Co-Design Of VCSELs And Heat Spreaders For Efficiency

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Technology Background and Efficiency Goals

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as a transformative technology in the optoelectronics industry since their initial development in the late 1970s. Unlike traditional edge-emitting lasers, VCSELs emit light perpendicular to their surface, offering advantages in manufacturing, testing, and integration capabilities. The evolution of VCSEL technology has been marked by continuous improvements in design, materials, and fabrication processes, leading to their widespread adoption in various applications including data communications, sensing, and consumer electronics.

The fundamental structure of a VCSEL consists of an active region sandwiched between two distributed Bragg reflector (DBR) mirrors, forming a resonant cavity that enhances stimulated emission at specific wavelengths. This unique architecture enables VCSELs to achieve single-mode operation, circular beam profiles, and low threshold currents, making them ideal for energy-efficient applications.

Despite these inherent advantages, thermal management remains a critical challenge in VCSEL technology. As current densities increase, particularly in high-power applications, self-heating effects significantly impact device performance, reliability, and lifetime. The temperature rise within the active region leads to reduced quantum efficiency, wavelength shifts, and accelerated degradation mechanisms. This thermal limitation has become increasingly prominent as market demands push for higher output powers and greater integration densities.

The technological trajectory of VCSELs is now heavily focused on enhancing thermal performance through innovative heat dissipation strategies. Historical approaches have included substrate thinning, improved heat sink designs, and the incorporation of thermally conductive materials. However, these methods often represent post-design solutions rather than integrated thermal management strategies developed concurrently with the VCSEL design itself.

The concept of co-designing VCSELs and heat spreaders represents a paradigm shift in addressing thermal challenges. This approach considers thermal management as an integral part of the device design process rather than an afterthought. By simultaneously optimizing both the optical/electrical characteristics of the VCSEL and the thermal properties of integrated heat spreaders, significant improvements in overall device efficiency can be achieved.

The primary efficiency goals for this co-design approach include: reducing thermal resistance to below 1.5 K/W for high-power arrays, maintaining wall-plug efficiency above 40% at elevated operating temperatures, extending reliable operation at junction temperatures up to 125°C, and achieving a 30% reduction in power consumption compared to conventional designs. These targets are driven by emerging applications in 3D sensing, LiDAR systems, and next-generation data centers, where power efficiency directly impacts system performance and operating costs.

As VCSEL technology continues to mature, the industry trend is moving toward more sophisticated thermal solutions that are considered from the earliest stages of device conception. This holistic design philosophy promises to overcome current efficiency limitations and enable VCSELs to meet the demanding requirements of future photonic systems.

The fundamental structure of a VCSEL consists of an active region sandwiched between two distributed Bragg reflector (DBR) mirrors, forming a resonant cavity that enhances stimulated emission at specific wavelengths. This unique architecture enables VCSELs to achieve single-mode operation, circular beam profiles, and low threshold currents, making them ideal for energy-efficient applications.

Despite these inherent advantages, thermal management remains a critical challenge in VCSEL technology. As current densities increase, particularly in high-power applications, self-heating effects significantly impact device performance, reliability, and lifetime. The temperature rise within the active region leads to reduced quantum efficiency, wavelength shifts, and accelerated degradation mechanisms. This thermal limitation has become increasingly prominent as market demands push for higher output powers and greater integration densities.

The technological trajectory of VCSELs is now heavily focused on enhancing thermal performance through innovative heat dissipation strategies. Historical approaches have included substrate thinning, improved heat sink designs, and the incorporation of thermally conductive materials. However, these methods often represent post-design solutions rather than integrated thermal management strategies developed concurrently with the VCSEL design itself.

The concept of co-designing VCSELs and heat spreaders represents a paradigm shift in addressing thermal challenges. This approach considers thermal management as an integral part of the device design process rather than an afterthought. By simultaneously optimizing both the optical/electrical characteristics of the VCSEL and the thermal properties of integrated heat spreaders, significant improvements in overall device efficiency can be achieved.

The primary efficiency goals for this co-design approach include: reducing thermal resistance to below 1.5 K/W for high-power arrays, maintaining wall-plug efficiency above 40% at elevated operating temperatures, extending reliable operation at junction temperatures up to 125°C, and achieving a 30% reduction in power consumption compared to conventional designs. These targets are driven by emerging applications in 3D sensing, LiDAR systems, and next-generation data centers, where power efficiency directly impacts system performance and operating costs.

As VCSEL technology continues to mature, the industry trend is moving toward more sophisticated thermal solutions that are considered from the earliest stages of device conception. This holistic design philosophy promises to overcome current efficiency limitations and enable VCSELs to meet the demanding requirements of future photonic systems.

Market Demand Analysis for High-Efficiency VCSELs

The global market for high-efficiency VCSELs (Vertical-Cavity Surface-Emitting Lasers) has experienced exponential growth over the past decade, primarily driven by their integration into consumer electronics, data communications, and emerging sensing applications. Current market valuations place the VCSEL sector at approximately 3.5 billion USD, with projections indicating a compound annual growth rate of 17.3% through 2028.

Consumer electronics represents the largest demand segment, with smartphone manufacturers incorporating VCSEL arrays for facial recognition, autofocus assistance, and proximity sensing. Apple's implementation of Face ID technology marked a watershed moment for VCSEL adoption, creating a ripple effect across the industry. This segment alone accounts for nearly 40% of the total VCSEL market.

Data center applications constitute the second-largest market segment, where the need for higher bandwidth, lower power consumption, and increased data transmission speeds has intensified demand for efficient optical interconnects. The transition from traditional data rates of 25-50 Gbps to 100-400 Gbps has placed significant thermal management challenges on VCSEL design, directly correlating to market demand for integrated thermal solutions.

Automotive LiDAR systems represent the fastest-growing application sector, with a projected five-year growth rate of 31.2%. As autonomous driving technologies advance from Level 2 to Levels 3 and 4, the requirements for more powerful, efficient, and thermally stable VCSEL arrays have become critical market drivers.

Industry surveys indicate that thermal management remains the primary limitation in VCSEL performance enhancement, with 78% of manufacturers citing heat dissipation as the key barrier to achieving higher output powers and operational efficiencies. This has created a specialized market demand for co-designed thermal solutions, particularly heat spreaders that can be integrated during the manufacturing process rather than added as aftermarket components.

The geographical distribution of demand shows Asia-Pacific leading with 43% market share, followed by North America (31%) and Europe (21%). China's rapid expansion in 5G infrastructure and consumer electronics manufacturing has significantly influenced regional demand patterns.

From an end-user perspective, the market increasingly values energy efficiency, with 67% of procurement specifications now including thermal performance metrics. This represents a marked shift from five years ago when only 28% of specifications addressed thermal considerations. The trend reflects broader industry movements toward sustainable technologies and reduced operational costs.

Market forecasts indicate that VCSELs with integrated heat spreader designs could command premium pricing of 15-22% over standard versions, with the additional cost offset by performance improvements and extended operational lifetimes. This value proposition is particularly compelling for applications requiring continuous operation or deployment in challenging environmental conditions.

Consumer electronics represents the largest demand segment, with smartphone manufacturers incorporating VCSEL arrays for facial recognition, autofocus assistance, and proximity sensing. Apple's implementation of Face ID technology marked a watershed moment for VCSEL adoption, creating a ripple effect across the industry. This segment alone accounts for nearly 40% of the total VCSEL market.

Data center applications constitute the second-largest market segment, where the need for higher bandwidth, lower power consumption, and increased data transmission speeds has intensified demand for efficient optical interconnects. The transition from traditional data rates of 25-50 Gbps to 100-400 Gbps has placed significant thermal management challenges on VCSEL design, directly correlating to market demand for integrated thermal solutions.

Automotive LiDAR systems represent the fastest-growing application sector, with a projected five-year growth rate of 31.2%. As autonomous driving technologies advance from Level 2 to Levels 3 and 4, the requirements for more powerful, efficient, and thermally stable VCSEL arrays have become critical market drivers.

Industry surveys indicate that thermal management remains the primary limitation in VCSEL performance enhancement, with 78% of manufacturers citing heat dissipation as the key barrier to achieving higher output powers and operational efficiencies. This has created a specialized market demand for co-designed thermal solutions, particularly heat spreaders that can be integrated during the manufacturing process rather than added as aftermarket components.

The geographical distribution of demand shows Asia-Pacific leading with 43% market share, followed by North America (31%) and Europe (21%). China's rapid expansion in 5G infrastructure and consumer electronics manufacturing has significantly influenced regional demand patterns.

From an end-user perspective, the market increasingly values energy efficiency, with 67% of procurement specifications now including thermal performance metrics. This represents a marked shift from five years ago when only 28% of specifications addressed thermal considerations. The trend reflects broader industry movements toward sustainable technologies and reduced operational costs.

Market forecasts indicate that VCSELs with integrated heat spreader designs could command premium pricing of 15-22% over standard versions, with the additional cost offset by performance improvements and extended operational lifetimes. This value proposition is particularly compelling for applications requiring continuous operation or deployment in challenging environmental conditions.

Current Thermal Management Challenges in VCSEL Design

Vertical-Cavity Surface-Emitting Lasers (VCSELs) face significant thermal management challenges that directly impact their performance, reliability, and efficiency. As these devices continue to miniaturize while power densities increase, heat dissipation has become a critical bottleneck in VCSEL design. The primary challenge stems from the inherent structure of VCSELs, where heat generation occurs in a highly localized active region, creating thermal hotspots that can reach temperatures exceeding 100°C above ambient conditions during operation.

The thermal resistance pathway in VCSELs presents a fundamental limitation, as heat must traverse multiple semiconductor layers with varying thermal conductivities before reaching heat sinks or spreaders. This thermal bottleneck is particularly pronounced in arrays where device density compounds the heating effect, creating thermal crosstalk between adjacent emitters that further degrades performance.

Current VCSEL designs struggle with the trade-off between electrical isolation and thermal conductivity. The dielectric layers necessary for electrical functionality often exhibit poor thermal properties, creating barriers to efficient heat transfer. Additionally, the substrate materials traditionally used in VCSEL fabrication, such as GaAs, have relatively low thermal conductivity compared to potential alternatives like diamond or silicon carbide.

Another significant challenge is the temperature-dependent performance degradation of VCSELs. As junction temperatures rise, threshold current increases while slope efficiency and maximum output power decrease. This temperature sensitivity creates a negative feedback loop where efficiency losses generate more heat, further exacerbating thermal issues and accelerating device degradation.

For high-power applications, particularly in sensing, LiDAR, and data communications, thermal management becomes even more critical as devices are pushed to higher output powers and duty cycles. The thermal expansion coefficient mismatch between different materials in the VCSEL structure introduces mechanical stress during thermal cycling, potentially leading to reliability issues and premature device failure.

Conventional cooling approaches such as thermoelectric coolers add complexity, cost, and power consumption to VCSEL systems, making them impractical for many applications, particularly in mobile and consumer electronics where space and power budgets are constrained. Meanwhile, passive cooling solutions often provide insufficient heat dissipation for high-density arrays operating at elevated power levels.

The integration of effective thermal management solutions directly into the VCSEL manufacturing process presents additional challenges related to material compatibility, process complexity, and cost considerations. Advanced techniques such as flip-chip bonding to high thermal conductivity substrates show promise but introduce manufacturing complexities and yield concerns that must be addressed for volume production.

The thermal resistance pathway in VCSELs presents a fundamental limitation, as heat must traverse multiple semiconductor layers with varying thermal conductivities before reaching heat sinks or spreaders. This thermal bottleneck is particularly pronounced in arrays where device density compounds the heating effect, creating thermal crosstalk between adjacent emitters that further degrades performance.

Current VCSEL designs struggle with the trade-off between electrical isolation and thermal conductivity. The dielectric layers necessary for electrical functionality often exhibit poor thermal properties, creating barriers to efficient heat transfer. Additionally, the substrate materials traditionally used in VCSEL fabrication, such as GaAs, have relatively low thermal conductivity compared to potential alternatives like diamond or silicon carbide.

Another significant challenge is the temperature-dependent performance degradation of VCSELs. As junction temperatures rise, threshold current increases while slope efficiency and maximum output power decrease. This temperature sensitivity creates a negative feedback loop where efficiency losses generate more heat, further exacerbating thermal issues and accelerating device degradation.

For high-power applications, particularly in sensing, LiDAR, and data communications, thermal management becomes even more critical as devices are pushed to higher output powers and duty cycles. The thermal expansion coefficient mismatch between different materials in the VCSEL structure introduces mechanical stress during thermal cycling, potentially leading to reliability issues and premature device failure.

Conventional cooling approaches such as thermoelectric coolers add complexity, cost, and power consumption to VCSEL systems, making them impractical for many applications, particularly in mobile and consumer electronics where space and power budgets are constrained. Meanwhile, passive cooling solutions often provide insufficient heat dissipation for high-density arrays operating at elevated power levels.

The integration of effective thermal management solutions directly into the VCSEL manufacturing process presents additional challenges related to material compatibility, process complexity, and cost considerations. Advanced techniques such as flip-chip bonding to high thermal conductivity substrates show promise but introduce manufacturing complexities and yield concerns that must be addressed for volume production.

Current Co-Design Approaches for Thermal Management

01 Heat spreader designs for VCSEL thermal management

Various heat spreader designs can be implemented to efficiently dissipate heat from VCSELs. These include copper or diamond-based heat spreaders that can be directly attached to the VCSEL structure. The heat spreaders can be designed with specific geometries and materials to maximize thermal conductivity and heat dissipation from the active region of the VCSEL. Effective heat spreader designs help maintain optimal operating temperature, thereby improving VCSEL efficiency and extending device lifetime.- Heat spreader designs for VCSEL thermal management: Various heat spreader designs can be implemented to efficiently dissipate heat from VCSELs. These include specialized materials with high thermal conductivity, optimized geometries for maximum heat transfer, and multi-layer structures that direct heat away from the active region. Effective heat spreader designs can significantly reduce the operating temperature of VCSELs, improving their efficiency, reliability, and lifetime while maintaining stable emission characteristics.

- Integration of heat spreaders in VCSEL packaging: The integration of heat spreaders into VCSEL packaging involves techniques such as direct bonding, soldering, or embedding heat dissipation structures within the package. Advanced packaging approaches include flip-chip mounting on heat sinks, submount integration with thermal vias, and hermetically sealed packages with optimized thermal paths. These integration methods ensure efficient heat transfer from the VCSEL to the external environment while maintaining optical alignment and electrical connectivity.

- Novel materials for enhanced thermal conductivity: Advanced materials with superior thermal conductivity properties are being developed for VCSEL heat spreaders. These include diamond-based composites, copper-tungsten alloys, aluminum nitride ceramics, and carbon-based materials like graphene and carbon nanotubes. These materials offer significantly higher thermal conductivity compared to traditional options, enabling more efficient heat dissipation from VCSELs while maintaining electrical isolation where needed.

- Active cooling techniques for high-power VCSELs: Active cooling solutions are implemented for high-power VCSEL applications where passive heat spreading is insufficient. These include thermoelectric coolers integrated into VCSEL packages, microfluidic cooling channels for direct heat extraction, pulsed operation modes to reduce average heat generation, and advanced thermal management control systems. These active cooling approaches enable VCSELs to operate at higher power levels while maintaining temperature stability.

- Thermal simulation and optimization for VCSEL arrays: Computational modeling and simulation techniques are employed to optimize thermal management in VCSEL arrays. These include finite element analysis of heat flow, multi-physics simulations coupling optical, electrical, and thermal effects, and design optimization algorithms. These approaches enable the prediction of thermal bottlenecks, optimization of heat spreader geometries, and development of more efficient cooling strategies for high-density VCSEL arrays used in applications such as 3D sensing and LiDAR.

02 Integration of thermal management in VCSEL packaging

Advanced packaging techniques incorporate thermal management solutions directly into VCSEL packages. These include submounts with high thermal conductivity, integrated micro-channel cooling, and thermally optimized bonding materials. The packaging approaches focus on minimizing thermal resistance between the VCSEL and the heat sink, allowing for more efficient heat extraction. Proper thermal integration in packaging helps maintain stable operating conditions and improves overall VCSEL performance.Expand Specific Solutions03 Novel materials for enhanced thermal conductivity

Advanced materials with superior thermal properties are being utilized to improve heat dissipation in VCSEL devices. These include diamond composites, graphene layers, metal matrix composites, and specialized ceramic materials. The implementation of these thermally conductive materials in heat spreaders significantly reduces the thermal resistance path from the active region to the heat sink. This results in lower junction temperatures and improved device reliability under high-power operation.Expand Specific Solutions04 Active cooling techniques for high-power VCSEL arrays

For high-power VCSEL arrays, active cooling techniques are implemented to manage the substantial heat generation. These include thermoelectric coolers, micro-fluidic cooling channels, and forced convection systems integrated with heat spreaders. Active cooling solutions provide dynamic thermal management that can respond to changing operational conditions. These techniques are particularly important for maintaining temperature uniformity across large VCSEL arrays and preventing thermal crosstalk between elements.Expand Specific Solutions05 Thermal simulation and optimization for VCSEL design

Computational thermal modeling and simulation techniques are employed to optimize VCSEL thermal management before fabrication. These approaches include finite element analysis, computational fluid dynamics, and multi-physics simulations that account for electro-thermal interactions. Simulation-based optimization helps identify critical thermal bottlenecks and guides the design of more efficient heat spreader geometries and material combinations. This results in VCSELs with improved thermal performance and higher operational efficiency.Expand Specific Solutions

Key Industry Players in VCSEL Manufacturing

The co-design of VCSELs and heat spreaders for efficiency is currently in a growth phase, with the market expanding rapidly due to increasing applications in data communications, 3D sensing, and automotive LiDAR. The global market is projected to reach significant scale as thermal management becomes critical for VCSEL performance and reliability. Leading players like Lumentum, II-VI (Coherent), Apple, and ams-OSRAM are driving technological advancements, while research institutions such as Beijing University of Technology and North China Electric Power University contribute fundamental innovations. Asian manufacturers including LG Innotek and Shandong Huaguang Optoelectronics are gaining market share through cost-effective solutions. The technology is approaching maturity for current applications but continues to evolve for higher-power density requirements.

II-VI Delaware, Inc.

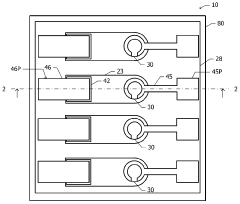

Technical Solution: II-VI Delaware has developed advanced thermal management solutions for VCSEL arrays that integrate diamond heat spreaders directly with the laser structure. Their approach involves using chemical vapor deposition (CVD) diamond as a submount material, which offers thermal conductivity up to 1500-2000 W/mK, approximately 3-5 times higher than copper. The company has pioneered a proprietary bonding technique that minimizes thermal boundary resistance between the VCSEL and diamond interface, enabling efficient heat extraction from the active region. Their designs incorporate microchannel cooling structures within the heat spreader to enhance thermal performance for high-power VCSEL arrays used in LiDAR and sensing applications. Recent developments include multi-layer heat spreading architectures that distribute heat more uniformly across larger arrays, preventing hotspot formation and extending device lifetime by maintaining more consistent junction temperatures across the entire array.

Strengths: Superior thermal conductivity of diamond materials provides exceptional heat dissipation; proprietary bonding techniques minimize interface thermal resistance; scalable for large VCSEL arrays. Weaknesses: Higher manufacturing costs compared to traditional materials; complex integration process requires specialized equipment; diamond material adds to overall device cost.

Lumentum Operations LLC

Technical Solution: Lumentum has developed a comprehensive co-design approach for VCSELs and heat spreaders focused on 3D sensing applications. Their technology integrates copper-tungsten composite heat spreaders with optimized thermal expansion coefficients matched to GaAs VCSEL structures. The company employs a multi-physics simulation platform that simultaneously models optical, electrical, and thermal behaviors to optimize device performance. Lumentum's proprietary "ThermaCore" technology incorporates micro-structured heat spreading layers directly into the VCSEL epitaxial structure, creating thermal pathways that channel heat away from the active region more efficiently. Their designs feature specialized submount geometries with integrated thermal vias that reduce thermal resistance by up to 40% compared to conventional designs. For high-power arrays, Lumentum implements active cooling solutions with miniaturized thermoelectric coolers (TECs) that maintain optimal operating temperatures even under extreme duty cycles.

Strengths: Integrated approach addressing both optical and thermal design simultaneously; proven technology deployed in millions of consumer devices; excellent reliability metrics with minimal performance degradation over time. Weaknesses: Higher initial design complexity requires extensive simulation; some solutions may increase manufacturing steps and costs; active cooling components increase power consumption.

Critical Patents in VCSEL Thermal Solution Integration

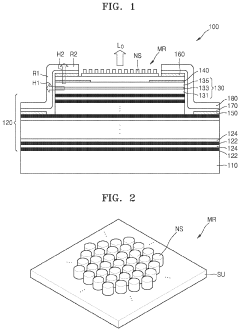

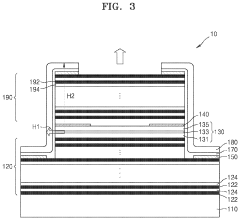

Vertical cavity surface emitting laser including meta structure reflector and optical device including the vertical cavity surface emitting laser

PatentActiveUS20210159670A1

Innovation

- Incorporating a meta structure reflector with nanostructures of sub-wavelength dimensions and a heat sink to efficiently dissipate heat generated by the gain layer, while maintaining high reflectance for light emission.

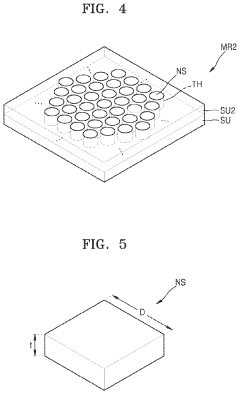

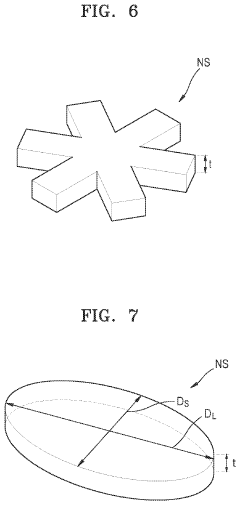

Vertical cavity surface emitting laser

PatentWO2023238428A1

Innovation

- A VCSEL design incorporating a heat transfer member with a high thermal conductivity portion and a restraining portion, where the high thermal conductivity portion has a larger linear expansion coefficient than the semiconductor layer, and the restraining portion has a smaller coefficient, along with penetrating portions that extend from the heat transfer member to the bottom of the mesa structure, to manage thermal stress and enhance heat dissipation.

Materials Science Advancements for Next-Generation Heat Spreaders

Recent advancements in materials science have opened new frontiers for heat spreader technologies critical to VCSEL (Vertical-Cavity Surface-Emitting Laser) thermal management. Traditional materials like copper and aluminum, while effective, have reached their theoretical limits in thermal conductivity and weight-to-performance ratios. The emergence of novel materials represents a paradigm shift in heat dissipation capabilities essential for next-generation VCSEL applications.

Carbon-based materials, particularly synthetic diamond and graphene, demonstrate exceptional thermal conductivity values exceeding 2000 W/m·K, significantly outperforming conventional copper (400 W/m·K). Diamond heat spreaders, though expensive, offer unparalleled thermal performance for high-power VCSEL arrays where efficiency is paramount. Graphene and its derivatives present a promising alternative with their two-dimensional structure facilitating directional heat flow away from active VCSEL regions.

Composite materials combining metallic matrices with ceramic or carbon reinforcements have emerged as cost-effective solutions balancing thermal performance and manufacturability. Aluminum-silicon carbide (Al-SiC) and copper-diamond composites provide tailored coefficient of thermal expansion (CTE) values that can be matched to VCSEL substrates, minimizing thermomechanical stress during operation cycles.

Nano-engineered materials represent the cutting edge of heat spreader development. Phase change materials (PCMs) incorporated into nano-structured matrices can absorb thermal energy during peak operation, releasing it during idle periods to maintain stable temperatures. Additionally, metamaterials with engineered thermal pathways can direct heat flow with unprecedented precision, creating optimized thermal channels away from sensitive VCSEL components.

Additive manufacturing techniques have revolutionized heat spreader design possibilities, enabling complex three-dimensional structures with internal cooling channels impossible to produce through traditional manufacturing methods. These structures can be specifically tailored to VCSEL geometries, creating integrated cooling solutions that maximize surface area while minimizing material volume.

Thin-film deposition technologies allow for atomic-level precision in creating multi-layered heat spreading structures directly integrated with VCSEL fabrication processes. These nanometer-scale thermal interface materials significantly reduce contact resistance, often the limiting factor in overall thermal management efficiency.

The integration of these advanced materials into practical VCSEL thermal management solutions requires interdisciplinary collaboration between materials scientists, thermal engineers, and optoelectronic specialists. The co-design approach, considering both VCSEL operational parameters and heat spreader material properties simultaneously, represents the most promising path toward achieving the efficiency levels required for emerging applications in data communications, sensing, and consumer electronics.

Carbon-based materials, particularly synthetic diamond and graphene, demonstrate exceptional thermal conductivity values exceeding 2000 W/m·K, significantly outperforming conventional copper (400 W/m·K). Diamond heat spreaders, though expensive, offer unparalleled thermal performance for high-power VCSEL arrays where efficiency is paramount. Graphene and its derivatives present a promising alternative with their two-dimensional structure facilitating directional heat flow away from active VCSEL regions.

Composite materials combining metallic matrices with ceramic or carbon reinforcements have emerged as cost-effective solutions balancing thermal performance and manufacturability. Aluminum-silicon carbide (Al-SiC) and copper-diamond composites provide tailored coefficient of thermal expansion (CTE) values that can be matched to VCSEL substrates, minimizing thermomechanical stress during operation cycles.

Nano-engineered materials represent the cutting edge of heat spreader development. Phase change materials (PCMs) incorporated into nano-structured matrices can absorb thermal energy during peak operation, releasing it during idle periods to maintain stable temperatures. Additionally, metamaterials with engineered thermal pathways can direct heat flow with unprecedented precision, creating optimized thermal channels away from sensitive VCSEL components.

Additive manufacturing techniques have revolutionized heat spreader design possibilities, enabling complex three-dimensional structures with internal cooling channels impossible to produce through traditional manufacturing methods. These structures can be specifically tailored to VCSEL geometries, creating integrated cooling solutions that maximize surface area while minimizing material volume.

Thin-film deposition technologies allow for atomic-level precision in creating multi-layered heat spreading structures directly integrated with VCSEL fabrication processes. These nanometer-scale thermal interface materials significantly reduce contact resistance, often the limiting factor in overall thermal management efficiency.

The integration of these advanced materials into practical VCSEL thermal management solutions requires interdisciplinary collaboration between materials scientists, thermal engineers, and optoelectronic specialists. The co-design approach, considering both VCSEL operational parameters and heat spreader material properties simultaneously, represents the most promising path toward achieving the efficiency levels required for emerging applications in data communications, sensing, and consumer electronics.

Environmental Impact and Sustainability Considerations

The environmental impact of VCSEL and heat spreader co-design extends far beyond performance metrics, touching critical sustainability considerations that modern technology development cannot ignore. As global regulations on electronic waste and carbon emissions tighten, manufacturers must evaluate the complete environmental footprint of these photonic devices throughout their lifecycle.

Material selection represents a primary environmental concern in VCSEL and heat spreader design. Traditional heat spreaders often incorporate metals with significant extraction impacts, such as copper and aluminum, whose mining operations contribute to habitat destruction and water pollution. Advanced co-design approaches are increasingly exploring alternatives like carbon-based materials, including graphene and carbon nanotubes, which potentially offer lower environmental impact while maintaining thermal performance.

Energy consumption during manufacturing presents another substantial environmental consideration. The production of VCSELs typically involves energy-intensive processes including epitaxial growth and clean room operations. Co-designed systems that optimize thermal management can reduce the rejection rate during manufacturing, thereby decreasing the energy and resources expended per functional device. This efficiency improvement translates directly to reduced carbon emissions across the production chain.

Operational efficiency gains from co-designed VCSEL and heat spreader systems deliver significant sustainability benefits during device use. By maintaining optimal operating temperatures, these systems extend device lifespan, reducing electronic waste generation. Additionally, improved thermal management allows VCSELs to operate at higher efficiency levels, consuming less power for the same optical output and consequently reducing the carbon footprint of applications ranging from data centers to consumer electronics.

End-of-life considerations must also factor into co-design strategies. The integration of heat spreaders with VCSELs can complicate disassembly and material recovery processes. Forward-thinking designs incorporate principles of circular economy by facilitating component separation and material reclamation. Some innovative approaches include designing for disassembly and selecting materials with established recycling pathways.

Water usage represents an often-overlooked environmental impact in semiconductor manufacturing. VCSEL production requires significant quantities of ultra-pure water for cleaning processes. Co-design strategies that improve manufacturing yield effectively reduce water consumption per functional device, contributing to water conservation efforts particularly in water-stressed regions where manufacturing facilities may operate.

Material selection represents a primary environmental concern in VCSEL and heat spreader design. Traditional heat spreaders often incorporate metals with significant extraction impacts, such as copper and aluminum, whose mining operations contribute to habitat destruction and water pollution. Advanced co-design approaches are increasingly exploring alternatives like carbon-based materials, including graphene and carbon nanotubes, which potentially offer lower environmental impact while maintaining thermal performance.

Energy consumption during manufacturing presents another substantial environmental consideration. The production of VCSELs typically involves energy-intensive processes including epitaxial growth and clean room operations. Co-designed systems that optimize thermal management can reduce the rejection rate during manufacturing, thereby decreasing the energy and resources expended per functional device. This efficiency improvement translates directly to reduced carbon emissions across the production chain.

Operational efficiency gains from co-designed VCSEL and heat spreader systems deliver significant sustainability benefits during device use. By maintaining optimal operating temperatures, these systems extend device lifespan, reducing electronic waste generation. Additionally, improved thermal management allows VCSELs to operate at higher efficiency levels, consuming less power for the same optical output and consequently reducing the carbon footprint of applications ranging from data centers to consumer electronics.

End-of-life considerations must also factor into co-design strategies. The integration of heat spreaders with VCSELs can complicate disassembly and material recovery processes. Forward-thinking designs incorporate principles of circular economy by facilitating component separation and material reclamation. Some innovative approaches include designing for disassembly and selecting materials with established recycling pathways.

Water usage represents an often-overlooked environmental impact in semiconductor manufacturing. VCSEL production requires significant quantities of ultra-pure water for cleaning processes. Co-design strategies that improve manufacturing yield effectively reduce water consumption per functional device, contributing to water conservation efforts particularly in water-stressed regions where manufacturing facilities may operate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!