Case Study: VCSEL Deployment In 400G/800G Optical Links

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Technology Evolution and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as a transformative technology in optical communications, evolving significantly since their inception in the late 1970s. The journey of VCSEL technology began with fundamental research at Tokyo Institute of Technology and University of Illinois, progressing through various developmental milestones to become a cornerstone of modern optical interconnects.

The evolution of VCSEL technology can be traced through several key phases. Initially, the focus was on achieving room-temperature continuous-wave operation, which was accomplished in the early 1990s. This breakthrough catalyzed commercial interest, leading to the first deployment in short-reach data communication applications. Subsequently, VCSEL development concentrated on enhancing modulation bandwidth, improving reliability, and increasing output power while maintaining single-mode operation.

In the context of 400G/800G optical links, VCSEL technology has undergone substantial refinement to meet escalating bandwidth demands. The transition from 25G to 50G and now toward 100G per channel has necessitated innovations in both device structure and manufacturing processes. Modern VCSELs incorporate sophisticated features such as oxide aperture confinement, optimized quantum well active regions, and advanced mirror designs to achieve the required performance metrics.

The primary technical objectives for VCSEL deployment in high-speed optical links center around several critical parameters. First, modulation bandwidth must exceed 25 GHz to support PAM-4 modulation at 50-100 Gbps per channel. Second, spectral characteristics must remain stable across operating temperatures to maintain signal integrity. Third, power efficiency must be optimized to address thermal management challenges in densely packed transceivers.

Current research trajectories indicate a continued push toward higher modulation speeds, with particular emphasis on reducing parasitic capacitance and optimizing carrier transport dynamics. Novel approaches including photonic crystal structures, tunnel junctions, and heterogeneous integration with silicon photonics are being explored to extend VCSEL capabilities beyond current limitations.

The technology roadmap for VCSELs in next-generation optical links aims to achieve 100G per channel operation with acceptable power consumption profiles. This progression aligns with industry demands for 800G and future 1.6T interconnects, where parallel VCSEL arrays will likely play a crucial role in meeting aggregate bandwidth requirements while maintaining cost-effectiveness and reliability advantages.

As data center architectures evolve toward disaggregated computing models, VCSEL technology objectives have expanded to include not only performance enhancements but also integration capabilities with co-packaged optics and silicon photonics platforms, representing a significant shift in deployment strategy for this mature yet continuously evolving technology.

The evolution of VCSEL technology can be traced through several key phases. Initially, the focus was on achieving room-temperature continuous-wave operation, which was accomplished in the early 1990s. This breakthrough catalyzed commercial interest, leading to the first deployment in short-reach data communication applications. Subsequently, VCSEL development concentrated on enhancing modulation bandwidth, improving reliability, and increasing output power while maintaining single-mode operation.

In the context of 400G/800G optical links, VCSEL technology has undergone substantial refinement to meet escalating bandwidth demands. The transition from 25G to 50G and now toward 100G per channel has necessitated innovations in both device structure and manufacturing processes. Modern VCSELs incorporate sophisticated features such as oxide aperture confinement, optimized quantum well active regions, and advanced mirror designs to achieve the required performance metrics.

The primary technical objectives for VCSEL deployment in high-speed optical links center around several critical parameters. First, modulation bandwidth must exceed 25 GHz to support PAM-4 modulation at 50-100 Gbps per channel. Second, spectral characteristics must remain stable across operating temperatures to maintain signal integrity. Third, power efficiency must be optimized to address thermal management challenges in densely packed transceivers.

Current research trajectories indicate a continued push toward higher modulation speeds, with particular emphasis on reducing parasitic capacitance and optimizing carrier transport dynamics. Novel approaches including photonic crystal structures, tunnel junctions, and heterogeneous integration with silicon photonics are being explored to extend VCSEL capabilities beyond current limitations.

The technology roadmap for VCSELs in next-generation optical links aims to achieve 100G per channel operation with acceptable power consumption profiles. This progression aligns with industry demands for 800G and future 1.6T interconnects, where parallel VCSEL arrays will likely play a crucial role in meeting aggregate bandwidth requirements while maintaining cost-effectiveness and reliability advantages.

As data center architectures evolve toward disaggregated computing models, VCSEL technology objectives have expanded to include not only performance enhancements but also integration capabilities with co-packaged optics and silicon photonics platforms, representing a significant shift in deployment strategy for this mature yet continuously evolving technology.

Market Demand Analysis for High-Speed Optical Links

The global demand for high-speed optical links has experienced exponential growth driven by the increasing bandwidth requirements of data centers, cloud computing, and telecommunications networks. The transition from 100G to 400G and now to 800G optical links represents a critical evolution in meeting these escalating data transmission needs. Market research indicates that the 400G optical transceiver market reached approximately $2.3 billion in 2022, with projections showing a compound annual growth rate (CAGR) of 27% through 2027.

Data center operators, including hyperscale providers like Amazon, Google, Microsoft, and Facebook, constitute the primary demand drivers for these advanced optical links. These companies are rapidly expanding their infrastructure to support cloud services, artificial intelligence applications, and video streaming platforms, all of which require massive data throughput capabilities.

The shift toward 400G and 800G technologies is further accelerated by the proliferation of 5G networks, which demand higher backhaul capacity. Telecommunications service providers are upgrading their infrastructure to support the increased data traffic, creating additional market demand for high-speed optical links.

VCSEL (Vertical-Cavity Surface-Emitting Laser) technology has emerged as a preferred solution for short-reach applications within data centers due to its cost-effectiveness, energy efficiency, and reliability. Market analysis shows that VCSELs account for approximately 60% of all optical transceivers deployed in data center environments for distances under 100 meters.

Regional market distribution reveals North America leading with 42% market share, followed by Asia-Pacific at 38%, and Europe at 17%. China's domestic market for high-speed optical links is growing at an exceptional rate of 35% annually, driven by government initiatives to enhance digital infrastructure.

Industry surveys indicate that power efficiency has become a critical factor in purchasing decisions, with data center operators prioritizing solutions that offer lower power consumption per gigabit. VCSEL-based solutions typically consume 30-40% less power than alternative technologies for comparable transmission rates.

Cost considerations remain paramount, with price-per-gigabit continuing to decline by approximately 15-20% annually. This trend is essential for market expansion as it enables broader adoption across various industry segments beyond hyperscale data centers.

The market is also witnessing increased demand for pluggable optical modules that support multi-vendor interoperability, with the 400G QSFP-DD and OSFP form factors gaining significant traction. For the emerging 800G market, similar standardization efforts are underway to ensure ecosystem compatibility and accelerate adoption.

Data center operators, including hyperscale providers like Amazon, Google, Microsoft, and Facebook, constitute the primary demand drivers for these advanced optical links. These companies are rapidly expanding their infrastructure to support cloud services, artificial intelligence applications, and video streaming platforms, all of which require massive data throughput capabilities.

The shift toward 400G and 800G technologies is further accelerated by the proliferation of 5G networks, which demand higher backhaul capacity. Telecommunications service providers are upgrading their infrastructure to support the increased data traffic, creating additional market demand for high-speed optical links.

VCSEL (Vertical-Cavity Surface-Emitting Laser) technology has emerged as a preferred solution for short-reach applications within data centers due to its cost-effectiveness, energy efficiency, and reliability. Market analysis shows that VCSELs account for approximately 60% of all optical transceivers deployed in data center environments for distances under 100 meters.

Regional market distribution reveals North America leading with 42% market share, followed by Asia-Pacific at 38%, and Europe at 17%. China's domestic market for high-speed optical links is growing at an exceptional rate of 35% annually, driven by government initiatives to enhance digital infrastructure.

Industry surveys indicate that power efficiency has become a critical factor in purchasing decisions, with data center operators prioritizing solutions that offer lower power consumption per gigabit. VCSEL-based solutions typically consume 30-40% less power than alternative technologies for comparable transmission rates.

Cost considerations remain paramount, with price-per-gigabit continuing to decline by approximately 15-20% annually. This trend is essential for market expansion as it enables broader adoption across various industry segments beyond hyperscale data centers.

The market is also witnessing increased demand for pluggable optical modules that support multi-vendor interoperability, with the 400G QSFP-DD and OSFP form factors gaining significant traction. For the emerging 800G market, similar standardization efforts are underway to ensure ecosystem compatibility and accelerate adoption.

VCSEL Implementation Challenges in 400G/800G Networks

The implementation of VCSELs in 400G/800G optical networks presents several significant technical challenges that must be addressed to achieve reliable high-speed data transmission. One of the primary obstacles is the inherent bandwidth limitation of traditional VCSEL designs. While VCSELs have successfully served lower data rate applications, scaling them to meet the stringent requirements of 400G and 800G links demands substantial improvements in modulation bandwidth, which currently typically maxes out at around 25-30 GHz for commercial devices.

Thermal management represents another critical challenge in high-speed VCSEL deployment. As data rates increase, so does power consumption, resulting in elevated operating temperatures that can significantly degrade VCSEL performance and reliability. The compact form factor of VCSEL arrays in multi-channel transceivers further complicates heat dissipation, requiring innovative thermal design solutions to maintain optimal operating conditions.

Signal integrity issues become increasingly pronounced at higher data rates. Modal dispersion in multimode fiber links using VCSELs creates intersymbol interference that limits transmission distance. Additionally, electrical parasitics in VCSEL driver circuits and packaging can severely impact signal quality, necessitating advanced circuit design techniques and packaging technologies to preserve signal integrity throughout the transmission chain.

Manufacturing challenges also present significant hurdles. The production of VCSELs with consistent performance characteristics across large volumes becomes more difficult as specifications tighten for higher-speed applications. Yield management and process control must be exceptionally precise to ensure uniformity in critical parameters such as threshold current, slope efficiency, and spectral width.

Integration complexity increases substantially in 400G/800G systems. VCSELs must be precisely aligned with optical components in increasingly dense multi-channel arrays, often requiring submicron positioning accuracy. The assembly process must accommodate not only the optical components but also sophisticated driver electronics and thermal management systems within compact transceiver form factors.

Reliability concerns are magnified at higher data rates and operating temperatures. VCSELs in 400G/800G applications must maintain performance over the expected lifetime of the system despite operating under more stressful conditions. Accelerated aging tests and reliability modeling become essential to predict and mitigate potential failure modes in these demanding environments.

Cost considerations remain paramount despite these technical challenges. The economic viability of VCSEL-based solutions for 400G/800G links depends on achieving acceptable manufacturing yields and developing cost-effective packaging and testing methodologies that can scale with increasing production volumes.

Thermal management represents another critical challenge in high-speed VCSEL deployment. As data rates increase, so does power consumption, resulting in elevated operating temperatures that can significantly degrade VCSEL performance and reliability. The compact form factor of VCSEL arrays in multi-channel transceivers further complicates heat dissipation, requiring innovative thermal design solutions to maintain optimal operating conditions.

Signal integrity issues become increasingly pronounced at higher data rates. Modal dispersion in multimode fiber links using VCSELs creates intersymbol interference that limits transmission distance. Additionally, electrical parasitics in VCSEL driver circuits and packaging can severely impact signal quality, necessitating advanced circuit design techniques and packaging technologies to preserve signal integrity throughout the transmission chain.

Manufacturing challenges also present significant hurdles. The production of VCSELs with consistent performance characteristics across large volumes becomes more difficult as specifications tighten for higher-speed applications. Yield management and process control must be exceptionally precise to ensure uniformity in critical parameters such as threshold current, slope efficiency, and spectral width.

Integration complexity increases substantially in 400G/800G systems. VCSELs must be precisely aligned with optical components in increasingly dense multi-channel arrays, often requiring submicron positioning accuracy. The assembly process must accommodate not only the optical components but also sophisticated driver electronics and thermal management systems within compact transceiver form factors.

Reliability concerns are magnified at higher data rates and operating temperatures. VCSELs in 400G/800G applications must maintain performance over the expected lifetime of the system despite operating under more stressful conditions. Accelerated aging tests and reliability modeling become essential to predict and mitigate potential failure modes in these demanding environments.

Cost considerations remain paramount despite these technical challenges. The economic viability of VCSEL-based solutions for 400G/800G links depends on achieving acceptable manufacturing yields and developing cost-effective packaging and testing methodologies that can scale with increasing production volumes.

Current VCSEL Integration Solutions for 400G/800G

01 VCSEL structure and fabrication

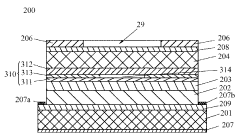

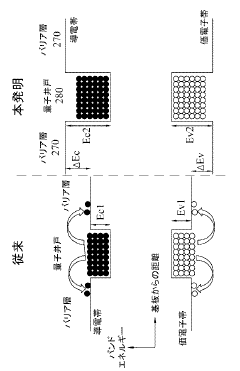

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have a unique structure where light is emitted perpendicular to the semiconductor surface. The structure typically includes distributed Bragg reflectors (DBRs) forming the top and bottom mirrors of the cavity, with an active region containing quantum wells in between. Fabrication techniques focus on optimizing the epitaxial growth of these layers to achieve desired wavelength emission and performance characteristics. Advanced manufacturing processes enable precise control of layer thicknesses and compositions, which are critical for VCSEL operation.- VCSEL structure and fabrication techniques: Vertical-Cavity Surface-Emitting Lasers (VCSELs) have a unique structure where light is emitted perpendicular to the semiconductor surface. The fabrication involves creating distributed Bragg reflectors (DBRs) on both sides of an active region. Advanced manufacturing techniques include epitaxial growth processes, wafer bonding, and precise control of layer thicknesses to achieve desired wavelength emission. These structural innovations enable VCSELs to have advantages such as circular beam profiles, low threshold currents, and the ability to be tested on-wafer before packaging.

- VCSEL arrays and integration technologies: VCSEL arrays consist of multiple VCSEL elements arranged in one or two-dimensional configurations on a single substrate. These arrays enable higher output power, parallel optical data transmission, and advanced sensing applications. Integration technologies focus on combining VCSELs with photodetectors, driver circuits, and other optical components to create compact optoelectronic modules. This integration facilitates applications in data centers, LiDAR systems, and consumer electronics where space constraints are significant.

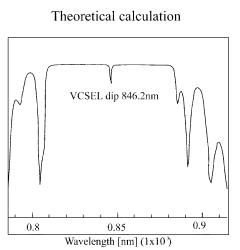

- Wavelength control and tuning mechanisms: Controlling and tuning the emission wavelength of VCSELs is crucial for applications requiring specific spectral characteristics. Various mechanisms include temperature control, mechanical tuning using MEMS structures, and electrical tuning through current injection. Advanced designs incorporate multiple cavities or specialized materials to achieve wider tuning ranges. These wavelength control techniques enable VCSELs to be used in wavelength division multiplexing (WDM) systems, spectroscopy, and sensing applications where precise wavelength control is essential.

- VCSEL-based sensing and measurement systems: VCSELs are increasingly used in various sensing and measurement applications due to their compact size, reliability, and spectral characteristics. These applications include 3D sensing for facial recognition, gesture control, proximity sensing, and environmental monitoring. VCSEL-based systems often incorporate specialized optics, beam steering mechanisms, and detection algorithms to enhance measurement accuracy. The narrow spectral linewidth and stability of VCSELs make them particularly suitable for interferometric measurements and spectroscopic applications.

- Power efficiency and thermal management: Improving power efficiency and thermal management is critical for VCSEL performance and reliability. Advanced designs incorporate optimized active regions, improved carrier confinement structures, and enhanced heat dissipation mechanisms. Thermal management techniques include specialized heat sinks, thermally conductive substrates, and optimized device geometries to reduce thermal resistance. These improvements enable VCSELs to operate at higher powers and temperatures without degradation, extending their application range to demanding environments and high-power applications such as materials processing and LiDAR systems.

02 VCSEL arrays and integration technologies

VCSEL arrays combine multiple emitters on a single chip to increase output power and enable advanced functionalities. These arrays can be designed with individual addressability for applications requiring beam steering or pattern generation. Integration technologies focus on combining VCSELs with photodetectors, control electronics, and optical elements to create compact optoelectronic modules. Such integration enables applications in 3D sensing, LiDAR, and high-speed data communications, while reducing overall system size and power consumption.Expand Specific Solutions03 VCSEL wavelength and emission control

Controlling the emission wavelength and beam characteristics of VCSELs is crucial for various applications. Techniques include adjusting the cavity length, modifying the active region composition, and implementing surface gratings. Single-mode operation can be achieved through oxide aperture confinement or other current confinement structures. Advanced designs incorporate wavelength tuning mechanisms to allow dynamic adjustment of emission characteristics, enabling applications in spectroscopy, sensing, and wavelength-division multiplexing communications.Expand Specific Solutions04 VCSEL-based sensing and measurement systems

VCSELs are increasingly used in sensing and measurement applications due to their compact size, reliability, and precise beam characteristics. These applications include 3D facial recognition, gesture sensing, proximity detection, and environmental monitoring. VCSEL-based systems can measure distance through time-of-flight principles or structured light approaches. The narrow spectral linewidth of VCSELs also makes them suitable for gas sensing and spectroscopic applications where specific absorption wavelengths need to be targeted.Expand Specific Solutions05 VCSEL power efficiency and thermal management

Improving power efficiency and thermal management are critical challenges in VCSEL development. Advanced designs incorporate heat dissipation structures, optimized current spreading layers, and improved thermal interfaces. Reducing threshold current while maintaining high output power is achieved through quantum well engineering and optimized cavity design. Thermal management techniques include flip-chip bonding to heat sinks, integration of thermal vias, and novel substrate materials with higher thermal conductivity. These improvements enable higher power operation while maintaining reliability and extending device lifetime.Expand Specific Solutions

Leading VCSEL Manufacturers and Ecosystem Players

The VCSEL deployment in 400G/800G optical links market is currently in a growth phase, with increasing adoption driven by data center expansion and AI computing demands. The market size is projected to grow significantly as high-speed optical interconnects become essential for next-generation networks. Technologically, VCSELs are maturing rapidly with key players advancing different aspects of the ecosystem. Lumentum, II-VI (now Coherent), and Vertilite lead in VCSEL array manufacturing, while Intel and Mellanox (NVIDIA) focus on integration into transceiver modules. Huawei and Fujitsu are developing complete optical link solutions. Chinese companies like Quanlei Optoelectronics and Fujian Huixin are emerging as competitive forces with government backing, particularly in high-speed VCSEL development for data center applications, challenging the traditional dominance of Western and Japanese manufacturers.

Intel Corp.

Technical Solution: Intel has developed a Silicon Photonics platform that integrates VCSEL technology for 400G/800G optical links. Their approach combines traditional VCSEL arrays with silicon photonic integrated circuits (PICs) to create a hybrid solution that leverages the strengths of both technologies. Intel's VCSELs operate at 1310nm wavelengths, departing from traditional 850nm designs to achieve longer transmission distances. Their architecture employs wavelength division multiplexing (WDM) with 4-8 channels operating at 50-100Gbps per channel using PAM-4 modulation. Intel's integration strategy places the VCSEL arrays in close proximity to their silicon photonic waveguides using advanced flip-chip bonding techniques that minimize coupling losses. Their solution incorporates built-in monitoring photodiodes and temperature sensors for real-time performance optimization. Intel's manufacturing approach leverages their advanced semiconductor fabrication capabilities, allowing for high-volume production with tight process control. For 800G applications, Intel implements sophisticated forward error correction (FEC) and digital signal processing (DSP) to maintain signal integrity over the required distances.

Strengths: Exceptional manufacturing scale and quality control; integration with silicon photonics enables advanced functionality; strong roadmap alignment with data center infrastructure evolution. Weaknesses: Higher complexity in the hybrid integration approach; potentially higher cost structure than pure VCSEL solutions; thermal management challenges at the silicon-VCSEL interface.

Lumentum Operations LLC

Technical Solution: Lumentum has developed advanced VCSEL array technology specifically optimized for 400G/800G optical links. Their solution features multi-channel VCSEL arrays with wavelength-division multiplexing (WDM) capabilities, enabling higher bandwidth density. Lumentum's VCSELs operate at 850-940nm wavelengths with modulation speeds exceeding 25Gbps per channel. Their proprietary epitaxial growth process creates highly uniform active regions with optimized quantum wells, resulting in lower threshold currents and higher slope efficiencies. For 400G/800G applications, Lumentum implements PAM-4 modulation schemes with integrated drivers that feature pre-emphasis and equalization to overcome bandwidth limitations. Their VCSELs incorporate sophisticated thermal management designs including integrated heat spreaders and optimized heat dissipation paths to maintain performance stability at high data rates. Lumentum's packaging technology includes hermetically sealed TO-cans and arrays with precise optical alignment for coupling efficiency.

Strengths: Industry-leading reliability with MTTF >100,000 hours at operating temperatures; superior modal and spectral characteristics enabling longer transmission distances; advanced manufacturing capabilities allowing cost-effective scaling. Weaknesses: Higher initial cost compared to some competitors; requires more sophisticated driving electronics; thermal management becomes challenging at highest data rates.

Key VCSEL Innovations and Performance Breakthroughs

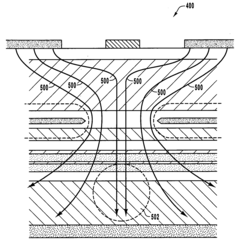

Single mode vertical cavity surface emitting laser

PatentInactiveUS20040213311A1

Innovation

- The VCSEL design features a current peak in the center, coincident with the peak of the fundamental mode, and uses an equipotential layer and insulating layers to confine current flow, minimizing higher order modes and maximizing loss for them, thereby maintaining single-mode operation over a wide current range.

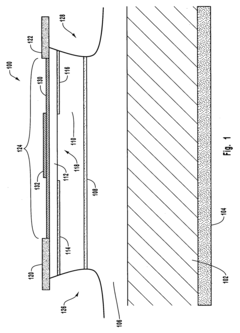

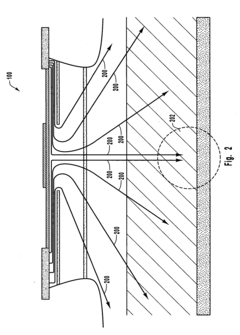

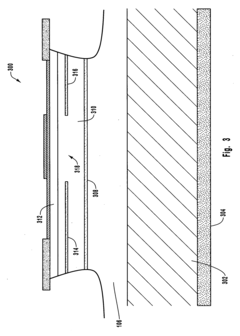

Vertical cavity surface light-emitting laser

PatentActiveJP2016178271A

Innovation

- A VCSEL design with InxGa1-xAs1-yPy quantum wells and AlGaAs barrier layers, featuring a separate confinement heterostructure and current-limiting layers, enhances optical confinement and prevents carrier leakage, while avoiding aluminum to improve high-temperature performance and product longevity.

Power Efficiency and Thermal Management Considerations

Power efficiency and thermal management represent critical challenges in the deployment of VCSELs for 400G/800G optical links. As data rates increase, power consumption escalates significantly, creating thermal issues that can degrade VCSEL performance and reliability. Current 400G modules typically consume 12-14W, while 800G implementations may reach 20-22W, necessitating sophisticated thermal solutions.

The temperature sensitivity of VCSELs presents a particular concern, as their threshold current increases exponentially with temperature, reducing efficiency and output power at elevated temperatures. Industry data indicates that VCSEL efficiency can decrease by 15-20% with a temperature rise of just 20°C, directly impacting link budget margins and system reliability.

Advanced thermal management approaches have emerged to address these challenges. Heat sinks with optimized fin structures and high thermal conductivity materials (copper, aluminum nitride) are being integrated directly with VCSEL arrays. These solutions have demonstrated the ability to maintain VCSEL junction temperatures within 10-15°C of ambient conditions even under full operational load.

Active cooling technologies, including thermoelectric coolers (TECs) and microfluidic cooling channels, are being explored for next-generation 800G implementations. While TECs add power overhead (typically 1-2W), they provide precise temperature control that can extend VCSEL operating range and lifetime. Microfluidic solutions show promise in laboratory settings, achieving thermal resistances below 0.1°C/W, though commercialization challenges remain.

Power management circuitry has evolved to optimize VCSEL driver efficiency. Advanced CMOS drivers with dynamic bias adjustment can reduce power consumption by 25-30% compared to previous generations. These drivers monitor VCSEL performance in real-time and adjust bias conditions to maintain optimal efficiency across temperature variations and aging effects.

Digital signal processing (DSP) techniques are increasingly employed to reduce overall system power requirements. Adaptive equalization and forward error correction allow operation at lower optical power levels, indirectly addressing thermal concerns by reducing required VCSEL drive currents. These approaches have demonstrated power savings of 10-15% in field deployments.

Industry consortia including the Optical Internetworking Forum (OIF) and IEEE 802.3 working groups are developing standardized approaches to thermal management for next-generation optical modules. These efforts focus on creating common thermal interfaces, measurement methodologies, and power budgets to ensure interoperability while addressing the growing thermal challenges in high-speed optical interconnects.

The temperature sensitivity of VCSELs presents a particular concern, as their threshold current increases exponentially with temperature, reducing efficiency and output power at elevated temperatures. Industry data indicates that VCSEL efficiency can decrease by 15-20% with a temperature rise of just 20°C, directly impacting link budget margins and system reliability.

Advanced thermal management approaches have emerged to address these challenges. Heat sinks with optimized fin structures and high thermal conductivity materials (copper, aluminum nitride) are being integrated directly with VCSEL arrays. These solutions have demonstrated the ability to maintain VCSEL junction temperatures within 10-15°C of ambient conditions even under full operational load.

Active cooling technologies, including thermoelectric coolers (TECs) and microfluidic cooling channels, are being explored for next-generation 800G implementations. While TECs add power overhead (typically 1-2W), they provide precise temperature control that can extend VCSEL operating range and lifetime. Microfluidic solutions show promise in laboratory settings, achieving thermal resistances below 0.1°C/W, though commercialization challenges remain.

Power management circuitry has evolved to optimize VCSEL driver efficiency. Advanced CMOS drivers with dynamic bias adjustment can reduce power consumption by 25-30% compared to previous generations. These drivers monitor VCSEL performance in real-time and adjust bias conditions to maintain optimal efficiency across temperature variations and aging effects.

Digital signal processing (DSP) techniques are increasingly employed to reduce overall system power requirements. Adaptive equalization and forward error correction allow operation at lower optical power levels, indirectly addressing thermal concerns by reducing required VCSEL drive currents. These approaches have demonstrated power savings of 10-15% in field deployments.

Industry consortia including the Optical Internetworking Forum (OIF) and IEEE 802.3 working groups are developing standardized approaches to thermal management for next-generation optical modules. These efforts focus on creating common thermal interfaces, measurement methodologies, and power budgets to ensure interoperability while addressing the growing thermal challenges in high-speed optical interconnects.

Standards and Interoperability in VCSEL Deployment

In the rapidly evolving landscape of high-speed optical communications, standardization plays a pivotal role in ensuring VCSEL deployment success across 400G/800G optical links. The IEEE 802.3 standards, particularly IEEE 802.3bs for 400G and IEEE 802.3ck for 800G Ethernet, have established critical frameworks governing VCSEL implementation in these high-speed applications. These standards define specific optical interface parameters, including wavelength ranges, power budgets, and transmission distances that VCSELs must adhere to.

The Multi-Source Agreement (MSA) groups have further enhanced interoperability through industry collaborations. Notable among these are the QSFP-DD (Quad Small Form Factor Pluggable Double Density) MSA for 400G and the OSFP (Octal Small Form Factor Pluggable) MSA for 800G applications. These agreements ensure that VCSEL-based transceivers from different manufacturers can operate seamlessly within the same network infrastructure, providing customers with flexibility in vendor selection.

Interoperability testing frameworks have emerged as essential components of the VCSEL ecosystem. The Ethernet Alliance and OIF (Optical Internetworking Forum) regularly conduct plugfests where vendors demonstrate cross-compatibility of their VCSEL-based solutions. These events have proven critical in identifying and resolving potential interoperability issues before widespread deployment, significantly reducing implementation risks for network operators.

Protocol compatibility represents another crucial dimension of VCSEL standardization. The transition to PAM4 (Pulse Amplitude Modulation with 4 levels) signaling from traditional NRZ (Non-Return to Zero) has necessitated new compliance specifications. Industry standards now define precise requirements for signal integrity, including eye diagram parameters, bit error rates, and forward error correction capabilities specific to VCSEL-based optical links.

Form factor standardization has enabled physical compatibility across different system architectures. The industry has converged on key form factors like QSFP-DD, OSFP, and QSFP56-DD for 400G/800G applications, with specific thermal and electrical specifications that accommodate VCSEL technology constraints. This standardization has facilitated smoother integration into existing data center infrastructures.

Looking forward, emerging standards like IEEE 802.3df for 800G/1.6T Ethernet are already addressing next-generation VCSEL deployment challenges. These include specifications for higher-order modulation schemes, enhanced forward error correction, and improved power efficiency metrics. The continuous evolution of these standards ensures that VCSEL technology remains viable as data rates continue to increase, providing a clear roadmap for future implementations.

The Multi-Source Agreement (MSA) groups have further enhanced interoperability through industry collaborations. Notable among these are the QSFP-DD (Quad Small Form Factor Pluggable Double Density) MSA for 400G and the OSFP (Octal Small Form Factor Pluggable) MSA for 800G applications. These agreements ensure that VCSEL-based transceivers from different manufacturers can operate seamlessly within the same network infrastructure, providing customers with flexibility in vendor selection.

Interoperability testing frameworks have emerged as essential components of the VCSEL ecosystem. The Ethernet Alliance and OIF (Optical Internetworking Forum) regularly conduct plugfests where vendors demonstrate cross-compatibility of their VCSEL-based solutions. These events have proven critical in identifying and resolving potential interoperability issues before widespread deployment, significantly reducing implementation risks for network operators.

Protocol compatibility represents another crucial dimension of VCSEL standardization. The transition to PAM4 (Pulse Amplitude Modulation with 4 levels) signaling from traditional NRZ (Non-Return to Zero) has necessitated new compliance specifications. Industry standards now define precise requirements for signal integrity, including eye diagram parameters, bit error rates, and forward error correction capabilities specific to VCSEL-based optical links.

Form factor standardization has enabled physical compatibility across different system architectures. The industry has converged on key form factors like QSFP-DD, OSFP, and QSFP56-DD for 400G/800G applications, with specific thermal and electrical specifications that accommodate VCSEL technology constraints. This standardization has facilitated smoother integration into existing data center infrastructures.

Looking forward, emerging standards like IEEE 802.3df for 800G/1.6T Ethernet are already addressing next-generation VCSEL deployment challenges. These include specifications for higher-order modulation schemes, enhanced forward error correction, and improved power efficiency metrics. The continuous evolution of these standards ensures that VCSEL technology remains viable as data rates continue to increase, providing a clear roadmap for future implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!