Advanced Thermal Interface Materials For High-Flux VCSELs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Thermal Management Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various applications including facial recognition, autonomous driving, and high-speed data communication. Since their commercial introduction in the 1990s, VCSELs have evolved from low-power devices to high-flux emitters capable of delivering significant optical output. This evolution has been driven by increasing demands for higher performance in sensing, illumination, and communication applications.

The thermal management of VCSELs represents one of the most significant challenges in their continued development. As power densities increase, the efficient dissipation of heat becomes paramount to maintaining device performance, reliability, and longevity. Historical data indicates that VCSEL performance degradation accelerates exponentially when junction temperatures exceed critical thresholds, typically around 70-80°C for GaAs-based devices.

Current thermal management solutions have progressed from basic heat sinks to more sophisticated approaches involving advanced materials and designs. The industry has witnessed a transition from traditional metal-based thermal interface materials (TIMs) with thermal conductivities of 1-5 W/mK to advanced solutions approaching 20-30 W/mK. However, as VCSEL arrays grow in density and power, these solutions are reaching their practical limits.

The primary objective of advancing thermal interface materials for high-flux VCSELs is to develop next-generation TIMs capable of efficiently transferring heat from increasingly powerful VCSEL arrays to heat dissipation systems. Specifically, the industry aims to achieve thermal conductivities exceeding 50 W/mK while maintaining other critical properties such as compliance, reliability under thermal cycling, and compatibility with existing manufacturing processes.

Recent technological trends indicate growing interest in nanomaterial-enhanced TIMs, including graphene, carbon nanotubes, and metallic nanoparticles. These materials show theoretical thermal conductivities orders of magnitude higher than conventional solutions. Additionally, phase change materials and liquid metal composites are emerging as promising alternatives for high-performance thermal management.

The evolution of VCSEL technology itself is driving these thermal management requirements. The transition from single emitters to arrays containing hundreds or thousands of elements has multiplied thermal challenges. Furthermore, the expansion of VCSEL applications into automotive, industrial, and consumer electronics markets has introduced new environmental and reliability requirements that directly impact thermal management strategies.

Achieving breakthrough performance in thermal interface materials will enable the next generation of high-power VCSEL applications, including longer-range LiDAR systems, higher-resolution 3D sensing, and more efficient optical communication systems. This represents a critical enabling technology for the continued advancement of photonics-based systems across multiple industries.

The thermal management of VCSELs represents one of the most significant challenges in their continued development. As power densities increase, the efficient dissipation of heat becomes paramount to maintaining device performance, reliability, and longevity. Historical data indicates that VCSEL performance degradation accelerates exponentially when junction temperatures exceed critical thresholds, typically around 70-80°C for GaAs-based devices.

Current thermal management solutions have progressed from basic heat sinks to more sophisticated approaches involving advanced materials and designs. The industry has witnessed a transition from traditional metal-based thermal interface materials (TIMs) with thermal conductivities of 1-5 W/mK to advanced solutions approaching 20-30 W/mK. However, as VCSEL arrays grow in density and power, these solutions are reaching their practical limits.

The primary objective of advancing thermal interface materials for high-flux VCSELs is to develop next-generation TIMs capable of efficiently transferring heat from increasingly powerful VCSEL arrays to heat dissipation systems. Specifically, the industry aims to achieve thermal conductivities exceeding 50 W/mK while maintaining other critical properties such as compliance, reliability under thermal cycling, and compatibility with existing manufacturing processes.

Recent technological trends indicate growing interest in nanomaterial-enhanced TIMs, including graphene, carbon nanotubes, and metallic nanoparticles. These materials show theoretical thermal conductivities orders of magnitude higher than conventional solutions. Additionally, phase change materials and liquid metal composites are emerging as promising alternatives for high-performance thermal management.

The evolution of VCSEL technology itself is driving these thermal management requirements. The transition from single emitters to arrays containing hundreds or thousands of elements has multiplied thermal challenges. Furthermore, the expansion of VCSEL applications into automotive, industrial, and consumer electronics markets has introduced new environmental and reliability requirements that directly impact thermal management strategies.

Achieving breakthrough performance in thermal interface materials will enable the next generation of high-power VCSEL applications, including longer-range LiDAR systems, higher-resolution 3D sensing, and more efficient optical communication systems. This represents a critical enabling technology for the continued advancement of photonics-based systems across multiple industries.

Market Analysis for High-Flux VCSEL Applications

The global market for high-flux Vertical-Cavity Surface-Emitting Lasers (VCSELs) has experienced remarkable growth in recent years, primarily driven by increasing adoption in consumer electronics, automotive LiDAR systems, and data communication applications. The market value reached approximately $2.1 billion in 2022 and is projected to grow at a CAGR of 17.3% through 2028, potentially reaching $5.4 billion by the end of the forecast period.

Consumer electronics represents the largest application segment, accounting for nearly 43% of the total market share. This dominance is largely attributed to the widespread integration of VCSEL arrays in facial recognition systems, proximity sensors, and 3D sensing modules in smartphones and tablets. Apple's implementation of Face ID technology has been a significant market catalyst, with other manufacturers following suit.

Automotive applications are emerging as the fastest-growing segment with a projected CAGR of 23.5%. The increasing development of autonomous driving technologies and advanced driver-assistance systems (ADAS) has created substantial demand for high-power VCSEL arrays in LiDAR systems. This trend is expected to accelerate as Level 3+ autonomous vehicles move closer to commercial deployment.

Data communication applications continue to provide a stable market foundation, with high-flux VCSELs being essential components in high-speed optical interconnects for data centers. The ongoing expansion of cloud computing infrastructure and the transition to higher data rates (50G, 100G, and beyond) are sustaining demand in this segment.

Geographically, North America leads the market with approximately 38% share, followed by Asia-Pacific at 35% and Europe at 22%. China is emerging as a particularly dynamic market due to its rapidly expanding consumer electronics manufacturing base and government initiatives supporting photonics technology development.

The market is characterized by increasing demand for higher power densities, with applications requiring VCSEL arrays capable of delivering optical power densities exceeding 5 W/mm². This trend is driving the need for advanced thermal management solutions, as thermal limitations have become the primary constraint on further power scaling in VCSEL arrays.

End-user industries are increasingly prioritizing VCSELs with improved thermal performance, as this directly impacts device reliability, operational lifetime, and overall system efficiency. Market research indicates that solutions offering a 30% improvement in thermal management could potentially unlock an additional $800 million in market opportunities by enabling new high-power applications currently limited by thermal constraints.

Consumer electronics represents the largest application segment, accounting for nearly 43% of the total market share. This dominance is largely attributed to the widespread integration of VCSEL arrays in facial recognition systems, proximity sensors, and 3D sensing modules in smartphones and tablets. Apple's implementation of Face ID technology has been a significant market catalyst, with other manufacturers following suit.

Automotive applications are emerging as the fastest-growing segment with a projected CAGR of 23.5%. The increasing development of autonomous driving technologies and advanced driver-assistance systems (ADAS) has created substantial demand for high-power VCSEL arrays in LiDAR systems. This trend is expected to accelerate as Level 3+ autonomous vehicles move closer to commercial deployment.

Data communication applications continue to provide a stable market foundation, with high-flux VCSELs being essential components in high-speed optical interconnects for data centers. The ongoing expansion of cloud computing infrastructure and the transition to higher data rates (50G, 100G, and beyond) are sustaining demand in this segment.

Geographically, North America leads the market with approximately 38% share, followed by Asia-Pacific at 35% and Europe at 22%. China is emerging as a particularly dynamic market due to its rapidly expanding consumer electronics manufacturing base and government initiatives supporting photonics technology development.

The market is characterized by increasing demand for higher power densities, with applications requiring VCSEL arrays capable of delivering optical power densities exceeding 5 W/mm². This trend is driving the need for advanced thermal management solutions, as thermal limitations have become the primary constraint on further power scaling in VCSEL arrays.

End-user industries are increasingly prioritizing VCSELs with improved thermal performance, as this directly impacts device reliability, operational lifetime, and overall system efficiency. Market research indicates that solutions offering a 30% improvement in thermal management could potentially unlock an additional $800 million in market opportunities by enabling new high-power applications currently limited by thermal constraints.

Current Thermal Interface Materials Limitations

Current thermal interface materials (TIMs) used in high-flux Vertical-Cavity Surface-Emitting Lasers (VCSELs) face significant limitations that impede optimal thermal management. Conventional TIMs such as thermal greases, phase change materials (PCMs), and thermal pads exhibit thermal conductivity values typically ranging from 0.5 to 8 W/m·K, which proves inadequate for the extreme heat flux generated by next-generation VCSELs that can exceed 500 W/cm².

Contact resistance represents a major bottleneck in thermal management systems. Even high-performance TIMs suffer from interface resistances at both the TIM-VCSEL and TIM-heat sink junctions, creating thermal bottlenecks that significantly reduce overall heat dissipation efficiency. These interface resistances can account for up to 30-40% of the total thermal resistance in a VCSEL package.

Reliability issues plague current TIMs when subjected to the operational conditions of high-flux VCSELs. Thermal greases experience pump-out and dry-out phenomena under thermal cycling, leading to performance degradation over time. Solder-based TIMs, while offering higher thermal conductivity, introduce mechanical stress due to coefficient of thermal expansion (CTE) mismatches, potentially causing device failure through delamination or cracking.

The thickness uniformity of applied TIMs presents another critical limitation. Variations in bond line thickness create localized hot spots that can accelerate device degradation. Current application methods struggle to achieve the consistent sub-50μm thicknesses required for optimal thermal performance in high-density VCSEL arrays.

Environmental and manufacturing constraints further complicate TIM selection. Many high-performance TIMs contain environmentally problematic materials facing increasing regulatory restrictions. Additionally, complex application processes for advanced TIMs like metal matrix composites or liquid metal alloys create manufacturing challenges that increase production costs and reduce yield rates.

Thermal stability at elevated temperatures represents another significant limitation. As VCSELs operate at increasingly higher power densities, junction temperatures can exceed 150°C. Many conventional TIMs degrade rapidly at these temperatures, with some organic-based materials experiencing chemical breakdown that permanently compromises their thermal performance.

The cost-performance ratio of current high-end TIMs poses economic barriers to widespread implementation. Materials offering the thermal performance necessary for high-flux VCSELs, such as diamond-filled composites or engineered carbon nanotube arrays, remain prohibitively expensive for mass-market applications, limiting their adoption despite their superior thermal characteristics.

Contact resistance represents a major bottleneck in thermal management systems. Even high-performance TIMs suffer from interface resistances at both the TIM-VCSEL and TIM-heat sink junctions, creating thermal bottlenecks that significantly reduce overall heat dissipation efficiency. These interface resistances can account for up to 30-40% of the total thermal resistance in a VCSEL package.

Reliability issues plague current TIMs when subjected to the operational conditions of high-flux VCSELs. Thermal greases experience pump-out and dry-out phenomena under thermal cycling, leading to performance degradation over time. Solder-based TIMs, while offering higher thermal conductivity, introduce mechanical stress due to coefficient of thermal expansion (CTE) mismatches, potentially causing device failure through delamination or cracking.

The thickness uniformity of applied TIMs presents another critical limitation. Variations in bond line thickness create localized hot spots that can accelerate device degradation. Current application methods struggle to achieve the consistent sub-50μm thicknesses required for optimal thermal performance in high-density VCSEL arrays.

Environmental and manufacturing constraints further complicate TIM selection. Many high-performance TIMs contain environmentally problematic materials facing increasing regulatory restrictions. Additionally, complex application processes for advanced TIMs like metal matrix composites or liquid metal alloys create manufacturing challenges that increase production costs and reduce yield rates.

Thermal stability at elevated temperatures represents another significant limitation. As VCSELs operate at increasingly higher power densities, junction temperatures can exceed 150°C. Many conventional TIMs degrade rapidly at these temperatures, with some organic-based materials experiencing chemical breakdown that permanently compromises their thermal performance.

The cost-performance ratio of current high-end TIMs poses economic barriers to widespread implementation. Materials offering the thermal performance necessary for high-flux VCSELs, such as diamond-filled composites or engineered carbon nanotube arrays, remain prohibitively expensive for mass-market applications, limiting their adoption despite their superior thermal characteristics.

State-of-the-Art Thermal Management Solutions

01 Carbon-based thermal interface materials

Carbon-based materials such as graphene, carbon nanotubes, and graphite are widely used in thermal interface materials due to their excellent thermal conductivity properties. These materials can be incorporated into polymer matrices to create composite materials with enhanced heat transfer capabilities. The resulting thermal interface materials provide efficient thermal management solutions for electronic devices, reducing thermal resistance between heat sources and heat sinks.- Carbon-based thermal interface materials: Carbon-based materials such as graphene, carbon nanotubes, and graphite are increasingly used in thermal interface materials due to their excellent thermal conductivity properties. These materials can be incorporated into polymer matrices to create composite materials that efficiently transfer heat from electronic components to heat sinks. The high aspect ratio and thermal conductivity of carbon allotropes allow for effective heat dissipation in high-power electronic devices, reducing thermal resistance at interfaces.

- Metal-based thermal interface materials: Metal-based thermal interface materials utilize metals and metal alloys to enhance thermal conductivity. These materials often include particles of copper, aluminum, silver, or other thermally conductive metals dispersed in a carrier matrix. Some formulations use liquid metal alloys that remain in a fluid state at operating temperatures, allowing for excellent contact with mating surfaces. Metal-based TIMs provide superior thermal performance compared to conventional polymer-based materials, making them suitable for high-performance computing and power electronics applications.

- Phase change materials for thermal management: Phase change materials (PCMs) are designed to change from solid to liquid at specific temperatures, filling microscopic gaps between surfaces and reducing thermal resistance. These materials combine the benefits of thermal greases with the handling convenience of pads. When heated above their transition temperature, PCMs flow to conform to surface irregularities, then solidify when cooled to provide stable thermal connections. This technology is particularly valuable in applications with thermal cycling, as the material can repeatedly melt and solidify to maintain optimal thermal contact.

- Polymer-based thermal interface composites: Polymer-based thermal interface materials combine thermally conductive fillers with polymer matrices to create flexible, conformable materials that can fill gaps between heat-generating components and heat sinks. These composites often use silicone, epoxy, or other polymers as the base material, with various fillers to enhance thermal conductivity. The polymer matrix provides mechanical compliance and ease of application, while the fillers create thermal pathways. These materials can be formulated as pads, putties, or adhesives to suit different application requirements and assembly processes.

- Advanced manufacturing and application techniques: Innovative manufacturing and application techniques are being developed to optimize the performance of thermal interface materials. These include precise dispensing methods, pre-applied TIM solutions, and techniques for controlling bond line thickness. Some approaches involve in-situ formation of thermal interfaces or hierarchical structures that maximize thermal conductivity while maintaining mechanical compliance. Advanced characterization methods are also being employed to better understand thermal resistance at interfaces and optimize material formulations for specific electronic packaging configurations.

02 Metal-based thermal interface materials

Metal-based thermal interface materials utilize metals and metal alloys with high thermal conductivity to improve heat dissipation in electronic devices. These materials can include metal particles, foils, or liquid metal formulations that conform to surface irregularities, minimizing thermal resistance. Metal-based thermal interface materials are particularly effective for high-power applications where efficient thermal management is critical for device performance and reliability.Expand Specific Solutions03 Phase change thermal interface materials

Phase change thermal interface materials are designed to transition from solid to liquid state at operating temperatures, allowing them to flow into microscopic surface irregularities and create optimal thermal contact. These materials combine the ease of handling in solid form with the gap-filling capabilities of liquids during operation. The phase change property enables these materials to maintain consistent thermal performance over time while accommodating thermal expansion and contraction cycles.Expand Specific Solutions04 Polymer-based composite thermal interface materials

Polymer-based composite thermal interface materials combine polymer matrices with thermally conductive fillers to create flexible, conformable materials with enhanced thermal conductivity. These composites can be formulated with various additives to improve specific properties such as adhesion, flexibility, and thermal stability. The polymer matrix provides mechanical support and environmental protection while the fillers create thermal conduction pathways, resulting in materials that effectively transfer heat while accommodating mechanical stress.Expand Specific Solutions05 Application-specific thermal interface solutions

Specialized thermal interface materials are developed for specific applications such as high-power electronics, automotive systems, aerospace components, and LED lighting. These materials are engineered with properties tailored to the unique thermal management challenges of each application, including considerations for operating temperature range, pressure conditions, reliability requirements, and installation methods. Application-specific solutions may incorporate novel material combinations or structural designs to optimize thermal performance in particular use environments.Expand Specific Solutions

Leading VCSEL and TIM Manufacturers

The thermal interface materials (TIM) market for high-flux VCSELs is in a growth phase, driven by increasing applications in 3D sensing, LiDAR, and data communications. The market is expected to expand significantly as VCSEL technology matures, with projections indicating substantial growth in the next five years. Key players demonstrate varying levels of technological maturity: established materials companies like Henkel, Dow, and Momentive offer commercial TIM solutions; semiconductor giants including Intel, IBM, and Sony are developing specialized thermal management for their VCSEL applications; while research institutions such as Changchun Institute of Optics and Zhejiang University are advancing fundamental materials science. VCSEL manufacturers like Vertilite and Suzhou Everbright Photonics are increasingly focused on integrated thermal solutions to maximize device performance and reliability in high-power applications.

Dow Global Technologies LLC

Technical Solution: Dow has developed a comprehensive suite of thermal interface materials for high-flux VCSELs under their DOWSIL™ brand. Their advanced solution incorporates a hybrid organic-inorganic polymer system with precisely engineered filler particles including aluminum oxide, boron nitride, and silver microparticles. This combination achieves thermal conductivity values of 7.2 W/m·K while maintaining excellent wetting properties and bond line thickness control. Dow's TIM technology features a controlled rheology that enables precise dispensing in automated manufacturing processes, with self-leveling properties that ensure uniform thermal contact across the VCSEL array. Their materials demonstrate minimal interfacial thermal resistance (0.06 cm²·K/W) and maintain performance stability through temperature cycling from -40°C to 150°C. Dow has also incorporated novel adhesion promoters that enhance long-term reliability by preventing delamination at the VCSEL-TIM interface, a critical factor in maintaining thermal performance over device lifetime.

Strengths: Excellent manufacturing compatibility with automated processes and superior long-term adhesion properties. Weaknesses: Requires specific surface preparation protocols and has limited reworkability once cured.

Henkel IP & Holding GmbH

Technical Solution: Henkel has developed advanced thermal interface materials specifically designed for high-flux VCSELs, featuring metal-filled silicone matrices with thermal conductivity exceeding 7.5 W/m·K. Their proprietary TIM solutions incorporate silver nanoparticles and aluminum nitride fillers in a hybrid polymer matrix, creating a phase-change material that optimizes thermal contact at VCSEL-heatsink interfaces. The company's latest generation materials employ a dual-cure mechanism combining UV-initiated and moisture-curing technologies, allowing for precise application and excellent gap-filling properties while maintaining low thermal resistance (< 0.05 cm²·K/W). Henkel's materials are engineered to withstand the thermal cycling inherent in VCSEL operations, with demonstrated stability through 1000+ thermal cycles between -40°C and 125°C without performance degradation.

Strengths: Superior thermal conductivity with excellent gap-filling capabilities and long-term reliability under thermal cycling. Weaknesses: Higher cost compared to conventional TIMs and potential for pump-out effects under certain operating conditions.

Key Patents in Advanced TIM Development

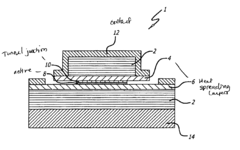

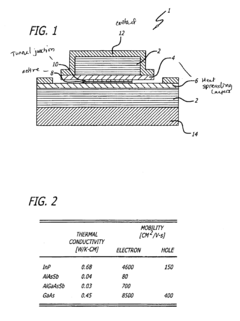

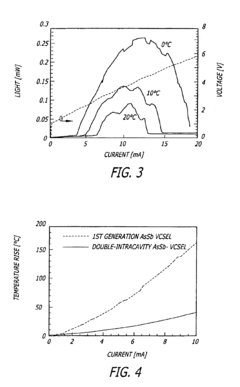

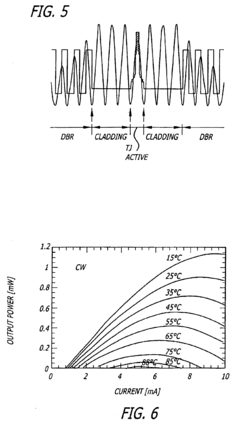

Heat spreading layers for vertical cavity surface emitting lasers

PatentInactiveUS6810064B1

Innovation

- Incorporating heat spreading layers doped with n-type material between reflecting surfaces to bypass the DBRs, allowing injected current and heat to flow laterally through InP cladding layers, reducing temperature and enabling continuous-wave operation.

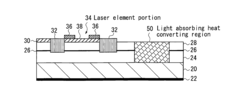

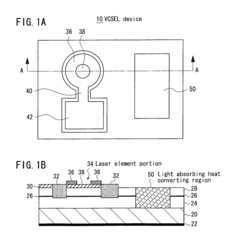

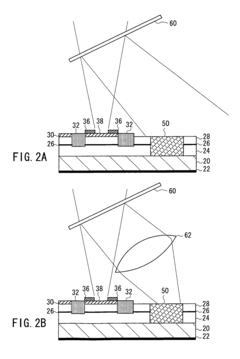

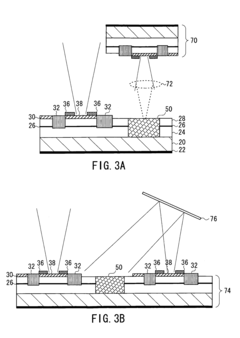

Vertical-cavity surface-emitting laser diode device

PatentInactiveUS7573929B2

Innovation

- A VCSEL device with a light absorbing heat converting region thermally connected to the laser element portion, where projected light is absorbed and converted into heat to stabilize temperature variations, eliminating the need for external temperature control components.

Reliability Testing Standards for VCSEL TIMs

Reliability testing standards for VCSEL Thermal Interface Materials (TIMs) have evolved significantly to address the unique thermal management challenges posed by high-flux VCSEL operations. These standards encompass a comprehensive framework designed to evaluate TIM performance under conditions that simulate real-world operational stresses and aging factors.

The primary reliability testing protocols include thermal cycling tests, which typically subject VCSEL-TIM assemblies to temperature fluctuations between -40°C and 125°C for 500-1000 cycles. This test evaluates the TIM's ability to maintain thermal conductivity and mechanical integrity despite repeated thermal expansion and contraction cycles.

High-temperature storage tests represent another critical standard, where TIMs are exposed to elevated temperatures (typically 150°C to 200°C) for extended periods ranging from 1000 to 2000 hours. These tests assess the material's resistance to thermal degradation, outgassing, and potential chemical changes that might compromise performance over time.

Power cycling tests specifically target the TIM's performance under rapid power fluctuations, simulating the on-off operational patterns of VCSELs in real-world applications. Standard protocols typically involve 10,000 to 100,000 power cycles with varying dwell times to comprehensively evaluate thermal fatigue resistance.

Humidity resistance testing has become increasingly important, with standard conditions typically involving 85% relative humidity at 85°C for 1000 hours. This test evaluates the TIM's susceptibility to moisture-induced degradation, particularly relevant for consumer electronics applications where environmental exposure varies significantly.

Mechanical shock and vibration testing standards have been established to ensure TIMs maintain their interface integrity under physical stresses. These tests typically follow MIL-STD-810 or JEDEC standards, with specific adaptations for VCSEL applications.

Industry standards organizations including JEDEC, IPC, and ASTM have developed specialized test methodologies for TIM reliability in high-power electronics. For VCSEL-specific applications, modified versions of JEDEC JESD22-A104 and JESD22-A103 are commonly employed, with parameters adjusted to reflect the unique thermal profiles and power densities of high-flux VCSELs.

Recent developments in reliability standards have begun incorporating accelerated aging models that correlate test results with projected field performance, allowing manufacturers to estimate TIM lifetime under various operational conditions. These models typically employ Arrhenius equations with activation energies specific to different TIM formulations and failure mechanisms.

The primary reliability testing protocols include thermal cycling tests, which typically subject VCSEL-TIM assemblies to temperature fluctuations between -40°C and 125°C for 500-1000 cycles. This test evaluates the TIM's ability to maintain thermal conductivity and mechanical integrity despite repeated thermal expansion and contraction cycles.

High-temperature storage tests represent another critical standard, where TIMs are exposed to elevated temperatures (typically 150°C to 200°C) for extended periods ranging from 1000 to 2000 hours. These tests assess the material's resistance to thermal degradation, outgassing, and potential chemical changes that might compromise performance over time.

Power cycling tests specifically target the TIM's performance under rapid power fluctuations, simulating the on-off operational patterns of VCSELs in real-world applications. Standard protocols typically involve 10,000 to 100,000 power cycles with varying dwell times to comprehensively evaluate thermal fatigue resistance.

Humidity resistance testing has become increasingly important, with standard conditions typically involving 85% relative humidity at 85°C for 1000 hours. This test evaluates the TIM's susceptibility to moisture-induced degradation, particularly relevant for consumer electronics applications where environmental exposure varies significantly.

Mechanical shock and vibration testing standards have been established to ensure TIMs maintain their interface integrity under physical stresses. These tests typically follow MIL-STD-810 or JEDEC standards, with specific adaptations for VCSEL applications.

Industry standards organizations including JEDEC, IPC, and ASTM have developed specialized test methodologies for TIM reliability in high-power electronics. For VCSEL-specific applications, modified versions of JEDEC JESD22-A104 and JESD22-A103 are commonly employed, with parameters adjusted to reflect the unique thermal profiles and power densities of high-flux VCSELs.

Recent developments in reliability standards have begun incorporating accelerated aging models that correlate test results with projected field performance, allowing manufacturers to estimate TIM lifetime under various operational conditions. These models typically employ Arrhenius equations with activation energies specific to different TIM formulations and failure mechanisms.

Environmental Impact of Advanced TIMs

The environmental implications of Advanced Thermal Interface Materials (TIMs) for high-flux VCSELs extend beyond their primary thermal management function, encompassing their entire lifecycle from production to disposal. Traditional TIMs often contain environmentally problematic components such as heavy metals, silicones, and other non-biodegradable substances that pose significant ecological challenges.

Manufacturing processes for advanced TIMs frequently involve energy-intensive procedures and potentially hazardous chemicals. Carbon-based TIMs, particularly those utilizing graphene or carbon nanotubes, require sophisticated synthesis methods that may generate substantial carbon footprints. Similarly, metal-based TIMs containing indium, gallium, or silver raise concerns regarding resource depletion of these finite materials and the environmental impact of their extraction processes.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have placed stringent limitations on certain materials commonly found in TIMs. These regulations are driving manufacturers toward developing more environmentally sustainable alternatives that maintain thermal performance while reducing ecological impact.

Recent innovations in eco-friendly TIMs show promising developments. Bio-derived thermal interface materials utilizing cellulose nanofibers or other plant-based components offer biodegradable alternatives with competitive thermal conductivity. Additionally, research into recyclable metal-polymer composites presents opportunities for circular economy approaches in TIM lifecycle management, particularly important for high-volume VCSEL applications in consumer electronics.

Energy efficiency considerations also factor into the environmental assessment of advanced TIMs. By enabling more efficient thermal management in high-flux VCSELs, these materials indirectly reduce overall energy consumption of devices throughout their operational lifetime. This energy saving must be balanced against the environmental costs of TIM production and disposal in comprehensive lifecycle assessments.

End-of-life management represents another critical environmental consideration. As VCSELs become increasingly integrated into consumer electronics, the volume of disposed devices containing advanced TIMs grows proportionally. Developing effective recycling methodologies for these composite materials presents significant technical challenges that researchers are actively addressing through design-for-disassembly approaches and novel separation techniques for composite TIM materials.

Manufacturing processes for advanced TIMs frequently involve energy-intensive procedures and potentially hazardous chemicals. Carbon-based TIMs, particularly those utilizing graphene or carbon nanotubes, require sophisticated synthesis methods that may generate substantial carbon footprints. Similarly, metal-based TIMs containing indium, gallium, or silver raise concerns regarding resource depletion of these finite materials and the environmental impact of their extraction processes.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have placed stringent limitations on certain materials commonly found in TIMs. These regulations are driving manufacturers toward developing more environmentally sustainable alternatives that maintain thermal performance while reducing ecological impact.

Recent innovations in eco-friendly TIMs show promising developments. Bio-derived thermal interface materials utilizing cellulose nanofibers or other plant-based components offer biodegradable alternatives with competitive thermal conductivity. Additionally, research into recyclable metal-polymer composites presents opportunities for circular economy approaches in TIM lifecycle management, particularly important for high-volume VCSEL applications in consumer electronics.

Energy efficiency considerations also factor into the environmental assessment of advanced TIMs. By enabling more efficient thermal management in high-flux VCSELs, these materials indirectly reduce overall energy consumption of devices throughout their operational lifetime. This energy saving must be balanced against the environmental costs of TIM production and disposal in comprehensive lifecycle assessments.

End-of-life management represents another critical environmental consideration. As VCSELs become increasingly integrated into consumer electronics, the volume of disposed devices containing advanced TIMs grows proportionally. Developing effective recycling methodologies for these composite materials presents significant technical challenges that researchers are actively addressing through design-for-disassembly approaches and novel separation techniques for composite TIM materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!