Die Attach Materials And Reliability For VCSEL Modules

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Die Attach Materials Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various optoelectronic applications, including facial recognition systems, LiDAR for autonomous vehicles, and high-speed data communication. The reliability and performance of VCSEL modules are significantly influenced by the die attach materials used in their packaging. These materials provide mechanical support, electrical connectivity, and thermal management, which are essential for the optimal functioning and longevity of VCSEL devices.

The evolution of die attach materials for VCSEL modules has progressed from traditional solders to advanced polymer-based adhesives and sintered materials. Early implementations primarily utilized eutectic gold-tin (AuSn) and gold-silicon (AuSi) solders due to their excellent thermal conductivity and reliability. However, these materials presented challenges related to high processing temperatures and potential thermal stress during operation, which could affect the optical alignment and performance of VCSELs.

Recent technological advancements have introduced silver sintering and transient liquid phase bonding as promising alternatives, offering improved thermal performance while reducing processing temperatures. Conductive adhesives have also gained traction, particularly in applications where flexibility and stress absorption are critical. The industry continues to seek materials that can balance thermal conductivity, electrical performance, mechanical stability, and processing compatibility.

The primary objective of this research is to comprehensively evaluate current and emerging die attach materials for VCSEL modules, focusing on their impact on device reliability and performance. Specifically, we aim to identify materials that can effectively address the thermal management challenges associated with high-power VCSEL arrays while maintaining long-term reliability under various operating conditions.

Additionally, this research seeks to establish correlations between die attach material properties and VCSEL module reliability metrics, including thermal resistance, optical output stability, and mean time to failure. By understanding these relationships, we can develop predictive models to guide material selection based on specific application requirements and operating environments.

Furthermore, this investigation aims to explore novel die attach solutions that can accommodate the increasing power densities and miniaturization trends in VCSEL technology. As VCSEL applications expand into more demanding environments, such as automotive and industrial settings, the need for robust die attach materials that can withstand extreme conditions becomes increasingly critical.

The outcomes of this research will provide valuable insights for VCSEL manufacturers and system integrators, enabling them to make informed decisions regarding die attach material selection and process optimization. These insights will contribute to the advancement of VCSEL technology and support its integration into next-generation optoelectronic systems.

The evolution of die attach materials for VCSEL modules has progressed from traditional solders to advanced polymer-based adhesives and sintered materials. Early implementations primarily utilized eutectic gold-tin (AuSn) and gold-silicon (AuSi) solders due to their excellent thermal conductivity and reliability. However, these materials presented challenges related to high processing temperatures and potential thermal stress during operation, which could affect the optical alignment and performance of VCSELs.

Recent technological advancements have introduced silver sintering and transient liquid phase bonding as promising alternatives, offering improved thermal performance while reducing processing temperatures. Conductive adhesives have also gained traction, particularly in applications where flexibility and stress absorption are critical. The industry continues to seek materials that can balance thermal conductivity, electrical performance, mechanical stability, and processing compatibility.

The primary objective of this research is to comprehensively evaluate current and emerging die attach materials for VCSEL modules, focusing on their impact on device reliability and performance. Specifically, we aim to identify materials that can effectively address the thermal management challenges associated with high-power VCSEL arrays while maintaining long-term reliability under various operating conditions.

Additionally, this research seeks to establish correlations between die attach material properties and VCSEL module reliability metrics, including thermal resistance, optical output stability, and mean time to failure. By understanding these relationships, we can develop predictive models to guide material selection based on specific application requirements and operating environments.

Furthermore, this investigation aims to explore novel die attach solutions that can accommodate the increasing power densities and miniaturization trends in VCSEL technology. As VCSEL applications expand into more demanding environments, such as automotive and industrial settings, the need for robust die attach materials that can withstand extreme conditions becomes increasingly critical.

The outcomes of this research will provide valuable insights for VCSEL manufacturers and system integrators, enabling them to make informed decisions regarding die attach material selection and process optimization. These insights will contribute to the advancement of VCSEL technology and support its integration into next-generation optoelectronic systems.

Market Demand Analysis for VCSEL Module Applications

The VCSEL (Vertical-Cavity Surface-Emitting Laser) module market has experienced significant growth in recent years, driven primarily by increasing applications in consumer electronics, automotive systems, and data communication sectors. The global VCSEL market was valued at approximately 2.1 billion USD in 2020 and is projected to reach 5.3 billion USD by 2026, representing a compound annual growth rate of 17.3% during this forecast period.

Consumer electronics represents the largest application segment for VCSEL modules, accounting for over 40% of the total market share. This dominance is primarily attributed to the widespread adoption of 3D sensing technologies in smartphones and tablets for facial recognition, augmented reality applications, and proximity sensing. Apple's implementation of Face ID technology in iPhones has been a significant market driver, establishing VCSEL as a standard component in premium smartphones.

The automotive sector presents the fastest-growing market opportunity for VCSEL modules, with an estimated growth rate of 23% annually through 2026. Advanced driver-assistance systems (ADAS) and autonomous driving technologies increasingly rely on LiDAR systems that incorporate VCSEL technology. The superior performance of VCSEL-based LiDAR in terms of range, accuracy, and reliability compared to traditional sensing technologies is driving this adoption trend.

Data communication applications constitute another substantial market segment, particularly in data centers and high-speed optical interconnects. The demand for higher bandwidth and energy-efficient data transmission solutions has accelerated the adoption of VCSEL arrays in optical transceivers. Industry reports indicate that data center operators are increasingly transitioning to VCSEL-based solutions to meet escalating data traffic demands while managing power consumption constraints.

Market analysis reveals regional variations in VCSEL module demand. North America leads with approximately 35% market share, followed by Asia-Pacific at 32%, Europe at 25%, and the rest of the world accounting for the remaining 8%. The Asia-Pacific region is expected to demonstrate the highest growth rate, driven by the expanding consumer electronics manufacturing base and increasing automotive production capabilities.

The reliability of die attach materials has emerged as a critical factor influencing market dynamics. End-users across all application segments are demanding VCSEL modules with extended operational lifetimes and enhanced thermal performance. This demand is particularly pronounced in automotive and industrial applications where operating conditions are more severe and replacement costs are substantial.

Industry surveys indicate that over 78% of VCSEL module customers consider reliability as a "very important" or "critical" factor in their purchasing decisions. This market preference is driving manufacturers to invest in advanced die attach materials and reliability testing methodologies to gain competitive advantages and command premium pricing in the marketplace.

Consumer electronics represents the largest application segment for VCSEL modules, accounting for over 40% of the total market share. This dominance is primarily attributed to the widespread adoption of 3D sensing technologies in smartphones and tablets for facial recognition, augmented reality applications, and proximity sensing. Apple's implementation of Face ID technology in iPhones has been a significant market driver, establishing VCSEL as a standard component in premium smartphones.

The automotive sector presents the fastest-growing market opportunity for VCSEL modules, with an estimated growth rate of 23% annually through 2026. Advanced driver-assistance systems (ADAS) and autonomous driving technologies increasingly rely on LiDAR systems that incorporate VCSEL technology. The superior performance of VCSEL-based LiDAR in terms of range, accuracy, and reliability compared to traditional sensing technologies is driving this adoption trend.

Data communication applications constitute another substantial market segment, particularly in data centers and high-speed optical interconnects. The demand for higher bandwidth and energy-efficient data transmission solutions has accelerated the adoption of VCSEL arrays in optical transceivers. Industry reports indicate that data center operators are increasingly transitioning to VCSEL-based solutions to meet escalating data traffic demands while managing power consumption constraints.

Market analysis reveals regional variations in VCSEL module demand. North America leads with approximately 35% market share, followed by Asia-Pacific at 32%, Europe at 25%, and the rest of the world accounting for the remaining 8%. The Asia-Pacific region is expected to demonstrate the highest growth rate, driven by the expanding consumer electronics manufacturing base and increasing automotive production capabilities.

The reliability of die attach materials has emerged as a critical factor influencing market dynamics. End-users across all application segments are demanding VCSEL modules with extended operational lifetimes and enhanced thermal performance. This demand is particularly pronounced in automotive and industrial applications where operating conditions are more severe and replacement costs are substantial.

Industry surveys indicate that over 78% of VCSEL module customers consider reliability as a "very important" or "critical" factor in their purchasing decisions. This market preference is driving manufacturers to invest in advanced die attach materials and reliability testing methodologies to gain competitive advantages and command premium pricing in the marketplace.

Current State and Challenges in Die Attach Technology

The die attach technology for VCSEL (Vertical-Cavity Surface-Emitting Laser) modules has evolved significantly over the past decade, yet continues to face substantial challenges in meeting the increasingly demanding requirements of modern optoelectronic applications. Currently, the industry employs several mainstream die attach materials, including gold-tin (AuSn) solders, silver sintering materials, and conductive epoxies, each with distinct advantages and limitations.

AuSn solders dominate high-reliability applications due to their excellent thermal conductivity and mechanical stability. However, they require high processing temperatures (>280°C), which can induce thermal stress in sensitive VCSEL structures. This thermal budget constraint represents a significant challenge for next-generation devices with more complex epitaxial structures.

Silver sintering technology has gained traction as a promising alternative, offering superior thermal performance (thermal conductivity >200 W/mK) and lower processing temperatures compared to traditional solders. Nevertheless, implementation challenges persist, including process complexity, pressure requirements during bonding, and potential silver migration concerns in high-humidity environments.

Conductive epoxies provide manufacturing advantages through simpler processing and lower temperatures but suffer from inferior thermal performance (typically 2-5 W/mK) and reliability concerns under thermal cycling conditions. This performance gap becomes particularly problematic as VCSEL power densities continue to increase in applications such as 3D sensing and LiDAR systems.

A critical challenge across all die attach technologies is the management of coefficient of thermal expansion (CTE) mismatch between the VCSEL die and substrate materials. This mismatch induces stress during thermal cycling, potentially leading to delamination, cracking, or bond-line degradation that compromises device reliability and operational lifetime.

The miniaturization trend in VCSEL modules presents additional challenges, as smaller die sizes result in higher power densities and more stringent thermal management requirements. Current die attach materials struggle to efficiently dissipate heat from these compact designs, particularly in consumer electronics applications where space constraints are severe.

Environmental concerns also impact the technology landscape, with regulatory pressure driving the industry away from lead-based solders toward more environmentally friendly alternatives. However, these lead-free options often present trade-offs in performance, processability, or reliability that have not been fully resolved.

Reliability testing methodologies represent another challenge area, as accelerated life testing protocols developed for traditional semiconductor packages may not adequately predict the unique failure modes of VCSEL modules. The industry lacks standardized testing frameworks specifically designed for optoelectronic die attach reliability assessment, creating uncertainty in lifetime predictions and qualification procedures.

AuSn solders dominate high-reliability applications due to their excellent thermal conductivity and mechanical stability. However, they require high processing temperatures (>280°C), which can induce thermal stress in sensitive VCSEL structures. This thermal budget constraint represents a significant challenge for next-generation devices with more complex epitaxial structures.

Silver sintering technology has gained traction as a promising alternative, offering superior thermal performance (thermal conductivity >200 W/mK) and lower processing temperatures compared to traditional solders. Nevertheless, implementation challenges persist, including process complexity, pressure requirements during bonding, and potential silver migration concerns in high-humidity environments.

Conductive epoxies provide manufacturing advantages through simpler processing and lower temperatures but suffer from inferior thermal performance (typically 2-5 W/mK) and reliability concerns under thermal cycling conditions. This performance gap becomes particularly problematic as VCSEL power densities continue to increase in applications such as 3D sensing and LiDAR systems.

A critical challenge across all die attach technologies is the management of coefficient of thermal expansion (CTE) mismatch between the VCSEL die and substrate materials. This mismatch induces stress during thermal cycling, potentially leading to delamination, cracking, or bond-line degradation that compromises device reliability and operational lifetime.

The miniaturization trend in VCSEL modules presents additional challenges, as smaller die sizes result in higher power densities and more stringent thermal management requirements. Current die attach materials struggle to efficiently dissipate heat from these compact designs, particularly in consumer electronics applications where space constraints are severe.

Environmental concerns also impact the technology landscape, with regulatory pressure driving the industry away from lead-based solders toward more environmentally friendly alternatives. However, these lead-free options often present trade-offs in performance, processability, or reliability that have not been fully resolved.

Reliability testing methodologies represent another challenge area, as accelerated life testing protocols developed for traditional semiconductor packages may not adequately predict the unique failure modes of VCSEL modules. The industry lacks standardized testing frameworks specifically designed for optoelectronic die attach reliability assessment, creating uncertainty in lifetime predictions and qualification procedures.

Current Die Attach Material Solutions for VCSEL Modules

01 Epoxy-based die attach materials

Epoxy-based materials are commonly used for die attachment due to their excellent adhesion properties and reliability. These materials typically contain epoxy resins, hardeners, and fillers that provide thermal conductivity and mechanical stability. The formulations are designed to withstand thermal cycling and provide long-term reliability in semiconductor packaging applications. Some epoxy formulations include conductive fillers to enhance electrical and thermal performance while maintaining strong adhesion between the die and substrate.- Epoxy-based die attach materials: Epoxy-based materials are commonly used for die attachment due to their excellent adhesion properties and reliability. These materials typically contain epoxy resins, hardeners, and fillers that provide thermal conductivity and mechanical stability. The formulations can be optimized to reduce stress on the semiconductor die during thermal cycling, improving long-term reliability. Some epoxy formulations include conductive fillers to enhance electrical and thermal performance while maintaining strong adhesion to various substrate materials.

- Silver sintering die attach materials: Silver sintering technology offers superior thermal performance and reliability for high-temperature applications. These materials consist of silver particles that, when subjected to heat and pressure, form solid interconnections through a sintering process rather than conventional melting. This results in higher thermal conductivity, better electrical performance, and improved reliability under thermal cycling conditions. Silver sintering materials demonstrate excellent resistance to thermal fatigue and can operate reliably at temperatures exceeding 200°C, making them suitable for power electronics and automotive applications.

- Reliability testing methods for die attach materials: Various testing methodologies are employed to evaluate the reliability of die attach materials under different stress conditions. These include thermal cycling tests, high-temperature storage tests, humidity tests, and power cycling. Advanced analytical techniques such as scanning acoustic microscopy, cross-sectional analysis, and shear strength measurements are used to detect delamination, cracking, or void formation in the die attach layer. Accelerated life testing protocols help predict long-term reliability by subjecting the materials to extreme conditions that simulate years of operational stress in a compressed timeframe.

- Novel polymer composites for die attachment: Innovative polymer composite materials have been developed to address the reliability challenges in semiconductor packaging. These composites incorporate specialized fillers such as ceramic particles, carbon nanotubes, or metallic flakes to enhance thermal conductivity while maintaining flexibility. The polymer matrices are engineered to provide low moisture absorption, reduced coefficient of thermal expansion, and improved adhesion to various substrate materials. Some formulations include self-healing components that can repair microcracks formed during thermal cycling, significantly extending the operational lifetime of the package.

- Die attach materials for specific package configurations: Specialized die attach materials have been formulated for specific package types and applications. For flip-chip packages, underfill materials with tailored flow characteristics and thermal properties ensure reliable connections between the die and substrate. For stacked die configurations, ultra-thin die attach films provide uniform bondlines while maintaining excellent reliability. In power electronics packages, die attach materials with high thermal conductivity and mechanical compliance help manage the severe thermal stresses. Materials designed for automotive and aerospace applications focus on withstanding extreme temperature ranges and vibration while maintaining long-term reliability.

02 Silver sintering die attach materials

Silver sintering technology offers superior thermal conductivity and reliability compared to traditional die attach materials. These materials consist of silver particles that sinter at relatively low temperatures to form a dense, void-free bond with excellent thermal and electrical properties. The sintering process creates a connection that can withstand high operating temperatures and thermal cycling, making these materials suitable for high-power and high-temperature applications. The reliability of silver sintered joints is enhanced by their resistance to thermal fatigue and crack propagation.Expand Specific Solutions03 Reliability testing methods for die attach materials

Various testing methodologies are employed to evaluate the reliability of die attach materials under different stress conditions. These include thermal cycling tests, high-temperature storage tests, humidity tests, and power cycling tests. Advanced analytical techniques such as scanning acoustic microscopy, cross-sectional analysis, and shear strength testing are used to detect delamination, voids, and cracks in the die attach layer. Accelerated life testing protocols help predict long-term reliability by subjecting the materials to extreme conditions that simulate years of operational stress in a compressed timeframe.Expand Specific Solutions04 Novel polymer composites for die attachment

Innovative polymer composite materials have been developed to enhance die attach reliability. These composites typically incorporate specialized fillers such as ceramic particles, carbon nanotubes, or metal flakes to improve thermal conductivity while maintaining flexibility. The polymer matrices are engineered to provide stress absorption during thermal cycling, reducing the risk of delamination and cracking. Some formulations include adhesion promoters and coupling agents to enhance bonding to various substrate materials and semiconductor dies, resulting in improved long-term reliability under harsh operating conditions.Expand Specific Solutions05 Flip chip die attach reliability solutions

Flip chip technology presents unique challenges for die attach reliability due to the direct connection between the die and substrate through solder bumps or other interconnect materials. Advanced underfill materials are used to enhance the mechanical stability and reliability of these connections by distributing stress and protecting against thermal cycling fatigue. The coefficient of thermal expansion (CTE) matching between die, interconnect, underfill, and substrate materials is critical for reliability. Novel approaches include reworkable underfills, corner bond reinforcements, and edge bond materials that provide additional mechanical support while accommodating the thermal expansion mismatch.Expand Specific Solutions

Key Industry Players in VCSEL Die Attach Solutions

The VCSEL module die attach materials market is currently in a growth phase, characterized by increasing demand for reliable optical components in data centers, automotive, and consumer electronics applications. The market size is expanding rapidly, driven by the proliferation of 3D sensing applications and high-speed data transmission requirements. From a technical maturity perspective, companies like Lumentum Operations, II-VI Delaware, and Finisar Corp. lead in VCSEL manufacturing technology, while materials specialists such as Henkel, Shin-Etsu Chemical, and Sekisui Chemical are advancing die attach solutions with enhanced thermal performance and reliability. Emerging players like Seoul Viosys and Vixar are focusing on specialized applications, while research institutions like IMEC and Beijing University of Technology are developing next-generation materials to address thermal management and reliability challenges in increasingly miniaturized and high-power VCSEL modules.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed a comprehensive portfolio of die attach materials specifically engineered for VCSEL applications under their LOCTITE brand. Their flagship solution features silver-filled conductive adhesives with optimized filler loading (>80% by weight) to achieve thermal conductivity exceeding 60 W/mK while maintaining sufficient compliance to accommodate CTE mismatches. The company's formulations incorporate proprietary coupling agents that enhance adhesion to both GaAs dies and various submount materials including AlN, SiC, and Cu-W composites. Henkel's die attach materials feature controlled rheology for precise dispensing in automated assembly processes, with thixotropic properties that prevent bleed-out during placement. Their materials undergo a specialized curing profile that minimizes internal stress development while achieving full cross-linking, resulting in robust mechanical stability. Reliability testing demonstrates stable performance after 3,000 thermal cycles (-40°C to +125°C) with shear strength retention exceeding 85% of initial values.

Strengths: Simplified processing without high-temperature reflow requirements; excellent manufacturing scalability for high-volume production. Weaknesses: Lower thermal conductivity compared to metallic solders; potential for higher electrical resistance that may impact device performance in high-frequency applications.

II-VI Delaware, Inc.

Technical Solution: II-VI has developed a proprietary gold-based die attach technology specifically optimized for high-reliability VCSEL modules. Their solution employs a gold-tin (AuSn) eutectic composition with precise control of the 80Au/20Sn ratio to achieve optimal melting characteristics and mechanical properties. The company has implemented a specialized metallization scheme on both the VCSEL die backside and submount surfaces, utilizing a Ti/Pt/Au stack that creates strong intermetallic bonds during the reflow process. II-VI's approach includes a vacuum reflow process that minimizes void formation, achieving less than 1% void content as verified through acoustic microscopy inspection. Their technology incorporates stress-relief features in the submount design to accommodate the CTE mismatch between GaAs VCSEL dies and ceramic or composite submount materials. Reliability testing demonstrates stable performance after 10,000 hours of high-temperature operating life testing at 85°C with drive current stress, showing less than 2% change in threshold current and slope efficiency.

Strengths: Exceptional thermal conductivity (>50 W/mK) enabling efficient heat dissipation; hermetic sealing properties that enhance long-term reliability in harsh environments. Weaknesses: Requires precise temperature control during reflow process; higher material costs compared to silver-epoxy alternatives.

Critical Technical Analysis of Die Attach Reliability

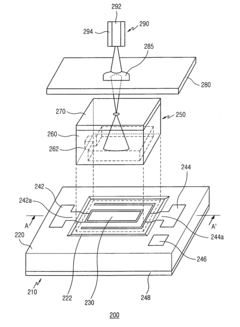

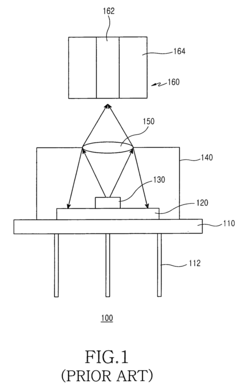

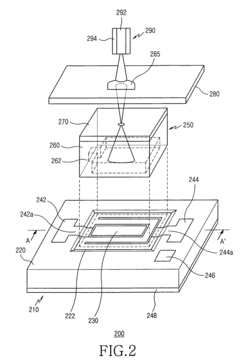

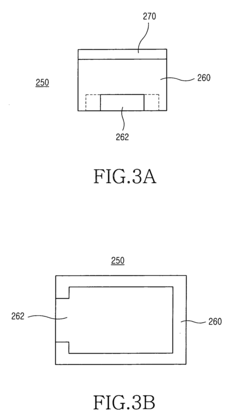

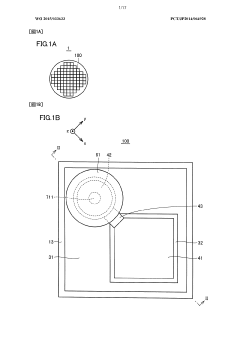

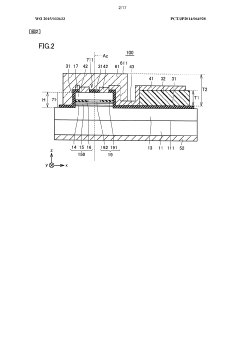

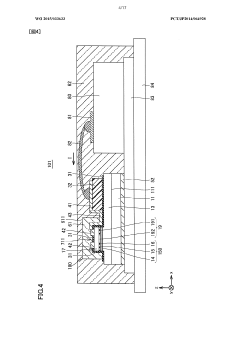

Vertical cavity surface emitting laser module

PatentInactiveUS20050147360A1

Innovation

- A VCSEL module design where the lower surface of the VCSEL is etched, allowing direct detection of light emitted downwards by a monitor photodiode region, eliminating the need for reflected light monitoring and minimizing light absorption, thereby enhancing the ability to monitor the output state of the VCSEL.

Vertical cavity surface emitting laser element, semiconductor wafer and light emitting module provided with vertical cavity surface emitting laser element, and method for manufacturing vertical cavity surface emitting laser element

PatentWO2015033633A1

Innovation

- A vertical cavity surface emitting laser element is designed with a semiconductor substrate, a light emitting section, an electrode pad, and a first transparent resin that covers the light emitting portion, using a photosensitive silicone resin with a low Young's modulus to reduce stress and protect the device from damage, while a second transparent resin with a higher modulus is used to cover the driving circuit.

Thermal Management Considerations for VCSEL Reliability

Thermal management is a critical factor in ensuring the reliability and performance of VCSEL (Vertical-Cavity Surface-Emitting Laser) modules. The operational temperature of VCSELs significantly impacts their lifetime, wavelength stability, threshold current, and overall efficiency. During operation, VCSELs generate substantial heat due to their high current density, which must be effectively dissipated to prevent thermal runaway and premature device failure.

Die attach materials play a pivotal role in the thermal management strategy for VCSEL modules. These materials create the primary thermal pathway between the VCSEL die and the package substrate, facilitating heat transfer away from the active region. The thermal conductivity of die attach materials directly influences the junction temperature of the VCSEL, with higher thermal conductivity materials enabling more efficient heat dissipation.

Common die attach materials for VCSEL applications include gold-tin (AuSn) solders, silver-filled epoxies, and sintered silver. AuSn solders offer excellent thermal conductivity (approximately 57 W/mK) and reliability but require precise temperature control during assembly. Silver-filled epoxies provide good thermal performance (15-80 W/mK depending on silver content) with simpler processing requirements. Sintered silver represents an emerging solution with superior thermal conductivity (>200 W/mK) but demands specialized processing equipment.

The coefficient of thermal expansion (CTE) matching between the die attach material, VCSEL die, and substrate is essential for preventing thermomechanical stress during temperature cycling. Mismatched CTEs can lead to delamination, cracking, or void formation in the die attach layer, compromising both thermal performance and mechanical integrity of the module.

Advanced thermal simulation techniques, including finite element analysis (FEA), are increasingly employed to optimize thermal management strategies for VCSEL modules. These simulations enable engineers to predict junction temperatures under various operating conditions and evaluate the effectiveness of different die attach materials and package designs before physical prototyping.

For high-power VCSEL arrays used in applications such as 3D sensing and LiDAR, additional thermal management solutions may be necessary. These include integration with thermoelectric coolers (TECs), implementation of micro-channel cooling, or utilization of advanced substrate materials like diamond or aluminum nitride with exceptional thermal conductivity properties.

Reliability testing protocols for VCSEL modules typically include thermal cycling, high-temperature operating life (HTOL) tests, and thermal shock testing to evaluate the robustness of die attach materials under extreme conditions. The degradation mechanisms observed during these tests provide valuable insights for improving both material formulations and assembly processes to enhance long-term reliability.

Die attach materials play a pivotal role in the thermal management strategy for VCSEL modules. These materials create the primary thermal pathway between the VCSEL die and the package substrate, facilitating heat transfer away from the active region. The thermal conductivity of die attach materials directly influences the junction temperature of the VCSEL, with higher thermal conductivity materials enabling more efficient heat dissipation.

Common die attach materials for VCSEL applications include gold-tin (AuSn) solders, silver-filled epoxies, and sintered silver. AuSn solders offer excellent thermal conductivity (approximately 57 W/mK) and reliability but require precise temperature control during assembly. Silver-filled epoxies provide good thermal performance (15-80 W/mK depending on silver content) with simpler processing requirements. Sintered silver represents an emerging solution with superior thermal conductivity (>200 W/mK) but demands specialized processing equipment.

The coefficient of thermal expansion (CTE) matching between the die attach material, VCSEL die, and substrate is essential for preventing thermomechanical stress during temperature cycling. Mismatched CTEs can lead to delamination, cracking, or void formation in the die attach layer, compromising both thermal performance and mechanical integrity of the module.

Advanced thermal simulation techniques, including finite element analysis (FEA), are increasingly employed to optimize thermal management strategies for VCSEL modules. These simulations enable engineers to predict junction temperatures under various operating conditions and evaluate the effectiveness of different die attach materials and package designs before physical prototyping.

For high-power VCSEL arrays used in applications such as 3D sensing and LiDAR, additional thermal management solutions may be necessary. These include integration with thermoelectric coolers (TECs), implementation of micro-channel cooling, or utilization of advanced substrate materials like diamond or aluminum nitride with exceptional thermal conductivity properties.

Reliability testing protocols for VCSEL modules typically include thermal cycling, high-temperature operating life (HTOL) tests, and thermal shock testing to evaluate the robustness of die attach materials under extreme conditions. The degradation mechanisms observed during these tests provide valuable insights for improving both material formulations and assembly processes to enhance long-term reliability.

Environmental Impact and Sustainability of Die Attach Materials

The environmental impact of die attach materials used in VCSEL modules has become increasingly important as sustainability concerns grow across the electronics industry. Traditional die attach materials, particularly those containing lead-based solders, pose significant environmental hazards throughout their lifecycle. Lead contamination from improper disposal can leach into soil and water systems, causing long-term ecological damage and potential human health risks.

Recent regulatory frameworks, including RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives, have accelerated the transition toward lead-free alternatives in die attach materials. This shift represents both a compliance necessity and an opportunity for developing more environmentally responsible manufacturing processes for VCSEL modules.

The carbon footprint associated with die attach material production presents another environmental consideration. High-temperature processing requirements for certain die attach materials contribute significantly to energy consumption during manufacturing. Gold-based die attach solutions, while offering excellent reliability, require energy-intensive mining operations that generate substantial greenhouse gas emissions and often involve environmentally destructive extraction practices.

Emerging eco-friendly alternatives include sintered silver pastes and nanosilver formulations, which offer reduced processing temperatures and lower environmental impact while maintaining thermal performance necessary for VCSEL reliability. These materials demonstrate promising sustainability profiles with reduced energy requirements during application and potential for end-of-life reclamation of precious metals.

Life cycle assessment (LCA) studies comparing traditional and newer die attach materials reveal that sustainability improvements can be achieved without compromising reliability. For instance, certain bismuth-based solders and conductive adhesives show comparable thermal performance to conventional materials while significantly reducing environmental impact scores across multiple categories including global warming potential, acidification, and resource depletion.

End-of-life considerations for VCSEL modules highlight the importance of designing die attach systems with recyclability in mind. The recoverability of precious metals from die attach materials represents both an environmental and economic opportunity. Advanced recycling technologies specifically targeting semiconductor components can recover up to 95% of gold and silver from die attach materials, substantially reducing the need for environmentally damaging primary metal extraction.

Water usage and contamination during manufacturing processes represent additional environmental concerns. Certain die attach materials require extensive cleaning procedures involving potentially harmful solvents. Water-soluble die attach alternatives and aqueous cleaning systems are being developed to address these issues, reducing both water consumption and hazardous waste generation in VCSEL module production facilities.

Recent regulatory frameworks, including RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives, have accelerated the transition toward lead-free alternatives in die attach materials. This shift represents both a compliance necessity and an opportunity for developing more environmentally responsible manufacturing processes for VCSEL modules.

The carbon footprint associated with die attach material production presents another environmental consideration. High-temperature processing requirements for certain die attach materials contribute significantly to energy consumption during manufacturing. Gold-based die attach solutions, while offering excellent reliability, require energy-intensive mining operations that generate substantial greenhouse gas emissions and often involve environmentally destructive extraction practices.

Emerging eco-friendly alternatives include sintered silver pastes and nanosilver formulations, which offer reduced processing temperatures and lower environmental impact while maintaining thermal performance necessary for VCSEL reliability. These materials demonstrate promising sustainability profiles with reduced energy requirements during application and potential for end-of-life reclamation of precious metals.

Life cycle assessment (LCA) studies comparing traditional and newer die attach materials reveal that sustainability improvements can be achieved without compromising reliability. For instance, certain bismuth-based solders and conductive adhesives show comparable thermal performance to conventional materials while significantly reducing environmental impact scores across multiple categories including global warming potential, acidification, and resource depletion.

End-of-life considerations for VCSEL modules highlight the importance of designing die attach systems with recyclability in mind. The recoverability of precious metals from die attach materials represents both an environmental and economic opportunity. Advanced recycling technologies specifically targeting semiconductor components can recover up to 95% of gold and silver from die attach materials, substantially reducing the need for environmentally damaging primary metal extraction.

Water usage and contamination during manufacturing processes represent additional environmental concerns. Certain die attach materials require extensive cleaning procedures involving potentially harmful solvents. Water-soluble die attach alternatives and aqueous cleaning systems are being developed to address these issues, reducing both water consumption and hazardous waste generation in VCSEL module production facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!