Gas Welding in Building Prefabrication Techniques

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution in Prefab Construction

Gas welding has played a significant role in the evolution of prefabricated construction techniques. The journey of gas welding in this field began in the early 20th century when prefabrication started gaining traction as a more efficient and cost-effective building method. Initially, gas welding was primarily used for joining metal components in small-scale prefab projects, such as temporary structures and military housing.

As prefabrication techniques advanced in the 1950s and 1960s, gas welding became more integral to the process. It was extensively used in the fabrication of steel frames and panels, which formed the backbone of many prefab buildings. The portability and versatility of gas welding equipment made it particularly suitable for on-site assembly of prefabricated components, allowing for greater flexibility in construction.

The 1970s and 1980s saw a shift towards more complex prefab designs, requiring more precise and efficient welding techniques. Gas welding, while still relevant, began to face competition from newer technologies like arc welding and resistance welding. However, it maintained its importance in certain applications, particularly in joining thinner materials and in situations where portability was crucial.

In the 1990s and early 2000s, the prefab industry experienced a renaissance, driven by advancements in materials and design software. Gas welding adapted to these changes, with improvements in gas mixtures and torch designs enhancing its precision and efficiency. It found a niche in the fabrication of specialized components and in the restoration of older prefab structures.

The turn of the 21st century brought about a focus on sustainable construction practices. Gas welding, with its relatively low energy consumption and minimal waste production, aligned well with these environmental concerns. It became a preferred method for joining recycled materials and in the construction of eco-friendly prefab modules.

Recent years have seen gas welding integrate with digital technologies. Computer-controlled gas welding systems have improved accuracy and consistency, particularly in mass-produced prefab components. Additionally, the technique has been adapted for use with new materials like high-strength alloys and composites, expanding its applications in modern prefab construction.

Today, while not as dominant as in its early years, gas welding continues to be an important tool in prefab construction. Its role has evolved from a primary joining method to a specialized technique used in conjunction with other welding technologies. The ongoing development of cleaner and more efficient gas mixtures ensures that gas welding remains relevant in the ever-evolving landscape of prefabricated construction techniques.

As prefabrication techniques advanced in the 1950s and 1960s, gas welding became more integral to the process. It was extensively used in the fabrication of steel frames and panels, which formed the backbone of many prefab buildings. The portability and versatility of gas welding equipment made it particularly suitable for on-site assembly of prefabricated components, allowing for greater flexibility in construction.

The 1970s and 1980s saw a shift towards more complex prefab designs, requiring more precise and efficient welding techniques. Gas welding, while still relevant, began to face competition from newer technologies like arc welding and resistance welding. However, it maintained its importance in certain applications, particularly in joining thinner materials and in situations where portability was crucial.

In the 1990s and early 2000s, the prefab industry experienced a renaissance, driven by advancements in materials and design software. Gas welding adapted to these changes, with improvements in gas mixtures and torch designs enhancing its precision and efficiency. It found a niche in the fabrication of specialized components and in the restoration of older prefab structures.

The turn of the 21st century brought about a focus on sustainable construction practices. Gas welding, with its relatively low energy consumption and minimal waste production, aligned well with these environmental concerns. It became a preferred method for joining recycled materials and in the construction of eco-friendly prefab modules.

Recent years have seen gas welding integrate with digital technologies. Computer-controlled gas welding systems have improved accuracy and consistency, particularly in mass-produced prefab components. Additionally, the technique has been adapted for use with new materials like high-strength alloys and composites, expanding its applications in modern prefab construction.

Today, while not as dominant as in its early years, gas welding continues to be an important tool in prefab construction. Its role has evolved from a primary joining method to a specialized technique used in conjunction with other welding technologies. The ongoing development of cleaner and more efficient gas mixtures ensures that gas welding remains relevant in the ever-evolving landscape of prefabricated construction techniques.

Market Demand for Prefabricated Building Solutions

The demand for prefabricated building solutions has been steadily increasing in recent years, driven by several key factors. The construction industry is facing significant challenges, including labor shortages, rising material costs, and the need for more sustainable building practices. Prefabrication techniques, including those utilizing gas welding, offer a promising solution to these challenges.

One of the primary drivers of market demand is the potential for cost savings. Prefabrication allows for more efficient use of materials and labor, reducing waste and on-site construction time. This can lead to substantial cost reductions, particularly in large-scale projects or in areas with high labor costs. Additionally, the controlled environment of prefabrication facilities enables higher quality control standards, resulting in fewer defects and reduced rework.

Time efficiency is another crucial factor driving demand. Prefabricated components can be manufactured concurrently with site preparation, significantly reducing overall project timelines. This is particularly attractive in urban areas where minimizing construction disruption is essential, or in regions with short building seasons due to weather constraints.

The push for sustainable construction practices is also fueling the growth of prefabrication. Prefab techniques typically result in less on-site waste, reduced energy consumption during construction, and improved thermal performance of finished buildings. This aligns well with increasingly stringent environmental regulations and growing consumer demand for eco-friendly buildings.

Safety considerations are further boosting the appeal of prefabrication. By moving a significant portion of construction work to controlled factory environments, the risk of on-site accidents is reduced. This is particularly relevant for complex welding operations, where gas welding techniques can be more safely and precisely applied in a prefab setting.

Market analysis indicates that the global prefabricated building market is expected to grow significantly in the coming years. The residential sector, particularly multi-family housing and affordable housing projects, shows strong potential for prefab solutions. Commercial and industrial sectors are also adopting prefabrication techniques at an increasing rate, especially for standardized structures like warehouses and office buildings.

Geographically, emerging economies in Asia-Pacific and Latin America are showing rapid growth in prefab adoption, driven by urbanization and the need for quick, affordable housing solutions. Mature markets in North America and Europe are also seeing increased demand, particularly in the high-end residential and specialized commercial segments.

However, challenges remain in widespread adoption. These include the need for standardization across the industry, transportation limitations for large prefab components, and the initial capital investment required for prefabrication facilities. Despite these challenges, the overall trend points towards continued growth in the prefabricated building market, with gas welding techniques playing a crucial role in this evolving landscape.

One of the primary drivers of market demand is the potential for cost savings. Prefabrication allows for more efficient use of materials and labor, reducing waste and on-site construction time. This can lead to substantial cost reductions, particularly in large-scale projects or in areas with high labor costs. Additionally, the controlled environment of prefabrication facilities enables higher quality control standards, resulting in fewer defects and reduced rework.

Time efficiency is another crucial factor driving demand. Prefabricated components can be manufactured concurrently with site preparation, significantly reducing overall project timelines. This is particularly attractive in urban areas where minimizing construction disruption is essential, or in regions with short building seasons due to weather constraints.

The push for sustainable construction practices is also fueling the growth of prefabrication. Prefab techniques typically result in less on-site waste, reduced energy consumption during construction, and improved thermal performance of finished buildings. This aligns well with increasingly stringent environmental regulations and growing consumer demand for eco-friendly buildings.

Safety considerations are further boosting the appeal of prefabrication. By moving a significant portion of construction work to controlled factory environments, the risk of on-site accidents is reduced. This is particularly relevant for complex welding operations, where gas welding techniques can be more safely and precisely applied in a prefab setting.

Market analysis indicates that the global prefabricated building market is expected to grow significantly in the coming years. The residential sector, particularly multi-family housing and affordable housing projects, shows strong potential for prefab solutions. Commercial and industrial sectors are also adopting prefabrication techniques at an increasing rate, especially for standardized structures like warehouses and office buildings.

Geographically, emerging economies in Asia-Pacific and Latin America are showing rapid growth in prefab adoption, driven by urbanization and the need for quick, affordable housing solutions. Mature markets in North America and Europe are also seeing increased demand, particularly in the high-end residential and specialized commercial segments.

However, challenges remain in widespread adoption. These include the need for standardization across the industry, transportation limitations for large prefab components, and the initial capital investment required for prefabrication facilities. Despite these challenges, the overall trend points towards continued growth in the prefabricated building market, with gas welding techniques playing a crucial role in this evolving landscape.

Current Gas Welding Challenges in Prefabrication

Gas welding in building prefabrication techniques faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary issues is the inconsistent quality of welds, which can compromise the structural integrity of prefabricated components. This inconsistency often stems from variations in welding parameters, such as gas flow rates, torch angles, and welding speeds, which are difficult to maintain uniformly across large-scale prefabrication projects.

Another major challenge is the limited automation potential of gas welding processes in prefabrication settings. While other welding methods have seen significant advancements in robotics and automation, gas welding remains largely a manual process. This reliance on skilled human welders not only increases labor costs but also introduces the risk of human error and fatigue, especially in high-volume production environments typical of prefabrication facilities.

The environmental impact of gas welding is also a growing concern in the prefabrication industry. The process generates significant amounts of fumes and gases, which can be harmful to workers' health and contribute to air pollution. Implementing effective ventilation systems and personal protective equipment adds complexity and cost to prefabrication operations, potentially offsetting some of the efficiency gains of prefabrication techniques.

Furthermore, the energy efficiency of gas welding is relatively low compared to more modern welding technologies. This inefficiency translates to higher operational costs and a larger carbon footprint, which is increasingly problematic as the construction industry faces pressure to reduce its environmental impact and meet sustainability targets.

The portability and flexibility of gas welding equipment, while traditionally seen as advantages, can become limitations in the context of large-scale prefabrication. The need to frequently move and set up gas cylinders and welding apparatus can slow down production processes and introduce safety risks in busy prefabrication facilities.

Lastly, the integration of gas welding into digital design and manufacturing workflows presents a significant challenge. Unlike more modern welding techniques, gas welding processes are less compatible with digital control systems and data collection methods. This incompatibility makes it difficult to incorporate gas welding into the broader trend of digitalization and Industry 4.0 practices that are increasingly being adopted in advanced prefabrication facilities.

Another major challenge is the limited automation potential of gas welding processes in prefabrication settings. While other welding methods have seen significant advancements in robotics and automation, gas welding remains largely a manual process. This reliance on skilled human welders not only increases labor costs but also introduces the risk of human error and fatigue, especially in high-volume production environments typical of prefabrication facilities.

The environmental impact of gas welding is also a growing concern in the prefabrication industry. The process generates significant amounts of fumes and gases, which can be harmful to workers' health and contribute to air pollution. Implementing effective ventilation systems and personal protective equipment adds complexity and cost to prefabrication operations, potentially offsetting some of the efficiency gains of prefabrication techniques.

Furthermore, the energy efficiency of gas welding is relatively low compared to more modern welding technologies. This inefficiency translates to higher operational costs and a larger carbon footprint, which is increasingly problematic as the construction industry faces pressure to reduce its environmental impact and meet sustainability targets.

The portability and flexibility of gas welding equipment, while traditionally seen as advantages, can become limitations in the context of large-scale prefabrication. The need to frequently move and set up gas cylinders and welding apparatus can slow down production processes and introduce safety risks in busy prefabrication facilities.

Lastly, the integration of gas welding into digital design and manufacturing workflows presents a significant challenge. Unlike more modern welding techniques, gas welding processes are less compatible with digital control systems and data collection methods. This incompatibility makes it difficult to incorporate gas welding into the broader trend of digitalization and Industry 4.0 practices that are increasingly being adopted in advanced prefabrication facilities.

Existing Gas Welding Solutions for Prefabrication

01 Welding torch design and improvements

Innovations in gas welding torch design focus on improving efficiency, safety, and ease of use. These advancements include optimized nozzle configurations, ergonomic handles, and integrated cooling systems. Such improvements enhance the precision and control of the welding process while reducing operator fatigue.- Gas welding equipment and techniques: This category covers various aspects of gas welding equipment and techniques, including improvements in welding torches, gas mixing systems, and flame control mechanisms. These advancements aim to enhance welding efficiency, precision, and safety in gas welding operations.

- Gas welding for specific materials: This point focuses on specialized gas welding methods and equipment designed for specific materials, such as aluminum, stainless steel, or exotic alloys. These techniques often involve tailored gas mixtures, temperature control, and specialized filler materials to achieve optimal weld quality for particular materials.

- Automation and robotics in gas welding: This category encompasses innovations in automated and robotic gas welding systems. These advancements include computer-controlled welding processes, robotic arm integration, and sensor-based feedback systems to improve welding consistency, speed, and quality while reducing human error.

- Safety features in gas welding: This point covers various safety innovations in gas welding equipment and processes. These may include improved gas leak detection systems, flame arrestors, automatic shut-off mechanisms, and personal protective equipment designed specifically for gas welding applications.

- Environmental and efficiency improvements: This category focuses on advancements in gas welding that aim to reduce environmental impact and improve overall efficiency. These innovations may include more efficient gas consumption, reduced emissions, improved heat management, and the use of alternative, more environmentally friendly gases in welding processes.

02 Gas mixture control and regulation

Precise control and regulation of gas mixtures are crucial for achieving optimal welding results. Developments in this area include advanced gas flow controllers, mixing systems, and pressure regulators. These innovations ensure consistent gas ratios, leading to improved weld quality and reduced material waste.Expand Specific Solutions03 Safety features in gas welding equipment

Enhanced safety features are being incorporated into gas welding equipment to protect operators and prevent accidents. These include flame arrestors, automatic shut-off valves, and improved gas leak detection systems. Such safety innovations reduce the risk of fire, explosions, and gas-related hazards in welding environments.Expand Specific Solutions04 Automation and robotics in gas welding

The integration of automation and robotics in gas welding processes is improving precision, consistency, and productivity. Robotic welding systems equipped with advanced sensors and control algorithms can perform complex welding tasks with high accuracy. These developments are particularly beneficial for large-scale industrial applications.Expand Specific Solutions05 Eco-friendly and energy-efficient gas welding techniques

Research is focused on developing more environmentally friendly and energy-efficient gas welding techniques. This includes the use of alternative fuel gases, improved combustion efficiency, and waste heat recovery systems. These innovations aim to reduce the environmental impact of gas welding while maintaining or improving weld quality.Expand Specific Solutions

Key Players in Prefab Gas Welding Industry

The gas welding market in building prefabrication techniques is in a mature stage, with established players and proven technologies. The global market size is substantial, driven by the construction industry's demand for efficient and cost-effective prefabrication methods. Key players like Illinois Tool Works, BOC Ltd., and Siemens AG dominate the market with their advanced welding solutions. These companies, along with others such as Fronius International and ULVAC, Inc., are continuously innovating to improve welding efficiency and quality. The technology's maturity is evident in the widespread adoption across various industries, with ongoing research and development focused on enhancing automation, precision, and environmental sustainability in gas welding processes.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding technologies for building prefabrication. Their system utilizes a proprietary mixture of gases to achieve optimal welding performance. The company's gas welding equipment features precise flow control and temperature regulation, ensuring consistent weld quality across various materials used in prefabricated construction[1]. ITW's gas welding solutions incorporate smart sensors that monitor and adjust gas composition in real-time, adapting to changing environmental conditions and material properties[3]. This adaptive technology significantly reduces weld defects and improves overall efficiency in prefabrication processes.

Strengths: Precise control, adaptive technology, and consistent weld quality. Weaknesses: Potentially higher initial equipment costs and the need for specialized training for operators.

Siemens AG

Technical Solution: Siemens has developed an innovative gas welding system for building prefabrication that integrates with their broader industrial automation solutions. Their approach combines traditional gas welding techniques with advanced robotics and AI-driven process control[9]. The system utilizes machine learning algorithms to optimize gas flow rates and torch movements in real-time, adapting to variations in material properties and environmental conditions[10]. Siemens' solution also incorporates digital twin technology, allowing for virtual simulation and optimization of welding processes before physical implementation in prefabrication facilities[11]. The company's gas welding equipment features IoT connectivity, enabling remote monitoring and predictive maintenance to minimize downtime in prefabrication operations.

Strengths: AI-driven optimization, integration with broader automation systems, and predictive maintenance capabilities. Weaknesses: High complexity and potential reliance on proprietary Siemens ecosystems.

Innovative Gas Welding Techniques for Prefab

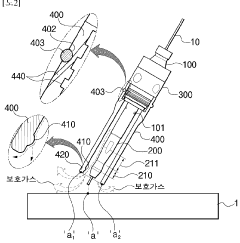

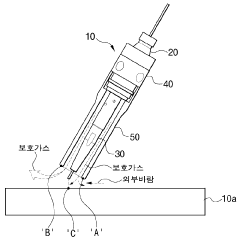

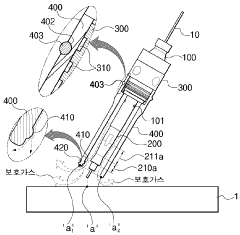

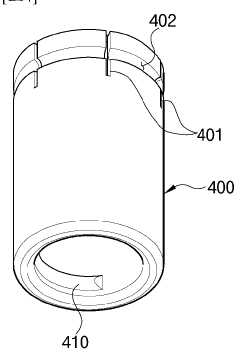

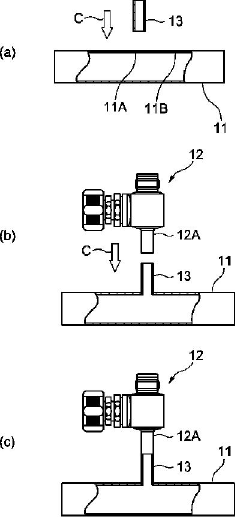

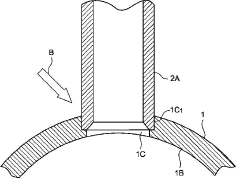

Torch head for gas welding

PatentWO2023128175A1

Innovation

- The torch head incorporates a gas spreading guide on the welding tip and a protective gas concentration guide on the nozzle, directing shielding gas flow towards the welding area and increasing its velocity vector, even when the nozzle is inclined, to effectively block external air and reduce gas consumption.

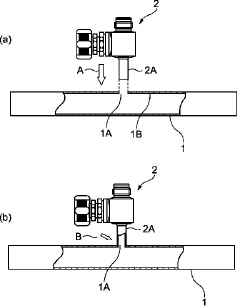

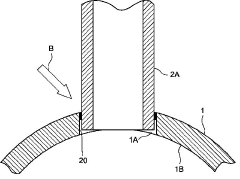

Work execution method of prefabricated piping

PatentInactiveJP2002089744A

Innovation

- A prefabricated pipe construction method that involves creating a connection hole in the main pipe for inserting and welding the branch pipe connection portion, utilizing a tapered branch pipe connection, and employing a stepped connection hole to lock and weld the branch pipe securely without protrusion, thereby eliminating the need for cutting and welding the main pipe.

Safety Regulations in Prefab Gas Welding

Safety regulations in prefab gas welding are of paramount importance in the building prefabrication industry. These regulations are designed to protect workers, ensure the integrity of structures, and maintain overall project safety. The Occupational Safety and Health Administration (OSHA) in the United States, along with similar regulatory bodies worldwide, have established comprehensive guidelines for gas welding in prefabrication settings.

One of the primary safety concerns in prefab gas welding is the proper handling and storage of compressed gas cylinders. Regulations mandate that cylinders must be secured in an upright position, stored in well-ventilated areas, and kept away from heat sources. Additionally, cylinders must be clearly labeled and equipped with appropriate valve protection caps when not in use.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Welders are required to wear appropriate eye protection, such as welding helmets with the correct shade of filter lens, to prevent eye damage from intense light and UV radiation. Fire-resistant clothing, gloves, and safety shoes are also mandatory to protect against burns and falling objects.

Ventilation requirements form a significant part of safety regulations in prefab gas welding. Adequate ventilation systems must be in place to remove harmful fumes and gases produced during the welding process. In enclosed spaces, mechanical ventilation or respiratory protection may be necessary to ensure worker safety.

Fire prevention measures are strictly regulated in prefab gas welding environments. Regulations require the removal of flammable materials from the welding area and the use of fire-resistant shields or curtains to contain sparks. Fire extinguishers must be readily available, and workers must be trained in their proper use.

Electrical safety is another crucial aspect of welding regulations. All welding equipment must be properly grounded, and electrical connections must be insulated and protected from moisture. Regular inspection and maintenance of welding equipment are mandated to prevent electrical hazards.

Training and certification requirements are also integral to safety regulations. Welders must undergo comprehensive training programs and obtain necessary certifications before operating gas welding equipment in prefabrication settings. These programs cover proper welding techniques, equipment operation, and emergency procedures.

Lastly, safety regulations emphasize the importance of proper workplace organization and housekeeping. Welding areas must be kept clean and free of tripping hazards, with clear pathways for emergency evacuation. Regular safety inspections and audits are required to ensure compliance with all applicable regulations and to identify potential hazards before they lead to accidents.

One of the primary safety concerns in prefab gas welding is the proper handling and storage of compressed gas cylinders. Regulations mandate that cylinders must be secured in an upright position, stored in well-ventilated areas, and kept away from heat sources. Additionally, cylinders must be clearly labeled and equipped with appropriate valve protection caps when not in use.

Personal protective equipment (PPE) is another critical aspect of safety regulations. Welders are required to wear appropriate eye protection, such as welding helmets with the correct shade of filter lens, to prevent eye damage from intense light and UV radiation. Fire-resistant clothing, gloves, and safety shoes are also mandatory to protect against burns and falling objects.

Ventilation requirements form a significant part of safety regulations in prefab gas welding. Adequate ventilation systems must be in place to remove harmful fumes and gases produced during the welding process. In enclosed spaces, mechanical ventilation or respiratory protection may be necessary to ensure worker safety.

Fire prevention measures are strictly regulated in prefab gas welding environments. Regulations require the removal of flammable materials from the welding area and the use of fire-resistant shields or curtains to contain sparks. Fire extinguishers must be readily available, and workers must be trained in their proper use.

Electrical safety is another crucial aspect of welding regulations. All welding equipment must be properly grounded, and electrical connections must be insulated and protected from moisture. Regular inspection and maintenance of welding equipment are mandated to prevent electrical hazards.

Training and certification requirements are also integral to safety regulations. Welders must undergo comprehensive training programs and obtain necessary certifications before operating gas welding equipment in prefabrication settings. These programs cover proper welding techniques, equipment operation, and emergency procedures.

Lastly, safety regulations emphasize the importance of proper workplace organization and housekeeping. Welding areas must be kept clean and free of tripping hazards, with clear pathways for emergency evacuation. Regular safety inspections and audits are required to ensure compliance with all applicable regulations and to identify potential hazards before they lead to accidents.

Environmental Impact of Gas Welding in Prefab

Gas welding in prefabrication techniques has significant environmental implications that warrant careful consideration. The process involves the combustion of gases, typically acetylene and oxygen, which produces emissions that can impact air quality and contribute to greenhouse gas levels. These emissions include carbon dioxide, nitrogen oxides, and particulate matter, all of which have known environmental and health effects.

The intensity of environmental impact varies depending on the scale of prefabrication operations and the specific welding techniques employed. Large-scale prefab facilities may have a more concentrated environmental footprint, but they also offer opportunities for more efficient emission control systems. In contrast, on-site welding in traditional construction may lead to more dispersed but potentially higher cumulative emissions due to less controlled environments.

Water pollution is another concern associated with gas welding in prefab construction. Cooling processes and cleaning of welded components can generate wastewater containing metal particles and other contaminants. If not properly managed, this wastewater can pose risks to local water systems and ecosystems.

The production and transportation of welding gases also contribute to the overall environmental impact. The extraction, processing, and distribution of acetylene and oxygen require energy and resources, adding to the carbon footprint of the welding process. However, prefabrication techniques generally allow for more efficient use of materials and reduced waste compared to on-site construction, potentially offsetting some of these impacts.

Noise pollution is an additional environmental factor to consider. While prefab facilities can contain and manage noise more effectively than open construction sites, the concentrated welding activities can still create significant noise levels that may affect surrounding areas and wildlife if not properly mitigated.

On a positive note, the controlled environment of prefab facilities allows for better implementation of environmental management systems. This can include more efficient fume extraction systems, recycling of materials, and optimization of energy use. Advanced welding technologies and automation in prefab settings can also lead to more precise welds, reducing material waste and improving overall efficiency.

The long-term environmental benefits of prefabrication, including gas welding techniques, should also be considered. Prefab structures often have better quality control, which can result in more durable and energy-efficient buildings. This longevity and improved performance can lead to reduced environmental impact over the lifecycle of the structure.

The intensity of environmental impact varies depending on the scale of prefabrication operations and the specific welding techniques employed. Large-scale prefab facilities may have a more concentrated environmental footprint, but they also offer opportunities for more efficient emission control systems. In contrast, on-site welding in traditional construction may lead to more dispersed but potentially higher cumulative emissions due to less controlled environments.

Water pollution is another concern associated with gas welding in prefab construction. Cooling processes and cleaning of welded components can generate wastewater containing metal particles and other contaminants. If not properly managed, this wastewater can pose risks to local water systems and ecosystems.

The production and transportation of welding gases also contribute to the overall environmental impact. The extraction, processing, and distribution of acetylene and oxygen require energy and resources, adding to the carbon footprint of the welding process. However, prefabrication techniques generally allow for more efficient use of materials and reduced waste compared to on-site construction, potentially offsetting some of these impacts.

Noise pollution is an additional environmental factor to consider. While prefab facilities can contain and manage noise more effectively than open construction sites, the concentrated welding activities can still create significant noise levels that may affect surrounding areas and wildlife if not properly mitigated.

On a positive note, the controlled environment of prefab facilities allows for better implementation of environmental management systems. This can include more efficient fume extraction systems, recycling of materials, and optimization of energy use. Advanced welding technologies and automation in prefab settings can also lead to more precise welds, reducing material waste and improving overall efficiency.

The long-term environmental benefits of prefabrication, including gas welding techniques, should also be considered. Prefab structures often have better quality control, which can result in more durable and energy-efficient buildings. This longevity and improved performance can lead to reduced environmental impact over the lifecycle of the structure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!