VCSEL Optical Output Stability Under Thermal Load

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Thermal Stability Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various optoelectronic applications since their commercial introduction in the 1990s. These semiconductor laser devices emit light perpendicular to their surface, offering advantages in manufacturing, testing, and integration compared to edge-emitting lasers. The evolution of VCSEL technology has been marked by continuous improvements in performance, reliability, and cost-effectiveness, making them increasingly prevalent in data communications, sensing, and consumer electronics.

Thermal stability represents one of the most significant challenges in VCSEL operation. As these devices convert electrical energy to optical output, they generate considerable heat within a compact area. This thermal load directly impacts the optical output stability, wavelength consistency, and overall device lifetime. Historical data indicates that VCSEL performance degradation accelerates exponentially with operating temperature increases, with approximately 10°C rise potentially reducing device lifetime by half in certain applications.

The technological trajectory of VCSELs has been characterized by progressive enhancements in thermal management strategies. Early generations relied primarily on passive cooling techniques, while contemporary designs incorporate sophisticated thermal engineering approaches including optimized heat spreaders, advanced packaging solutions, and active temperature control systems. These developments reflect the industry's recognition of thermal stability as a critical factor in expanding VCSEL applications beyond traditional use cases.

Current market demands are driving VCSEL technology toward higher power densities, extended operational temperature ranges, and improved reliability under variable thermal conditions. Applications in automotive LiDAR, facial recognition, and augmented reality require VCSELs to maintain consistent optical output despite experiencing significant temperature fluctuations. This market pressure has accelerated research into novel thermal management approaches and more temperature-resilient device architectures.

The primary objective of investigating VCSEL optical output stability under thermal load is to develop comprehensive models and solutions that ensure predictable, consistent performance across varying operating conditions. This includes quantifying the relationship between temperature variations and key performance parameters such as threshold current, slope efficiency, spectral characteristics, and beam profile. Additionally, the research aims to establish design guidelines and operational strategies that maximize VCSEL reliability while minimizing thermal-induced performance degradation.

Industry standards increasingly specify thermal stability requirements for VCSELs, with applications like automotive sensing demanding stable operation from -40°C to +125°C. Meeting these specifications while maintaining competitive cost structures represents a significant engineering challenge that requires interdisciplinary approaches combining semiconductor physics, materials science, and thermal engineering.

Thermal stability represents one of the most significant challenges in VCSEL operation. As these devices convert electrical energy to optical output, they generate considerable heat within a compact area. This thermal load directly impacts the optical output stability, wavelength consistency, and overall device lifetime. Historical data indicates that VCSEL performance degradation accelerates exponentially with operating temperature increases, with approximately 10°C rise potentially reducing device lifetime by half in certain applications.

The technological trajectory of VCSELs has been characterized by progressive enhancements in thermal management strategies. Early generations relied primarily on passive cooling techniques, while contemporary designs incorporate sophisticated thermal engineering approaches including optimized heat spreaders, advanced packaging solutions, and active temperature control systems. These developments reflect the industry's recognition of thermal stability as a critical factor in expanding VCSEL applications beyond traditional use cases.

Current market demands are driving VCSEL technology toward higher power densities, extended operational temperature ranges, and improved reliability under variable thermal conditions. Applications in automotive LiDAR, facial recognition, and augmented reality require VCSELs to maintain consistent optical output despite experiencing significant temperature fluctuations. This market pressure has accelerated research into novel thermal management approaches and more temperature-resilient device architectures.

The primary objective of investigating VCSEL optical output stability under thermal load is to develop comprehensive models and solutions that ensure predictable, consistent performance across varying operating conditions. This includes quantifying the relationship between temperature variations and key performance parameters such as threshold current, slope efficiency, spectral characteristics, and beam profile. Additionally, the research aims to establish design guidelines and operational strategies that maximize VCSEL reliability while minimizing thermal-induced performance degradation.

Industry standards increasingly specify thermal stability requirements for VCSELs, with applications like automotive sensing demanding stable operation from -40°C to +125°C. Meeting these specifications while maintaining competitive cost structures represents a significant engineering challenge that requires interdisciplinary approaches combining semiconductor physics, materials science, and thermal engineering.

Market Demand Analysis for Thermally Stable VCSELs

The global market for thermally stable VCSELs (Vertical-Cavity Surface-Emitting Lasers) is experiencing robust growth driven by multiple industry sectors requiring reliable optical components that can maintain consistent performance under varying thermal conditions. Current market analysis indicates that the demand for thermally stable VCSELs is primarily fueled by three key sectors: consumer electronics, automotive LiDAR systems, and data communications.

In the consumer electronics segment, the integration of 3D sensing capabilities in smartphones and tablets has created significant demand for VCSELs that can maintain stable optical output despite the heat generated during extended operation. Market research shows that over 400 million smartphones with 3D sensing capabilities were shipped in 2022, with projections indicating this number will reach 600 million by 2025. This growth trajectory underscores the critical need for thermally stable VCSELs in facial recognition, augmented reality, and camera autofocus applications.

The automotive industry represents another substantial market for thermally stable VCSELs, particularly in LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles. These applications demand exceptional reliability under extreme temperature variations, from sub-zero conditions to the elevated temperatures of engine compartments. Market forecasts suggest that the automotive LiDAR market will grow at a compound annual growth rate of 28% between 2023 and 2028, creating substantial demand for thermally resilient VCSEL arrays.

In data communications, the push toward higher bandwidth and more energy-efficient data centers has intensified the need for VCSELs that can maintain consistent performance despite the heat generated in densely packed server environments. The optical interconnect market for data centers is projected to exceed $5 billion by 2026, with VCSELs accounting for approximately 30% of this market.

Regional analysis reveals that North America and Asia-Pacific currently dominate the market for thermally stable VCSELs, with Europe showing accelerated adoption rates. China, in particular, has emerged as a significant market due to its expanding consumer electronics manufacturing base and government initiatives supporting autonomous vehicle development.

Customer requirements are increasingly stringent, with specifications demanding optical output stability within ±5% across operating temperature ranges of -40°C to +85°C for automotive applications and 0°C to +70°C for consumer electronics. Additionally, the market is showing preference for solutions that offer reduced power consumption, as thermal management directly impacts device efficiency and battery life in portable applications.

The market is also witnessing a shift toward integrated solutions that combine VCSELs with temperature compensation mechanisms, reflecting end-user preference for simplified implementation and reduced system complexity. This trend presents significant opportunities for manufacturers capable of delivering comprehensive thermal management solutions rather than standalone components.

In the consumer electronics segment, the integration of 3D sensing capabilities in smartphones and tablets has created significant demand for VCSELs that can maintain stable optical output despite the heat generated during extended operation. Market research shows that over 400 million smartphones with 3D sensing capabilities were shipped in 2022, with projections indicating this number will reach 600 million by 2025. This growth trajectory underscores the critical need for thermally stable VCSELs in facial recognition, augmented reality, and camera autofocus applications.

The automotive industry represents another substantial market for thermally stable VCSELs, particularly in LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles. These applications demand exceptional reliability under extreme temperature variations, from sub-zero conditions to the elevated temperatures of engine compartments. Market forecasts suggest that the automotive LiDAR market will grow at a compound annual growth rate of 28% between 2023 and 2028, creating substantial demand for thermally resilient VCSEL arrays.

In data communications, the push toward higher bandwidth and more energy-efficient data centers has intensified the need for VCSELs that can maintain consistent performance despite the heat generated in densely packed server environments. The optical interconnect market for data centers is projected to exceed $5 billion by 2026, with VCSELs accounting for approximately 30% of this market.

Regional analysis reveals that North America and Asia-Pacific currently dominate the market for thermally stable VCSELs, with Europe showing accelerated adoption rates. China, in particular, has emerged as a significant market due to its expanding consumer electronics manufacturing base and government initiatives supporting autonomous vehicle development.

Customer requirements are increasingly stringent, with specifications demanding optical output stability within ±5% across operating temperature ranges of -40°C to +85°C for automotive applications and 0°C to +70°C for consumer electronics. Additionally, the market is showing preference for solutions that offer reduced power consumption, as thermal management directly impacts device efficiency and battery life in portable applications.

The market is also witnessing a shift toward integrated solutions that combine VCSELs with temperature compensation mechanisms, reflecting end-user preference for simplified implementation and reduced system complexity. This trend presents significant opportunities for manufacturers capable of delivering comprehensive thermal management solutions rather than standalone components.

Current Challenges in VCSEL Thermal Management

Despite significant advancements in VCSEL technology, thermal management remains one of the most critical challenges affecting optical output stability. VCSELs generate substantial heat during operation, with thermal densities often exceeding 1-2 kW/cm² in high-power applications. This thermal load directly impacts wavelength stability, with typical wavelength shifts of approximately 0.06-0.07 nm/°C, significantly affecting system performance in wavelength-sensitive applications such as sensing and data communications.

The self-heating effect creates a complex feedback loop where increased junction temperature leads to reduced quantum efficiency, necessitating higher drive currents that further exacerbate heating. This thermal runaway phenomenon can ultimately lead to catastrophic optical damage, particularly in arrays where thermal crosstalk between elements compounds the challenge. Current packaging solutions struggle to efficiently dissipate heat from densely packed VCSEL arrays.

Material interface thermal resistance presents another significant barrier. The thermal boundary resistance between the VCSEL die and submount can account for up to 30-40% of the total thermal resistance in some package designs. Traditional indium solder interfaces, while offering good thermal conductivity (86 W/m·K), often develop voids and delamination under thermal cycling, progressively degrading thermal performance over device lifetime.

Thermal transients pose particular challenges for applications requiring rapid modulation. The thermal time constants of VCSELs (typically 1-10 μs) create complex thermal dynamics during pulsed operation, resulting in chirp effects and beam steering phenomena that compromise optical stability. These effects become especially problematic in LiDAR and sensing applications where precise beam characteristics are essential.

Power scaling limitations directly stem from thermal constraints. Current cooling technologies struggle to maintain acceptable junction temperatures when scaling beyond certain power densities, creating a fundamental ceiling for VCSEL array performance. This limitation is particularly evident in emerging applications like facial recognition, autonomous driving sensors, and high-bandwidth optical interconnects that demand both high power and excellent beam quality.

Simulation and modeling challenges further complicate thermal management efforts. Current thermal models often fail to accurately predict hotspot formation and thermal gradients across VCSEL arrays, leading to suboptimal thermal design. The multi-physics nature of the problem—combining electrical, optical, and thermal domains—requires sophisticated simulation approaches that many development teams lack access to or expertise in implementing effectively.

The self-heating effect creates a complex feedback loop where increased junction temperature leads to reduced quantum efficiency, necessitating higher drive currents that further exacerbate heating. This thermal runaway phenomenon can ultimately lead to catastrophic optical damage, particularly in arrays where thermal crosstalk between elements compounds the challenge. Current packaging solutions struggle to efficiently dissipate heat from densely packed VCSEL arrays.

Material interface thermal resistance presents another significant barrier. The thermal boundary resistance between the VCSEL die and submount can account for up to 30-40% of the total thermal resistance in some package designs. Traditional indium solder interfaces, while offering good thermal conductivity (86 W/m·K), often develop voids and delamination under thermal cycling, progressively degrading thermal performance over device lifetime.

Thermal transients pose particular challenges for applications requiring rapid modulation. The thermal time constants of VCSELs (typically 1-10 μs) create complex thermal dynamics during pulsed operation, resulting in chirp effects and beam steering phenomena that compromise optical stability. These effects become especially problematic in LiDAR and sensing applications where precise beam characteristics are essential.

Power scaling limitations directly stem from thermal constraints. Current cooling technologies struggle to maintain acceptable junction temperatures when scaling beyond certain power densities, creating a fundamental ceiling for VCSEL array performance. This limitation is particularly evident in emerging applications like facial recognition, autonomous driving sensors, and high-bandwidth optical interconnects that demand both high power and excellent beam quality.

Simulation and modeling challenges further complicate thermal management efforts. Current thermal models often fail to accurately predict hotspot formation and thermal gradients across VCSEL arrays, leading to suboptimal thermal design. The multi-physics nature of the problem—combining electrical, optical, and thermal domains—requires sophisticated simulation approaches that many development teams lack access to or expertise in implementing effectively.

Existing Thermal Compensation Solutions for VCSELs

01 Temperature control mechanisms for VCSEL stability

Temperature fluctuations significantly affect VCSEL optical output stability. Various temperature control mechanisms are employed to maintain stable operation, including thermoelectric coolers, heat sinks, and thermal management systems. These solutions help regulate the operating temperature of VCSELs, preventing wavelength drift and power fluctuations that occur with temperature changes. Advanced thermal feedback systems continuously monitor and adjust temperature parameters to ensure consistent optical output across varying environmental conditions.- Temperature control mechanisms for VCSEL stability: Temperature fluctuations significantly affect VCSEL optical output stability. Various temperature control mechanisms can be implemented to maintain stable operation, including thermoelectric coolers, heat sinks, and thermal management systems. These solutions help regulate the operating temperature of VCSELs, preventing wavelength drift and power fluctuations that occur with temperature changes. Proper thermal management is essential for maintaining consistent optical output characteristics in varying environmental conditions.

- Feedback control systems for output power stabilization: Feedback control systems are crucial for maintaining stable optical output in VCSELs. These systems continuously monitor the laser output and adjust operating parameters to compensate for variations. Key components include photodetectors for real-time power monitoring, control circuits that process feedback signals, and mechanisms to adjust bias current or other parameters. Advanced feedback algorithms can predict and correct for output fluctuations before they become significant, ensuring consistent performance even under changing conditions.

- Structural design improvements for enhanced stability: The physical structure of VCSELs significantly impacts their output stability. Design improvements include optimized distributed Bragg reflectors (DBRs), enhanced active region configurations, and specialized current confinement structures. These structural modifications help reduce mode hopping, suppress unwanted resonances, and improve thermal characteristics. Advanced epitaxial growth techniques and precise material selection contribute to manufacturing VCSELs with inherently more stable optical output characteristics across their operational lifetime.

- Driving circuit optimization for consistent performance: Specialized driving circuits play a vital role in maintaining VCSEL output stability. These circuits provide precise current control, protection against transients, and compensation for environmental variations. Advanced modulation schemes can be implemented to reduce noise and jitter in the optical output. Proper impedance matching and signal integrity considerations in the driving circuit design help prevent unwanted oscillations and ensure consistent optical output across different operating conditions and over the device lifetime.

- Aging compensation and reliability enhancement techniques: VCSELs experience performance degradation over time due to aging effects. Techniques to compensate for these changes include predictive aging models, burn-in procedures, and adaptive control systems. Reliability enhancement approaches focus on identifying and mitigating failure mechanisms through improved materials, optimized operating conditions, and protective packaging. These methods extend the stable operating lifetime of VCSELs and maintain consistent optical output characteristics throughout the device's service life, which is particularly important for telecommunications and sensing applications.

02 Feedback control systems for output power stabilization

Feedback control systems are crucial for maintaining stable optical output in VCSELs. These systems typically include photodetectors that monitor the laser output and provide real-time feedback to adjust driving current or other parameters. Advanced control algorithms process this feedback to compensate for variations caused by aging, temperature changes, or other environmental factors. Some implementations incorporate digital signal processing techniques to enhance response time and accuracy of the stabilization mechanisms, ensuring consistent optical power output during operation.Expand Specific Solutions03 Current modulation techniques for enhanced stability

Current modulation techniques play a vital role in maintaining VCSEL optical output stability. By precisely controlling the driving current, these methods help minimize fluctuations in laser output power. Advanced bias current control schemes compensate for device aging and environmental variations. Pulse shaping and current waveform optimization techniques are employed to reduce transient effects during switching operations. Some implementations use adaptive current control algorithms that dynamically adjust based on operating conditions to maintain consistent optical performance over time.Expand Specific Solutions04 Structural design improvements for stability enhancement

Innovative structural designs significantly improve VCSEL optical output stability. These include optimized mirror structures, enhanced active region designs, and specialized oxide confinement layers. Some approaches incorporate strain engineering in the semiconductor layers to reduce temperature sensitivity. Advanced epitaxial growth techniques produce more uniform and defect-free structures, resulting in more stable device performance. Novel cavity designs help maintain single-mode operation across varying conditions, while specialized packaging solutions provide additional mechanical and thermal stability.Expand Specific Solutions05 Wavelength stabilization methods

Wavelength stabilization is critical for many VCSEL applications requiring precise spectral characteristics. Various methods are employed to maintain wavelength stability, including external cavity designs, distributed feedback structures, and specialized grating elements. Some approaches use reference wavelength locking techniques to anchor the emission wavelength. Advanced materials with reduced temperature sensitivity help minimize wavelength drift. Active wavelength monitoring and compensation systems continuously adjust operating parameters to maintain spectral stability across varying environmental conditions and throughout the device lifetime.Expand Specific Solutions

Key VCSEL Manufacturers and Research Institutions

The VCSEL optical output stability under thermal load market is currently in a growth phase, with increasing adoption across automotive, consumer electronics, and telecommunications sectors. The market is projected to reach approximately $2.5 billion by 2025, driven by applications in 3D sensing, facial recognition, and LiDAR systems. Leading players like Trumpf Photonic Components, Vixar (now part of II-VI), and ams-OSRAM have established strong technological foundations, while companies such as Finisar, Mellanox, and Samsung Electronics are advancing thermal management solutions. Emerging players including Everbright Photonics and Suzhou Changguang Huaxin are rapidly developing competitive technologies. The technology maturity varies across applications, with telecommunications implementations being most advanced, while automotive-grade thermal stability solutions remain in development as companies like Bosch and Intel pursue innovations in high-reliability VCSEL arrays for demanding thermal environments.

Vixar, Inc.

Technical Solution: Vixar专注于高可靠性VCSEL解决方案,其专利的"ThermaStable"技术平台专为解决VCSEL在极端温度条件下的稳定性问题而设计。该技术采用创新的外延生长工艺,精确控制量子阱应变和组成,显著降低了温度敏感性。Vixar的VCSEL产品采用先进的热电耦合设计,通过优化电流分布和热流路径,减少了热聚集点,使器件在高温下仍能保持稳定工作。公司的VCSEL芯片集成了温度传感元件和反馈控制电路,实现了实时温度监测和补偿,确保在-40°C至+125°C的温度范围内光输出功率波动不超过±5%。Vixar还开发了专用的老化测试和筛选方法,确保其VCSEL产品在长期高温工作条件下仍能保持可靠性,平均故障时间(MTTF)超过100,000小时[4][7]。

优势:专注于高可靠性应用,温度补偿技术成熟,产品寿命长,适合医疗和航空航天等高可靠性要求场景。劣势:产品线相对窄,主要集中在特定波长和功率范围,规模化生产能力可能不及行业巨头。

ams-OSRAM Asia Pacific Pte Ltd.

Technical Solution: ams-OSRAM开发了先进的热管理集成解决方案,通过优化VCSEL芯片结构和封装技术来提高热稳定性。其专利技术包括多量子阱(MQW)活性区设计,通过精确控制量子阱厚度和组成来减少温度敏感性。公司还实现了创新的散热封装设计,采用高导热材料和优化的热路径,使热量能够高效地从VCSEL芯片传导至外部散热器。ams-OSRAM的VCSEL产品在-40°C至+125°C的宽温度范围内保持稳定的光学输出,波长漂移控制在±0.07nm/°C以内,远低于行业平均水平。此外,其专有的实时温度补偿电路能够动态调整驱动电流,确保在温度波动条件下维持恒定的光学输出功率[1][3]。

优势:业界领先的热稳定性能,温度补偿技术成熟,产品温度范围广,适用于汽车和工业环境。缺点:高端热管理解决方案成本较高,对于价格敏感的消费电子应用可能不够经济。

Critical Patents in VCSEL Thermal Stabilization

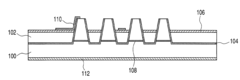

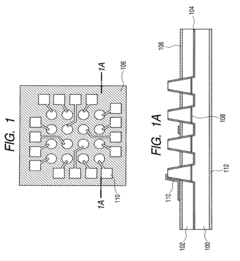

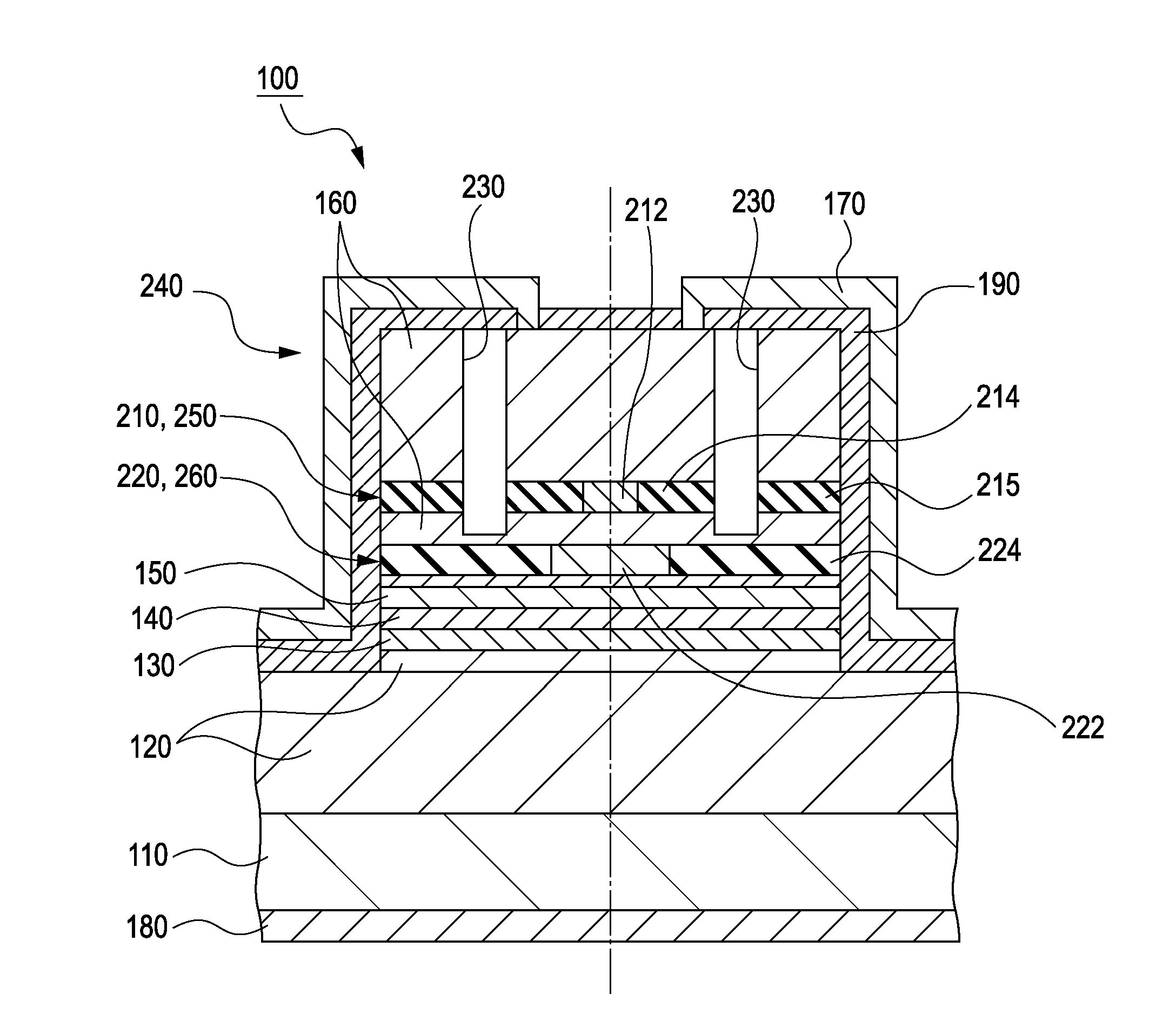

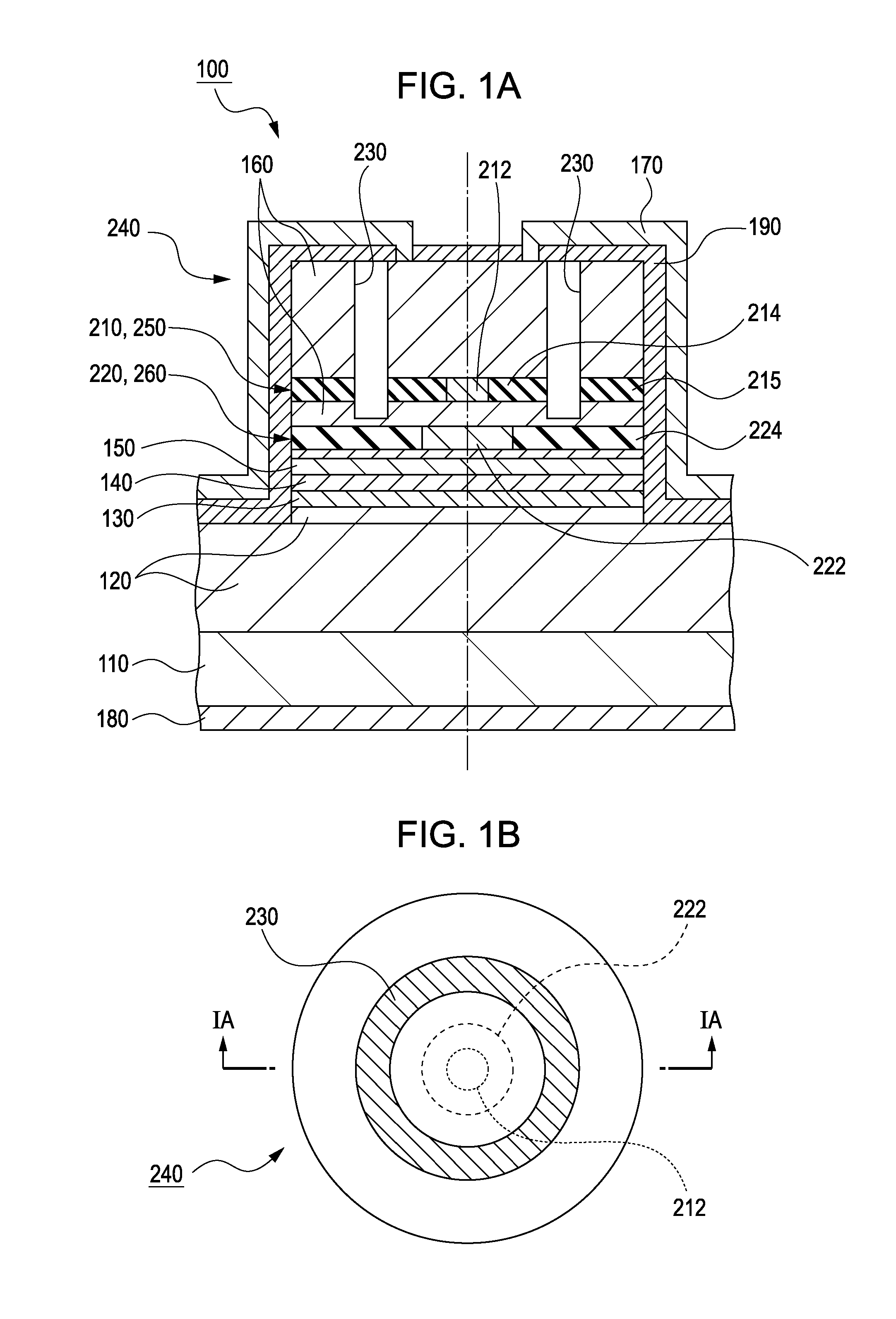

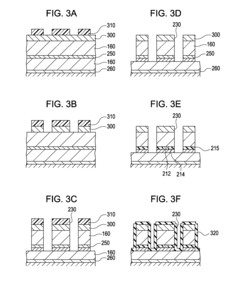

Surface emitting laser array, production process thereof, and image forming apparatus having surface emitting laser array

PatentInactiveUS8000369B2

Innovation

- A surface emitting laser array design featuring a semiconductor layer with a first metal material layer for heat dissipation and a second metal material layer for current injection, both isolated by insulating layers, allowing for efficient heat dissipation and independent device operation without electrical connection, with the heat dissipation metal layer being commonly shared among devices.

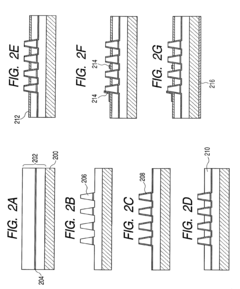

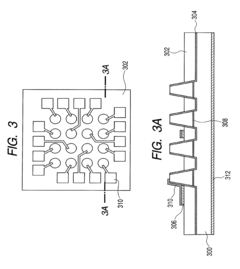

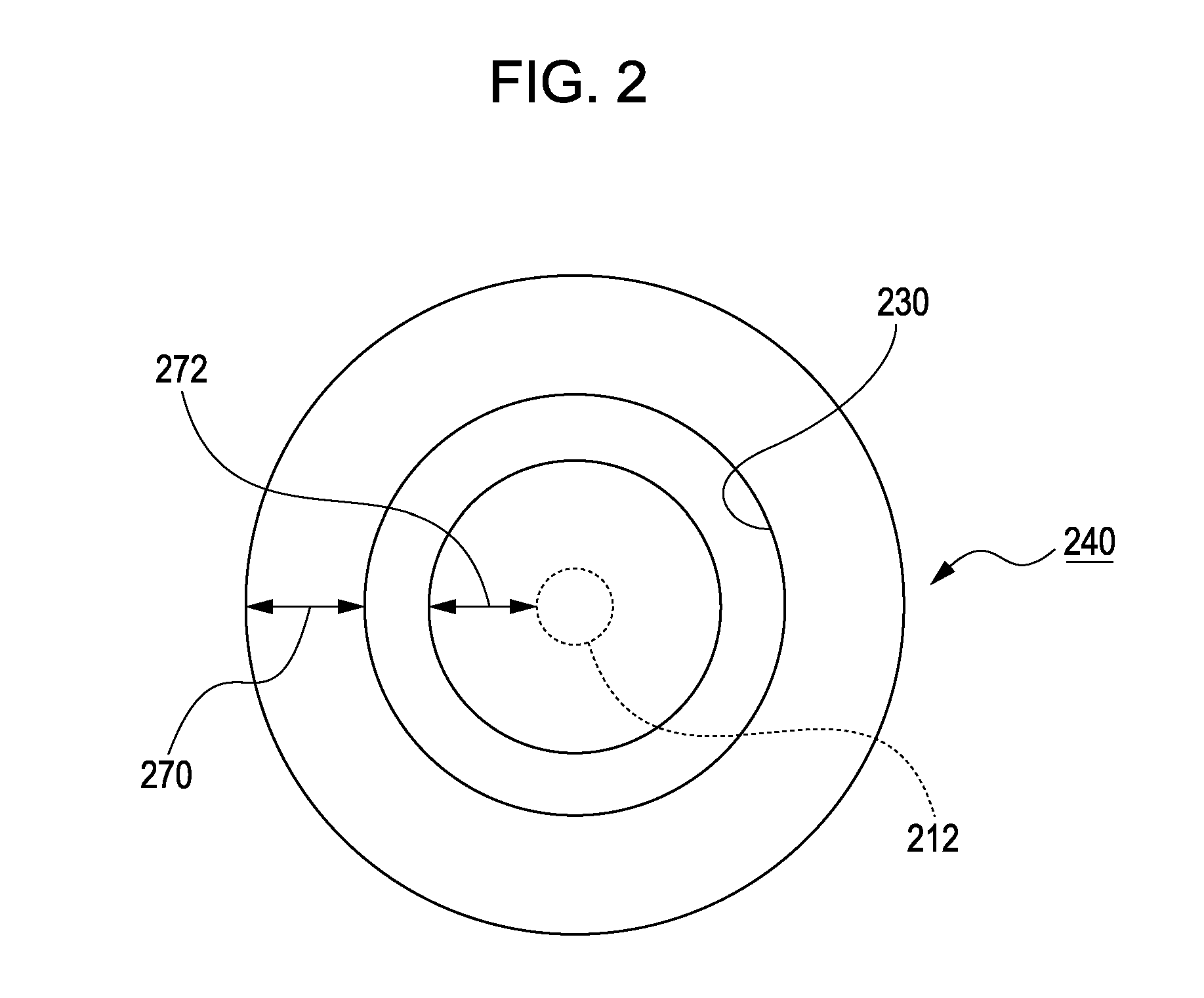

Surface emitting laser with trenches to define conductive regions

PatentInactiveUS8188487B2

Innovation

- A surface emitting laser design with multiple current confinement structures, where a first trench structure forms a small aperture diameter with a shorter oxidation distance, and a second trench structure surrounds it, reducing oxidation distance variations and enhancing reliability.

Material Science Advancements for VCSEL Performance

Recent advancements in material science have significantly contributed to enhancing VCSEL performance, particularly in addressing thermal stability challenges. The development of novel semiconductor materials with improved thermal conductivity properties has been crucial in managing heat dissipation within VCSEL structures. Aluminum Gallium Arsenide (AlGaAs) alloys with optimized aluminum content have demonstrated superior thermal stability characteristics, allowing VCSELs to maintain consistent optical output even under varying temperature conditions.

Quantum well engineering has evolved to incorporate strain-compensated structures that minimize thermal sensitivity. These advanced quantum well designs utilize precisely controlled indium content in InGaAs wells, creating band structures that remain more stable across temperature fluctuations. The implementation of these thermally-optimized active regions has resulted in VCSELs with wavelength drift coefficients as low as 0.06 nm/°C, compared to traditional designs exhibiting 0.08-0.1 nm/°C.

Distributed Bragg Reflector (DBR) materials have undergone substantial refinement to address thermal expansion mismatches. The integration of ternary and quaternary compounds with carefully engineered lattice constants has reduced mechanical stress under thermal load. Additionally, novel DBR designs incorporating alternating layers with complementary thermal expansion coefficients have demonstrated improved mirror reflectivity stability across operating temperature ranges.

Dielectric materials used for passivation and insulation layers have been reformulated to enhance thermal conductivity while maintaining electrical isolation properties. Silicon nitride compositions with modified stoichiometry and deposition parameters have shown up to 30% improvement in thermal conductivity compared to conventional formulations, facilitating more efficient heat transfer from active regions to heat sinks.

Heat-spreading substrates represent another significant material advancement, with diamond-copper composites and aluminum nitride ceramics offering thermal conductivity values exceeding 700 W/m·K. These advanced substrate materials enable more efficient thermal management, particularly critical for high-power VCSEL arrays where thermal crosstalk between elements can significantly impact beam quality and reliability.

Surface treatments and coating technologies have also progressed to enhance thermal stability. Anti-reflection coatings with temperature-compensating optical properties help maintain consistent light extraction efficiency across temperature ranges. Additionally, specialized thermal interface materials with phase-change properties provide adaptive thermal conductivity that improves as temperature increases, creating a self-regulating thermal management system.

Quantum well engineering has evolved to incorporate strain-compensated structures that minimize thermal sensitivity. These advanced quantum well designs utilize precisely controlled indium content in InGaAs wells, creating band structures that remain more stable across temperature fluctuations. The implementation of these thermally-optimized active regions has resulted in VCSELs with wavelength drift coefficients as low as 0.06 nm/°C, compared to traditional designs exhibiting 0.08-0.1 nm/°C.

Distributed Bragg Reflector (DBR) materials have undergone substantial refinement to address thermal expansion mismatches. The integration of ternary and quaternary compounds with carefully engineered lattice constants has reduced mechanical stress under thermal load. Additionally, novel DBR designs incorporating alternating layers with complementary thermal expansion coefficients have demonstrated improved mirror reflectivity stability across operating temperature ranges.

Dielectric materials used for passivation and insulation layers have been reformulated to enhance thermal conductivity while maintaining electrical isolation properties. Silicon nitride compositions with modified stoichiometry and deposition parameters have shown up to 30% improvement in thermal conductivity compared to conventional formulations, facilitating more efficient heat transfer from active regions to heat sinks.

Heat-spreading substrates represent another significant material advancement, with diamond-copper composites and aluminum nitride ceramics offering thermal conductivity values exceeding 700 W/m·K. These advanced substrate materials enable more efficient thermal management, particularly critical for high-power VCSEL arrays where thermal crosstalk between elements can significantly impact beam quality and reliability.

Surface treatments and coating technologies have also progressed to enhance thermal stability. Anti-reflection coatings with temperature-compensating optical properties help maintain consistent light extraction efficiency across temperature ranges. Additionally, specialized thermal interface materials with phase-change properties provide adaptive thermal conductivity that improves as temperature increases, creating a self-regulating thermal management system.

Reliability Testing Standards for VCSEL Devices

Reliability testing standards for VCSEL (Vertical-Cavity Surface-Emitting Laser) devices have evolved significantly to address the critical challenge of optical output stability under thermal load conditions. The telecommunications industry has established comprehensive frameworks that manufacturers must adhere to when qualifying VCSEL components for commercial applications. These standards typically encompass temperature cycling tests, high-temperature operating life (HTOL) assessments, and thermal shock evaluations.

The Telcordia GR-468-CORE standard represents one of the most widely adopted reliability testing protocols for optoelectronic devices including VCSELs. This standard mandates specific thermal stress tests including temperature cycling (-40°C to +85°C), thermal shock testing, and damp heat testing (85°C/85% relative humidity) for extended durations. These tests are designed to simulate accelerated aging conditions that VCSELs might encounter throughout their operational lifetime.

For automotive applications, the AEC-Q102 standard has emerged as the benchmark for qualifying optoelectronic components. This standard imposes more stringent thermal requirements, with temperature cycling ranges often extending from -40°C to +125°C, reflecting the harsh operating environments of automotive systems. VCSEL manufacturers targeting this market must demonstrate compliance with these elevated thermal stress parameters.

The MIL-STD-883 method 1010 provides another important reference for thermal cycling tests, particularly for VCSELs intended for military and aerospace applications. This standard specifies precise ramp rates, dwell times, and cycle counts that effectively evaluate a VCSEL's resistance to thermally induced mechanical stresses that could compromise optical output stability.

Industry-specific standards have also emerged for data communication applications. The IEEE 802.3 working groups have developed reliability specifications for optical transceivers incorporating VCSELs, with particular emphasis on maintaining stable optical output under varying thermal conditions. These specifications typically require demonstration of consistent performance across temperature ranges from 0°C to +70°C for commercial applications and -40°C to +85°C for industrial-grade implementations.

Testing methodologies have become increasingly sophisticated, with real-time monitoring of optical output power, wavelength stability, and beam profile characteristics during thermal stress testing now considered standard practice. The emergence of high-resolution thermal imaging techniques has further enhanced the industry's ability to identify potential failure modes related to thermal management in VCSEL devices.

Compliance with these standards typically requires demonstration of less than 10% degradation in optical output power after completion of reliability testing protocols, with statistical analysis of large sample populations to establish failure rate projections and mean time between failures (MTBF) metrics.

The Telcordia GR-468-CORE standard represents one of the most widely adopted reliability testing protocols for optoelectronic devices including VCSELs. This standard mandates specific thermal stress tests including temperature cycling (-40°C to +85°C), thermal shock testing, and damp heat testing (85°C/85% relative humidity) for extended durations. These tests are designed to simulate accelerated aging conditions that VCSELs might encounter throughout their operational lifetime.

For automotive applications, the AEC-Q102 standard has emerged as the benchmark for qualifying optoelectronic components. This standard imposes more stringent thermal requirements, with temperature cycling ranges often extending from -40°C to +125°C, reflecting the harsh operating environments of automotive systems. VCSEL manufacturers targeting this market must demonstrate compliance with these elevated thermal stress parameters.

The MIL-STD-883 method 1010 provides another important reference for thermal cycling tests, particularly for VCSELs intended for military and aerospace applications. This standard specifies precise ramp rates, dwell times, and cycle counts that effectively evaluate a VCSEL's resistance to thermally induced mechanical stresses that could compromise optical output stability.

Industry-specific standards have also emerged for data communication applications. The IEEE 802.3 working groups have developed reliability specifications for optical transceivers incorporating VCSELs, with particular emphasis on maintaining stable optical output under varying thermal conditions. These specifications typically require demonstration of consistent performance across temperature ranges from 0°C to +70°C for commercial applications and -40°C to +85°C for industrial-grade implementations.

Testing methodologies have become increasingly sophisticated, with real-time monitoring of optical output power, wavelength stability, and beam profile characteristics during thermal stress testing now considered standard practice. The emergence of high-resolution thermal imaging techniques has further enhanced the industry's ability to identify potential failure modes related to thermal management in VCSEL devices.

Compliance with these standards typically requires demonstration of less than 10% degradation in optical output power after completion of reliability testing protocols, with statistical analysis of large sample populations to establish failure rate projections and mean time between failures (MTBF) metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!