How Gas Welding Affects Metal Foam Structures

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding and Metal Foam Evolution

Gas welding has played a significant role in the evolution of metal foam structures, shaping their development and applications over time. The journey of metal foams began in the early 20th century, with initial experiments focusing on creating lightweight materials for various industries. However, it wasn't until the 1950s that gas welding techniques were first applied to metal foam production, marking a pivotal moment in their evolution.

The introduction of gas welding to metal foam fabrication brought about several key advancements. Firstly, it allowed for more precise control over the pore structure and distribution within the foam. This was achieved by carefully regulating the gas mixture and flame temperature during the welding process, enabling the creation of foams with tailored properties for specific applications.

As gas welding techniques improved, so did the quality and consistency of metal foams. The 1960s and 1970s saw significant progress in understanding the relationship between welding parameters and foam characteristics. Researchers discovered that by adjusting factors such as gas flow rates, torch movement, and cooling rates, they could influence the foam's density, pore size, and overall structural integrity.

The 1980s marked a turning point in metal foam evolution, as gas welding techniques were refined to produce closed-cell foams. This development expanded the potential applications of metal foams, particularly in industries requiring materials with high strength-to-weight ratios and excellent energy absorption properties. The ability to create closed-cell structures through gas welding opened up new possibilities in aerospace, automotive, and defense sectors.

In the 1990s and early 2000s, the focus shifted towards optimizing gas welding processes for large-scale production of metal foams. This period saw the development of automated welding systems and computer-controlled manufacturing techniques, which greatly improved the efficiency and repeatability of foam production. These advancements made metal foams more commercially viable and accelerated their adoption in various industries.

Recent years have witnessed further innovations in gas welding techniques for metal foam fabrication. The integration of advanced sensors and real-time monitoring systems has allowed for unprecedented control over the welding process, resulting in foams with highly customized properties. Additionally, the combination of gas welding with other manufacturing methods, such as additive manufacturing, has led to the creation of hybrid metal foam structures with enhanced performance characteristics.

Looking ahead, the evolution of gas welding in metal foam production continues to push the boundaries of material science. Ongoing research focuses on developing new alloys and composite foams that can be efficiently produced using advanced gas welding techniques. These efforts aim to create metal foams with even greater strength, lighter weight, and improved functional properties, opening up new possibilities for their application in emerging technologies and industries.

The introduction of gas welding to metal foam fabrication brought about several key advancements. Firstly, it allowed for more precise control over the pore structure and distribution within the foam. This was achieved by carefully regulating the gas mixture and flame temperature during the welding process, enabling the creation of foams with tailored properties for specific applications.

As gas welding techniques improved, so did the quality and consistency of metal foams. The 1960s and 1970s saw significant progress in understanding the relationship between welding parameters and foam characteristics. Researchers discovered that by adjusting factors such as gas flow rates, torch movement, and cooling rates, they could influence the foam's density, pore size, and overall structural integrity.

The 1980s marked a turning point in metal foam evolution, as gas welding techniques were refined to produce closed-cell foams. This development expanded the potential applications of metal foams, particularly in industries requiring materials with high strength-to-weight ratios and excellent energy absorption properties. The ability to create closed-cell structures through gas welding opened up new possibilities in aerospace, automotive, and defense sectors.

In the 1990s and early 2000s, the focus shifted towards optimizing gas welding processes for large-scale production of metal foams. This period saw the development of automated welding systems and computer-controlled manufacturing techniques, which greatly improved the efficiency and repeatability of foam production. These advancements made metal foams more commercially viable and accelerated their adoption in various industries.

Recent years have witnessed further innovations in gas welding techniques for metal foam fabrication. The integration of advanced sensors and real-time monitoring systems has allowed for unprecedented control over the welding process, resulting in foams with highly customized properties. Additionally, the combination of gas welding with other manufacturing methods, such as additive manufacturing, has led to the creation of hybrid metal foam structures with enhanced performance characteristics.

Looking ahead, the evolution of gas welding in metal foam production continues to push the boundaries of material science. Ongoing research focuses on developing new alloys and composite foams that can be efficiently produced using advanced gas welding techniques. These efforts aim to create metal foams with even greater strength, lighter weight, and improved functional properties, opening up new possibilities for their application in emerging technologies and industries.

Market Demand for Metal Foam Welding

The market demand for metal foam welding has been steadily growing in recent years, driven by the unique properties and applications of metal foam structures. Metal foams, characterized by their low density, high strength-to-weight ratio, and excellent energy absorption capabilities, have found increasing use in various industries, including aerospace, automotive, construction, and biomedical engineering.

In the aerospace sector, metal foam welding is particularly sought after for its potential to create lightweight yet strong components for aircraft and spacecraft. The ability to join metal foam structures without compromising their inherent properties has led to increased demand for advanced welding techniques. This demand is further fueled by the industry's continuous push for fuel efficiency and improved performance through weight reduction.

The automotive industry has also shown significant interest in metal foam welding, primarily for crash protection and energy absorption applications. As vehicle safety standards become more stringent, manufacturers are exploring innovative ways to enhance impact resistance while maintaining or reducing overall vehicle weight. Metal foam structures, when properly welded, offer an excellent solution to these challenges, driving the demand for specialized welding processes.

In the construction sector, metal foam welding is gaining traction for its potential in creating structurally efficient and thermally insulating building components. The ability to weld metal foams into complex shapes and integrate them into larger structures opens up new possibilities for architectural design and energy-efficient buildings. This has led to increased demand from construction companies and architects seeking innovative materials and joining techniques.

The biomedical industry represents another growing market for metal foam welding, particularly in the field of implant technology. Porous metal structures, when properly welded, can promote better osseointegration and reduce the risk of implant rejection. As the global population ages and the demand for medical implants rises, the need for advanced metal foam welding techniques in this sector is expected to grow significantly.

Market analysis indicates that the global metal foam market, including welding technologies, is projected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. This growth is largely attributed to the increasing adoption of metal foams in high-performance applications and the development of more efficient welding techniques that preserve the unique properties of these materials.

However, the market demand for metal foam welding also faces certain challenges. The complexity of welding metal foams without compromising their porous structure requires specialized equipment and expertise, which can be a barrier to widespread adoption. Additionally, the higher cost of metal foams compared to traditional materials may limit their use in price-sensitive applications. Despite these challenges, ongoing research and development in welding technologies are expected to address these issues and further drive market growth.

In the aerospace sector, metal foam welding is particularly sought after for its potential to create lightweight yet strong components for aircraft and spacecraft. The ability to join metal foam structures without compromising their inherent properties has led to increased demand for advanced welding techniques. This demand is further fueled by the industry's continuous push for fuel efficiency and improved performance through weight reduction.

The automotive industry has also shown significant interest in metal foam welding, primarily for crash protection and energy absorption applications. As vehicle safety standards become more stringent, manufacturers are exploring innovative ways to enhance impact resistance while maintaining or reducing overall vehicle weight. Metal foam structures, when properly welded, offer an excellent solution to these challenges, driving the demand for specialized welding processes.

In the construction sector, metal foam welding is gaining traction for its potential in creating structurally efficient and thermally insulating building components. The ability to weld metal foams into complex shapes and integrate them into larger structures opens up new possibilities for architectural design and energy-efficient buildings. This has led to increased demand from construction companies and architects seeking innovative materials and joining techniques.

The biomedical industry represents another growing market for metal foam welding, particularly in the field of implant technology. Porous metal structures, when properly welded, can promote better osseointegration and reduce the risk of implant rejection. As the global population ages and the demand for medical implants rises, the need for advanced metal foam welding techniques in this sector is expected to grow significantly.

Market analysis indicates that the global metal foam market, including welding technologies, is projected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. This growth is largely attributed to the increasing adoption of metal foams in high-performance applications and the development of more efficient welding techniques that preserve the unique properties of these materials.

However, the market demand for metal foam welding also faces certain challenges. The complexity of welding metal foams without compromising their porous structure requires specialized equipment and expertise, which can be a barrier to widespread adoption. Additionally, the higher cost of metal foams compared to traditional materials may limit their use in price-sensitive applications. Despite these challenges, ongoing research and development in welding technologies are expected to address these issues and further drive market growth.

Challenges in Gas Welding Metal Foams

Gas welding metal foams presents several significant challenges that researchers and engineers must overcome to effectively utilize this joining technique. One of the primary difficulties lies in the inherent structural characteristics of metal foams. These materials possess a highly porous nature, with interconnected cells that make up a significant portion of their volume. This unique structure complicates the welding process, as the heat distribution and material flow behave differently compared to solid metals.

The low thermal conductivity of metal foams poses another substantial challenge. Due to their porous structure, heat transfer through the material is impeded, leading to localized overheating and potential structural damage. This can result in the collapse of cell walls and a reduction in the foam's overall integrity. Controlling the heat input and distribution becomes crucial to maintain the foam's properties and prevent degradation of its cellular structure.

Another significant hurdle is the risk of oxidation during the welding process. The high surface area of metal foams makes them particularly susceptible to oxidation when exposed to high temperatures. This can lead to the formation of oxide layers that interfere with proper bonding and compromise the weld's strength. Implementing effective shielding techniques to protect the foam from atmospheric exposure during welding is essential but can be challenging due to the material's complex geometry.

The selection of appropriate filler materials presents yet another challenge in gas welding metal foams. Traditional filler metals may not be suitable due to the unique properties and structure of metal foams. Developing specialized filler materials that can effectively bond with the foam structure while maintaining its porosity and mechanical properties is an ongoing area of research and development.

Furthermore, the control of weld pool dynamics in metal foam welding is particularly challenging. The porous structure can lead to unpredictable melt flow and solidification patterns, making it difficult to achieve consistent and reliable welds. This unpredictability can result in weld defects such as incomplete fusion, porosity, or excessive penetration, which can significantly impact the joint's strength and performance.

Lastly, the post-weld evaluation and quality control of metal foam welds present unique challenges. Traditional non-destructive testing methods may not be as effective or applicable due to the foam's complex internal structure. Developing specialized inspection techniques and criteria for assessing the quality and integrity of metal foam welds is crucial for ensuring the reliability and safety of welded foam structures.

The low thermal conductivity of metal foams poses another substantial challenge. Due to their porous structure, heat transfer through the material is impeded, leading to localized overheating and potential structural damage. This can result in the collapse of cell walls and a reduction in the foam's overall integrity. Controlling the heat input and distribution becomes crucial to maintain the foam's properties and prevent degradation of its cellular structure.

Another significant hurdle is the risk of oxidation during the welding process. The high surface area of metal foams makes them particularly susceptible to oxidation when exposed to high temperatures. This can lead to the formation of oxide layers that interfere with proper bonding and compromise the weld's strength. Implementing effective shielding techniques to protect the foam from atmospheric exposure during welding is essential but can be challenging due to the material's complex geometry.

The selection of appropriate filler materials presents yet another challenge in gas welding metal foams. Traditional filler metals may not be suitable due to the unique properties and structure of metal foams. Developing specialized filler materials that can effectively bond with the foam structure while maintaining its porosity and mechanical properties is an ongoing area of research and development.

Furthermore, the control of weld pool dynamics in metal foam welding is particularly challenging. The porous structure can lead to unpredictable melt flow and solidification patterns, making it difficult to achieve consistent and reliable welds. This unpredictability can result in weld defects such as incomplete fusion, porosity, or excessive penetration, which can significantly impact the joint's strength and performance.

Lastly, the post-weld evaluation and quality control of metal foam welds present unique challenges. Traditional non-destructive testing methods may not be as effective or applicable due to the foam's complex internal structure. Developing specialized inspection techniques and criteria for assessing the quality and integrity of metal foam welds is crucial for ensuring the reliability and safety of welded foam structures.

Current Gas Welding Techniques for Metal Foams

01 Manufacturing methods for metal foam structures

Various techniques are employed to create metal foam structures, including powder metallurgy, melt foaming, and additive manufacturing. These methods allow for the production of lightweight, porous metal structures with unique properties such as high strength-to-weight ratio and energy absorption capabilities.- Manufacturing methods for metal foam structures: Various techniques are employed to create metal foam structures, including powder metallurgy, melt gas injection, and casting processes. These methods allow for the production of lightweight, porous metal structures with unique properties such as high strength-to-weight ratio and energy absorption capabilities.

- Structural design and optimization of metal foams: The internal structure of metal foams can be engineered and optimized to enhance specific properties. This includes controlling pore size, distribution, and interconnectivity to achieve desired mechanical, thermal, or acoustic characteristics. Advanced modeling and simulation techniques are often used to design these structures.

- Applications of metal foam structures: Metal foam structures find applications in various industries due to their unique properties. They are used in aerospace for lightweight components, in automotive for crash energy absorption, in construction for sound insulation, and in heat exchangers for improved thermal management. The versatility of metal foams makes them suitable for a wide range of innovative applications.

- Surface treatment and functionalization of metal foams: The surface of metal foam structures can be modified to enhance their properties or add functionality. This includes coating techniques to improve corrosion resistance, surface texturing for better adhesion in composite structures, and functionalization for catalytic applications. These treatments expand the potential uses of metal foam structures in various environments.

- Composite metal foam structures: Combining metal foams with other materials creates composite structures with enhanced properties. This includes metal-polymer composites for improved damping, metal-ceramic composites for high-temperature applications, and gradient foam structures for optimized performance in specific areas. These composites offer tailored solutions for demanding applications.

02 Structural design and optimization of metal foams

The internal structure of metal foams can be engineered to achieve specific mechanical properties. This includes controlling pore size, distribution, and shape to optimize characteristics such as compressive strength, energy absorption, and thermal conductivity. Advanced modeling and simulation techniques are often used to design these structures.Expand Specific Solutions03 Applications of metal foam structures

Metal foam structures find applications in various industries due to their unique properties. They are used in automotive and aerospace for lightweight components and crash protection, in construction for sound and vibration damping, and in heat exchangers for improved thermal management. Their high surface area also makes them suitable for catalytic applications.Expand Specific Solutions04 Surface treatment and functionalization of metal foams

The surface of metal foam structures can be modified to enhance their properties or add functionality. This includes coating for corrosion resistance, surface activation for catalytic applications, and functionalization for specific chemical or biological interactions. These treatments can significantly expand the range of applications for metal foam structures.Expand Specific Solutions05 Characterization and testing of metal foam structures

Specialized techniques are used to analyze and test the properties of metal foam structures. This includes methods for measuring porosity, mechanical strength, energy absorption, and thermal conductivity. Advanced imaging techniques such as X-ray tomography are often employed to visualize and quantify the internal structure of these materials.Expand Specific Solutions

Key Players in Metal Foam Welding Industry

The gas welding impact on metal foam structures represents an emerging field at the intersection of materials science and manufacturing. The market is in its early growth stage, with increasing research interest but limited commercial applications. The global metal foam market, estimated at $85 million in 2020, is projected to reach $113 million by 2025, driven by automotive and aerospace industries. Technical maturity varies among key players. Beihang University and Forschungszentrum Jülich lead in academic research, while companies like MTU Aero Engines and Kobe Steel focus on industrial applications. The U.S. Army's involvement suggests potential defense applications, indicating a diverse and evolving competitive landscape in this niche technological area.

Beihang University

Technical Solution: Beihang University has developed a novel gas welding technique for metal foam structures that utilizes a controlled heat input to minimize structural damage. Their method involves precise temperature control and gas flow regulation to maintain the integrity of the foam's cellular structure during welding. The process incorporates a shielding gas mixture optimized for different metal foam compositions, which helps to prevent oxidation and maintain the foam's unique properties[1]. Additionally, they have implemented a post-welding heat treatment protocol to relieve residual stresses and enhance the overall mechanical properties of the welded foam structure[3].

Strengths: Preserves foam structure integrity, minimizes oxidation, and enhances mechanical properties. Weaknesses: May require specialized equipment and expertise, potentially limiting widespread adoption.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich GmbH has pioneered a gas welding technique specifically tailored for metal foam structures. Their approach utilizes a low-temperature gas welding process that minimizes thermal distortion of the foam cells. The method employs a proprietary gas mixture that promotes rapid heat dissipation, reducing the heat-affected zone and maintaining the foam's porosity[2]. They have also developed a computer-controlled welding system that adjusts gas flow and torch movement in real-time based on the foam's specific geometry and composition, ensuring consistent weld quality across complex foam structures[4].

Strengths: Minimizes thermal distortion, maintains foam porosity, and offers precise control. Weaknesses: May be more time-consuming and costly compared to traditional welding methods.

Innovations in Metal Foam Welding

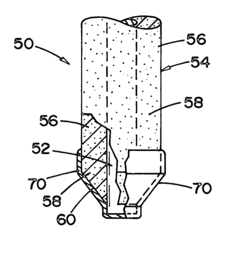

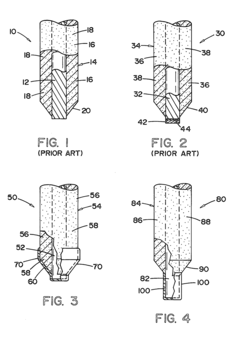

Stick electrode

PatentInactiveUS20050247688A1

Innovation

- A self-shielding stick electrode with a flux composition and an end coating material that generates a shielding gas to protect the weld metal from atmospheric gases, reducing porosity by increasing surface tension and forming a shielding environment around the molten metal droplets.

Safety Considerations in Metal Foam Welding

Safety considerations in metal foam welding are paramount due to the unique properties and challenges associated with these materials. The porous structure of metal foams presents specific risks during the gas welding process that must be carefully managed to ensure worker safety and maintain the integrity of the foam structure.

One of the primary safety concerns is the potential for rapid heat dissipation through the foam's interconnected pores. This can lead to unexpected temperature gradients and hotspots, increasing the risk of burns and material failure. Welders must be trained to anticipate and mitigate these thermal behaviors, using appropriate personal protective equipment (PPE) and implementing strict temperature monitoring protocols.

The presence of trapped gases within the foam structure poses another significant hazard. During welding, these gases can expand rapidly, potentially causing localized explosions or ejection of molten material. To address this, proper ventilation systems must be in place, and welders should be trained to recognize signs of gas buildup. Pre-heating techniques may also be employed to gradually release trapped gases before welding commences.

Metal foam's high surface area-to-volume ratio increases its susceptibility to oxidation during welding. This can compromise the structural integrity of the foam and release harmful fumes. Implementing inert gas shielding techniques and ensuring proper respiratory protection for workers are essential steps in mitigating these risks.

The potential for collapse or deformation of the foam structure during welding necessitates careful consideration of support structures and welding sequences. Proper fixturing and strategic application of heat can help maintain the foam's shape and prevent sudden structural failures that could endanger workers or compromise the final product.

Chemical treatments often used in metal foam production may leave residues that can react unpredictably during welding. A thorough cleaning process and material analysis should be conducted prior to welding to identify and neutralize any potentially hazardous substances.

Lastly, the unique acoustic properties of metal foams can affect the propagation of welding-related sounds, potentially masking auditory cues that welders rely on for process control. This necessitates additional sensory awareness training and the use of alternative feedback mechanisms to ensure weld quality and safety.

By addressing these specific safety considerations, organizations can significantly reduce the risks associated with gas welding of metal foam structures, ensuring both worker safety and product integrity.

One of the primary safety concerns is the potential for rapid heat dissipation through the foam's interconnected pores. This can lead to unexpected temperature gradients and hotspots, increasing the risk of burns and material failure. Welders must be trained to anticipate and mitigate these thermal behaviors, using appropriate personal protective equipment (PPE) and implementing strict temperature monitoring protocols.

The presence of trapped gases within the foam structure poses another significant hazard. During welding, these gases can expand rapidly, potentially causing localized explosions or ejection of molten material. To address this, proper ventilation systems must be in place, and welders should be trained to recognize signs of gas buildup. Pre-heating techniques may also be employed to gradually release trapped gases before welding commences.

Metal foam's high surface area-to-volume ratio increases its susceptibility to oxidation during welding. This can compromise the structural integrity of the foam and release harmful fumes. Implementing inert gas shielding techniques and ensuring proper respiratory protection for workers are essential steps in mitigating these risks.

The potential for collapse or deformation of the foam structure during welding necessitates careful consideration of support structures and welding sequences. Proper fixturing and strategic application of heat can help maintain the foam's shape and prevent sudden structural failures that could endanger workers or compromise the final product.

Chemical treatments often used in metal foam production may leave residues that can react unpredictably during welding. A thorough cleaning process and material analysis should be conducted prior to welding to identify and neutralize any potentially hazardous substances.

Lastly, the unique acoustic properties of metal foams can affect the propagation of welding-related sounds, potentially masking auditory cues that welders rely on for process control. This necessitates additional sensory awareness training and the use of alternative feedback mechanisms to ensure weld quality and safety.

By addressing these specific safety considerations, organizations can significantly reduce the risks associated with gas welding of metal foam structures, ensuring both worker safety and product integrity.

Environmental Impact of Gas Welding Metal Foams

Gas welding of metal foams presents significant environmental considerations that warrant careful examination. The process involves the combustion of fuel gases, typically acetylene or propane, which releases various emissions into the atmosphere. These emissions primarily consist of carbon dioxide, a major greenhouse gas contributing to climate change. Additionally, the welding process can produce nitrogen oxides and volatile organic compounds, which are precursors to ground-level ozone formation and can negatively impact air quality.

The production of metal foams itself is an energy-intensive process, and the subsequent gas welding further increases the overall energy consumption and carbon footprint. This cumulative effect amplifies the environmental impact, particularly when considering large-scale industrial applications. Moreover, the high temperatures involved in gas welding can lead to the vaporization of metal particles and other potentially hazardous substances, which may pose risks to both human health and the surrounding ecosystem if not properly controlled.

Waste management is another crucial aspect of the environmental impact of gas welding metal foams. The process generates slag and other solid waste materials that require proper disposal or recycling. Improper handling of these byproducts can lead to soil and water contamination, further exacerbating the environmental concerns associated with the technique.

Water usage and potential contamination are additional factors to consider. Some gas welding operations may require cooling systems or quenching processes that consume water resources. The resulting wastewater may contain dissolved metals or other pollutants, necessitating treatment before discharge to prevent water pollution.

Despite these challenges, there are opportunities to mitigate the environmental impact of gas welding metal foams. Implementing more efficient welding techniques, optimizing gas mixtures, and improving overall process efficiency can reduce emissions and energy consumption. Additionally, the use of cleaner fuel alternatives and the adoption of advanced filtration and capture systems for emissions can significantly decrease the environmental footprint of the process.

Research into more sustainable metal foam production methods and welding techniques is ongoing. This includes exploring the potential of renewable energy sources to power welding operations and developing novel approaches to minimize waste generation and maximize material recycling. As environmental regulations become more stringent, the industry is likely to see increased innovation in eco-friendly welding practices for metal foams, balancing technological advancements with environmental stewardship.

The production of metal foams itself is an energy-intensive process, and the subsequent gas welding further increases the overall energy consumption and carbon footprint. This cumulative effect amplifies the environmental impact, particularly when considering large-scale industrial applications. Moreover, the high temperatures involved in gas welding can lead to the vaporization of metal particles and other potentially hazardous substances, which may pose risks to both human health and the surrounding ecosystem if not properly controlled.

Waste management is another crucial aspect of the environmental impact of gas welding metal foams. The process generates slag and other solid waste materials that require proper disposal or recycling. Improper handling of these byproducts can lead to soil and water contamination, further exacerbating the environmental concerns associated with the technique.

Water usage and potential contamination are additional factors to consider. Some gas welding operations may require cooling systems or quenching processes that consume water resources. The resulting wastewater may contain dissolved metals or other pollutants, necessitating treatment before discharge to prevent water pollution.

Despite these challenges, there are opportunities to mitigate the environmental impact of gas welding metal foams. Implementing more efficient welding techniques, optimizing gas mixtures, and improving overall process efficiency can reduce emissions and energy consumption. Additionally, the use of cleaner fuel alternatives and the adoption of advanced filtration and capture systems for emissions can significantly decrease the environmental footprint of the process.

Research into more sustainable metal foam production methods and welding techniques is ongoing. This includes exploring the potential of renewable energy sources to power welding operations and developing novel approaches to minimize waste generation and maximize material recycling. As environmental regulations become more stringent, the industry is likely to see increased innovation in eco-friendly welding practices for metal foams, balancing technological advancements with environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!