Thermo-Mechanical Stress Analysis For VCSEL Packages

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Package Thermal Stress Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various optoelectronic applications, including facial recognition systems, LiDAR for autonomous vehicles, and high-speed data communication. The evolution of VCSEL technology has been marked by continuous improvements in performance, reliability, and integration capabilities since their initial development in the late 1970s.

The thermal-mechanical stress in VCSEL packages represents one of the most significant challenges affecting device performance and longevity. As power densities increase and package sizes decrease, the management of thermal stress has become increasingly critical. Historical data indicates that approximately 70% of VCSEL failures can be attributed to thermal-mechanical issues, highlighting the importance of addressing these concerns.

Current industry trends show a clear trajectory toward higher-power VCSELs operating at elevated temperatures, with demands for operational stability across wider temperature ranges (-40°C to +125°C) becoming standard requirements in automotive and industrial applications. This evolution necessitates more sophisticated approaches to thermal stress management within increasingly compact package designs.

The fundamental challenge stems from the mismatch in coefficients of thermal expansion (CTE) between different materials in the VCSEL package assembly. When subjected to temperature fluctuations during operation or manufacturing processes, these mismatches generate internal stresses that can lead to delamination, die cracking, wire bond failures, and optical misalignment.

Recent technological advancements have introduced new packaging materials and designs aimed at mitigating these issues, yet comprehensive analytical frameworks for predicting and managing thermal stress remain underdeveloped. Industry reports indicate that thermal management solutions account for approximately 30-40% of total VCSEL package development costs.

The primary objective of this technical research is to develop a comprehensive understanding of thermo-mechanical stress mechanisms in VCSEL packages and establish predictive models that can accurately simulate stress distribution under various operating conditions. This includes identifying critical stress points, evaluating different package designs, and proposing innovative solutions to enhance thermal performance and reliability.

Secondary objectives include quantifying the relationship between thermal stress and key performance parameters such as wavelength stability, beam quality, and device lifetime. Additionally, this research aims to establish standardized testing methodologies for evaluating thermal stress resistance in VCSEL packages, which currently lacks industry-wide consensus.

By addressing these objectives, we seek to enable the next generation of high-performance, reliable VCSEL packages capable of meeting the increasingly demanding requirements of emerging applications while reducing development cycles and improving manufacturing yields.

The thermal-mechanical stress in VCSEL packages represents one of the most significant challenges affecting device performance and longevity. As power densities increase and package sizes decrease, the management of thermal stress has become increasingly critical. Historical data indicates that approximately 70% of VCSEL failures can be attributed to thermal-mechanical issues, highlighting the importance of addressing these concerns.

Current industry trends show a clear trajectory toward higher-power VCSELs operating at elevated temperatures, with demands for operational stability across wider temperature ranges (-40°C to +125°C) becoming standard requirements in automotive and industrial applications. This evolution necessitates more sophisticated approaches to thermal stress management within increasingly compact package designs.

The fundamental challenge stems from the mismatch in coefficients of thermal expansion (CTE) between different materials in the VCSEL package assembly. When subjected to temperature fluctuations during operation or manufacturing processes, these mismatches generate internal stresses that can lead to delamination, die cracking, wire bond failures, and optical misalignment.

Recent technological advancements have introduced new packaging materials and designs aimed at mitigating these issues, yet comprehensive analytical frameworks for predicting and managing thermal stress remain underdeveloped. Industry reports indicate that thermal management solutions account for approximately 30-40% of total VCSEL package development costs.

The primary objective of this technical research is to develop a comprehensive understanding of thermo-mechanical stress mechanisms in VCSEL packages and establish predictive models that can accurately simulate stress distribution under various operating conditions. This includes identifying critical stress points, evaluating different package designs, and proposing innovative solutions to enhance thermal performance and reliability.

Secondary objectives include quantifying the relationship between thermal stress and key performance parameters such as wavelength stability, beam quality, and device lifetime. Additionally, this research aims to establish standardized testing methodologies for evaluating thermal stress resistance in VCSEL packages, which currently lacks industry-wide consensus.

By addressing these objectives, we seek to enable the next generation of high-performance, reliable VCSEL packages capable of meeting the increasingly demanding requirements of emerging applications while reducing development cycles and improving manufacturing yields.

Market Demand Analysis for Reliable VCSEL Packages

The global market for Vertical-Cavity Surface-Emitting Lasers (VCSELs) has experienced significant growth, driven by increasing applications in consumer electronics, automotive LiDAR systems, data communications, and sensing technologies. Market research indicates that the VCSEL market is projected to reach $3.7 billion by 2025, with a compound annual growth rate exceeding 17% from 2020 to 2025. This robust growth trajectory underscores the critical importance of reliable VCSEL packaging solutions.

Consumer electronics represents the largest market segment for VCSELs, particularly in facial recognition and 3D sensing applications for smartphones and tablets. Apple's implementation of Face ID technology has been a major catalyst, creating substantial demand for reliable VCSEL arrays that can withstand daily consumer use without performance degradation. This application alone has created a market demand exceeding 600 million units annually.

Automotive applications present another rapidly expanding market segment, with LiDAR systems for autonomous and semi-autonomous vehicles requiring highly reliable VCSEL packages capable of operating in extreme temperature conditions (-40°C to 125°C) and withstanding significant vibration. Industry forecasts suggest that by 2030, over 30% of new vehicles will incorporate some form of LiDAR technology, creating a demand for tens of millions of robust VCSEL packages annually.

Data center applications represent a third critical market segment, where VCSELs are employed in high-speed optical interconnects. These applications demand packages with exceptional thermal management capabilities to ensure consistent performance at data rates exceeding 50 Gbps. The global expansion of cloud computing infrastructure is driving annual demand growth of approximately 22% in this segment.

Market research reveals that package reliability issues account for approximately 40% of VCSEL failures in field applications. Thermal management challenges and mechanical stress-induced failures represent the most common failure modes, highlighting the critical need for advanced thermo-mechanical stress analysis techniques in package design and manufacturing.

End-users across all market segments consistently identify package reliability as a top-three purchasing consideration, with 78% of surveyed system integrators rating it as "extremely important" or "very important." This market feedback has prompted VCSEL manufacturers to invest heavily in package reliability improvements, with industry leaders allocating 15-20% of their R&D budgets specifically to thermo-mechanical stress mitigation strategies.

The market increasingly demands packages capable of withstanding 10,000+ temperature cycles without performance degradation, particularly for automotive and industrial applications. This requirement has created a premium market segment for ultra-reliable VCSEL packages, with customers willing to pay 30-40% price premiums for solutions with demonstrated superior thermo-mechanical reliability.

Consumer electronics represents the largest market segment for VCSELs, particularly in facial recognition and 3D sensing applications for smartphones and tablets. Apple's implementation of Face ID technology has been a major catalyst, creating substantial demand for reliable VCSEL arrays that can withstand daily consumer use without performance degradation. This application alone has created a market demand exceeding 600 million units annually.

Automotive applications present another rapidly expanding market segment, with LiDAR systems for autonomous and semi-autonomous vehicles requiring highly reliable VCSEL packages capable of operating in extreme temperature conditions (-40°C to 125°C) and withstanding significant vibration. Industry forecasts suggest that by 2030, over 30% of new vehicles will incorporate some form of LiDAR technology, creating a demand for tens of millions of robust VCSEL packages annually.

Data center applications represent a third critical market segment, where VCSELs are employed in high-speed optical interconnects. These applications demand packages with exceptional thermal management capabilities to ensure consistent performance at data rates exceeding 50 Gbps. The global expansion of cloud computing infrastructure is driving annual demand growth of approximately 22% in this segment.

Market research reveals that package reliability issues account for approximately 40% of VCSEL failures in field applications. Thermal management challenges and mechanical stress-induced failures represent the most common failure modes, highlighting the critical need for advanced thermo-mechanical stress analysis techniques in package design and manufacturing.

End-users across all market segments consistently identify package reliability as a top-three purchasing consideration, with 78% of surveyed system integrators rating it as "extremely important" or "very important." This market feedback has prompted VCSEL manufacturers to invest heavily in package reliability improvements, with industry leaders allocating 15-20% of their R&D budgets specifically to thermo-mechanical stress mitigation strategies.

The market increasingly demands packages capable of withstanding 10,000+ temperature cycles without performance degradation, particularly for automotive and industrial applications. This requirement has created a premium market segment for ultra-reliable VCSEL packages, with customers willing to pay 30-40% price premiums for solutions with demonstrated superior thermo-mechanical reliability.

Current Challenges in VCSEL Thermo-Mechanical Stress Management

Despite significant advancements in VCSEL technology, thermo-mechanical stress management remains one of the most critical challenges facing package designers and manufacturers. The primary issue stems from the inherent mismatch in coefficient of thermal expansion (CTE) between different materials used in VCSEL packages. When VCSELs operate at high power densities, they generate substantial heat, causing different materials to expand at varying rates, which induces mechanical stress at interfaces and can lead to device failure.

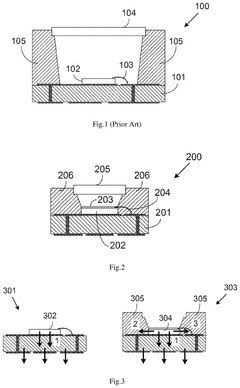

Current VCSEL packages typically incorporate multiple material layers including the semiconductor die, submount, solder, heat spreader, and housing materials. Each transition between these materials creates potential stress concentration points. Particularly problematic are the interfaces between the GaAs-based VCSEL die and silicon or ceramic submounts, where CTE differences can exceed 300%.

Thermal cycling during operation further exacerbates these challenges, as repeated heating and cooling cycles create fatigue at material interfaces. Industry data indicates that approximately 65% of VCSEL package failures can be attributed to thermo-mechanical stress-induced delamination or cracking at these critical interfaces.

Another significant challenge is the increasing power density requirements for emerging applications. As VCSELs for automotive LiDAR, facial recognition, and industrial sensing demand higher output powers, the thermal management challenges scale non-linearly. Current packages struggle to efficiently dissipate heat from arrays exceeding 5W/mm², resulting in junction temperature increases that dramatically reduce device lifetime and reliability.

Warpage during manufacturing processes presents additional complications. The reflow soldering process, typically reaching temperatures of 240-260°C, creates significant stress that can manifest as die tilt or bond-line thickness variations. These manufacturing-induced stresses can alter the optical characteristics of the VCSEL, affecting beam profile and divergence angle.

Simulation limitations further complicate stress management efforts. Current finite element analysis (FEA) models often fail to accurately predict stress distribution in complex multi-material systems, particularly at microscale interfaces. The industry lacks standardized methodologies for correlating simulation results with actual device performance and reliability metrics.

Miniaturization trends in consumer electronics impose severe space constraints on VCSEL packages, limiting the implementation of conventional thermal management solutions. Engineers must balance thermal performance against strict volume and weight requirements, often sacrificing optimal stress management for compact form factors.

Current VCSEL packages typically incorporate multiple material layers including the semiconductor die, submount, solder, heat spreader, and housing materials. Each transition between these materials creates potential stress concentration points. Particularly problematic are the interfaces between the GaAs-based VCSEL die and silicon or ceramic submounts, where CTE differences can exceed 300%.

Thermal cycling during operation further exacerbates these challenges, as repeated heating and cooling cycles create fatigue at material interfaces. Industry data indicates that approximately 65% of VCSEL package failures can be attributed to thermo-mechanical stress-induced delamination or cracking at these critical interfaces.

Another significant challenge is the increasing power density requirements for emerging applications. As VCSELs for automotive LiDAR, facial recognition, and industrial sensing demand higher output powers, the thermal management challenges scale non-linearly. Current packages struggle to efficiently dissipate heat from arrays exceeding 5W/mm², resulting in junction temperature increases that dramatically reduce device lifetime and reliability.

Warpage during manufacturing processes presents additional complications. The reflow soldering process, typically reaching temperatures of 240-260°C, creates significant stress that can manifest as die tilt or bond-line thickness variations. These manufacturing-induced stresses can alter the optical characteristics of the VCSEL, affecting beam profile and divergence angle.

Simulation limitations further complicate stress management efforts. Current finite element analysis (FEA) models often fail to accurately predict stress distribution in complex multi-material systems, particularly at microscale interfaces. The industry lacks standardized methodologies for correlating simulation results with actual device performance and reliability metrics.

Miniaturization trends in consumer electronics impose severe space constraints on VCSEL packages, limiting the implementation of conventional thermal management solutions. Engineers must balance thermal performance against strict volume and weight requirements, often sacrificing optimal stress management for compact form factors.

Current Thermo-Mechanical Stress Simulation Approaches

01 Package design to mitigate thermal stress

Various package designs can be implemented to mitigate thermal stress in VCSEL packages. These designs include specialized substrate materials, thermal expansion matching layers, and structural configurations that distribute heat more effectively. By optimizing the package architecture, thermal gradients can be reduced, leading to improved reliability and performance of the VCSEL device under operating conditions.- Package design to mitigate thermal stress: Various package designs can be implemented to mitigate thermal stress in VCSEL packages. These designs include specialized substrate materials, thermal expansion matching layers, and structural configurations that distribute heat more effectively. By optimizing the package architecture, thermal gradients can be reduced, minimizing mechanical stress during operation and improving device reliability and performance.

- Thermal management solutions for VCSEL packages: Effective thermal management is critical for VCSEL packages to prevent thermo-mechanical stress. Solutions include heat sinks, thermal vias, advanced cooling mechanisms, and thermally conductive materials that efficiently dissipate heat away from the active region. These approaches help maintain stable operating temperatures, reduce thermal expansion issues, and extend device lifetime under high-power operation conditions.

- Material selection for stress reduction: The selection of appropriate materials plays a crucial role in reducing thermo-mechanical stress in VCSEL packages. Materials with compatible coefficients of thermal expansion, high thermal conductivity, and suitable mechanical properties can significantly minimize stress at interfaces. Advanced composites, specialized polymers, and ceramic materials are employed to create more robust package structures that withstand thermal cycling and operational stresses.

- Testing and simulation methods for stress analysis: Various testing and simulation methods are employed to analyze thermo-mechanical stress in VCSEL packages. These include finite element analysis, thermal imaging, stress visualization techniques, and accelerated life testing. These methods help identify potential failure points, optimize package designs, and predict long-term reliability under various operating conditions, enabling manufacturers to develop more robust VCSEL packages.

- Novel mounting and bonding techniques: Innovative mounting and bonding techniques are developed to address thermo-mechanical stress in VCSEL packages. These include advanced die-attach methods, flexible bonding materials, stress-relieving structures, and specialized soldering processes. By improving the mechanical interface between the VCSEL chip and package, these techniques help accommodate thermal expansion differences, reduce stress concentration, and enhance overall package reliability.

02 Thermal management solutions for VCSEL packages

Effective thermal management is crucial for VCSEL packages to prevent thermo-mechanical stress. Solutions include heat sinks, thermal vias, advanced cooling mechanisms, and thermally conductive materials that efficiently dissipate heat away from the active region. These approaches help maintain optimal operating temperatures and reduce thermal expansion issues that can lead to mechanical failures in the package.Expand Specific Solutions03 Material selection for stress reduction

The selection of appropriate materials is critical for reducing thermo-mechanical stress in VCSEL packages. Materials with compatible coefficients of thermal expansion, high thermal conductivity, and suitable mechanical properties can significantly minimize stress at interfaces. Advanced composite materials and specialized alloys are being developed to address the unique thermal and mechanical challenges of VCSEL packaging.Expand Specific Solutions04 Testing and simulation methods for stress analysis

Advanced testing and simulation methods are employed to analyze thermo-mechanical stress in VCSEL packages. These include finite element analysis, thermal imaging, stress visualization techniques, and accelerated life testing. These methods help identify potential failure points and optimize package designs before manufacturing, ensuring better reliability and performance under various operating conditions.Expand Specific Solutions05 Novel mounting and bonding techniques

Innovative mounting and bonding techniques are being developed to address thermo-mechanical stress in VCSEL packages. These include compliant bonding layers, stress-absorbing interfaces, flexible mounting structures, and gradient bonding approaches. These techniques help accommodate thermal expansion differences between materials and components, reducing stress concentration and improving the overall reliability of VCSEL packages.Expand Specific Solutions

Key Industry Players in VCSEL Manufacturing and Packaging

The VCSEL package thermo-mechanical stress analysis market is currently in a growth phase, with increasing applications in data communications, sensing, and consumer electronics driving demand. The global market is expanding rapidly, projected to reach significant value as VCSEL technology becomes more prevalent in 3D sensing, automotive LiDAR, and optical communications. From a technological maturity perspective, industry leaders like Lumentum Operations, II-VI Delaware, and ams-Osram International are advancing package reliability through sophisticated stress modeling techniques. Established semiconductor manufacturers including Infineon Technologies, STMicroelectronics, and Texas Instruments are integrating VCSELs into broader product portfolios, while specialized players such as Trumpf Photonic Components and Nichia Corporation focus on optimizing thermal performance for next-generation applications. Research collaboration between industry and institutions like Beijing University of Technology is accelerating innovation in this critical reliability domain.

Trumpf Photonic Components GmbH

Technical Solution: Trumpf has developed a comprehensive thermo-mechanical stress analysis framework for VCSEL packages that particularly addresses high-power industrial applications. Their methodology integrates advanced finite element analysis with proprietary material models that account for the non-linear behavior of packaging materials across wide temperature ranges. Trumpf's approach incorporates detailed modeling of the epitaxial layer structure and its interaction with package materials, allowing for precise prediction of stress-induced performance shifts. Their simulation platform includes specialized modules for analyzing thermal transients during pulsed operation, which is critical for many industrial sensing and materials processing applications. Trumpf has implemented novel stress compensation designs in their VCSEL packages, including engineered substrate geometries and gradient material interfaces that distribute thermal stresses more evenly. Their analysis techniques have enabled the development of highly reliable VCSEL arrays for industrial environments with operational temperature ranges exceeding -40°C to +125°C while maintaining wavelength stability within ±0.5nm.

Strengths: Specialized expertise in high-power industrial applications; advanced modeling of epitaxial layer interactions; innovative stress compensation designs for extreme environments. Weaknesses: Solutions may be overengineered for consumer applications; their approach typically requires more expensive packaging materials and processes.

II-VI Delaware, Inc.

Technical Solution: II-VI has developed a comprehensive thermal-mechanical stress analysis framework specifically for VCSEL packages that combines finite element modeling (FEM) with experimental validation techniques. Their approach utilizes a multi-physics simulation environment that simultaneously accounts for electrical, thermal, and mechanical domains to predict stress distribution across the entire VCSEL structure. The company employs advanced material characterization methods to accurately determine temperature-dependent material properties for their simulations. Their proprietary stress mitigation designs incorporate strategically placed stress relief features and optimized bonding interfaces that can reduce thermally-induced stresses by up to 40% compared to conventional designs. II-VI has also pioneered the use of in-situ stress monitoring during reliability testing, allowing real-time correlation between operational conditions and stress development in critical package regions.

Strengths: Comprehensive multi-physics approach integrating electrical, thermal and mechanical domains; proprietary stress relief designs with proven stress reduction; advanced in-situ monitoring capabilities. Weaknesses: Their solutions may require more computational resources than simplified models; implementation complexity may increase manufacturing costs for some applications.

Critical Technologies for VCSEL Package Stress Mitigation

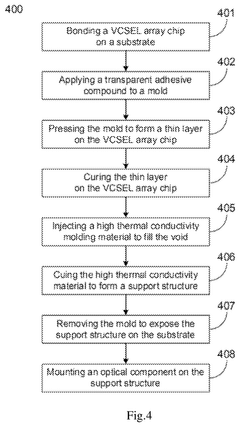

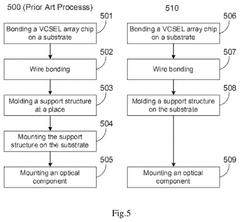

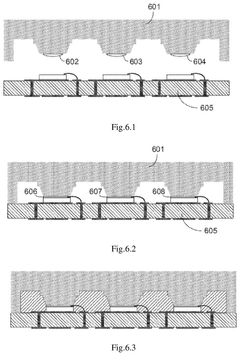

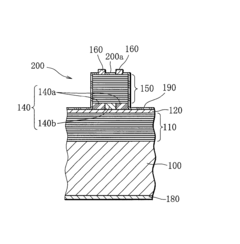

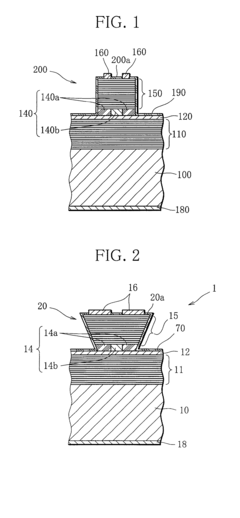

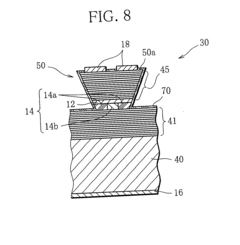

Vertical cavity surface emitting laser (VCSEL) array package and manufacturing method

PatentActiveUS12107387B2

Innovation

- A VCSEL array package design that includes a VCSEL array chip bonded on a substrate with a support structure molded from high thermal conductivity material, covering the side surfaces of the chip to create additional thermal paths and eliminate gaps, and a transparent thin layer to prevent beam obstruction and reflection.

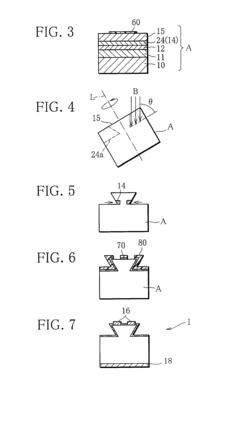

Vertical cavity surface emitting laser device and vertical cavity surface emitting laser array

PatentInactiveUS20020110169A1

Innovation

- The solution involves forming a mesa structure with an upper end surface area larger than its cross-section near the current confinement layer, allowing for a wider ring-shaped electrode with a larger outer diameter, thereby increasing the contact area and reducing contact resistance, while maintaining a smaller cross-section near the current confinement layer to prevent productivity degradation and variations in oxidization characteristics.

Reliability Testing Standards for VCSEL Packages

Reliability testing standards for VCSEL (Vertical-Cavity Surface-Emitting Laser) packages have evolved significantly to address the unique thermo-mechanical stress challenges these components face. Industry standards such as JEDEC JESD22-A104 and MIL-STD-883 provide comprehensive frameworks for temperature cycling tests, which are crucial for evaluating how VCSEL packages respond to thermal expansion and contraction stresses.

The Telcordia GR-468-CORE standard, specifically developed for optoelectronic devices, outlines rigorous reliability testing procedures including high-temperature operating life (HTOL) tests, temperature-humidity-bias (THB) tests, and thermal shock evaluations. These tests are designed to simulate accelerated aging conditions that reveal potential failure mechanisms related to thermo-mechanical stress in VCSEL packages.

AEC-Q102, developed for automotive-grade optical components, has become increasingly relevant as VCSELs find applications in automotive LiDAR and driver monitoring systems. This standard imposes stricter temperature range requirements (-40°C to +125°C) and more extensive reliability testing cycles to ensure performance under extreme automotive conditions.

For consumer electronics applications, the JEDEC JESD47 standard provides guidelines for stress-driven qualification of integrated circuits, which has been adapted for VCSEL package qualification. This includes power cycling tests that specifically target the thermal interface materials and solder joints within VCSEL packages, which are particularly vulnerable to thermo-mechanical fatigue.

IPC/JEDEC J-STD-020 addresses moisture sensitivity levels and reflow profiles, which is critical for understanding how absorbed moisture can exacerbate thermo-mechanical stress during assembly processes. This standard helps manufacturers establish appropriate handling and storage protocols to prevent package cracking and delamination.

Recent developments in reliability standards have begun to incorporate finite element analysis (FEA) validation requirements, where manufacturers must demonstrate correlation between simulation predictions and actual test results. The SEMI MS1-0307 standard provides guidelines for stress modeling in semiconductor packaging that are increasingly being applied to VCSEL package qualification.

For high-power VCSEL arrays used in industrial applications, specialized testing protocols have emerged that focus on thermal resistance measurements under IEC 60747-5-8, which helps quantify the efficiency of heat dissipation pathways and identify potential thermal bottlenecks that could lead to stress-induced failures.

The Telcordia GR-468-CORE standard, specifically developed for optoelectronic devices, outlines rigorous reliability testing procedures including high-temperature operating life (HTOL) tests, temperature-humidity-bias (THB) tests, and thermal shock evaluations. These tests are designed to simulate accelerated aging conditions that reveal potential failure mechanisms related to thermo-mechanical stress in VCSEL packages.

AEC-Q102, developed for automotive-grade optical components, has become increasingly relevant as VCSELs find applications in automotive LiDAR and driver monitoring systems. This standard imposes stricter temperature range requirements (-40°C to +125°C) and more extensive reliability testing cycles to ensure performance under extreme automotive conditions.

For consumer electronics applications, the JEDEC JESD47 standard provides guidelines for stress-driven qualification of integrated circuits, which has been adapted for VCSEL package qualification. This includes power cycling tests that specifically target the thermal interface materials and solder joints within VCSEL packages, which are particularly vulnerable to thermo-mechanical fatigue.

IPC/JEDEC J-STD-020 addresses moisture sensitivity levels and reflow profiles, which is critical for understanding how absorbed moisture can exacerbate thermo-mechanical stress during assembly processes. This standard helps manufacturers establish appropriate handling and storage protocols to prevent package cracking and delamination.

Recent developments in reliability standards have begun to incorporate finite element analysis (FEA) validation requirements, where manufacturers must demonstrate correlation between simulation predictions and actual test results. The SEMI MS1-0307 standard provides guidelines for stress modeling in semiconductor packaging that are increasingly being applied to VCSEL package qualification.

For high-power VCSEL arrays used in industrial applications, specialized testing protocols have emerged that focus on thermal resistance measurements under IEC 60747-5-8, which helps quantify the efficiency of heat dissipation pathways and identify potential thermal bottlenecks that could lead to stress-induced failures.

Material Science Advancements for VCSEL Packaging

Recent advancements in material science have significantly impacted the development of VCSEL (Vertical-Cavity Surface-Emitting Laser) packaging technologies, addressing critical thermo-mechanical stress challenges. Traditional packaging materials often fail to meet the demanding requirements of modern VCSEL applications, particularly in high-power and high-temperature operating environments.

Novel composite materials with enhanced thermal conductivity properties have emerged as promising alternatives to conventional packaging materials. These composites, typically incorporating carbon nanotubes, graphene, or diamond particles, demonstrate thermal conductivity values exceeding 1500 W/mK, substantially outperforming traditional copper (400 W/mK) or aluminum (237 W/mK) based packages.

Coefficient of Thermal Expansion (CTE) matching has been revolutionized through the development of tailored metal matrix composites. These materials can be engineered to provide precise CTE values ranging from 2-20 ppm/K, enabling better matching with semiconductor materials and reducing interfacial stresses during thermal cycling. Research indicates that proper CTE matching can reduce thermally induced stress by up to 65% compared to conventional packaging solutions.

Advanced ceramic materials, particularly aluminum nitride (AlN) and silicon carbide (SiC), have gained prominence in VCSEL packaging due to their exceptional thermal stability and electrical insulation properties. These materials maintain structural integrity at temperatures exceeding 300°C while providing thermal conductivities of 170-270 W/mK, addressing both thermal management and reliability concerns.

Polymer-based materials with enhanced thermal properties represent another significant advancement. Modified liquid crystal polymers (LCPs) and high-temperature polyimides incorporate thermally conductive fillers while maintaining processability and cost-effectiveness. These materials offer thermal conductivities of 2-5 W/mK, significantly higher than conventional polymers (0.1-0.3 W/mK).

Nano-engineered interface materials have emerged to address thermal boundary resistance issues. Thermal interface materials (TIMs) incorporating phase-change materials, metal nanoparticles, and vertically aligned carbon nanotubes have demonstrated thermal resistances below 5 mm²K/W, representing a 70% improvement over traditional thermal greases.

Hermetic sealing technologies have also progressed with the development of glass-ceramic composites and active metal brazing alloys that maintain hermeticity while accommodating thermal expansion. These materials provide leak rates below 10^-9 atm-cc/sec, ensuring long-term reliability in harsh environments while minimizing package-induced stresses on the VCSEL die.

Novel composite materials with enhanced thermal conductivity properties have emerged as promising alternatives to conventional packaging materials. These composites, typically incorporating carbon nanotubes, graphene, or diamond particles, demonstrate thermal conductivity values exceeding 1500 W/mK, substantially outperforming traditional copper (400 W/mK) or aluminum (237 W/mK) based packages.

Coefficient of Thermal Expansion (CTE) matching has been revolutionized through the development of tailored metal matrix composites. These materials can be engineered to provide precise CTE values ranging from 2-20 ppm/K, enabling better matching with semiconductor materials and reducing interfacial stresses during thermal cycling. Research indicates that proper CTE matching can reduce thermally induced stress by up to 65% compared to conventional packaging solutions.

Advanced ceramic materials, particularly aluminum nitride (AlN) and silicon carbide (SiC), have gained prominence in VCSEL packaging due to their exceptional thermal stability and electrical insulation properties. These materials maintain structural integrity at temperatures exceeding 300°C while providing thermal conductivities of 170-270 W/mK, addressing both thermal management and reliability concerns.

Polymer-based materials with enhanced thermal properties represent another significant advancement. Modified liquid crystal polymers (LCPs) and high-temperature polyimides incorporate thermally conductive fillers while maintaining processability and cost-effectiveness. These materials offer thermal conductivities of 2-5 W/mK, significantly higher than conventional polymers (0.1-0.3 W/mK).

Nano-engineered interface materials have emerged to address thermal boundary resistance issues. Thermal interface materials (TIMs) incorporating phase-change materials, metal nanoparticles, and vertically aligned carbon nanotubes have demonstrated thermal resistances below 5 mm²K/W, representing a 70% improvement over traditional thermal greases.

Hermetic sealing technologies have also progressed with the development of glass-ceramic composites and active metal brazing alloys that maintain hermeticity while accommodating thermal expansion. These materials provide leak rates below 10^-9 atm-cc/sec, ensuring long-term reliability in harsh environments while minimizing package-induced stresses on the VCSEL die.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!