pollution is a less obvious but still relevant environmental concern. Cooling water used in welding processes can become contaminated with metals and other pollutants, requiring treatment before discharge. Additionally, improper disposal of welding-related chemicals or cleaning agents can lead to soil and groundwater contamination.

Energy consumption is a significant factor in the environmental footprint of gas welding in electrode production. The high temperatures required for welding consume substantial amounts of fuel, contributing to overall energy demand and associated environmental impacts.

To address these environmental challenges, the industry is exploring various mitigation strategies. These include optimizing welding processes to reduce gas consumption, implementing more efficient waste management and recycling programs, and investing in cleaner technologies. Some manufacturers are also investigating alternative welding methods that may have lower environmental impacts, such as laser welding or friction stir welding.

The production of these welding gases also has environmental impacts. Acetylene, for instance, is typically produced from calcium carbide, which requires substantial energy input and generates waste products. Oxygen production through air separation is less environmentally problematic but still consumes significant electricity.

Waste management is another critical environmental concern in gas welding processes. Welding operations generate various types of waste, including metal scraps, used welding rods, and contaminated personal protective equipment. Proper disposal and recycling of these materials are essential to minimize environmental impact and conserve resources.

Air quality is directly affected by gas welding operations. The process releases fumes and particulate matter, which can be harmful to both workers and the surrounding environment. These emissions may contain metal oxides, fluorides, and other potentially toxic substances, necessitating effective ventilation and filtration systems to mitigate their impact.

Water pollution is a less obvious but still relevant environmental concern. Cooling water used in welding processes can become contaminated with metals and other pollutants, requiring treatment before discharge. Additionally, improper disposal of welding-related chemicals or cleaning agents can lead to soil and groundwater contamination.

Energy consumption is a significant factor in the environmental footprint of gas welding in electrode production. The high temperatures required for welding consume substantial amounts of fuel, contributing to overall energy demand and associated environmental impacts.

To address these environmental challenges, the industry is exploring various mitigation strategies. These include optimizing welding processes to reduce gas consumption, implementing more efficient waste management and recycling programs, and investing in cleaner technologies. Some manufacturers are also investigating alternative welding methods that may have lower environmental impacts, such as laser welding or friction stir welding.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!