Reliability Testing Protocols For VCSEL Packages

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Package Reliability Testing Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various optoelectronic applications, including data communications, sensing, and consumer electronics. The reliability of VCSEL packages directly impacts the performance, longevity, and safety of these applications, making standardized testing protocols essential for industry advancement.

The evolution of VCSEL technology dates back to the 1970s, with significant commercial breakthroughs occurring in the 1990s. Initially deployed primarily in short-range optical data transmission, VCSELs have since expanded into diverse applications including facial recognition, LiDAR systems for autonomous vehicles, and medical devices. This technological diversification has necessitated increasingly sophisticated reliability testing methodologies to address application-specific failure modes.

Current industry standards for VCSEL package reliability testing have evolved from broader semiconductor and optoelectronic testing frameworks, including Telcordia GR-468, MIL-STD-883, and various IEC standards. However, the unique characteristics of VCSELs—such as their temperature sensitivity, susceptibility to mechanical stress, and complex optical-electrical interfaces—demand specialized testing protocols that traditional standards do not fully address.

The primary objective of VCSEL package reliability testing is to predict and prevent failures throughout the product lifecycle by subjecting devices to accelerated stress conditions that simulate long-term operational environments. Key reliability metrics include mean time to failure (MTTF), failure in time (FIT) rates, and activation energy values that characterize degradation mechanisms.

Testing objectives typically encompass multiple dimensions: environmental robustness (temperature cycling, humidity resistance), mechanical integrity (shock, vibration, die shear strength), optical stability (power output degradation, wavelength drift), and electrical performance (threshold current stability, forward voltage changes). These dimensions must be evaluated across various operational modes and environmental conditions relevant to target applications.

Recent technological trends driving the evolution of VCSEL reliability testing include the miniaturization of packages for mobile applications, higher power densities for sensing applications, and integration with complex optical systems. These trends introduce new failure mechanisms that must be characterized through enhanced testing methodologies.

The establishment of standardized, comprehensive reliability testing protocols for VCSEL packages aims to achieve several industry-wide benefits: enabling meaningful comparison between different manufacturers' products, reducing qualification time and costs, improving predictive accuracy for lifetime estimations, and ultimately enhancing end-product reliability. As VCSEL technology continues to penetrate critical applications like automotive safety systems and medical diagnostics, the importance of robust reliability testing frameworks becomes increasingly paramount.

The evolution of VCSEL technology dates back to the 1970s, with significant commercial breakthroughs occurring in the 1990s. Initially deployed primarily in short-range optical data transmission, VCSELs have since expanded into diverse applications including facial recognition, LiDAR systems for autonomous vehicles, and medical devices. This technological diversification has necessitated increasingly sophisticated reliability testing methodologies to address application-specific failure modes.

Current industry standards for VCSEL package reliability testing have evolved from broader semiconductor and optoelectronic testing frameworks, including Telcordia GR-468, MIL-STD-883, and various IEC standards. However, the unique characteristics of VCSELs—such as their temperature sensitivity, susceptibility to mechanical stress, and complex optical-electrical interfaces—demand specialized testing protocols that traditional standards do not fully address.

The primary objective of VCSEL package reliability testing is to predict and prevent failures throughout the product lifecycle by subjecting devices to accelerated stress conditions that simulate long-term operational environments. Key reliability metrics include mean time to failure (MTTF), failure in time (FIT) rates, and activation energy values that characterize degradation mechanisms.

Testing objectives typically encompass multiple dimensions: environmental robustness (temperature cycling, humidity resistance), mechanical integrity (shock, vibration, die shear strength), optical stability (power output degradation, wavelength drift), and electrical performance (threshold current stability, forward voltage changes). These dimensions must be evaluated across various operational modes and environmental conditions relevant to target applications.

Recent technological trends driving the evolution of VCSEL reliability testing include the miniaturization of packages for mobile applications, higher power densities for sensing applications, and integration with complex optical systems. These trends introduce new failure mechanisms that must be characterized through enhanced testing methodologies.

The establishment of standardized, comprehensive reliability testing protocols for VCSEL packages aims to achieve several industry-wide benefits: enabling meaningful comparison between different manufacturers' products, reducing qualification time and costs, improving predictive accuracy for lifetime estimations, and ultimately enhancing end-product reliability. As VCSEL technology continues to penetrate critical applications like automotive safety systems and medical diagnostics, the importance of robust reliability testing frameworks becomes increasingly paramount.

Market Demand Analysis for Reliable VCSEL Packages

The global market for Vertical-Cavity Surface-Emitting Laser (VCSEL) packages is experiencing robust growth, driven primarily by increasing applications in consumer electronics, automotive LiDAR systems, and data communications. Market research indicates that the VCSEL market is projected to reach $3.89 billion by 2026, growing at a CAGR of 17.3% from 2021. This significant growth trajectory underscores the critical importance of reliability in VCSEL packages.

Consumer electronics represents the largest market segment for VCSEL applications, particularly in facial recognition systems for smartphones and tablets. Apple's implementation of Face ID technology has been a major catalyst, creating substantial demand for highly reliable VCSEL arrays that can operate consistently over the device's lifetime. The automotive sector is emerging as another significant market driver, with advanced driver-assistance systems (ADAS) and autonomous vehicles requiring VCSELs with exceptional reliability under harsh environmental conditions.

Data center applications constitute another crucial market segment, where VCSEL-based optical interconnects are increasingly replacing copper connections for high-speed data transmission. In this environment, reliability is paramount as system downtime can result in substantial financial losses. Industry reports suggest that data center operators are willing to pay premium prices for VCSEL packages that demonstrate superior reliability metrics and extended operational lifetimes.

The telecommunications industry's transition to 5G infrastructure is further accelerating demand for reliable VCSEL packages. These components are essential for the high-bandwidth, low-latency communication systems that form the backbone of next-generation networks. Market analysis reveals that telecom equipment manufacturers are specifically seeking VCSEL packages with documented reliability testing protocols that conform to Telcordia GR-468 standards.

Regional market analysis shows Asia-Pacific leading VCSEL package demand, with China, Taiwan, and South Korea serving as manufacturing hubs. North America follows closely, driven by data center expansion and defense applications. European demand centers on automotive and industrial automation sectors, where reliability requirements are exceptionally stringent.

End-user feedback indicates growing dissatisfaction with current reliability testing standards, which many consider insufficient for emerging applications. A survey of 150 electronics manufacturers revealed that 78% believe existing reliability testing protocols for VCSEL packages fail to adequately predict field performance in new use cases such as wearable devices and augmented reality systems. This market gap presents a significant opportunity for testing protocol innovation.

The market is increasingly demanding standardized, comprehensive reliability testing protocols that address thermal cycling, humidity resistance, mechanical shock, and long-term performance degradation. Companies that can demonstrate superior reliability through rigorous testing methodologies are gaining competitive advantages in premium market segments where failure is not an option.

Consumer electronics represents the largest market segment for VCSEL applications, particularly in facial recognition systems for smartphones and tablets. Apple's implementation of Face ID technology has been a major catalyst, creating substantial demand for highly reliable VCSEL arrays that can operate consistently over the device's lifetime. The automotive sector is emerging as another significant market driver, with advanced driver-assistance systems (ADAS) and autonomous vehicles requiring VCSELs with exceptional reliability under harsh environmental conditions.

Data center applications constitute another crucial market segment, where VCSEL-based optical interconnects are increasingly replacing copper connections for high-speed data transmission. In this environment, reliability is paramount as system downtime can result in substantial financial losses. Industry reports suggest that data center operators are willing to pay premium prices for VCSEL packages that demonstrate superior reliability metrics and extended operational lifetimes.

The telecommunications industry's transition to 5G infrastructure is further accelerating demand for reliable VCSEL packages. These components are essential for the high-bandwidth, low-latency communication systems that form the backbone of next-generation networks. Market analysis reveals that telecom equipment manufacturers are specifically seeking VCSEL packages with documented reliability testing protocols that conform to Telcordia GR-468 standards.

Regional market analysis shows Asia-Pacific leading VCSEL package demand, with China, Taiwan, and South Korea serving as manufacturing hubs. North America follows closely, driven by data center expansion and defense applications. European demand centers on automotive and industrial automation sectors, where reliability requirements are exceptionally stringent.

End-user feedback indicates growing dissatisfaction with current reliability testing standards, which many consider insufficient for emerging applications. A survey of 150 electronics manufacturers revealed that 78% believe existing reliability testing protocols for VCSEL packages fail to adequately predict field performance in new use cases such as wearable devices and augmented reality systems. This market gap presents a significant opportunity for testing protocol innovation.

The market is increasingly demanding standardized, comprehensive reliability testing protocols that address thermal cycling, humidity resistance, mechanical shock, and long-term performance degradation. Companies that can demonstrate superior reliability through rigorous testing methodologies are gaining competitive advantages in premium market segments where failure is not an option.

Current State and Challenges in VCSEL Reliability Testing

The global VCSEL (Vertical-Cavity Surface-Emitting Laser) market has witnessed significant growth, with applications expanding across telecommunications, sensing, and consumer electronics. However, this growth has highlighted critical challenges in reliability testing protocols for VCSEL packages. Current industry standards primarily focus on traditional laser diode testing methodologies, which often fail to address the unique characteristics and failure modes specific to VCSELs.

Internationally, reliability testing for VCSELs follows several established standards, including Telcordia GR-468-CORE and MIL-STD-883. These standards provide general guidelines for optoelectronic device testing but lack VCSEL-specific protocols. This gap has led to inconsistent testing approaches across manufacturers, making comparative reliability assessments challenging for end-users and system integrators.

The primary technical challenges in VCSEL reliability testing center around three key areas: thermal management evaluation, optical degradation mechanisms, and package integrity under various environmental conditions. Current testing methodologies struggle to accurately simulate real-world operating conditions, particularly for emerging applications like facial recognition, LiDAR, and data centers where VCSELs experience unique stress patterns.

Thermal characterization remains particularly problematic, with conventional testing unable to fully capture the complex thermal behavior of VCSEL arrays. The industry lacks standardized protocols for evaluating thermal resistance and junction temperature under dynamic operating conditions, leading to potential underestimation of thermal-related failure mechanisms.

Accelerated life testing (ALT) protocols for VCSELs present another significant challenge. The acceleration factors used in traditional semiconductor testing may not accurately translate to VCSEL lifetime predictions due to their unique degradation mechanisms. This discrepancy creates uncertainty in reliability projections, particularly for applications requiring extended operational lifetimes.

Geographically, VCSEL reliability testing expertise is concentrated in North America, Europe, and East Asia, with significant variations in testing methodologies and acceptance criteria. This regional fragmentation has hindered the development of unified global standards, creating market inefficiencies and potential reliability blind spots.

Recent advancements in testing equipment have partially addressed these challenges through improved in-situ monitoring capabilities and more sophisticated environmental chambers. However, the rapid evolution of VCSEL technology—particularly the trend toward higher-power arrays and novel package designs—continues to outpace testing protocol development.

The integration of VCSELs into increasingly diverse applications has further complicated reliability assessment, as each application presents unique environmental stresses and performance requirements. Current testing frameworks struggle to accommodate this diversity, often resulting in either overly conservative or insufficiently rigorous evaluation protocols.

Internationally, reliability testing for VCSELs follows several established standards, including Telcordia GR-468-CORE and MIL-STD-883. These standards provide general guidelines for optoelectronic device testing but lack VCSEL-specific protocols. This gap has led to inconsistent testing approaches across manufacturers, making comparative reliability assessments challenging for end-users and system integrators.

The primary technical challenges in VCSEL reliability testing center around three key areas: thermal management evaluation, optical degradation mechanisms, and package integrity under various environmental conditions. Current testing methodologies struggle to accurately simulate real-world operating conditions, particularly for emerging applications like facial recognition, LiDAR, and data centers where VCSELs experience unique stress patterns.

Thermal characterization remains particularly problematic, with conventional testing unable to fully capture the complex thermal behavior of VCSEL arrays. The industry lacks standardized protocols for evaluating thermal resistance and junction temperature under dynamic operating conditions, leading to potential underestimation of thermal-related failure mechanisms.

Accelerated life testing (ALT) protocols for VCSELs present another significant challenge. The acceleration factors used in traditional semiconductor testing may not accurately translate to VCSEL lifetime predictions due to their unique degradation mechanisms. This discrepancy creates uncertainty in reliability projections, particularly for applications requiring extended operational lifetimes.

Geographically, VCSEL reliability testing expertise is concentrated in North America, Europe, and East Asia, with significant variations in testing methodologies and acceptance criteria. This regional fragmentation has hindered the development of unified global standards, creating market inefficiencies and potential reliability blind spots.

Recent advancements in testing equipment have partially addressed these challenges through improved in-situ monitoring capabilities and more sophisticated environmental chambers. However, the rapid evolution of VCSEL technology—particularly the trend toward higher-power arrays and novel package designs—continues to outpace testing protocol development.

The integration of VCSELs into increasingly diverse applications has further complicated reliability assessment, as each application presents unique environmental stresses and performance requirements. Current testing frameworks struggle to accommodate this diversity, often resulting in either overly conservative or insufficiently rigorous evaluation protocols.

Current VCSEL Package Reliability Testing Protocols

01 Thermal management solutions for VCSEL packages

Effective thermal management is crucial for VCSEL package reliability. Various solutions include advanced heat sinks, thermal interface materials, and optimized package designs that facilitate heat dissipation. These approaches help maintain operational temperature within safe limits, preventing thermal runaway and extending device lifetime. Improved thermal conductivity pathways and efficient heat spreading mechanisms ensure stable performance under high-power operation conditions.- Thermal management solutions for VCSEL packages: Effective thermal management is crucial for VCSEL package reliability. Various solutions include optimized heat sinks, thermal interface materials, and package designs that facilitate efficient heat dissipation. These approaches help prevent thermal runaway and degradation of the VCSEL device during operation, extending device lifetime and maintaining performance stability under high-power conditions.

- Hermetic sealing and moisture protection: Hermetic sealing techniques protect VCSEL devices from environmental factors such as moisture and contaminants that can cause reliability issues. Advanced packaging methods include glass-to-metal seals, ceramic packages with metal lids, and specialized encapsulation materials. These protection mechanisms prevent oxidation of optical surfaces and electrical contacts, ensuring long-term operational stability.

- Mechanical stress mitigation in VCSEL packages: Mechanical stress from thermal cycling, assembly processes, or operational conditions can significantly impact VCSEL reliability. Package designs incorporating stress-relief features, flexible mounting techniques, and carefully selected materials with matched coefficients of thermal expansion help mitigate these issues. These approaches prevent misalignment of optical components and reduce the risk of package failure during operation.

- Advanced testing and reliability qualification methods: Comprehensive testing methodologies are essential for ensuring VCSEL package reliability. These include accelerated life testing, environmental stress screening, burn-in procedures, and real-time monitoring systems. Advanced analytical techniques help identify potential failure modes and establish reliability metrics, enabling manufacturers to predict device lifetime and improve package designs for enhanced durability.

- Novel package architectures for improved reliability: Innovative VCSEL package architectures incorporate features specifically designed to enhance reliability. These include flip-chip configurations, through-silicon vias, wafer-level packaging, and integrated optical elements. Such designs minimize wire bonds, reduce parasitic effects, improve thermal performance, and protect sensitive optical surfaces, resulting in more robust and reliable VCSEL devices for demanding applications.

02 Hermetic sealing and environmental protection

Hermetic sealing techniques protect VCSEL devices from moisture, contaminants, and environmental factors that could degrade performance. Advanced packaging materials and sealing methods create robust barriers against external elements while maintaining optical alignment. These protection strategies include specialized encapsulants, glass-to-metal seals, and moisture-resistant coatings that significantly enhance long-term reliability and prevent corrosion-related failures in various operating environments.Expand Specific Solutions03 Stress management and mechanical stability

Managing mechanical stress in VCSEL packages is essential for reliability. Techniques include stress-relieving package designs, coefficient of thermal expansion (CTE) matching between materials, and specialized mounting approaches. These solutions minimize stress-induced failures during temperature cycling and mechanical shock. Advanced bonding techniques and flexible interconnects help absorb mechanical strain, while reinforced structures provide stability against vibration and physical impacts.Expand Specific Solutions04 Optical coupling and alignment stability

Maintaining stable optical alignment is critical for VCSEL package reliability. Precision assembly techniques, active alignment methods, and specialized mounting structures ensure consistent optical performance over time. These approaches minimize coupling losses and prevent misalignment due to thermal or mechanical stresses. Advanced fixation methods and self-aligning features help maintain optimal beam characteristics throughout the device lifetime, even under varying operating conditions.Expand Specific Solutions05 Reliability testing and qualification methods

Comprehensive reliability testing protocols are essential for qualifying VCSEL packages. These include accelerated aging tests, temperature cycling, humidity testing, and mechanical shock evaluations. Advanced monitoring techniques and failure analysis methods help identify potential reliability issues before field deployment. Statistical modeling approaches enable lifetime prediction under various operating conditions, while standardized qualification procedures ensure consistent quality and performance benchmarks across different manufacturing batches.Expand Specific Solutions

Key Industry Players in VCSEL Testing and Certification

The VCSEL package reliability testing market is in a growth phase, characterized by increasing demand for standardized protocols across telecommunications, data centers, and automotive applications. The market is expanding rapidly with a projected CAGR of 15-20% through 2025, driven by 5G deployment and data center expansion. Technologically, the field shows moderate maturity with established players like Vixar (specialized VCSEL manufacturer) and Qualcomm leading innovation, while Huawei, Mellanox, and Hewlett Packard Enterprise contribute significant advancements in integration and testing methodologies. Chinese institutions including Beijing University of Technology and academic-industry partnerships with Semiconductor Manufacturing International are accelerating development of indigenous testing capabilities, challenging traditional market dominance.

Vixar, Inc.

Technical Solution: Vixar has developed comprehensive reliability testing protocols for VCSEL packages that include accelerated aging tests under various temperature and humidity conditions. Their approach incorporates high-temperature operating life (HTOL) testing at temperatures up to 150°C while monitoring optical power output and spectral characteristics. Vixar's protocols also feature temperature cycling tests (-40°C to +125°C) to evaluate package integrity and wire bond reliability. Their methodology includes stress-driven qualification testing with particular emphasis on electrostatic discharge (ESD) sensitivity assessment and sulfur resistance testing for applications in harsh environments. Vixar implements real-time degradation monitoring during reliability testing, allowing for precise lifetime prediction models based on actual performance data rather than theoretical calculations.

Strengths: Specialized expertise in VCSEL technology with comprehensive testing protocols specifically designed for VCSEL applications. Weakness: As a smaller company compared to some competitors, they may have limited resources for implementing the most advanced testing equipment across all reliability parameters.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has established advanced reliability testing protocols for VCSEL packages used in their telecommunications and consumer electronics products. Their approach includes a multi-stage reliability assessment framework that begins with component-level testing and progresses to system-level integration testing. Huawei's protocols incorporate temperature-humidity-bias (THB) testing at 85°C/85% RH for extended durations to evaluate moisture sensitivity and package hermeticity. They employ automated optical inspection systems during reliability testing to detect subtle changes in beam profile and far-field patterns. Huawei has developed proprietary algorithms for analyzing degradation trends in VCSEL performance metrics, enabling early failure prediction. Their testing protocols also include mechanical shock and vibration testing tailored to specific end-product requirements, such as smartphone drop tests for facial recognition VCSELs.

Strengths: Extensive resources and integration of reliability testing with actual application scenarios in consumer electronics and telecommunications. Weakness: Their testing protocols may be heavily optimized for their own product ecosystem rather than general industry standards.

Critical Test Methods and Standards for VCSEL Packages

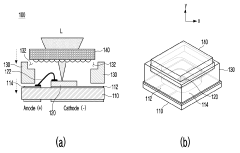

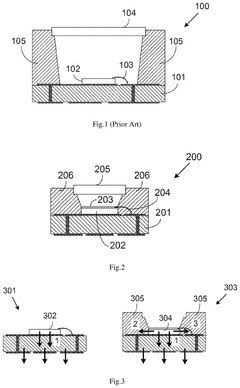

Package of Vertical Cavity Surface Emitting Laser Having Out-gassing Passage and Method Thereof

PatentActiveKR1020200116300A

Innovation

- A VCSEL package design featuring a diffuser-supporting housing formed as a panel with integrated outgas passages, eliminating the need for injection molding and allowing gas discharge, using a DPC substrate with AlN and a micro lens array, and a second housing with curvature to prevent gas passage blockage.

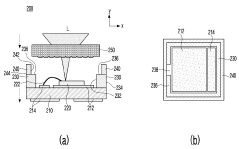

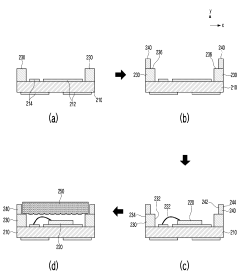

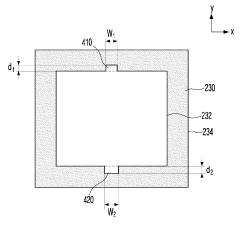

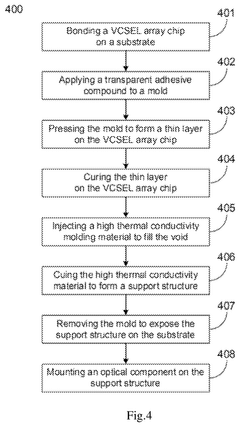

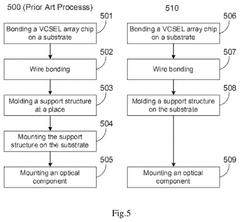

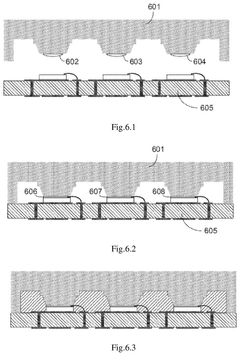

Vertical cavity surface emitting laser (VCSEL) array package and manufacturing method

PatentActiveUS12107387B2

Innovation

- A VCSEL array package design that includes a VCSEL array chip bonded on a substrate with a support structure molded from high thermal conductivity material, covering the side surfaces of the chip to create additional thermal paths and eliminate gaps, and a transparent thin layer to prevent beam obstruction and reflection.

Failure Analysis Techniques for VCSEL Packages

Failure analysis techniques for VCSEL packages have evolved significantly to address the complex reliability challenges in these optoelectronic components. When VCSELs fail during reliability testing protocols, systematic failure analysis becomes crucial for understanding root causes and implementing corrective measures. Non-destructive techniques form the first line of investigation, with optical microscopy providing initial visual inspection for package delamination, wire bond issues, or surface contamination. More advanced imaging methods include scanning acoustic microscopy (SAM), which excels at detecting internal delamination, voids, and cracks within the package structure through ultrasonic wave reflection analysis.

X-ray imaging represents another critical non-destructive technique, allowing engineers to examine internal structures without compromising package integrity. This method proves particularly valuable for identifying solder joint defects, wire bond positioning issues, and die attachment problems that may contribute to VCSEL failure during reliability testing. Thermal imaging techniques, including infrared microscopy, help identify hotspots and thermal distribution anomalies that often precede catastrophic failures.

Destructive analysis techniques become necessary when non-destructive methods cannot provide sufficient information about failure mechanisms. Cross-sectioning involves precisely cutting through specific areas of the VCSEL package to expose internal structures for microscopic examination. This technique enables direct observation of interface quality, material degradation, and electromigration effects. Focused Ion Beam (FIB) analysis offers even more precise sectioning capabilities, allowing for nanometer-scale investigation of specific failure sites.

Chemical analysis techniques complement physical inspection methods in VCSEL failure analysis. Energy Dispersive X-ray Spectroscopy (EDS) identifies elemental composition at failure sites, helping detect contamination or unexpected material interactions. Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) provides surface chemical analysis with extremely high sensitivity, capable of detecting trace contaminants that may impact VCSEL performance during reliability testing.

Electrical characterization techniques form another essential component of comprehensive failure analysis. Current-voltage (I-V) and light-current-voltage (L-I-V) measurements help identify electrical performance degradation patterns. Radio frequency (RF) characterization assesses modulation capabilities and signal integrity, particularly important for VCSELs in high-speed data communication applications. These electrical measurements often provide the first indication of reliability issues before physical damage becomes apparent.

Advanced correlation techniques have emerged as powerful tools in modern VCSEL failure analysis. By combining multiple analytical methods and establishing temporal relationships between different failure indicators, analysts can construct comprehensive failure models. Machine learning algorithms increasingly assist in pattern recognition across large datasets from reliability testing, helping identify subtle precursors to failure that might otherwise go unnoticed in manual analysis.

X-ray imaging represents another critical non-destructive technique, allowing engineers to examine internal structures without compromising package integrity. This method proves particularly valuable for identifying solder joint defects, wire bond positioning issues, and die attachment problems that may contribute to VCSEL failure during reliability testing. Thermal imaging techniques, including infrared microscopy, help identify hotspots and thermal distribution anomalies that often precede catastrophic failures.

Destructive analysis techniques become necessary when non-destructive methods cannot provide sufficient information about failure mechanisms. Cross-sectioning involves precisely cutting through specific areas of the VCSEL package to expose internal structures for microscopic examination. This technique enables direct observation of interface quality, material degradation, and electromigration effects. Focused Ion Beam (FIB) analysis offers even more precise sectioning capabilities, allowing for nanometer-scale investigation of specific failure sites.

Chemical analysis techniques complement physical inspection methods in VCSEL failure analysis. Energy Dispersive X-ray Spectroscopy (EDS) identifies elemental composition at failure sites, helping detect contamination or unexpected material interactions. Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) provides surface chemical analysis with extremely high sensitivity, capable of detecting trace contaminants that may impact VCSEL performance during reliability testing.

Electrical characterization techniques form another essential component of comprehensive failure analysis. Current-voltage (I-V) and light-current-voltage (L-I-V) measurements help identify electrical performance degradation patterns. Radio frequency (RF) characterization assesses modulation capabilities and signal integrity, particularly important for VCSELs in high-speed data communication applications. These electrical measurements often provide the first indication of reliability issues before physical damage becomes apparent.

Advanced correlation techniques have emerged as powerful tools in modern VCSEL failure analysis. By combining multiple analytical methods and establishing temporal relationships between different failure indicators, analysts can construct comprehensive failure models. Machine learning algorithms increasingly assist in pattern recognition across large datasets from reliability testing, helping identify subtle precursors to failure that might otherwise go unnoticed in manual analysis.

Industry Standardization and Compliance Requirements

The VCSEL industry operates within a complex framework of international standards and compliance requirements that ensure product reliability, safety, and interoperability. The Telcordia GR-468-CORE standard serves as the foundational document for VCSEL reliability testing, providing comprehensive guidelines for qualification and ongoing reliability monitoring. This standard has been widely adopted across the industry and specifies critical test conditions, sample sizes, and acceptance criteria for various environmental and operational stressors.

Beyond Telcordia, VCSEL packages must often comply with additional standards depending on their application domain. For automotive LiDAR applications, the AEC-Q102 qualification requirements impose stringent reliability standards with extended temperature ranges and more rigorous vibration testing protocols. Medical device implementations must adhere to ISO 13485 quality management systems and FDA requirements for component traceability and reliability documentation.

The International Electrotechnical Commission (IEC) has developed several standards relevant to VCSEL packaging, including IEC 60068 for environmental testing and IEC 60749 for semiconductor device mechanical and climatic test methods. These standards define specific test procedures for temperature cycling, humidity resistance, and mechanical shock that VCSEL packages must withstand to achieve certification.

Military and aerospace applications introduce additional compliance requirements through MIL-STD-883 and MIL-STD-750, which mandate enhanced reliability testing for harsh operational environments. These standards specify more stringent failure criteria and often require additional testing for radiation hardness and extended temperature operation.

Compliance with Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives is mandatory for VCSEL packages sold in many global markets, requiring manufacturers to eliminate lead and other hazardous materials from their packaging solutions while maintaining reliability performance.

Testing laboratories providing certification services must themselves be accredited according to ISO/IEC 17025 standards, ensuring the validity and reproducibility of test results across different facilities. This accreditation requirement creates a standardized ecosystem for reliability verification that manufacturers can leverage for global product acceptance.

Emerging applications in consumer electronics have prompted the development of new industry-specific standards, with organizations like JEDEC introducing specialized reliability testing protocols for VCSELs used in mobile devices and wearable technology. These standards address unique reliability concerns such as drop testing and repeated thermal cycling under miniaturized packaging constraints.

Beyond Telcordia, VCSEL packages must often comply with additional standards depending on their application domain. For automotive LiDAR applications, the AEC-Q102 qualification requirements impose stringent reliability standards with extended temperature ranges and more rigorous vibration testing protocols. Medical device implementations must adhere to ISO 13485 quality management systems and FDA requirements for component traceability and reliability documentation.

The International Electrotechnical Commission (IEC) has developed several standards relevant to VCSEL packaging, including IEC 60068 for environmental testing and IEC 60749 for semiconductor device mechanical and climatic test methods. These standards define specific test procedures for temperature cycling, humidity resistance, and mechanical shock that VCSEL packages must withstand to achieve certification.

Military and aerospace applications introduce additional compliance requirements through MIL-STD-883 and MIL-STD-750, which mandate enhanced reliability testing for harsh operational environments. These standards specify more stringent failure criteria and often require additional testing for radiation hardness and extended temperature operation.

Compliance with Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives is mandatory for VCSEL packages sold in many global markets, requiring manufacturers to eliminate lead and other hazardous materials from their packaging solutions while maintaining reliability performance.

Testing laboratories providing certification services must themselves be accredited according to ISO/IEC 17025 standards, ensuring the validity and reproducibility of test results across different facilities. This accreditation requirement creates a standardized ecosystem for reliability verification that manufacturers can leverage for global product acceptance.

Emerging applications in consumer electronics have prompted the development of new industry-specific standards, with organizations like JEDEC introducing specialized reliability testing protocols for VCSELs used in mobile devices and wearable technology. These standards address unique reliability concerns such as drop testing and repeated thermal cycling under miniaturized packaging constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!