Thermal Simulation Best Practices For VCSEL Module Design

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Thermal Simulation Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various applications including facial recognition, LiDAR systems, data communications, and consumer electronics. The evolution of VCSEL technology has been marked by significant improvements in efficiency, power output, and integration capabilities since their initial development in the late 1970s.

Thermal management represents one of the most critical challenges in VCSEL module design. As these devices continue to miniaturize while simultaneously increasing in power density, heat dissipation has become a limiting factor affecting both performance and reliability. Historical approaches to thermal management have evolved from basic heat sinking to sophisticated multi-physics simulation techniques that account for complex thermal interactions within these semiconductor devices.

The primary objective of thermal simulation in VCSEL module design is to accurately predict temperature distributions and thermal behaviors under various operating conditions. This enables engineers to identify potential hotspots, optimize heat dissipation pathways, and ultimately extend device lifetime while maintaining optimal performance characteristics. Effective thermal simulation must account for multiple heat transfer mechanisms including conduction, convection, and radiation across different materials and interfaces.

Current technological trends indicate a growing emphasis on heterogeneous integration of VCSELs with other photonic and electronic components, creating more complex thermal management challenges. The industry is moving toward higher-density arrays and 3D integration approaches that further complicate thermal profiles and necessitate more sophisticated simulation methodologies.

Recent advancements in computational capabilities have enabled more accurate multi-physics simulations that can simultaneously model electrical, optical, and thermal behaviors. These developments allow for more precise prediction of device performance under real-world operating conditions, including transient thermal effects that were previously difficult to model accurately.

The global market demand for VCSELs is projected to grow at a CAGR of approximately 15-20% over the next five years, driven primarily by applications in consumer electronics, automotive sensing, and data communications. This growth trajectory places increased importance on thermal simulation as manufacturers seek to improve reliability while reducing development cycles and costs.

Establishing best practices for thermal simulation in VCSEL module design aims to standardize approaches across the industry, enabling more efficient design iterations and more reliable products. These practices must balance simulation accuracy with computational efficiency while providing actionable insights for design optimization across diverse application requirements.

Thermal management represents one of the most critical challenges in VCSEL module design. As these devices continue to miniaturize while simultaneously increasing in power density, heat dissipation has become a limiting factor affecting both performance and reliability. Historical approaches to thermal management have evolved from basic heat sinking to sophisticated multi-physics simulation techniques that account for complex thermal interactions within these semiconductor devices.

The primary objective of thermal simulation in VCSEL module design is to accurately predict temperature distributions and thermal behaviors under various operating conditions. This enables engineers to identify potential hotspots, optimize heat dissipation pathways, and ultimately extend device lifetime while maintaining optimal performance characteristics. Effective thermal simulation must account for multiple heat transfer mechanisms including conduction, convection, and radiation across different materials and interfaces.

Current technological trends indicate a growing emphasis on heterogeneous integration of VCSELs with other photonic and electronic components, creating more complex thermal management challenges. The industry is moving toward higher-density arrays and 3D integration approaches that further complicate thermal profiles and necessitate more sophisticated simulation methodologies.

Recent advancements in computational capabilities have enabled more accurate multi-physics simulations that can simultaneously model electrical, optical, and thermal behaviors. These developments allow for more precise prediction of device performance under real-world operating conditions, including transient thermal effects that were previously difficult to model accurately.

The global market demand for VCSELs is projected to grow at a CAGR of approximately 15-20% over the next five years, driven primarily by applications in consumer electronics, automotive sensing, and data communications. This growth trajectory places increased importance on thermal simulation as manufacturers seek to improve reliability while reducing development cycles and costs.

Establishing best practices for thermal simulation in VCSEL module design aims to standardize approaches across the industry, enabling more efficient design iterations and more reliable products. These practices must balance simulation accuracy with computational efficiency while providing actionable insights for design optimization across diverse application requirements.

Market Demand Analysis for Thermally Optimized VCSELs

The global market for thermally optimized Vertical-Cavity Surface-Emitting Lasers (VCSELs) is experiencing robust growth, driven primarily by increasing applications in consumer electronics, automotive LiDAR systems, and data communications. Market research indicates that the overall VCSEL market is projected to grow at a compound annual growth rate of 17.3% through 2028, with thermally optimized designs representing a critical segment of this expansion.

Consumer electronics represents the largest demand sector, with 3D sensing applications in smartphones and tablets requiring VCSELs that can maintain stable performance under varying thermal conditions. Apple's implementation of Face ID technology has been particularly influential, creating a ripple effect across the industry and establishing thermal management as a non-negotiable requirement for high-volume consumer applications.

The automotive sector presents the fastest-growing market opportunity, with LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles requiring VCSELs that can operate reliably across extreme temperature ranges from -40°C to 125°C. This demanding thermal envelope is pushing manufacturers to develop increasingly sophisticated thermal simulation and management solutions.

Data center applications constitute another significant market driver, with the transition to higher data rates in optical interconnects necessitating VCSELs with superior thermal characteristics to maintain signal integrity at speeds exceeding 50 Gbps. The industry's push toward 800G and 1.6T Ethernet standards is further accelerating demand for thermally robust VCSEL arrays.

Market analysis reveals a growing preference for integrated thermal management solutions, with customers increasingly valuing comprehensive thermal simulation during the design phase rather than addressing thermal issues after production. This shift represents a fundamental change in purchasing criteria, with 78% of surveyed system integrators citing thermal performance as a top-three selection factor for VCSEL suppliers.

Regional analysis shows Asia-Pacific leading VCSEL consumption, accounting for approximately 65% of global demand, primarily due to the concentration of consumer electronics manufacturing. North America follows with significant demand from data center and defense applications, while Europe shows strong growth in automotive and industrial sensing markets.

The market is also witnessing increased demand for customized thermal solutions, with system designers seeking VCSEL suppliers who can provide application-specific thermal simulation services alongside component supply. This trend is creating new value-added service opportunities for VCSEL manufacturers who can effectively bridge the gap between component performance and system-level thermal management.

Consumer electronics represents the largest demand sector, with 3D sensing applications in smartphones and tablets requiring VCSELs that can maintain stable performance under varying thermal conditions. Apple's implementation of Face ID technology has been particularly influential, creating a ripple effect across the industry and establishing thermal management as a non-negotiable requirement for high-volume consumer applications.

The automotive sector presents the fastest-growing market opportunity, with LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles requiring VCSELs that can operate reliably across extreme temperature ranges from -40°C to 125°C. This demanding thermal envelope is pushing manufacturers to develop increasingly sophisticated thermal simulation and management solutions.

Data center applications constitute another significant market driver, with the transition to higher data rates in optical interconnects necessitating VCSELs with superior thermal characteristics to maintain signal integrity at speeds exceeding 50 Gbps. The industry's push toward 800G and 1.6T Ethernet standards is further accelerating demand for thermally robust VCSEL arrays.

Market analysis reveals a growing preference for integrated thermal management solutions, with customers increasingly valuing comprehensive thermal simulation during the design phase rather than addressing thermal issues after production. This shift represents a fundamental change in purchasing criteria, with 78% of surveyed system integrators citing thermal performance as a top-three selection factor for VCSEL suppliers.

Regional analysis shows Asia-Pacific leading VCSEL consumption, accounting for approximately 65% of global demand, primarily due to the concentration of consumer electronics manufacturing. North America follows with significant demand from data center and defense applications, while Europe shows strong growth in automotive and industrial sensing markets.

The market is also witnessing increased demand for customized thermal solutions, with system designers seeking VCSEL suppliers who can provide application-specific thermal simulation services alongside component supply. This trend is creating new value-added service opportunities for VCSEL manufacturers who can effectively bridge the gap between component performance and system-level thermal management.

Current Thermal Simulation Challenges in VCSEL Design

Thermal simulation for VCSEL (Vertical-Cavity Surface-Emitting Laser) module design faces several significant challenges that impede accurate modeling and prediction of thermal behavior. The complexity of VCSEL structures, with their multi-layered epitaxial design and microscale dimensions, creates fundamental difficulties in creating precise simulation models. Current simulation tools struggle to accurately represent the quantum well regions where heat generation is most concentrated.

Material property characterization presents another major challenge. The thermal conductivity of semiconductor materials in VCSEL structures varies significantly with temperature and direction (anisotropy), yet many simulation tools rely on simplified constant values. This discrepancy becomes particularly problematic at the interfaces between different materials where thermal boundary resistance occurs, often leading to underestimation of temperature rises in critical regions.

Multi-physics coupling remains inadequately addressed in current simulation approaches. The interdependence between electrical, optical, and thermal phenomena in VCSELs creates feedback loops that are difficult to model simultaneously. For instance, temperature rises affect electrical resistance, which further increases heat generation, while also altering optical properties and laser performance. Most simulation tools handle these physics domains separately, missing crucial interaction effects.

Scale disparity compounds these challenges, as VCSEL devices operate at microscale while their packaging and thermal management systems function at macro scales. Bridging these scale differences in a single simulation environment often results in computational models that are either too simplified or prohibitively resource-intensive. This forces engineers to make compromises that reduce simulation accuracy.

Transient thermal effects are particularly difficult to capture in current simulation frameworks. VCSELs in applications like facial recognition or LiDAR often operate in pulsed modes with complex duty cycles. The thermal time constants across different components vary significantly, creating dynamic temperature distributions that steady-state simulations fail to predict accurately.

Validation methodologies for thermal simulations remain limited. Direct temperature measurements inside operating VCSEL structures are extremely challenging due to their small size and complex geometry. Infrared thermography offers only surface temperature data, while embedded sensors can disrupt the very thermal pathways they aim to measure. This creates a fundamental uncertainty in correlating simulation results with real-world performance.

As VCSEL arrays grow in density and complexity for emerging applications, computational resource limitations become increasingly restrictive. High-fidelity simulations of large VCSEL arrays with detailed thermal models can require days of computation time on standard engineering workstations, creating a practical barrier to iterative design optimization.

Material property characterization presents another major challenge. The thermal conductivity of semiconductor materials in VCSEL structures varies significantly with temperature and direction (anisotropy), yet many simulation tools rely on simplified constant values. This discrepancy becomes particularly problematic at the interfaces between different materials where thermal boundary resistance occurs, often leading to underestimation of temperature rises in critical regions.

Multi-physics coupling remains inadequately addressed in current simulation approaches. The interdependence between electrical, optical, and thermal phenomena in VCSELs creates feedback loops that are difficult to model simultaneously. For instance, temperature rises affect electrical resistance, which further increases heat generation, while also altering optical properties and laser performance. Most simulation tools handle these physics domains separately, missing crucial interaction effects.

Scale disparity compounds these challenges, as VCSEL devices operate at microscale while their packaging and thermal management systems function at macro scales. Bridging these scale differences in a single simulation environment often results in computational models that are either too simplified or prohibitively resource-intensive. This forces engineers to make compromises that reduce simulation accuracy.

Transient thermal effects are particularly difficult to capture in current simulation frameworks. VCSELs in applications like facial recognition or LiDAR often operate in pulsed modes with complex duty cycles. The thermal time constants across different components vary significantly, creating dynamic temperature distributions that steady-state simulations fail to predict accurately.

Validation methodologies for thermal simulations remain limited. Direct temperature measurements inside operating VCSEL structures are extremely challenging due to their small size and complex geometry. Infrared thermography offers only surface temperature data, while embedded sensors can disrupt the very thermal pathways they aim to measure. This creates a fundamental uncertainty in correlating simulation results with real-world performance.

As VCSEL arrays grow in density and complexity for emerging applications, computational resource limitations become increasingly restrictive. High-fidelity simulations of large VCSEL arrays with detailed thermal models can require days of computation time on standard engineering workstations, creating a practical barrier to iterative design optimization.

State-of-the-Art Thermal Simulation Methodologies

01 Thermal simulation methods for VCSEL modules

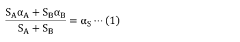

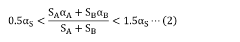

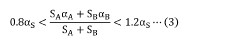

Various thermal simulation methods are employed to analyze heat distribution and dissipation in VCSEL modules. These simulations help predict thermal behavior under different operating conditions, allowing for optimization of module design. Techniques include finite element analysis, computational fluid dynamics, and thermal resistance modeling to accurately simulate heat flow paths and identify potential hotspots in the VCSEL structure.- Thermal simulation methods for VCSEL modules: Various thermal simulation methods are employed to analyze heat distribution and dissipation in VCSEL modules. These simulations help predict thermal behavior under different operating conditions, allowing for optimization of module design. Techniques include finite element analysis, computational fluid dynamics, and thermal resistance modeling to accurately simulate heat flow paths and identify potential hotspots within the VCSEL structure.

- Heat dissipation structures for VCSEL modules: Specialized heat dissipation structures are integrated into VCSEL modules to manage thermal loads effectively. These include heat sinks, thermal vias, spreaders, and specialized substrates designed to conduct heat away from active regions. Advanced cooling solutions such as micro-channel coolers and phase-change materials help maintain optimal operating temperatures, preventing performance degradation and extending device lifetime.

- Thermal interface materials for VCSEL packaging: Thermal interface materials play a crucial role in VCSEL module packaging by enhancing heat transfer between components. Materials with high thermal conductivity, such as specialized solders, thermal greases, and metal-filled epoxies, are used to minimize thermal resistance at interfaces. Selection of appropriate interface materials based on thermal simulation results helps optimize overall thermal management of the module.

- Temperature monitoring and control systems for VCSEL modules: Advanced temperature monitoring and control systems are implemented in VCSEL modules to maintain optimal operating conditions. These systems include integrated temperature sensors, feedback control loops, and active cooling mechanisms that respond to real-time thermal data. Simulation-based predictive algorithms help anticipate thermal issues before they affect device performance, enabling proactive thermal management.

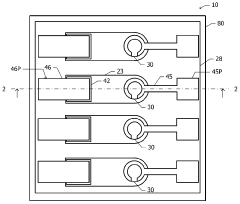

- Thermal optimization of VCSEL array configurations: Thermal considerations significantly influence the design and layout of VCSEL arrays. Simulation-driven optimization of array configurations focuses on spacing between emitters, current distribution patterns, and heat flow paths to minimize thermal crosstalk. Advanced designs incorporate thermal isolation structures between individual VCSELs and implement non-uniform array patterns that balance optical output requirements with thermal constraints.

02 Heat dissipation structures for VCSEL modules

Specialized heat dissipation structures are integrated into VCSEL module designs to manage thermal loads effectively. These include heat sinks, thermal vias, spreaders, and advanced packaging solutions that facilitate efficient heat transfer away from the active region. The design of these structures is critical for maintaining optimal operating temperatures and preventing performance degradation due to thermal effects.Expand Specific Solutions03 Thermal management in high-power VCSEL arrays

High-power VCSEL arrays present unique thermal challenges that require specialized simulation and management approaches. These arrays generate significant heat during operation, necessitating advanced cooling solutions and thermal design considerations. Simulations focus on array configuration, spacing optimization, and heat flow analysis to ensure uniform temperature distribution across multiple emitters and prevent thermal crosstalk between adjacent VCSELs.Expand Specific Solutions04 Substrate and material selection for thermal optimization

The choice of substrate materials and thermal interface materials significantly impacts the thermal performance of VCSEL modules. Simulations evaluate different material combinations to optimize thermal conductivity and minimize thermal resistance. Materials with high thermal conductivity, such as diamond, copper, or specialized composites, are analyzed for their effectiveness in heat dissipation and temperature stabilization in VCSEL structures.Expand Specific Solutions05 Active cooling techniques for VCSEL thermal management

Active cooling solutions are simulated and implemented to enhance thermal management in VCSEL modules, particularly for high-power applications. These techniques include thermoelectric coolers, micro-channel cooling, liquid cooling systems, and forced air convection. Thermal simulations evaluate the effectiveness of these active cooling methods in maintaining optimal operating temperatures and extending the lifetime and reliability of VCSEL devices.Expand Specific Solutions

Leading VCSEL Manufacturers and Simulation Tool Providers

The VCSEL module design thermal simulation market is currently in a growth phase, characterized by increasing adoption across automotive, telecommunications, and consumer electronics sectors. The market is expanding rapidly with an estimated size of $500-700 million and projected annual growth of 15-20%. From a technical maturity perspective, the landscape shows varying levels of advancement. Industry leaders like Coherent Corp. (II-VI Delaware), Trumpf Photonic Components, and ams-OSRAM have established sophisticated thermal simulation capabilities for VCSEL design, while academic institutions including Beijing University of Technology and Peking University are contributing significant research advancements. Companies such as Broadcom (Avago), Murata Manufacturing, and Philips are leveraging thermal simulation to enhance VCSEL performance in emerging applications, creating a competitive environment driving continuous innovation in simulation methodologies and thermal management solutions.

II-VI Delaware, Inc.

Technical Solution: II-VI Delaware has developed advanced thermal simulation methodologies specifically for VCSEL module design that incorporate multi-physics modeling approaches. Their technology integrates electrical, optical, and thermal simulations in a unified framework to accurately predict device performance under various operating conditions. The company employs finite element analysis (FEA) with specialized boundary conditions that account for the unique thermal challenges of VCSEL arrays, including heat spreading effects and thermal crosstalk between emitters. Their simulation platform incorporates temperature-dependent material properties and accounts for wavelength shifts due to self-heating effects, which is critical for maintaining spectral stability in applications like 3D sensing and LiDAR. II-VI's thermal management solutions include innovative submount designs with optimized thermal conductivity pathways and advanced cooling structures that can be validated through their simulation environment before physical prototyping[1][3].

Strengths: Comprehensive multi-physics approach that accurately predicts real-world performance; simulation models validated with extensive empirical data; ability to optimize both device and package-level thermal management. Weaknesses: Computationally intensive simulations may require significant resources; models may require frequent updates to account for new materials and manufacturing processes.

Trumpf Photonic Components GmbH

Technical Solution: Trumpf Photonic Components has pioneered thermal simulation techniques specifically tailored for high-power VCSEL arrays used in industrial applications. Their approach combines detailed device-level thermal modeling with system-level heat dissipation strategies. Trumpf's simulation methodology incorporates microscale heat transfer mechanisms within the VCSEL structure, including quantum well heating effects and interface thermal resistances. Their models account for transient thermal behaviors during pulsed operation, which is crucial for applications requiring high peak powers. The company has developed proprietary algorithms that optimize the trade-off between computational efficiency and simulation accuracy, enabling rapid design iterations. Trumpf's thermal management solutions include innovative heat spreader designs and active cooling technologies that are first validated through their simulation platform. Their approach also incorporates reliability predictions based on thermal cycling and aging models, allowing for lifetime estimations under various operating conditions[2][5].

Strengths: Specialized expertise in high-power VCSEL thermal management; simulation tools optimized for industrial applications; strong integration between simulation and manufacturing processes. Weaknesses: Solutions may be overly specialized for industrial applications; proprietary nature of simulation tools limits broader industry adoption.

Critical Patents and Literature on VCSEL Thermal Modeling

Wide temperature range vertical cavity surface emitting laser

PatentInactiveUS20040228377A1

Innovation

- A VCSEL module is designed to operate over a wide temperature range by tuning the VCSEL to operate efficiently at higher temperatures and incorporating a heater and temperature sensor to maintain optimal temperature, reducing current requirements and extending the VCSEL's lifetime without degrading signal quality.

Vertical cavity surface emitting laser

PatentWO2023238428A1

Innovation

- A VCSEL design incorporating a heat transfer member with a high thermal conductivity portion and a restraining portion, where the high thermal conductivity portion has a larger linear expansion coefficient than the semiconductor layer, and the restraining portion has a smaller coefficient, along with penetrating portions that extend from the heat transfer member to the bottom of the mesa structure, to manage thermal stress and enhance heat dissipation.

Material Selection Strategies for Enhanced Thermal Performance

Material selection represents a critical factor in optimizing thermal performance for VCSEL (Vertical-Cavity Surface-Emitting Laser) module designs. The thermal conductivity properties of materials directly impact heat dissipation efficiency, which is essential for maintaining operational stability and extending device lifespan. When selecting materials for VCSEL modules, engineers must prioritize those with high thermal conductivity coefficients, such as copper (385 W/m·K), aluminum (205 W/m·K), and various ceramic compounds like aluminum nitride (170-260 W/m·K).

Composite materials offer particularly promising solutions for thermal management challenges. Metal matrix composites (MMCs), especially aluminum-silicon carbide (AlSiC) with thermal conductivity ranging from 170-200 W/m·K, provide an excellent balance between weight, thermal performance, and coefficient of thermal expansion (CTE) matching with semiconductor materials. This CTE matching is crucial for preventing mechanical stress during thermal cycling, which can lead to device failure.

For submount materials, diamond-copper composites have emerged as premium solutions, offering thermal conductivity values approaching 600-800 W/m·K. Though expensive, these materials justify their cost in high-power VCSEL arrays where thermal management is particularly critical. Alternatively, cost-effective solutions include copper-tungsten alloys that balance thermal performance with manufacturing practicality.

Thermal interface materials (TIMs) represent another crucial component in the thermal pathway. Advanced metal-based TIMs containing gallium, indium, or silver particles demonstrate superior performance compared to traditional silicone-based compounds. Recent developments in graphene and carbon nanotube-enhanced TIMs show promising results, with thermal conductivity improvements of 35-60% over conventional materials.

Packaging substrate selection must consider both thermal and electrical requirements. High-temperature co-fired ceramics (HTCC) and low-temperature co-fired ceramics (LTCC) offer excellent thermal stability, while direct-bonded copper (DBC) substrates provide superior heat spreading capabilities for high-power applications. For cost-sensitive applications, FR-4 with enhanced thermal vias remains viable, though with performance limitations.

Material selection strategies must also account for manufacturing constraints and economic considerations. Advanced materials like diamond heat spreaders may offer theoretical advantages but present significant manufacturing challenges. A balanced approach considering thermal simulation data, production scalability, and cost-effectiveness typically yields optimal results. Simulation-guided material selection enables engineers to identify the most critical thermal pathways and allocate premium materials strategically where they deliver maximum benefit.

Composite materials offer particularly promising solutions for thermal management challenges. Metal matrix composites (MMCs), especially aluminum-silicon carbide (AlSiC) with thermal conductivity ranging from 170-200 W/m·K, provide an excellent balance between weight, thermal performance, and coefficient of thermal expansion (CTE) matching with semiconductor materials. This CTE matching is crucial for preventing mechanical stress during thermal cycling, which can lead to device failure.

For submount materials, diamond-copper composites have emerged as premium solutions, offering thermal conductivity values approaching 600-800 W/m·K. Though expensive, these materials justify their cost in high-power VCSEL arrays where thermal management is particularly critical. Alternatively, cost-effective solutions include copper-tungsten alloys that balance thermal performance with manufacturing practicality.

Thermal interface materials (TIMs) represent another crucial component in the thermal pathway. Advanced metal-based TIMs containing gallium, indium, or silver particles demonstrate superior performance compared to traditional silicone-based compounds. Recent developments in graphene and carbon nanotube-enhanced TIMs show promising results, with thermal conductivity improvements of 35-60% over conventional materials.

Packaging substrate selection must consider both thermal and electrical requirements. High-temperature co-fired ceramics (HTCC) and low-temperature co-fired ceramics (LTCC) offer excellent thermal stability, while direct-bonded copper (DBC) substrates provide superior heat spreading capabilities for high-power applications. For cost-sensitive applications, FR-4 with enhanced thermal vias remains viable, though with performance limitations.

Material selection strategies must also account for manufacturing constraints and economic considerations. Advanced materials like diamond heat spreaders may offer theoretical advantages but present significant manufacturing challenges. A balanced approach considering thermal simulation data, production scalability, and cost-effectiveness typically yields optimal results. Simulation-guided material selection enables engineers to identify the most critical thermal pathways and allocate premium materials strategically where they deliver maximum benefit.

Integration Considerations for System-Level Thermal Management

When integrating VCSEL modules into larger systems, thermal management must be approached holistically. The thermal behavior of VCSELs cannot be considered in isolation, as it significantly impacts and is impacted by the entire system's thermal profile. System designers must account for thermal coupling between the VCSEL module and adjacent components, which can create complex heat transfer pathways and potential thermal bottlenecks.

Heat dissipation strategies should be coordinated across the system architecture. For instance, if the VCSEL module is placed near other heat-generating components such as processors or power electronics, the cumulative thermal load may exceed the capacity of localized cooling solutions. Thermal simulation models must therefore incorporate the entire thermal network, including all significant heat sources and thermal interfaces within the system.

Material selection for surrounding components becomes critical in system-level thermal management. Thermally conductive materials strategically placed can create effective heat spreading pathways, while thermal insulators can protect temperature-sensitive components from heat-generating VCSELs. The simulation must accurately represent these material properties and their spatial arrangement to predict system behavior correctly.

Transient thermal effects require special attention in system integration. Many applications involve intermittent VCSEL operation, creating dynamic thermal conditions throughout the system. Simulations should capture these time-dependent behaviors, including thermal capacitance effects and the thermal response times of different system components.

Environmental conditions significantly influence system-level thermal performance. Ambient temperature variations, airflow restrictions, and enclosure designs all affect the thermal equilibrium of the integrated system. Comprehensive thermal simulations should include these environmental factors, potentially using computational fluid dynamics (CFD) to model airflow patterns around and through the system.

Thermal management solutions must be compatible with other system requirements. For example, EMI shielding, optical alignment tolerances, mechanical robustness, and size constraints may limit thermal design options. Multi-physics simulations that couple thermal, mechanical, and electromagnetic analyses can help identify optimal compromises between competing requirements.

Finally, system-level thermal verification testing should validate simulation results under realistic operating conditions. This includes thermal cycling, power cycling, and long-term reliability testing to ensure that the integrated VCSEL module performs reliably within the thermal environment of the complete system.

Heat dissipation strategies should be coordinated across the system architecture. For instance, if the VCSEL module is placed near other heat-generating components such as processors or power electronics, the cumulative thermal load may exceed the capacity of localized cooling solutions. Thermal simulation models must therefore incorporate the entire thermal network, including all significant heat sources and thermal interfaces within the system.

Material selection for surrounding components becomes critical in system-level thermal management. Thermally conductive materials strategically placed can create effective heat spreading pathways, while thermal insulators can protect temperature-sensitive components from heat-generating VCSELs. The simulation must accurately represent these material properties and their spatial arrangement to predict system behavior correctly.

Transient thermal effects require special attention in system integration. Many applications involve intermittent VCSEL operation, creating dynamic thermal conditions throughout the system. Simulations should capture these time-dependent behaviors, including thermal capacitance effects and the thermal response times of different system components.

Environmental conditions significantly influence system-level thermal performance. Ambient temperature variations, airflow restrictions, and enclosure designs all affect the thermal equilibrium of the integrated system. Comprehensive thermal simulations should include these environmental factors, potentially using computational fluid dynamics (CFD) to model airflow patterns around and through the system.

Thermal management solutions must be compatible with other system requirements. For example, EMI shielding, optical alignment tolerances, mechanical robustness, and size constraints may limit thermal design options. Multi-physics simulations that couple thermal, mechanical, and electromagnetic analyses can help identify optimal compromises between competing requirements.

Finally, system-level thermal verification testing should validate simulation results under realistic operating conditions. This includes thermal cycling, power cycling, and long-term reliability testing to ensure that the integrated VCSEL module performs reliably within the thermal environment of the complete system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!