VCSEL Performance Under High Vibration And Shock

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Technology Background and Performance Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as a transformative technology in the optoelectronics industry since their initial development in the late 1970s. Unlike edge-emitting lasers, VCSELs emit light perpendicular to their surface, offering advantages in manufacturing, testing, and integration. The evolution of VCSEL technology has accelerated significantly over the past decade, driven by increasing demands in consumer electronics, automotive LiDAR systems, and high-speed data communication applications.

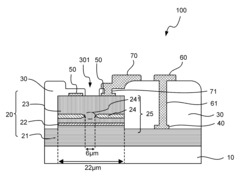

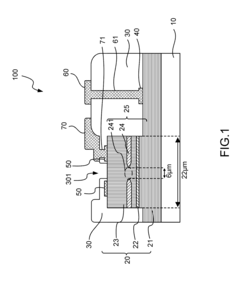

The fundamental structure of VCSELs consists of an active region sandwiched between two distributed Bragg reflector (DBR) mirrors, creating a resonant cavity that enables efficient light emission. This unique architecture provides VCSELs with inherent benefits including circular beam profiles, low threshold currents, and the ability for wafer-level testing, which significantly reduces production costs compared to traditional laser technologies.

Recent technological advancements have focused on enhancing VCSEL performance parameters including power efficiency, beam quality, modulation bandwidth, and reliability under varying environmental conditions. Particularly noteworthy is the growing requirement for VCSELs to maintain stable performance under mechanical stress conditions, including high vibration and shock environments, which has become increasingly critical as these devices find applications in automotive, aerospace, and industrial settings.

The performance degradation of VCSELs under mechanical stress presents significant challenges that must be addressed to ensure reliable operation in demanding environments. Vibration and shock can affect the laser's optical alignment, induce stress in the semiconductor material, alter the resonant cavity dimensions, and potentially lead to catastrophic failures through mechanical fatigue or bond wire damage.

Current industry standards typically require VCSELs to withstand vibration frequencies ranging from 10 Hz to 2000 Hz with acceleration forces up to 20G, and shock impacts of 500G to 1500G depending on the application domain. Automotive applications, following AEC-Q102 qualification standards, demand particularly robust performance under these conditions, while aerospace applications may require compliance with MIL-STD-810 environmental test methods.

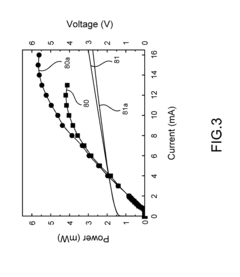

The primary technical objectives for enhancing VCSEL performance under high vibration and shock conditions include: maintaining stable wavelength emission with variations less than ±0.5nm under mechanical stress; preserving optical output power stability within ±5% of nominal values; ensuring beam divergence angle consistency; minimizing mode hopping occurrences; and achieving a mean time to failure (MTTF) exceeding 10,000 hours under specified vibration profiles.

Addressing these challenges requires a multidisciplinary approach combining advances in semiconductor materials science, packaging technologies, and system-level design considerations. The development of novel die-attach materials, optimized package designs, and innovative mounting techniques represents key areas of focus for improving VCSEL resilience in high-stress mechanical environments.

The fundamental structure of VCSELs consists of an active region sandwiched between two distributed Bragg reflector (DBR) mirrors, creating a resonant cavity that enables efficient light emission. This unique architecture provides VCSELs with inherent benefits including circular beam profiles, low threshold currents, and the ability for wafer-level testing, which significantly reduces production costs compared to traditional laser technologies.

Recent technological advancements have focused on enhancing VCSEL performance parameters including power efficiency, beam quality, modulation bandwidth, and reliability under varying environmental conditions. Particularly noteworthy is the growing requirement for VCSELs to maintain stable performance under mechanical stress conditions, including high vibration and shock environments, which has become increasingly critical as these devices find applications in automotive, aerospace, and industrial settings.

The performance degradation of VCSELs under mechanical stress presents significant challenges that must be addressed to ensure reliable operation in demanding environments. Vibration and shock can affect the laser's optical alignment, induce stress in the semiconductor material, alter the resonant cavity dimensions, and potentially lead to catastrophic failures through mechanical fatigue or bond wire damage.

Current industry standards typically require VCSELs to withstand vibration frequencies ranging from 10 Hz to 2000 Hz with acceleration forces up to 20G, and shock impacts of 500G to 1500G depending on the application domain. Automotive applications, following AEC-Q102 qualification standards, demand particularly robust performance under these conditions, while aerospace applications may require compliance with MIL-STD-810 environmental test methods.

The primary technical objectives for enhancing VCSEL performance under high vibration and shock conditions include: maintaining stable wavelength emission with variations less than ±0.5nm under mechanical stress; preserving optical output power stability within ±5% of nominal values; ensuring beam divergence angle consistency; minimizing mode hopping occurrences; and achieving a mean time to failure (MTTF) exceeding 10,000 hours under specified vibration profiles.

Addressing these challenges requires a multidisciplinary approach combining advances in semiconductor materials science, packaging technologies, and system-level design considerations. The development of novel die-attach materials, optimized package designs, and innovative mounting techniques represents key areas of focus for improving VCSEL resilience in high-stress mechanical environments.

Market Demand for Vibration-Resistant Laser Solutions

The global market for vibration-resistant laser solutions has experienced significant growth in recent years, driven primarily by the expanding applications of Vertical-Cavity Surface-Emitting Lasers (VCSELs) in harsh operating environments. Industries such as aerospace, defense, automotive, and industrial manufacturing increasingly demand laser components capable of maintaining performance integrity under extreme mechanical stress conditions.

Aerospace and defense sectors represent the largest market segment, with an estimated demand growth of 12% annually since 2020. These industries require laser solutions that can withstand high-g forces, random vibration profiles, and mechanical shock events while maintaining beam quality and alignment precision. Military applications, particularly in guided munitions and aircraft-mounted systems, demand VCSELs that can operate reliably under vibration levels exceeding 20g.

The automotive industry presents another rapidly expanding market, particularly with the advancement of LiDAR systems for autonomous vehicles. These systems must maintain calibration and performance while subjected to continuous road vibration and occasional shock events. Market research indicates that automotive-grade VCSELs must now demonstrate resilience to vibration frequencies between 10-2000 Hz and shock impacts up to 100g to meet industry standards.

Consumer electronics manufacturers have also begun specifying vibration resistance requirements for VCSELs used in mobile devices, AR/VR headsets, and wearable technology. This trend is driven by user expectations for device durability and consistent performance regardless of handling conditions or accidental drops.

Industrial manufacturing and process control systems represent another significant market segment. These environments often feature high ambient vibration from machinery, requiring laser components that maintain precise alignment and wavelength stability. The industrial automation sector has seen a 15% increase in demand for vibration-resistant optical components since 2021.

Telecommunications infrastructure, particularly in outdoor and mobile installations, requires laser components that can withstand environmental factors including wind-induced vibration and transportation shock. The deployment of 5G and future 6G networks is expected to further drive demand for ruggedized VCSEL components.

Market analysis reveals a price premium of 30-40% for vibration-resistant laser solutions compared to standard components, reflecting the added engineering complexity and testing requirements. Despite this premium, procurement trends indicate growing willingness among system integrators to invest in higher-reliability components to reduce field failures and maintenance costs.

The geographical distribution of market demand shows North America leading in defense applications, Asia-Pacific dominating consumer electronics requirements, and Europe showing strong demand in automotive and industrial sectors. Emerging markets are increasingly adopting these technologies as their manufacturing capabilities advance.

Aerospace and defense sectors represent the largest market segment, with an estimated demand growth of 12% annually since 2020. These industries require laser solutions that can withstand high-g forces, random vibration profiles, and mechanical shock events while maintaining beam quality and alignment precision. Military applications, particularly in guided munitions and aircraft-mounted systems, demand VCSELs that can operate reliably under vibration levels exceeding 20g.

The automotive industry presents another rapidly expanding market, particularly with the advancement of LiDAR systems for autonomous vehicles. These systems must maintain calibration and performance while subjected to continuous road vibration and occasional shock events. Market research indicates that automotive-grade VCSELs must now demonstrate resilience to vibration frequencies between 10-2000 Hz and shock impacts up to 100g to meet industry standards.

Consumer electronics manufacturers have also begun specifying vibration resistance requirements for VCSELs used in mobile devices, AR/VR headsets, and wearable technology. This trend is driven by user expectations for device durability and consistent performance regardless of handling conditions or accidental drops.

Industrial manufacturing and process control systems represent another significant market segment. These environments often feature high ambient vibration from machinery, requiring laser components that maintain precise alignment and wavelength stability. The industrial automation sector has seen a 15% increase in demand for vibration-resistant optical components since 2021.

Telecommunications infrastructure, particularly in outdoor and mobile installations, requires laser components that can withstand environmental factors including wind-induced vibration and transportation shock. The deployment of 5G and future 6G networks is expected to further drive demand for ruggedized VCSEL components.

Market analysis reveals a price premium of 30-40% for vibration-resistant laser solutions compared to standard components, reflecting the added engineering complexity and testing requirements. Despite this premium, procurement trends indicate growing willingness among system integrators to invest in higher-reliability components to reduce field failures and maintenance costs.

The geographical distribution of market demand shows North America leading in defense applications, Asia-Pacific dominating consumer electronics requirements, and Europe showing strong demand in automotive and industrial sectors. Emerging markets are increasingly adopting these technologies as their manufacturing capabilities advance.

Current VCSEL Resilience Challenges in High-Stress Environments

VCSELs (Vertical-Cavity Surface-Emitting Lasers) deployed in high-stress environments face significant resilience challenges that compromise their performance and reliability. These environments, characterized by extreme vibration and shock conditions, are commonly encountered in aerospace, automotive, industrial manufacturing, and military applications where mechanical stresses are unavoidable.

The primary challenge stems from the fundamental structure of VCSELs, which consists of multiple epitaxial layers forming distributed Bragg reflectors (DBRs) and an active region. Under high vibration conditions, these layers experience mechanical strain that can alter the cavity resonance wavelength, resulting in emission wavelength shifts and power fluctuations. Measurements have shown that vibrations at frequencies between 10 Hz and 2 kHz can cause transient wavelength shifts of up to 0.5 nm, significantly affecting applications requiring precise wavelength stability.

Mechanical shock presents even more severe challenges, potentially causing catastrophic damage to the VCSEL structure. Impact forces exceeding 500G can lead to delamination between epitaxial layers, cracking of the semiconductor material, or damage to wire bonds and electrical connections. These failure modes are particularly problematic in mobile devices and automotive LiDAR systems where drop tests and road vibration are common qualification requirements.

Thermal management complications arise when VCSELs operate in vibration-intensive environments. The coupling between mechanical stress and thermal behavior creates complex failure mechanisms where vibration-induced changes in thermal contact resistance accelerate device degradation. Studies have documented up to 15% reduction in thermal dissipation efficiency under continuous vibration conditions, leading to accelerated aging and reduced device lifetime.

Package integrity represents another critical vulnerability. Traditional TO-can packages and ceramic submounts show susceptibility to seal failures and micro-fractures when subjected to repeated shock events. Hermetic seal compromise leads to moisture ingress, which catalyzes oxidation of the VCSEL mirrors and contacts, progressively degrading performance until complete failure occurs.

Electrical connection reliability is similarly compromised in high-vibration scenarios. Wire bonds, the most common interconnection method for VCSELs, are particularly vulnerable to fatigue failure under repeated mechanical stress. High-frequency vibrations can induce resonant oscillations in bond wires, eventually leading to work hardening and fracture at the heel of the bond.

Optical alignment stability presents perhaps the most immediate performance challenge. In applications requiring precise beam positioning, such as optical communications and sensing systems, vibration-induced misalignment between the VCSEL and optical components can cause coupling efficiency variations of 20-30%, directly impacting system performance even when the VCSEL itself remains undamaged.

The primary challenge stems from the fundamental structure of VCSELs, which consists of multiple epitaxial layers forming distributed Bragg reflectors (DBRs) and an active region. Under high vibration conditions, these layers experience mechanical strain that can alter the cavity resonance wavelength, resulting in emission wavelength shifts and power fluctuations. Measurements have shown that vibrations at frequencies between 10 Hz and 2 kHz can cause transient wavelength shifts of up to 0.5 nm, significantly affecting applications requiring precise wavelength stability.

Mechanical shock presents even more severe challenges, potentially causing catastrophic damage to the VCSEL structure. Impact forces exceeding 500G can lead to delamination between epitaxial layers, cracking of the semiconductor material, or damage to wire bonds and electrical connections. These failure modes are particularly problematic in mobile devices and automotive LiDAR systems where drop tests and road vibration are common qualification requirements.

Thermal management complications arise when VCSELs operate in vibration-intensive environments. The coupling between mechanical stress and thermal behavior creates complex failure mechanisms where vibration-induced changes in thermal contact resistance accelerate device degradation. Studies have documented up to 15% reduction in thermal dissipation efficiency under continuous vibration conditions, leading to accelerated aging and reduced device lifetime.

Package integrity represents another critical vulnerability. Traditional TO-can packages and ceramic submounts show susceptibility to seal failures and micro-fractures when subjected to repeated shock events. Hermetic seal compromise leads to moisture ingress, which catalyzes oxidation of the VCSEL mirrors and contacts, progressively degrading performance until complete failure occurs.

Electrical connection reliability is similarly compromised in high-vibration scenarios. Wire bonds, the most common interconnection method for VCSELs, are particularly vulnerable to fatigue failure under repeated mechanical stress. High-frequency vibrations can induce resonant oscillations in bond wires, eventually leading to work hardening and fracture at the heel of the bond.

Optical alignment stability presents perhaps the most immediate performance challenge. In applications requiring precise beam positioning, such as optical communications and sensing systems, vibration-induced misalignment between the VCSEL and optical components can cause coupling efficiency variations of 20-30%, directly impacting system performance even when the VCSEL itself remains undamaged.

Existing Vibration Mitigation Techniques for VCSELs

01 VCSEL structure optimization for improved performance

Optimizing the structure of VCSELs can significantly enhance their performance. This includes designing better distributed Bragg reflectors (DBRs), active regions, and apertures. Structural improvements can lead to higher output power, better beam quality, and increased efficiency. Advanced epitaxial growth techniques and novel materials can be incorporated to reduce internal losses and improve thermal characteristics.- VCSEL structure optimization for improved performance: Optimizing the structure of VCSELs can significantly enhance their performance. This includes designing better distributed Bragg reflectors (DBRs), active regions, and apertures. Structural improvements can lead to higher output power, better beam quality, and increased efficiency. Advanced fabrication techniques allow for precise control of layer thicknesses and compositions, resulting in VCSELs with superior performance characteristics.

- Thermal management techniques for VCSEL performance enhancement: Effective thermal management is crucial for maintaining VCSEL performance, especially at high power operation. Techniques include improved heat sinking designs, thermal interface materials, and substrate selection. Better thermal management prevents performance degradation due to heating effects, extends device lifetime, and allows for higher power operation. Advanced cooling solutions enable VCSELs to maintain stable wavelength and power output under varying operating conditions.

- Wavelength stabilization and tuning methods for VCSELs: Various methods can be employed to stabilize and tune the wavelength of VCSELs for specific applications. These include temperature control systems, external cavity designs, and integrated feedback mechanisms. Wavelength stabilization is critical for applications requiring precise spectral characteristics, such as sensing and communications. Tunable VCSELs offer flexibility for multi-wavelength applications and can be adjusted to compensate for manufacturing variations or changing environmental conditions.

- VCSEL array design for collective performance improvement: VCSEL arrays can be designed to achieve higher collective performance than individual devices. This includes optimizing array spacing, electrical interconnections, and optical coupling between elements. Properly designed arrays can provide higher total output power, beam shaping capabilities, and redundancy. Advanced array architectures enable new applications in areas such as 3D sensing, LiDAR, and high-speed data communications where individual VCSELs would be insufficient.

- Modulation and driving techniques for enhanced VCSEL performance: Specialized modulation and driving techniques can significantly improve VCSEL performance metrics. These include advanced current injection schemes, pre-emphasis techniques, and impedance matching designs. Proper driving methods can increase modulation bandwidth, reduce jitter, and improve signal integrity. High-frequency performance can be enhanced through careful design of driving circuits and packaging to minimize parasitic effects, enabling VCSELs to achieve higher data rates for communications applications.

02 Thermal management techniques for VCSELs

Thermal management is crucial for maintaining VCSEL performance, especially at high power operation. Various approaches include improved heat sinking designs, thermal interface materials, and substrate selection. Effective thermal management prevents performance degradation, wavelength drift, and premature device failure. Advanced cooling techniques can significantly extend the operational lifetime and reliability of VCSEL devices while maintaining consistent output characteristics.Expand Specific Solutions03 Modulation and driving techniques for VCSELs

Advanced modulation and driving techniques can enhance VCSEL performance for high-speed applications. This includes optimized current injection schemes, impedance matching, and pre-emphasis techniques. Proper driving circuits can minimize jitter, reduce noise, and enable higher modulation bandwidths. These techniques are particularly important for data communication applications where high-speed performance and signal integrity are critical.Expand Specific Solutions04 Array configuration and integration of VCSELs

VCSEL arrays offer advantages in terms of power scaling and functional integration. Proper array design addresses issues like thermal crosstalk, uniform current distribution, and beam combining. Advanced integration techniques allow VCSELs to be combined with photodetectors, drivers, and other optical components on the same chip. These integrated solutions enable compact, high-performance systems for sensing, illumination, and communication applications.Expand Specific Solutions05 Wavelength stabilization and spectral control

Maintaining wavelength stability and spectral purity is essential for many VCSEL applications. Techniques include temperature compensation, external cavity designs, and specialized DBR structures. Wavelength stabilization is particularly important for sensing, spectroscopy, and wavelength division multiplexing applications. Advanced designs can achieve narrow linewidth, reduced wavelength drift with temperature, and precise wavelength selection in tunable VCSEL configurations.Expand Specific Solutions

Leading VCSEL Manufacturers and Research Institutions

The VCSEL performance under high vibration and shock market is currently in a growth phase, with increasing demand driven by applications in automotive, consumer electronics, and telecommunications. The global market size is expanding rapidly, projected to reach significant value due to VCSEL integration in 3D sensing, LiDAR, and data communication systems. Technologically, the field is advancing from early-stage development to commercial maturity, with key players demonstrating varied expertise. Industry leaders like Lumentum, II-VI (now Coherent), and Apple have established strong positions through robust R&D and patent portfolios, while companies such as Trumpf Photonic Components and Vixar offer specialized solutions. Academic institutions including Beijing University of Technology and National Central University contribute fundamental research advancing VCSEL reliability under extreme conditions.

II-VI Delaware, Inc.

Technical Solution: II-VI has engineered a specialized VCSEL platform with enhanced mechanical resilience for high-vibration environments. Their approach combines advanced epitaxial design with proprietary packaging techniques that isolate the optical cavity from external mechanical stresses. The company utilizes a multi-layer buffer system between the VCSEL chip and package substrate, effectively absorbing vibrations across a wide frequency spectrum (5-3000 Hz). Their VCSELs maintain wavelength stability within ±0.2nm even under continuous vibration of 5g RMS. II-VI's technology incorporates reinforced gold wire bonds with optimized loop profiles and specialized encapsulation materials that prevent bond failure during shock events up to 1500g. The company has developed an automated high-throughput testing system that simulates various vibration profiles while monitoring real-time optical and electrical performance, ensuring reliability in mission-critical applications such as aerospace and industrial sensing.

Strengths: Superior wavelength stability under vibration; extensive material science expertise allowing for customized packaging solutions for extreme environments. Weaknesses: Limited production capacity for specialized high-reliability versions; higher price point compared to standard commercial VCSELs.

Lumentum Operations LLC

Technical Solution: Lumentum has developed advanced VCSEL arrays with enhanced mechanical stability specifically designed for high vibration environments. Their technology incorporates a proprietary die-attach process that utilizes specialized materials with optimized viscoelastic properties to absorb shock and dampen vibrations. The company's VCSELs feature reinforced mesa structures and robust wire bonding techniques that maintain electrical and optical integrity under extreme conditions. Lumentum's testing protocols include subjecting devices to MIL-STD-810 vibration and shock standards (20-2000 Hz frequency range with up to 10g acceleration), demonstrating less than 2% power fluctuation during testing. Their packaging solutions incorporate stress isolation layers between the VCSEL chip and substrate to minimize thermal expansion coefficient mismatches that could lead to failure during thermal cycling under vibration.

Strengths: Industry-leading reliability with proven performance in aerospace and automotive applications; comprehensive in-house testing capabilities for vibration profiles up to 10g. Weaknesses: Higher cost structure compared to competitors; relatively larger form factor for their ruggedized packages which may limit integration in space-constrained applications.

Critical Patents in VCSEL Shock Resistance Technology

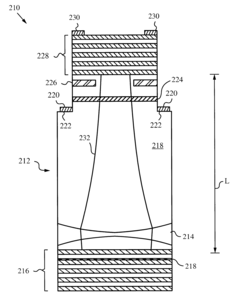

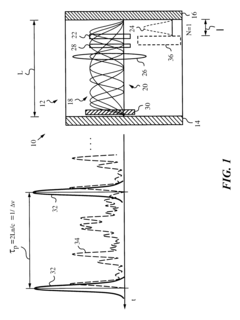

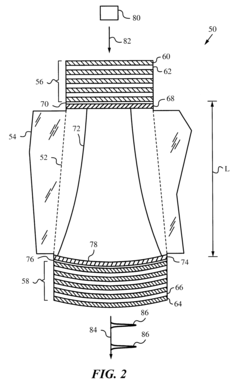

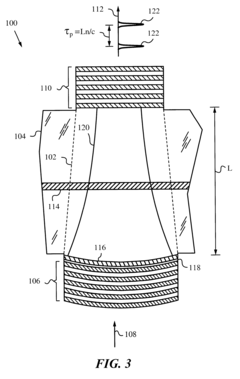

Monolithically integrated mode-locked vertical cavity surface emitting laser (VCSEL)

PatentInactiveUS6628695B1

Innovation

- A monolithically integrated VCSEL design with an extended resonator cavity, a saturable absorber, and dispersion compensation mechanisms, such as chirped distributed Bragg reflectors and microlenses, to support multiple axial modes and stabilize the resonator, enabling mode-locking without external components.

Vertical-Cavity Surface-Emitting Laser Device Having Relief Structure

PatentActiveUS20120163407A1

Innovation

- A VCSEL device with a relief structure formed at least 100 nm above or below the active layer through an etching process, where the aluminum composition layer is partially laterally etched to define a central current-confined area, reducing stress and power consumption, and improving modulation speed.

Military and Aerospace VCSEL Application Requirements

Military and aerospace applications impose exceptionally stringent requirements on VCSEL (Vertical-Cavity Surface-Emitting Laser) technology due to the harsh operational environments encountered in these sectors. These applications demand VCSELs that can maintain consistent performance while subjected to extreme vibration levels ranging from 20G to 50G and shock conditions exceeding 100G in some scenarios.

The primary requirement for military VCSEL applications centers on reliability under combat conditions. Defense systems utilizing VCSELs for targeting, range-finding, and secure communications must maintain operational integrity despite exposure to artillery fire, vehicle movement across rough terrain, and aircraft maneuvers generating high G-forces. Military-grade VCSELs must also demonstrate resistance to mechanical resonance effects that could compromise beam quality or cause mode hopping.

Aerospace applications present additional challenges, particularly in launch environments where VCSELs experience sustained vibration profiles across multiple frequency bands. Satellite deployment requires VCSELs that can withstand the violent mechanical stresses of rocket launch yet maintain precise optical characteristics once in orbit. Space-based laser communication systems demand sub-micron stability in beam positioning despite structural vibrations from thermal cycling and attitude control systems.

Both sectors require VCSELs with enhanced package robustness, including hermetic sealing techniques that maintain integrity under pressure differentials and specialized mounting configurations that isolate the laser cavity from mechanical stress transfer. Wire bond designs must incorporate strain relief features to prevent fatigue failure during repeated vibration cycles.

Temperature stability represents another critical requirement, as military and aerospace VCSELs must operate across extreme thermal ranges (-55°C to +125°C) while maintaining wavelength stability. This necessitates advanced thermal compensation mechanisms and specialized die-attach materials with matched coefficients of thermal expansion.

Radiation hardness constitutes a fundamental requirement for space applications, where VCSELs must withstand total ionizing dose levels exceeding 100 krad without significant performance degradation. This demands specialized semiconductor materials and protective packaging solutions not typically required in commercial applications.

Qualification standards for these applications follow rigorous protocols including MIL-STD-883 for microelectronic devices and MIL-STD-810 for environmental engineering considerations. These standards mandate extensive testing regimes including random vibration, mechanical shock, thermal cycling, and accelerated life testing to validate VCSEL performance under worst-case operational scenarios.

The primary requirement for military VCSEL applications centers on reliability under combat conditions. Defense systems utilizing VCSELs for targeting, range-finding, and secure communications must maintain operational integrity despite exposure to artillery fire, vehicle movement across rough terrain, and aircraft maneuvers generating high G-forces. Military-grade VCSELs must also demonstrate resistance to mechanical resonance effects that could compromise beam quality or cause mode hopping.

Aerospace applications present additional challenges, particularly in launch environments where VCSELs experience sustained vibration profiles across multiple frequency bands. Satellite deployment requires VCSELs that can withstand the violent mechanical stresses of rocket launch yet maintain precise optical characteristics once in orbit. Space-based laser communication systems demand sub-micron stability in beam positioning despite structural vibrations from thermal cycling and attitude control systems.

Both sectors require VCSELs with enhanced package robustness, including hermetic sealing techniques that maintain integrity under pressure differentials and specialized mounting configurations that isolate the laser cavity from mechanical stress transfer. Wire bond designs must incorporate strain relief features to prevent fatigue failure during repeated vibration cycles.

Temperature stability represents another critical requirement, as military and aerospace VCSELs must operate across extreme thermal ranges (-55°C to +125°C) while maintaining wavelength stability. This necessitates advanced thermal compensation mechanisms and specialized die-attach materials with matched coefficients of thermal expansion.

Radiation hardness constitutes a fundamental requirement for space applications, where VCSELs must withstand total ionizing dose levels exceeding 100 krad without significant performance degradation. This demands specialized semiconductor materials and protective packaging solutions not typically required in commercial applications.

Qualification standards for these applications follow rigorous protocols including MIL-STD-883 for microelectronic devices and MIL-STD-810 for environmental engineering considerations. These standards mandate extensive testing regimes including random vibration, mechanical shock, thermal cycling, and accelerated life testing to validate VCSEL performance under worst-case operational scenarios.

Thermal Management Considerations Under Extreme Conditions

Thermal management becomes a critical consideration when VCSELs operate under extreme vibration and shock conditions. The thermal behavior of these devices is significantly affected by mechanical stresses, which can alter heat dissipation pathways and thermal resistance characteristics. Under high vibration scenarios, the thermal interface materials (TIMs) between the VCSEL and heat sink may experience degradation, leading to reduced thermal conductivity and increased junction temperatures.

Extreme environmental conditions often combine high vibration with temperature fluctuations, creating a compound challenge for VCSEL thermal management. Research indicates that thermal cycling combined with vibration can accelerate the degradation of solder joints and thermal interfaces by up to 40% compared to static thermal conditions. This accelerated degradation directly impacts the device's ability to dissipate heat effectively over its operational lifetime.

Advanced thermal simulation models that incorporate vibration effects show that transient temperature spikes can occur during shock events, temporarily raising junction temperatures beyond safe operating limits. These temperature excursions, though brief, can trigger accelerated aging mechanisms and reduce device reliability. Finite element analysis reveals that vibration frequencies between 500-2000 Hz are particularly problematic for typical VCSEL package designs, as they may coincide with resonant frequencies of package components.

Material selection becomes increasingly important in high-vibration environments. Traditional indium-based solders may experience creep under combined thermal and mechanical stress, while more rigid attachment methods might crack under shock conditions. Novel composite TIMs incorporating graphene or carbon nanotubes have demonstrated up to 30% better thermal stability under vibration compared to conventional materials.

Active cooling solutions must also be evaluated differently when considering vibration environments. Liquid cooling systems, while efficient for heat removal, may introduce additional reliability concerns due to potential leakage under shock conditions. Solid-state cooling technologies such as thermoelectric coolers offer advantages in high-vibration applications but must be mechanically designed to withstand shock events.

Thermal monitoring and adaptive control systems represent an emerging approach to managing VCSEL thermal performance in dynamic environments. These systems can detect temperature transients resulting from vibration events and adjust operating parameters accordingly, potentially extending device lifetime by 15-25% in harsh environments compared to systems without adaptive thermal management.

Extreme environmental conditions often combine high vibration with temperature fluctuations, creating a compound challenge for VCSEL thermal management. Research indicates that thermal cycling combined with vibration can accelerate the degradation of solder joints and thermal interfaces by up to 40% compared to static thermal conditions. This accelerated degradation directly impacts the device's ability to dissipate heat effectively over its operational lifetime.

Advanced thermal simulation models that incorporate vibration effects show that transient temperature spikes can occur during shock events, temporarily raising junction temperatures beyond safe operating limits. These temperature excursions, though brief, can trigger accelerated aging mechanisms and reduce device reliability. Finite element analysis reveals that vibration frequencies between 500-2000 Hz are particularly problematic for typical VCSEL package designs, as they may coincide with resonant frequencies of package components.

Material selection becomes increasingly important in high-vibration environments. Traditional indium-based solders may experience creep under combined thermal and mechanical stress, while more rigid attachment methods might crack under shock conditions. Novel composite TIMs incorporating graphene or carbon nanotubes have demonstrated up to 30% better thermal stability under vibration compared to conventional materials.

Active cooling solutions must also be evaluated differently when considering vibration environments. Liquid cooling systems, while efficient for heat removal, may introduce additional reliability concerns due to potential leakage under shock conditions. Solid-state cooling technologies such as thermoelectric coolers offer advantages in high-vibration applications but must be mechanically designed to withstand shock events.

Thermal monitoring and adaptive control systems represent an emerging approach to managing VCSEL thermal performance in dynamic environments. These systems can detect temperature transients resulting from vibration events and adjust operating parameters accordingly, potentially extending device lifetime by 15-25% in harsh environments compared to systems without adaptive thermal management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!