Innovations in Gas Flow Control for Reduction of Weld Anomalies

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Flow Control Evolution and Objectives

Gas flow control has been a critical aspect of welding processes since the early days of arc welding. The evolution of gas flow control techniques has been driven by the need to improve weld quality, reduce defects, and increase productivity. In the 1940s and 1950s, basic shielding gas systems were introduced, primarily using argon or helium to protect the weld pool from atmospheric contamination. These early systems relied on simple flow meters and manual adjustments, often resulting in inconsistent gas coverage and weld quality.

The 1960s and 1970s saw significant advancements in gas flow control technology. The introduction of gas mixtures, such as argon-CO2 blends, allowed for better control of the arc characteristics and weld pool behavior. Pulse-controlled gas flow systems emerged, offering more precise control over gas delivery and reducing gas consumption. This period also marked the beginning of automated welding processes, which demanded more sophisticated gas flow control mechanisms.

In the 1980s and 1990s, the integration of electronic controls and sensors revolutionized gas flow management. Microprocessor-based systems enabled real-time monitoring and adjustment of gas flow rates, responding to changes in welding parameters and environmental conditions. This era also saw the development of advanced nozzle designs and gas diffusers, which improved gas coverage and reduced turbulence at the weld site.

The turn of the millennium brought about a new focus on energy efficiency and environmental concerns. Gas flow control systems began incorporating features to minimize gas waste and optimize consumption. Adaptive control algorithms were developed to automatically adjust gas flow based on weld joint geometry and position, further enhancing weld quality and consistency.

Today, the objectives of gas flow control innovations are multifaceted. Researchers and engineers are striving to develop systems that can provide ultra-precise gas delivery, capable of responding to millisecond-level changes in welding conditions. There is a growing emphasis on integrating gas flow control with other welding parameters, such as arc current and voltage, to create holistic welding process control systems.

Another key objective is the reduction of weld anomalies through advanced gas flow management. This includes the development of intelligent systems that can predict and prevent common defects such as porosity, lack of fusion, and contamination. Machine learning and artificial intelligence are being leveraged to analyze vast amounts of welding data and optimize gas flow patterns for specific applications and materials.

Furthermore, there is a push towards more sustainable and cost-effective gas flow solutions. This involves the creation of hybrid shielding gas systems that can dynamically mix gases to achieve optimal weld properties while minimizing resource consumption. The integration of IoT (Internet of Things) technologies is also a significant objective, allowing for remote monitoring and control of gas flow systems across multiple welding stations or even entire manufacturing facilities.

The 1960s and 1970s saw significant advancements in gas flow control technology. The introduction of gas mixtures, such as argon-CO2 blends, allowed for better control of the arc characteristics and weld pool behavior. Pulse-controlled gas flow systems emerged, offering more precise control over gas delivery and reducing gas consumption. This period also marked the beginning of automated welding processes, which demanded more sophisticated gas flow control mechanisms.

In the 1980s and 1990s, the integration of electronic controls and sensors revolutionized gas flow management. Microprocessor-based systems enabled real-time monitoring and adjustment of gas flow rates, responding to changes in welding parameters and environmental conditions. This era also saw the development of advanced nozzle designs and gas diffusers, which improved gas coverage and reduced turbulence at the weld site.

The turn of the millennium brought about a new focus on energy efficiency and environmental concerns. Gas flow control systems began incorporating features to minimize gas waste and optimize consumption. Adaptive control algorithms were developed to automatically adjust gas flow based on weld joint geometry and position, further enhancing weld quality and consistency.

Today, the objectives of gas flow control innovations are multifaceted. Researchers and engineers are striving to develop systems that can provide ultra-precise gas delivery, capable of responding to millisecond-level changes in welding conditions. There is a growing emphasis on integrating gas flow control with other welding parameters, such as arc current and voltage, to create holistic welding process control systems.

Another key objective is the reduction of weld anomalies through advanced gas flow management. This includes the development of intelligent systems that can predict and prevent common defects such as porosity, lack of fusion, and contamination. Machine learning and artificial intelligence are being leveraged to analyze vast amounts of welding data and optimize gas flow patterns for specific applications and materials.

Furthermore, there is a push towards more sustainable and cost-effective gas flow solutions. This involves the creation of hybrid shielding gas systems that can dynamically mix gases to achieve optimal weld properties while minimizing resource consumption. The integration of IoT (Internet of Things) technologies is also a significant objective, allowing for remote monitoring and control of gas flow systems across multiple welding stations or even entire manufacturing facilities.

Market Analysis for Advanced Welding Technologies

The advanced welding technologies market is experiencing significant growth, driven by the increasing demand for precision and efficiency in manufacturing processes across various industries. The global welding equipment market, which includes advanced technologies, is projected to reach a substantial value by 2025, with a compound annual growth rate (CAGR) of over 5% during the forecast period. This growth is primarily attributed to the rising adoption of automation and robotics in welding processes, particularly in automotive, aerospace, and construction sectors.

The market for innovations in gas flow control for reduction of weld anomalies is a crucial segment within the broader welding technologies market. As industries strive for higher quality standards and reduced defects in welded components, the demand for advanced gas flow control systems has surged. This trend is particularly evident in industries where weld integrity is critical, such as aerospace, automotive, and energy sectors.

In the automotive industry, the push towards lightweight materials and complex designs has intensified the need for precise welding techniques. Advanced gas flow control systems play a vital role in ensuring consistent weld quality, especially when working with materials like aluminum and high-strength steels. The aerospace sector, with its stringent quality requirements, is another major driver for innovations in gas flow control. The need for flawless welds in aircraft components has led to increased investment in advanced welding technologies.

The energy sector, including oil and gas, power generation, and renewable energy, represents a significant market for advanced welding technologies. As these industries expand and upgrade infrastructure, the demand for high-quality welding solutions, particularly those that can reduce weld anomalies, continues to grow. The construction industry, with its increasing use of prefabricated components and modular construction techniques, is also contributing to the market growth for advanced welding technologies.

Geographically, Asia-Pacific is expected to be the fastest-growing market for advanced welding technologies, including gas flow control innovations. This growth is fueled by rapid industrialization, infrastructure development, and the expansion of manufacturing sectors in countries like China and India. North America and Europe remain significant markets, driven by the adoption of automation and the need for high-precision welding in advanced manufacturing industries.

The market is characterized by ongoing research and development efforts aimed at improving gas flow control systems to further reduce weld anomalies. Key areas of focus include the development of intelligent gas flow controllers, integration of sensors for real-time monitoring, and the use of data analytics to optimize welding parameters. These innovations are expected to drive market growth and offer significant opportunities for manufacturers and suppliers in the welding technology sector.

The market for innovations in gas flow control for reduction of weld anomalies is a crucial segment within the broader welding technologies market. As industries strive for higher quality standards and reduced defects in welded components, the demand for advanced gas flow control systems has surged. This trend is particularly evident in industries where weld integrity is critical, such as aerospace, automotive, and energy sectors.

In the automotive industry, the push towards lightweight materials and complex designs has intensified the need for precise welding techniques. Advanced gas flow control systems play a vital role in ensuring consistent weld quality, especially when working with materials like aluminum and high-strength steels. The aerospace sector, with its stringent quality requirements, is another major driver for innovations in gas flow control. The need for flawless welds in aircraft components has led to increased investment in advanced welding technologies.

The energy sector, including oil and gas, power generation, and renewable energy, represents a significant market for advanced welding technologies. As these industries expand and upgrade infrastructure, the demand for high-quality welding solutions, particularly those that can reduce weld anomalies, continues to grow. The construction industry, with its increasing use of prefabricated components and modular construction techniques, is also contributing to the market growth for advanced welding technologies.

Geographically, Asia-Pacific is expected to be the fastest-growing market for advanced welding technologies, including gas flow control innovations. This growth is fueled by rapid industrialization, infrastructure development, and the expansion of manufacturing sectors in countries like China and India. North America and Europe remain significant markets, driven by the adoption of automation and the need for high-precision welding in advanced manufacturing industries.

The market is characterized by ongoing research and development efforts aimed at improving gas flow control systems to further reduce weld anomalies. Key areas of focus include the development of intelligent gas flow controllers, integration of sensors for real-time monitoring, and the use of data analytics to optimize welding parameters. These innovations are expected to drive market growth and offer significant opportunities for manufacturers and suppliers in the welding technology sector.

Current Challenges in Gas Flow Control Systems

Gas flow control systems in welding processes face several significant challenges that hinder optimal performance and contribute to weld anomalies. One of the primary issues is the difficulty in maintaining consistent gas flow rates throughout the welding process. Fluctuations in gas flow can lead to inadequate shielding of the weld pool, resulting in porosity, oxidation, and other defects that compromise weld quality.

Another challenge lies in the precise control of gas mixture ratios for multi-gas welding applications. Achieving and maintaining the correct balance of gases is crucial for specific welding requirements, yet current systems often struggle to provide real-time adjustments to compensate for environmental changes or variations in welding parameters.

The responsiveness of gas flow control systems to rapid changes in welding conditions is also a significant concern. Many existing systems have inherent lag times that prevent immediate adjustments to gas flow, leading to momentary lapses in weld protection during critical phases of the welding process.

Furthermore, the integration of gas flow control with other welding parameters, such as arc current and voltage, remains a complex task. The lack of sophisticated feedback mechanisms and adaptive control algorithms limits the ability of current systems to optimize gas flow in real-time based on the dynamic conditions of the welding process.

Miniaturization of gas flow control components presents another hurdle, particularly in robotic and automated welding applications where space is at a premium. Balancing the need for compact design with the requirement for precise control and high flow capacity is an ongoing challenge for system designers.

Additionally, the energy efficiency of gas flow control systems is becoming increasingly important. Many current systems are not optimized for minimal gas consumption, leading to unnecessary waste and increased operational costs. Developing more efficient systems that maintain weld quality while reducing gas usage is a key area for improvement.

Lastly, the reliability and durability of gas flow control components in harsh welding environments remain problematic. Exposure to heat, spatter, and corrosive gases can degrade system performance over time, necessitating frequent maintenance and replacement. Enhancing the robustness of these systems to withstand challenging conditions without compromising accuracy is a critical area for technological advancement in the field of gas flow control for welding applications.

Another challenge lies in the precise control of gas mixture ratios for multi-gas welding applications. Achieving and maintaining the correct balance of gases is crucial for specific welding requirements, yet current systems often struggle to provide real-time adjustments to compensate for environmental changes or variations in welding parameters.

The responsiveness of gas flow control systems to rapid changes in welding conditions is also a significant concern. Many existing systems have inherent lag times that prevent immediate adjustments to gas flow, leading to momentary lapses in weld protection during critical phases of the welding process.

Furthermore, the integration of gas flow control with other welding parameters, such as arc current and voltage, remains a complex task. The lack of sophisticated feedback mechanisms and adaptive control algorithms limits the ability of current systems to optimize gas flow in real-time based on the dynamic conditions of the welding process.

Miniaturization of gas flow control components presents another hurdle, particularly in robotic and automated welding applications where space is at a premium. Balancing the need for compact design with the requirement for precise control and high flow capacity is an ongoing challenge for system designers.

Additionally, the energy efficiency of gas flow control systems is becoming increasingly important. Many current systems are not optimized for minimal gas consumption, leading to unnecessary waste and increased operational costs. Developing more efficient systems that maintain weld quality while reducing gas usage is a key area for improvement.

Lastly, the reliability and durability of gas flow control components in harsh welding environments remain problematic. Exposure to heat, spatter, and corrosive gases can degrade system performance over time, necessitating frequent maintenance and replacement. Enhancing the robustness of these systems to withstand challenging conditions without compromising accuracy is a critical area for technological advancement in the field of gas flow control for welding applications.

Existing Gas Flow Control Solutions for Weld Quality

01 Gas flow control systems for welding

Advanced gas flow control systems are implemented in welding processes to regulate and optimize gas flow. These systems help maintain consistent weld quality, reduce gas consumption, and prevent anomalies caused by improper gas flow. They may include sensors, valves, and digital controllers to precisely manage gas delivery during welding operations.- Gas flow control systems for welding: Advanced gas flow control systems are implemented in welding processes to regulate and optimize gas flow. These systems help maintain consistent weld quality by precisely controlling shielding gas delivery, which can prevent weld anomalies caused by improper gas coverage or flow rates.

- Weld anomaly detection and prevention: Sophisticated sensors and monitoring systems are employed to detect and prevent weld anomalies in real-time. These technologies can identify issues related to gas flow, such as insufficient shielding or turbulence, allowing for immediate corrective actions to maintain weld integrity.

- Adaptive gas flow control algorithms: Intelligent algorithms are developed to adaptively control gas flow based on various welding parameters and environmental conditions. These algorithms can adjust gas flow rates dynamically to compensate for changes in welding speed, material properties, or ambient conditions, reducing the likelihood of weld anomalies.

- Integration of gas flow control with welding power sources: Gas flow control systems are integrated with welding power sources to create a synchronized welding process. This integration allows for coordinated adjustments of gas flow and welding parameters, ensuring optimal conditions for weld formation and minimizing anomalies caused by mismatched gas flow and power settings.

- Data analysis and machine learning for weld quality improvement: Advanced data analysis techniques and machine learning algorithms are applied to historical welding data to identify patterns and correlations between gas flow parameters and weld anomalies. This knowledge is used to refine gas flow control strategies and predict potential issues before they occur, leading to improved weld quality and reduced anomalies.

02 Weld anomaly detection and prevention

Techniques for detecting and preventing weld anomalies are developed, incorporating real-time monitoring systems and data analysis. These methods use sensors, imaging technologies, and machine learning algorithms to identify potential issues during the welding process, allowing for immediate corrective actions and ensuring high-quality welds.Expand Specific Solutions03 Adaptive gas flow control in welding

Adaptive gas flow control systems are designed to automatically adjust gas flow parameters based on real-time welding conditions. These systems use feedback from various sensors to optimize gas flow rates, pressure, and composition, adapting to changes in welding speed, material properties, and environmental factors to maintain weld quality and efficiency.Expand Specific Solutions04 Integration of gas flow control with welding power sources

Advanced welding systems integrate gas flow control directly with welding power sources. This integration allows for synchronized control of gas flow and welding parameters, enabling more precise and efficient welding processes. It can help prevent anomalies caused by mismatched gas flow and welding power settings.Expand Specific Solutions05 Digital twin technology for weld process optimization

Digital twin technology is applied to welding processes, creating virtual models of the welding system including gas flow control. This allows for simulation, prediction, and optimization of welding parameters and gas flow settings. It helps in identifying potential anomalies before they occur in the physical welding process, improving overall weld quality and efficiency.Expand Specific Solutions

Key Players in Welding Gas Flow Control Industry

The gas flow control technology for reducing weld anomalies is in a mature stage of development, with a competitive landscape dominated by established players. The market size is substantial, driven by the widespread application of welding across industries such as automotive, construction, and manufacturing. Companies like Lincoln Global, Illinois Tool Works, and Fronius International are at the forefront, leveraging their extensive experience and R&D capabilities to innovate in this space. The technology's maturity is evident in the diverse range of solutions offered by these companies, including advanced gas flow control systems integrated with digital welding equipment. However, there's still room for innovation, particularly in areas like IoT integration and AI-driven process optimization, as demonstrated by emerging players like Suxin IoT Technology.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has developed advanced gas flow control systems for welding applications. Their STT (Surface Tension Transfer) technology precisely controls the gas flow and weld current to reduce spatter and improve weld quality[1]. They have also introduced the Power Wave advanced process welders with built-in gas flow sensors and controls. These systems use adaptive algorithms to optimize shielding gas flow rates in real-time based on welding parameters and environmental conditions[2]. Lincoln's gas flow innovations include pulsed gas delivery systems that can reduce overall gas consumption by up to 60% while maintaining weld quality[3].

Strengths: Precise control of gas flow and welding parameters, reduced spatter and improved weld quality, significant reduction in gas consumption. Weaknesses: May require more complex and expensive equipment, potential for increased maintenance needs.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has made significant advancements in gas flow control for welding through their Miller Electric division. They have developed the Auto-Continuum system, which incorporates advanced gas flow control algorithms to optimize shielding gas delivery[4]. This system uses pulsed MIG welding technology combined with precise gas flow regulation to reduce weld defects. ITW has also introduced the Intellx gas flow control module, which automatically adjusts gas flow rates based on welding parameters and arc characteristics[5]. Their innovations include smart gas savers that can reduce gas consumption by up to 50% without compromising weld quality[6].

Strengths: Integrated systems for optimized gas flow and welding parameters, significant gas savings, improved weld quality. Weaknesses: Higher initial investment cost, may require operator training for full utilization of advanced features.

Innovative Gas Flow Control Techniques Analysis

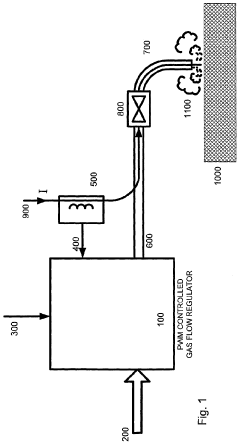

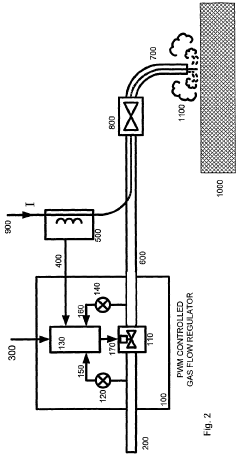

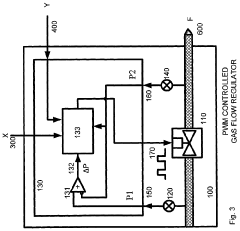

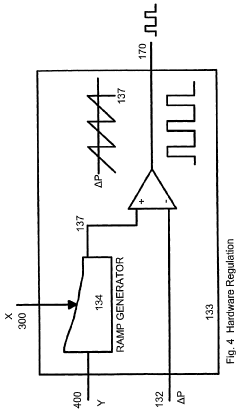

Shielding gas flow controller for a welding apparatus

PatentActiveUS8258421B2

Innovation

- A gas flow controller with input and output pressure sensors and a controllable valve that adjusts the pulse width modulation based on pressure measurements to maintain a constant gas flow, incorporating a leak detector and idle pressure maintenance to ensure reliable operation.

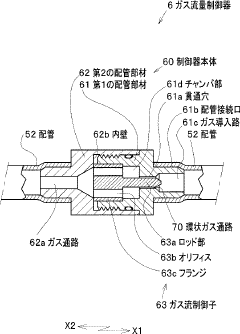

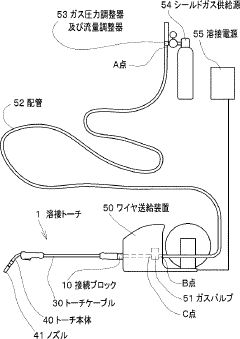

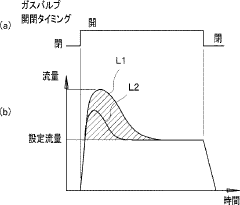

Gas flow controller for arc welding

PatentActiveJP2012091211A

Innovation

- A gas flow controller with an annular gas passage formed by a rod portion and a through hole in the shielding gas pipe, which reduces gas surges by maintaining a steady flow rate through a minute gap, suppressing turbulent flow and air entrainment.

Environmental Impact of Gas Flow Control Systems

Gas flow control systems in welding processes have significant environmental implications that extend beyond the immediate manufacturing context. These systems, while crucial for reducing weld anomalies, also contribute to various environmental concerns that need careful consideration.

The primary environmental impact of gas flow control systems stems from the use of shielding gases. Common gases like argon, helium, and carbon dioxide are used in large quantities during welding processes. The production, storage, and transportation of these gases contribute to greenhouse gas emissions and energy consumption. Moreover, the release of these gases into the atmosphere, even in small quantities, can have cumulative effects on air quality and climate change.

Inefficient gas flow control can lead to excessive gas consumption, exacerbating the environmental footprint of welding operations. Overuse of shielding gases not only wastes resources but also increases the carbon footprint of the manufacturing process. Conversely, innovations in gas flow control that optimize gas usage can significantly reduce environmental impact by minimizing waste and improving overall efficiency.

The disposal of gas cylinders and associated equipment presents another environmental challenge. While many components are recyclable, the process of recycling and proper disposal requires energy and resources. Innovations in gas flow control that extend the life of equipment or reduce the frequency of cylinder replacements can help mitigate this impact.

Water contamination is a potential risk associated with certain gas flow control systems, particularly in underwater welding applications. Leakage of gases or lubricants used in flow control equipment can harm aquatic ecosystems. Advanced sealing technologies and environmentally friendly lubricants are areas of innovation that can address this concern.

Noise pollution is an often-overlooked environmental impact of gas flow control systems. High-pressure gas releases and the operation of control valves can contribute to workplace noise levels, potentially affecting the surrounding environment and wildlife if not properly managed. Innovations in noise reduction technologies for gas flow systems can help mitigate this issue.

The manufacturing of gas flow control equipment itself has environmental implications. The production of precision components often involves energy-intensive processes and the use of materials with significant environmental footprints. Innovations in manufacturing techniques and materials science can lead to more environmentally friendly production methods and components.

As industries move towards more sustainable practices, the environmental impact of gas flow control systems in welding is likely to face increased scrutiny. This presents opportunities for innovation in areas such as renewable energy-powered systems, closed-loop gas recycling, and smart control systems that optimize gas usage based on real-time welding parameters. Such advancements could significantly reduce the environmental footprint of welding operations while simultaneously improving weld quality and reducing anomalies.

The primary environmental impact of gas flow control systems stems from the use of shielding gases. Common gases like argon, helium, and carbon dioxide are used in large quantities during welding processes. The production, storage, and transportation of these gases contribute to greenhouse gas emissions and energy consumption. Moreover, the release of these gases into the atmosphere, even in small quantities, can have cumulative effects on air quality and climate change.

Inefficient gas flow control can lead to excessive gas consumption, exacerbating the environmental footprint of welding operations. Overuse of shielding gases not only wastes resources but also increases the carbon footprint of the manufacturing process. Conversely, innovations in gas flow control that optimize gas usage can significantly reduce environmental impact by minimizing waste and improving overall efficiency.

The disposal of gas cylinders and associated equipment presents another environmental challenge. While many components are recyclable, the process of recycling and proper disposal requires energy and resources. Innovations in gas flow control that extend the life of equipment or reduce the frequency of cylinder replacements can help mitigate this impact.

Water contamination is a potential risk associated with certain gas flow control systems, particularly in underwater welding applications. Leakage of gases or lubricants used in flow control equipment can harm aquatic ecosystems. Advanced sealing technologies and environmentally friendly lubricants are areas of innovation that can address this concern.

Noise pollution is an often-overlooked environmental impact of gas flow control systems. High-pressure gas releases and the operation of control valves can contribute to workplace noise levels, potentially affecting the surrounding environment and wildlife if not properly managed. Innovations in noise reduction technologies for gas flow systems can help mitigate this issue.

The manufacturing of gas flow control equipment itself has environmental implications. The production of precision components often involves energy-intensive processes and the use of materials with significant environmental footprints. Innovations in manufacturing techniques and materials science can lead to more environmentally friendly production methods and components.

As industries move towards more sustainable practices, the environmental impact of gas flow control systems in welding is likely to face increased scrutiny. This presents opportunities for innovation in areas such as renewable energy-powered systems, closed-loop gas recycling, and smart control systems that optimize gas usage based on real-time welding parameters. Such advancements could significantly reduce the environmental footprint of welding operations while simultaneously improving weld quality and reducing anomalies.

Safety Standards in Gas Flow Control for Welding

Safety standards in gas flow control for welding are critical to ensure the protection of workers, equipment, and the environment. These standards encompass a wide range of regulations and guidelines that govern the design, implementation, and operation of gas flow control systems in welding processes. The primary focus is on preventing hazards associated with gas leaks, explosions, and exposure to harmful fumes.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the American Welding Society (AWS) have established comprehensive safety standards for gas flow control in welding. These standards address various aspects, including equipment specifications, installation requirements, maintenance procedures, and operational protocols. They emphasize the importance of proper gas storage, handling, and distribution systems to minimize risks.

One key aspect of safety standards is the requirement for proper ventilation and exhaust systems. These systems are designed to remove welding fumes and maintain safe levels of atmospheric gases in the work area. Standards often specify minimum airflow rates, exhaust system designs, and monitoring requirements to ensure adequate air quality.

Gas flow control equipment must meet stringent safety certifications and undergo regular inspections. This includes pressure regulators, flow meters, valves, and hoses used in the gas delivery system. Standards typically mandate the use of specific materials, pressure ratings, and safety features such as check valves and flashback arrestors to prevent reverse gas flow and potential explosions.

Training and certification requirements for personnel involved in gas flow control operations are also outlined in safety standards. Workers must be educated on proper equipment operation, emergency procedures, and the recognition of potential hazards. Regular refresher courses and competency assessments are often mandated to ensure ongoing compliance and safety awareness.

Emergency response protocols form a crucial component of safety standards in gas flow control for welding. These protocols include procedures for gas leak detection, emergency shutoff systems, and evacuation plans. Standards often require the installation of gas detection systems and alarms to provide early warning of potential leaks or dangerous gas concentrations.

Continuous monitoring and documentation of gas flow control systems are essential elements of safety standards. This includes regular calibration of flow meters, pressure checks, and leak tests. Detailed records of maintenance activities, inspections, and any incidents must be maintained to ensure compliance and facilitate ongoing improvements in safety measures.

As technology advances, safety standards in gas flow control for welding continue to evolve. New innovations in sensor technology, automated control systems, and data analytics are being incorporated into updated standards to enhance safety and efficiency. These advancements aim to provide real-time monitoring, predictive maintenance capabilities, and improved risk management in gas flow control operations.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the American Welding Society (AWS) have established comprehensive safety standards for gas flow control in welding. These standards address various aspects, including equipment specifications, installation requirements, maintenance procedures, and operational protocols. They emphasize the importance of proper gas storage, handling, and distribution systems to minimize risks.

One key aspect of safety standards is the requirement for proper ventilation and exhaust systems. These systems are designed to remove welding fumes and maintain safe levels of atmospheric gases in the work area. Standards often specify minimum airflow rates, exhaust system designs, and monitoring requirements to ensure adequate air quality.

Gas flow control equipment must meet stringent safety certifications and undergo regular inspections. This includes pressure regulators, flow meters, valves, and hoses used in the gas delivery system. Standards typically mandate the use of specific materials, pressure ratings, and safety features such as check valves and flashback arrestors to prevent reverse gas flow and potential explosions.

Training and certification requirements for personnel involved in gas flow control operations are also outlined in safety standards. Workers must be educated on proper equipment operation, emergency procedures, and the recognition of potential hazards. Regular refresher courses and competency assessments are often mandated to ensure ongoing compliance and safety awareness.

Emergency response protocols form a crucial component of safety standards in gas flow control for welding. These protocols include procedures for gas leak detection, emergency shutoff systems, and evacuation plans. Standards often require the installation of gas detection systems and alarms to provide early warning of potential leaks or dangerous gas concentrations.

Continuous monitoring and documentation of gas flow control systems are essential elements of safety standards. This includes regular calibration of flow meters, pressure checks, and leak tests. Detailed records of maintenance activities, inspections, and any incidents must be maintained to ensure compliance and facilitate ongoing improvements in safety measures.

As technology advances, safety standards in gas flow control for welding continue to evolve. New innovations in sensor technology, automated control systems, and data analytics are being incorporated into updated standards to enhance safety and efficiency. These advancements aim to provide real-time monitoring, predictive maintenance capabilities, and improved risk management in gas flow control operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!