Predictive Analytics Integration in Gas Welding Quality Control

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Predictive Analytics in Gas Welding: Background and Objectives

Predictive analytics in gas welding represents a significant leap forward in quality control and process optimization. This technology has evolved from traditional statistical methods to advanced machine learning algorithms, capable of processing vast amounts of real-time data. The journey of predictive analytics in welding began with simple statistical process control charts and has now progressed to complex neural networks that can anticipate weld defects before they occur.

The primary objective of integrating predictive analytics into gas welding quality control is to enhance weld quality, reduce defects, and improve overall production efficiency. By leveraging historical data, real-time sensor inputs, and advanced algorithms, predictive analytics aims to provide actionable insights that can prevent weld failures, optimize welding parameters, and minimize material waste.

The evolution of this technology has been driven by the increasing demands for precision and reliability in industries such as aerospace, automotive, and energy. As welding processes become more complex and quality standards more stringent, the need for advanced predictive capabilities has grown exponentially. The integration of Internet of Things (IoT) devices and sensors in welding equipment has further accelerated the adoption of predictive analytics, providing a wealth of data for analysis.

One of the key trends in this field is the move towards real-time predictive modeling. Unlike traditional post-process inspection methods, real-time analytics allow for immediate adjustments to welding parameters, significantly reducing the likelihood of defects. This shift from reactive to proactive quality control represents a paradigm change in welding technology.

Another important trend is the development of multi-variable predictive models that can account for a wide range of factors affecting weld quality. These models consider not only the direct welding parameters but also environmental conditions, material properties, and even operator performance. The goal is to create a holistic view of the welding process, enabling more accurate predictions and better-informed decision-making.

The future of predictive analytics in gas welding is likely to see increased integration with artificial intelligence and machine learning technologies. This convergence promises to deliver more sophisticated predictive models capable of self-learning and adaptation to new welding scenarios. As these technologies mature, the vision of fully automated, self-optimizing welding systems becomes increasingly attainable, marking a new era in manufacturing quality control.

The primary objective of integrating predictive analytics into gas welding quality control is to enhance weld quality, reduce defects, and improve overall production efficiency. By leveraging historical data, real-time sensor inputs, and advanced algorithms, predictive analytics aims to provide actionable insights that can prevent weld failures, optimize welding parameters, and minimize material waste.

The evolution of this technology has been driven by the increasing demands for precision and reliability in industries such as aerospace, automotive, and energy. As welding processes become more complex and quality standards more stringent, the need for advanced predictive capabilities has grown exponentially. The integration of Internet of Things (IoT) devices and sensors in welding equipment has further accelerated the adoption of predictive analytics, providing a wealth of data for analysis.

One of the key trends in this field is the move towards real-time predictive modeling. Unlike traditional post-process inspection methods, real-time analytics allow for immediate adjustments to welding parameters, significantly reducing the likelihood of defects. This shift from reactive to proactive quality control represents a paradigm change in welding technology.

Another important trend is the development of multi-variable predictive models that can account for a wide range of factors affecting weld quality. These models consider not only the direct welding parameters but also environmental conditions, material properties, and even operator performance. The goal is to create a holistic view of the welding process, enabling more accurate predictions and better-informed decision-making.

The future of predictive analytics in gas welding is likely to see increased integration with artificial intelligence and machine learning technologies. This convergence promises to deliver more sophisticated predictive models capable of self-learning and adaptation to new welding scenarios. As these technologies mature, the vision of fully automated, self-optimizing welding systems becomes increasingly attainable, marking a new era in manufacturing quality control.

Market Demand for Advanced Welding Quality Control

The market demand for advanced welding quality control, particularly in gas welding, has been steadily increasing due to the growing complexity of manufacturing processes and the need for higher precision in various industries. This demand is driven by several factors, including the push for improved product quality, increased safety standards, and the need for cost reduction through minimized waste and rework.

In the automotive and aerospace sectors, where safety is paramount, there is a significant demand for predictive analytics integration in gas welding quality control. These industries require welding processes that can consistently produce high-quality joints, as even minor defects can lead to catastrophic failures. The integration of predictive analytics allows for real-time monitoring and adjustment of welding parameters, ensuring optimal weld quality and reducing the likelihood of defects.

The construction and infrastructure industries are also showing increased interest in advanced welding quality control systems. As projects become more complex and timelines more stringent, the ability to predict and prevent welding issues before they occur can lead to substantial time and cost savings. Predictive analytics can help identify potential weak points in structures before they are built, enhancing overall project safety and longevity.

In the energy sector, particularly in oil and gas pipeline construction and maintenance, the demand for predictive analytics in welding quality control is driven by the need to ensure the integrity of critical infrastructure. Leaks or failures in these systems can have severe environmental and economic consequences, making the ability to predict and prevent welding defects crucial.

The shipbuilding industry is another significant market for advanced welding quality control. With the increasing size and complexity of modern vessels, ensuring the quality of welds is essential for structural integrity and safety. Predictive analytics can help shipbuilders identify potential issues early in the construction process, reducing costly rework and delays.

Manufacturing industries, in general, are seeking ways to improve efficiency and reduce waste. Predictive analytics in gas welding quality control offers the potential to optimize material usage, reduce scrap rates, and improve overall production efficiency. This aligns with the broader industry trends towards lean manufacturing and Industry 4.0 principles.

The market demand is further fueled by regulatory pressures and industry standards that require higher levels of quality assurance and traceability in welding processes. Predictive analytics can provide the necessary data and insights to meet these stringent requirements, making it an attractive solution for companies looking to maintain compliance and competitive edge.

In the automotive and aerospace sectors, where safety is paramount, there is a significant demand for predictive analytics integration in gas welding quality control. These industries require welding processes that can consistently produce high-quality joints, as even minor defects can lead to catastrophic failures. The integration of predictive analytics allows for real-time monitoring and adjustment of welding parameters, ensuring optimal weld quality and reducing the likelihood of defects.

The construction and infrastructure industries are also showing increased interest in advanced welding quality control systems. As projects become more complex and timelines more stringent, the ability to predict and prevent welding issues before they occur can lead to substantial time and cost savings. Predictive analytics can help identify potential weak points in structures before they are built, enhancing overall project safety and longevity.

In the energy sector, particularly in oil and gas pipeline construction and maintenance, the demand for predictive analytics in welding quality control is driven by the need to ensure the integrity of critical infrastructure. Leaks or failures in these systems can have severe environmental and economic consequences, making the ability to predict and prevent welding defects crucial.

The shipbuilding industry is another significant market for advanced welding quality control. With the increasing size and complexity of modern vessels, ensuring the quality of welds is essential for structural integrity and safety. Predictive analytics can help shipbuilders identify potential issues early in the construction process, reducing costly rework and delays.

Manufacturing industries, in general, are seeking ways to improve efficiency and reduce waste. Predictive analytics in gas welding quality control offers the potential to optimize material usage, reduce scrap rates, and improve overall production efficiency. This aligns with the broader industry trends towards lean manufacturing and Industry 4.0 principles.

The market demand is further fueled by regulatory pressures and industry standards that require higher levels of quality assurance and traceability in welding processes. Predictive analytics can provide the necessary data and insights to meet these stringent requirements, making it an attractive solution for companies looking to maintain compliance and competitive edge.

Current Challenges in Gas Welding Quality Assurance

Gas welding quality assurance faces several significant challenges in today's industrial landscape. One of the primary issues is the inconsistency in weld quality due to variations in operator skill and experience. Even with standardized procedures, human factors can lead to deviations in weld integrity, affecting overall product reliability.

The complexity of modern welding processes, particularly in high-precision industries such as aerospace and automotive manufacturing, demands increasingly stringent quality control measures. Traditional inspection methods, often relying on visual examination or destructive testing, are becoming inadequate for detecting subtle defects that can compromise weld strength and durability.

Environmental factors pose another substantial challenge. Fluctuations in temperature, humidity, and air quality can significantly impact weld quality, yet these variables are often difficult to control consistently in industrial settings. This variability introduces an element of unpredictability that complicates quality assurance efforts.

The speed of production in modern manufacturing environments creates pressure to maintain high throughput without compromising quality. This balance is particularly challenging in gas welding, where rushed processes can lead to inadequate fusion, porosity, or other defects that may not be immediately apparent.

Material diversity presents another hurdle. As industries increasingly utilize advanced alloys and composite materials, welding processes must adapt to ensure proper fusion and strength across a wide range of material properties. This diversity complicates the establishment of universal quality standards and inspection protocols.

Real-time monitoring and feedback systems, while advancing, still face limitations in their ability to detect and respond to quality issues instantaneously. The lag between defect occurrence and detection can result in significant waste and rework, impacting both cost and efficiency.

Data management and integration pose significant challenges in quality assurance. Many welding operations generate vast amounts of data, but effectively collecting, analyzing, and acting upon this information in real-time remains a complex task. The lack of seamless integration between welding equipment, quality control systems, and enterprise management software hinders the development of truly adaptive and responsive quality assurance processes.

Lastly, the industry faces a skills gap, with a shortage of qualified welders and quality control specialists. This shortage not only affects production capacity but also impacts the ability to implement and maintain sophisticated quality assurance systems, particularly those leveraging advanced technologies like predictive analytics and machine learning.

The complexity of modern welding processes, particularly in high-precision industries such as aerospace and automotive manufacturing, demands increasingly stringent quality control measures. Traditional inspection methods, often relying on visual examination or destructive testing, are becoming inadequate for detecting subtle defects that can compromise weld strength and durability.

Environmental factors pose another substantial challenge. Fluctuations in temperature, humidity, and air quality can significantly impact weld quality, yet these variables are often difficult to control consistently in industrial settings. This variability introduces an element of unpredictability that complicates quality assurance efforts.

The speed of production in modern manufacturing environments creates pressure to maintain high throughput without compromising quality. This balance is particularly challenging in gas welding, where rushed processes can lead to inadequate fusion, porosity, or other defects that may not be immediately apparent.

Material diversity presents another hurdle. As industries increasingly utilize advanced alloys and composite materials, welding processes must adapt to ensure proper fusion and strength across a wide range of material properties. This diversity complicates the establishment of universal quality standards and inspection protocols.

Real-time monitoring and feedback systems, while advancing, still face limitations in their ability to detect and respond to quality issues instantaneously. The lag between defect occurrence and detection can result in significant waste and rework, impacting both cost and efficiency.

Data management and integration pose significant challenges in quality assurance. Many welding operations generate vast amounts of data, but effectively collecting, analyzing, and acting upon this information in real-time remains a complex task. The lack of seamless integration between welding equipment, quality control systems, and enterprise management software hinders the development of truly adaptive and responsive quality assurance processes.

Lastly, the industry faces a skills gap, with a shortage of qualified welders and quality control specialists. This shortage not only affects production capacity but also impacts the ability to implement and maintain sophisticated quality assurance systems, particularly those leveraging advanced technologies like predictive analytics and machine learning.

Existing Predictive Solutions for Welding Quality Control

01 Data-driven quality control systems

Predictive analytics are used to develop data-driven quality control systems that can anticipate and prevent defects in manufacturing processes. These systems analyze historical and real-time data to identify patterns and predict potential quality issues before they occur, allowing for proactive interventions and optimized production.- Data-driven quality control systems: Predictive analytics can be used to develop data-driven quality control systems that analyze historical and real-time data to identify potential issues before they occur. These systems can help optimize manufacturing processes, reduce defects, and improve overall product quality by leveraging machine learning algorithms and statistical models.

- Predictive maintenance for equipment: Implementing predictive analytics in quality control can enable predictive maintenance for manufacturing equipment. By analyzing sensor data and performance metrics, the system can forecast potential equipment failures, allowing for proactive maintenance and minimizing unplanned downtime, thus ensuring consistent product quality.

- Real-time process monitoring and adjustment: Predictive analytics can be used for real-time monitoring of production processes, allowing for immediate detection of deviations from quality standards. This enables rapid adjustments to process parameters, reducing waste and ensuring consistent product quality throughout the manufacturing cycle.

- Supply chain quality management: Predictive analytics can be applied to supply chain management to improve overall quality control. By analyzing supplier performance data, transportation conditions, and inventory levels, companies can predict and mitigate potential quality issues arising from the supply chain, ensuring consistent input quality for manufacturing processes.

- Customer feedback integration for quality improvement: Predictive analytics can be used to analyze customer feedback, warranty claims, and product returns data to identify patterns and predict potential quality issues. This information can be integrated into the quality control process to drive continuous improvement and enhance product design and manufacturing processes.

02 Machine learning algorithms for defect detection

Advanced machine learning algorithms are employed to enhance defect detection capabilities in quality control processes. These algorithms can learn from large datasets of product images and sensor data to identify subtle anomalies and classify defects with high accuracy, improving overall product quality and reducing false positives.Expand Specific Solutions03 Real-time monitoring and adaptive control

Predictive analytics enable real-time monitoring of production processes and adaptive control mechanisms. By continuously analyzing sensor data and process parameters, these systems can automatically adjust manufacturing settings to maintain optimal quality levels and prevent deviations from specifications.Expand Specific Solutions04 Predictive maintenance for quality assurance

Predictive analytics are utilized to implement predictive maintenance strategies that ensure equipment reliability and prevent quality issues caused by machine failures. By analyzing equipment performance data and historical maintenance records, these systems can forecast potential breakdowns and schedule maintenance activities proactively.Expand Specific Solutions05 Supply chain quality management

Predictive analytics are applied to supply chain management to improve overall product quality. These systems analyze supplier performance data, logistics information, and quality metrics to identify potential risks in the supply chain that could impact product quality, allowing for proactive mitigation strategies and supplier optimization.Expand Specific Solutions

Key Players in Welding and Predictive Analytics Industries

The integration of predictive analytics in gas welding quality control is in a nascent stage, with the market showing significant growth potential. The industry is transitioning from traditional quality control methods to more advanced, data-driven approaches. Market size is expanding as manufacturers recognize the value of predictive analytics in reducing defects and improving efficiency. Technologically, the field is evolving rapidly, with companies like Linde GmbH, Illinois Tool Works Inc., and Fronius International GmbH leading innovation. These firms are developing sophisticated algorithms and sensor technologies to enhance welding processes. However, the technology's maturity varies across different applications, with some areas still requiring further research and development to achieve full implementation and widespread adoption.

Linde GmbH

Technical Solution: Linde GmbH has developed an advanced predictive analytics system for gas welding quality control. Their solution integrates real-time sensor data with machine learning algorithms to predict weld quality issues before they occur. The system monitors key parameters such as gas flow rates, temperature, and pressure, analyzing patterns to identify potential defects[1]. Linde's predictive model can adjust welding parameters automatically, optimizing the process for consistent high-quality welds. The company has also implemented a cloud-based platform that allows for remote monitoring and analysis of welding operations across multiple sites[3].

Strengths: Comprehensive real-time monitoring, automatic parameter adjustment, and multi-site integration. Weaknesses: May require significant initial investment and staff training for implementation.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has implemented a predictive analytics solution for gas welding quality control that focuses on end-to-end process optimization. Their system incorporates data from various stages of the welding process, including pre-weld material preparation, welding execution, and post-weld inspection. ITW's predictive model uses historical data and real-time inputs to forecast potential quality issues and suggest corrective actions[2]. The company has also developed a proprietary algorithm that can predict weld strength based on input parameters, allowing for proactive adjustments to ensure optimal weld quality[4]. Additionally, ITW's system includes a user-friendly interface that provides operators with clear, actionable insights derived from complex data analysis.

Strengths: Comprehensive process coverage, user-friendly interface, and proactive quality assurance. Weaknesses: May be less flexible for integration with third-party equipment or software.

Core Innovations in Welding Data Analysis

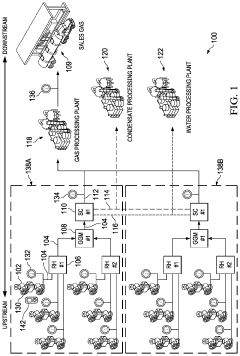

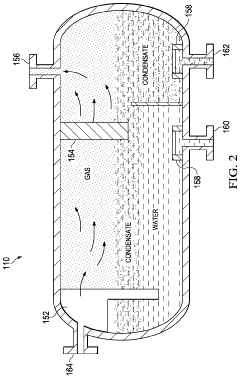

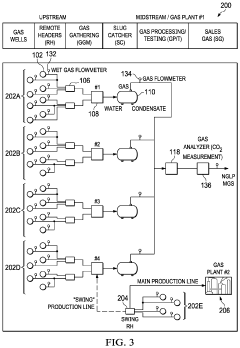

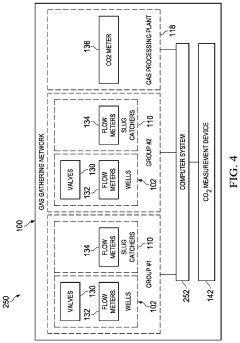

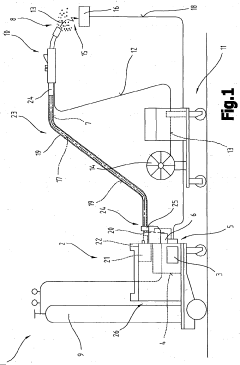

Reducing co2 production levels in a gas operation network using a predictive model

PatentPendingUS20230251628A1

Innovation

- A predictive modeling system is trained using historical data from oil and gas wells to optimize flowrates, reducing overall CO2 production by controlling valves based on predicted CO2 production targets, while also considering condensate and ethane-plus production levels.

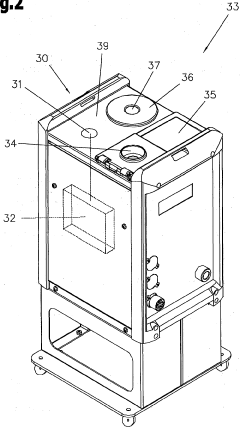

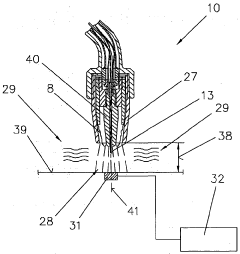

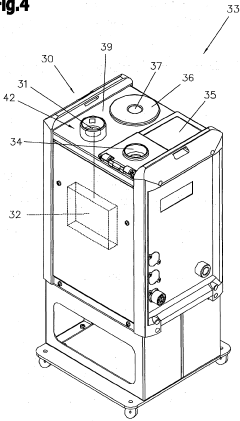

Device and method for shielding gas measurement

PatentWO2008101264A1

Innovation

- Positioning sensors at a distance equivalent to the torch-workpiece distance to simulate real welding conditions, connecting them to an evaluation unit for accurate gas property analysis, and using a cleaning device with compressed air to automate and enhance measurement precision.

Regulatory Compliance in Predictive Welding Analytics

The integration of predictive analytics in gas welding quality control has significant implications for regulatory compliance. As the technology advances, regulatory bodies are adapting their frameworks to accommodate these new capabilities while ensuring safety and quality standards are maintained. Compliance requirements for predictive welding analytics typically focus on data integrity, model validation, and process transparency.

Data integrity is a crucial aspect of regulatory compliance in this field. Manufacturers must ensure that the data used for predictive analytics is accurate, complete, and securely stored. This includes implementing robust data collection systems, regular calibration of sensors, and maintaining detailed records of data sources and processing methods. Regulatory bodies often require companies to demonstrate their data management practices and provide evidence of data quality assurance measures.

Model validation is another key area of regulatory focus. Predictive models used in welding quality control must undergo rigorous testing and validation to ensure their accuracy and reliability. Regulatory guidelines often specify the minimum performance criteria for these models, as well as the required validation methodologies. Companies may need to conduct extensive testing under various operating conditions and provide documentation of model performance over time.

Process transparency is essential for regulatory compliance in predictive welding analytics. Manufacturers must be able to explain how their predictive models work and demonstrate that they are not introducing bias or unfair practices. This often involves maintaining detailed documentation of model development, training data, and decision-making processes. Some regulations may require companies to provide interpretable results from their predictive models, allowing for human oversight and intervention when necessary.

Regulatory bodies are also increasingly concerned with the cybersecurity aspects of predictive analytics systems. As these systems often rely on networked sensors and cloud-based data processing, companies must implement robust security measures to protect against data breaches and unauthorized access. Compliance requirements may include regular security audits, encryption of sensitive data, and strict access controls for predictive analytics systems.

As the field of predictive analytics in gas welding quality control continues to evolve, regulatory frameworks are likely to become more sophisticated. Companies investing in these technologies must stay informed about changing compliance requirements and be prepared to adapt their systems and processes accordingly. This may involve ongoing collaboration with regulatory bodies, participation in industry standards development, and continuous improvement of internal compliance processes.

Data integrity is a crucial aspect of regulatory compliance in this field. Manufacturers must ensure that the data used for predictive analytics is accurate, complete, and securely stored. This includes implementing robust data collection systems, regular calibration of sensors, and maintaining detailed records of data sources and processing methods. Regulatory bodies often require companies to demonstrate their data management practices and provide evidence of data quality assurance measures.

Model validation is another key area of regulatory focus. Predictive models used in welding quality control must undergo rigorous testing and validation to ensure their accuracy and reliability. Regulatory guidelines often specify the minimum performance criteria for these models, as well as the required validation methodologies. Companies may need to conduct extensive testing under various operating conditions and provide documentation of model performance over time.

Process transparency is essential for regulatory compliance in predictive welding analytics. Manufacturers must be able to explain how their predictive models work and demonstrate that they are not introducing bias or unfair practices. This often involves maintaining detailed documentation of model development, training data, and decision-making processes. Some regulations may require companies to provide interpretable results from their predictive models, allowing for human oversight and intervention when necessary.

Regulatory bodies are also increasingly concerned with the cybersecurity aspects of predictive analytics systems. As these systems often rely on networked sensors and cloud-based data processing, companies must implement robust security measures to protect against data breaches and unauthorized access. Compliance requirements may include regular security audits, encryption of sensitive data, and strict access controls for predictive analytics systems.

As the field of predictive analytics in gas welding quality control continues to evolve, regulatory frameworks are likely to become more sophisticated. Companies investing in these technologies must stay informed about changing compliance requirements and be prepared to adapt their systems and processes accordingly. This may involve ongoing collaboration with regulatory bodies, participation in industry standards development, and continuous improvement of internal compliance processes.

Economic Impact of Predictive Analytics in Welding

The integration of predictive analytics in gas welding quality control has the potential to significantly impact the economic landscape of the welding industry. By leveraging advanced data analysis techniques and machine learning algorithms, companies can optimize their welding processes, reduce waste, and improve overall product quality. This, in turn, leads to substantial cost savings and increased profitability.

One of the primary economic benefits of implementing predictive analytics in welding is the reduction of material waste. Traditional quality control methods often rely on post-production inspections, resulting in the scrapping of defective parts. Predictive analytics allows for real-time monitoring and adjustment of welding parameters, significantly reducing the occurrence of defects and minimizing material waste. This not only cuts down on raw material costs but also reduces the energy consumption associated with rework and scrap processing.

Labor costs are another area where predictive analytics can drive economic improvements. By automating the quality control process and providing real-time insights, the need for manual inspections and interventions is greatly reduced. This allows skilled welders to focus on more complex tasks, improving overall productivity and reducing labor costs associated with quality control activities.

The implementation of predictive analytics also has the potential to extend equipment lifespan and reduce maintenance costs. By continuously monitoring welding equipment performance and predicting potential failures, companies can schedule preventive maintenance more effectively. This proactive approach minimizes unexpected downtime, extends the useful life of expensive welding equipment, and optimizes maintenance schedules, resulting in significant cost savings over time.

Furthermore, the improved quality and consistency of welds achieved through predictive analytics can lead to enhanced customer satisfaction and potentially increased market share. Higher quality products may command premium prices, while the ability to consistently meet or exceed quality standards can lead to preferred supplier status and long-term contracts. This can result in increased revenue and improved profit margins for welding companies.

The economic impact extends beyond individual companies to the broader supply chain. As welding quality improves and becomes more consistent, downstream manufacturers benefit from reduced inspection requirements and fewer quality-related issues. This ripple effect can lead to overall cost reductions and efficiency improvements throughout the manufacturing ecosystem.

However, it is important to consider the initial investment required to implement predictive analytics systems in welding operations. While the long-term economic benefits are substantial, companies must carefully evaluate the upfront costs of technology acquisition, integration, and workforce training against the projected returns. The payback period and return on investment will vary depending on the scale of operations and the specific applications of predictive analytics within the welding process.

One of the primary economic benefits of implementing predictive analytics in welding is the reduction of material waste. Traditional quality control methods often rely on post-production inspections, resulting in the scrapping of defective parts. Predictive analytics allows for real-time monitoring and adjustment of welding parameters, significantly reducing the occurrence of defects and minimizing material waste. This not only cuts down on raw material costs but also reduces the energy consumption associated with rework and scrap processing.

Labor costs are another area where predictive analytics can drive economic improvements. By automating the quality control process and providing real-time insights, the need for manual inspections and interventions is greatly reduced. This allows skilled welders to focus on more complex tasks, improving overall productivity and reducing labor costs associated with quality control activities.

The implementation of predictive analytics also has the potential to extend equipment lifespan and reduce maintenance costs. By continuously monitoring welding equipment performance and predicting potential failures, companies can schedule preventive maintenance more effectively. This proactive approach minimizes unexpected downtime, extends the useful life of expensive welding equipment, and optimizes maintenance schedules, resulting in significant cost savings over time.

Furthermore, the improved quality and consistency of welds achieved through predictive analytics can lead to enhanced customer satisfaction and potentially increased market share. Higher quality products may command premium prices, while the ability to consistently meet or exceed quality standards can lead to preferred supplier status and long-term contracts. This can result in increased revenue and improved profit margins for welding companies.

The economic impact extends beyond individual companies to the broader supply chain. As welding quality improves and becomes more consistent, downstream manufacturers benefit from reduced inspection requirements and fewer quality-related issues. This ripple effect can lead to overall cost reductions and efficiency improvements throughout the manufacturing ecosystem.

However, it is important to consider the initial investment required to implement predictive analytics systems in welding operations. While the long-term economic benefits are substantial, companies must carefully evaluate the upfront costs of technology acquisition, integration, and workforce training against the projected returns. The payback period and return on investment will vary depending on the scale of operations and the specific applications of predictive analytics within the welding process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!