Packaging Materials To Mitigate Thermal Drift In VCSELs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Thermal Packaging Background & Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various applications including facial recognition, LiDAR systems, data communications, and consumer electronics. Since their commercial introduction in the 1990s, VCSELs have undergone significant technological evolution, transitioning from laboratory curiosities to mass-produced optoelectronic devices. The fundamental challenge that has persisted throughout this evolution is thermal management, particularly thermal drift, which directly impacts wavelength stability, output power, and overall device reliability.

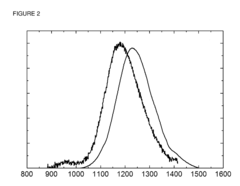

Thermal drift in VCSELs occurs when heat generated during operation causes changes in the refractive index of the semiconductor materials and thermal expansion of the cavity, resulting in wavelength shifts typically at a rate of 0.06-0.07 nm/°C. This phenomenon becomes increasingly problematic as applications demand greater precision and stability, particularly in sensing and measurement systems where wavelength consistency is paramount.

The historical approach to mitigating thermal issues in VCSELs has primarily focused on heat sinks and active cooling systems. However, these solutions add complexity, cost, and size constraints that limit their practicality in modern miniaturized applications. The industry has gradually shifted toward addressing thermal challenges through advanced packaging materials and designs that can passively manage heat while maintaining or reducing form factors.

Recent technological trends indicate growing interest in novel thermal interface materials (TIMs), thermally conductive adhesives, and composite substrates specifically engineered for optoelectronic applications. The integration of materials science advancements with VCSEL packaging represents a promising frontier for overcoming thermal limitations without compromising device performance or manufacturability.

The primary objectives of this technical research are to comprehensively evaluate existing and emerging packaging materials specifically designed to mitigate thermal drift in VCSELs, assess their effectiveness across various operating conditions, and identify potential breakthrough materials that could enable next-generation VCSEL applications. Additionally, we aim to establish quantifiable metrics for thermal performance that can guide material selection and packaging design decisions.

Furthermore, this research seeks to map the relationship between packaging material properties and VCSEL thermal behavior, creating predictive models that can accelerate future development cycles. By understanding the fundamental mechanisms of heat transfer within VCSEL packages and the material interfaces, we can establish design principles that optimize thermal management while maintaining optical alignment precision and mechanical integrity throughout the device lifetime.

Thermal drift in VCSELs occurs when heat generated during operation causes changes in the refractive index of the semiconductor materials and thermal expansion of the cavity, resulting in wavelength shifts typically at a rate of 0.06-0.07 nm/°C. This phenomenon becomes increasingly problematic as applications demand greater precision and stability, particularly in sensing and measurement systems where wavelength consistency is paramount.

The historical approach to mitigating thermal issues in VCSELs has primarily focused on heat sinks and active cooling systems. However, these solutions add complexity, cost, and size constraints that limit their practicality in modern miniaturized applications. The industry has gradually shifted toward addressing thermal challenges through advanced packaging materials and designs that can passively manage heat while maintaining or reducing form factors.

Recent technological trends indicate growing interest in novel thermal interface materials (TIMs), thermally conductive adhesives, and composite substrates specifically engineered for optoelectronic applications. The integration of materials science advancements with VCSEL packaging represents a promising frontier for overcoming thermal limitations without compromising device performance or manufacturability.

The primary objectives of this technical research are to comprehensively evaluate existing and emerging packaging materials specifically designed to mitigate thermal drift in VCSELs, assess their effectiveness across various operating conditions, and identify potential breakthrough materials that could enable next-generation VCSEL applications. Additionally, we aim to establish quantifiable metrics for thermal performance that can guide material selection and packaging design decisions.

Furthermore, this research seeks to map the relationship between packaging material properties and VCSEL thermal behavior, creating predictive models that can accelerate future development cycles. By understanding the fundamental mechanisms of heat transfer within VCSEL packages and the material interfaces, we can establish design principles that optimize thermal management while maintaining optical alignment precision and mechanical integrity throughout the device lifetime.

Market Analysis for Thermally Stable VCSELs

The global market for VCSELs (Vertical-Cavity Surface-Emitting Lasers) has been experiencing robust growth, with a market value reaching approximately $2.1 billion in 2022 and projected to grow at a CAGR of 17.3% through 2028. This growth is primarily driven by increasing applications in facial recognition, 3D sensing, data communication, and automotive LiDAR systems. Thermally stable VCSELs represent a critical segment within this market, as thermal drift significantly impacts device performance and reliability.

Consumer electronics remains the dominant application sector, accounting for nearly 40% of the VCSEL market. Apple's implementation of VCSEL arrays in Face ID technology has been a major catalyst, establishing high standards for thermal stability in consumer applications. The automotive sector is emerging as the fastest-growing segment, with a projected CAGR of 23.5% as LiDAR systems become essential components in advanced driver-assistance systems (ADAS) and autonomous vehicles.

Geographically, North America leads the market with approximately 35% share, followed closely by Asia-Pacific at 33%, which is expected to demonstrate the highest growth rate due to expanding manufacturing capabilities in China, Taiwan, and South Korea. Europe holds about 25% of the market, with particular strength in automotive and industrial applications.

The demand for thermally stable VCSELs is particularly acute in applications requiring precise wavelength control. Data centers, which utilize VCSELs for optical interconnects, require devices that maintain consistent performance across varying temperature conditions to ensure reliable high-speed data transmission. Similarly, automotive LiDAR systems operate in harsh environmental conditions with temperature fluctuations from -40°C to +85°C, necessitating exceptional thermal stability.

Market analysis indicates that customers are willing to pay a premium of 15-20% for VCSELs with enhanced thermal stability, particularly in mission-critical applications. This price premium reflects the downstream cost savings achieved through improved system reliability and reduced need for temperature compensation circuitry.

The competitive landscape shows increasing focus on thermal management solutions. Leading VCSEL manufacturers are investing heavily in advanced packaging technologies, with thermal management patents increasing by 28% over the past three years. Industry surveys indicate that 73% of system designers consider thermal stability a top-three criterion when selecting VCSEL suppliers, highlighting the market's recognition of this challenge.

Market forecasts suggest that innovations in packaging materials specifically designed to mitigate thermal drift could capture significant market share, potentially creating a specialized sub-segment worth $350 million by 2026. This represents a substantial opportunity for materials science companies and VCSEL manufacturers who can develop effective solutions to the thermal drift challenge.

Consumer electronics remains the dominant application sector, accounting for nearly 40% of the VCSEL market. Apple's implementation of VCSEL arrays in Face ID technology has been a major catalyst, establishing high standards for thermal stability in consumer applications. The automotive sector is emerging as the fastest-growing segment, with a projected CAGR of 23.5% as LiDAR systems become essential components in advanced driver-assistance systems (ADAS) and autonomous vehicles.

Geographically, North America leads the market with approximately 35% share, followed closely by Asia-Pacific at 33%, which is expected to demonstrate the highest growth rate due to expanding manufacturing capabilities in China, Taiwan, and South Korea. Europe holds about 25% of the market, with particular strength in automotive and industrial applications.

The demand for thermally stable VCSELs is particularly acute in applications requiring precise wavelength control. Data centers, which utilize VCSELs for optical interconnects, require devices that maintain consistent performance across varying temperature conditions to ensure reliable high-speed data transmission. Similarly, automotive LiDAR systems operate in harsh environmental conditions with temperature fluctuations from -40°C to +85°C, necessitating exceptional thermal stability.

Market analysis indicates that customers are willing to pay a premium of 15-20% for VCSELs with enhanced thermal stability, particularly in mission-critical applications. This price premium reflects the downstream cost savings achieved through improved system reliability and reduced need for temperature compensation circuitry.

The competitive landscape shows increasing focus on thermal management solutions. Leading VCSEL manufacturers are investing heavily in advanced packaging technologies, with thermal management patents increasing by 28% over the past three years. Industry surveys indicate that 73% of system designers consider thermal stability a top-three criterion when selecting VCSEL suppliers, highlighting the market's recognition of this challenge.

Market forecasts suggest that innovations in packaging materials specifically designed to mitigate thermal drift could capture significant market share, potentially creating a specialized sub-segment worth $350 million by 2026. This represents a substantial opportunity for materials science companies and VCSEL manufacturers who can develop effective solutions to the thermal drift challenge.

Current Packaging Challenges & Thermal Drift Issues

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various applications including facial recognition, LiDAR systems, and high-speed data communications. However, these devices face significant challenges related to thermal management that directly impact their performance and reliability. The primary issue is thermal drift, where changes in temperature cause wavelength shifts, power fluctuations, and beam profile alterations.

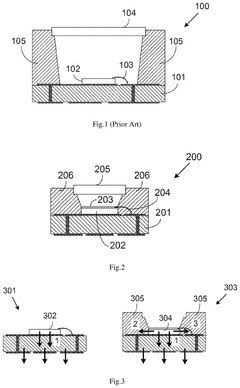

Current packaging solutions for VCSELs exhibit several limitations that exacerbate thermal drift issues. Traditional materials like aluminum nitride (AlN) and aluminum oxide (Al2O3) provide insufficient thermal conductivity for high-power VCSEL arrays, resulting in localized hotspots and thermal gradients across the device. These thermal gradients lead to non-uniform emission characteristics and reduced device lifetime.

Coefficient of Thermal Expansion (CTE) mismatch between the VCSEL die and packaging materials represents another critical challenge. When VCSELs operate through temperature cycles, the differential expansion rates create mechanical stress at interfaces, potentially causing delamination, microcracks, or bond failures. This mechanical stress further contributes to wavelength instability and reliability concerns, particularly in automotive and industrial applications where temperature fluctuations are common.

Existing thermal interface materials (TIMs) used between the VCSEL and heat sink often demonstrate degradation over time, with decreasing thermal conductivity after thermal cycling. This degradation pathway creates a compounding problem where thermal management becomes progressively worse throughout the device lifetime, accelerating performance deterioration.

The miniaturization trend in consumer electronics has imposed severe space constraints on VCSEL packaging, limiting the implementation of more effective but bulkier thermal management solutions. This size restriction forces engineers to make compromises between thermal performance and form factor, often resulting in suboptimal thermal designs that cannot adequately address drift issues.

Current hermetic sealing approaches, while necessary for protecting VCSELs from environmental contaminants, frequently impede efficient heat dissipation. The materials used for hermetic packaging typically exhibit poor thermal conductivity, creating a thermal bottleneck that traps heat within the package and accelerates thermal drift effects.

Multi-chip VCSEL arrays face particularly complex thermal challenges, as heat generated by individual emitters can affect neighboring devices, creating thermal crosstalk. This phenomenon results in non-uniform thermal profiles across the array, causing inconsistent wavelength emission and beam characteristics that compromise system-level performance in applications requiring precise optical output.

Current packaging solutions for VCSELs exhibit several limitations that exacerbate thermal drift issues. Traditional materials like aluminum nitride (AlN) and aluminum oxide (Al2O3) provide insufficient thermal conductivity for high-power VCSEL arrays, resulting in localized hotspots and thermal gradients across the device. These thermal gradients lead to non-uniform emission characteristics and reduced device lifetime.

Coefficient of Thermal Expansion (CTE) mismatch between the VCSEL die and packaging materials represents another critical challenge. When VCSELs operate through temperature cycles, the differential expansion rates create mechanical stress at interfaces, potentially causing delamination, microcracks, or bond failures. This mechanical stress further contributes to wavelength instability and reliability concerns, particularly in automotive and industrial applications where temperature fluctuations are common.

Existing thermal interface materials (TIMs) used between the VCSEL and heat sink often demonstrate degradation over time, with decreasing thermal conductivity after thermal cycling. This degradation pathway creates a compounding problem where thermal management becomes progressively worse throughout the device lifetime, accelerating performance deterioration.

The miniaturization trend in consumer electronics has imposed severe space constraints on VCSEL packaging, limiting the implementation of more effective but bulkier thermal management solutions. This size restriction forces engineers to make compromises between thermal performance and form factor, often resulting in suboptimal thermal designs that cannot adequately address drift issues.

Current hermetic sealing approaches, while necessary for protecting VCSELs from environmental contaminants, frequently impede efficient heat dissipation. The materials used for hermetic packaging typically exhibit poor thermal conductivity, creating a thermal bottleneck that traps heat within the package and accelerates thermal drift effects.

Multi-chip VCSEL arrays face particularly complex thermal challenges, as heat generated by individual emitters can affect neighboring devices, creating thermal crosstalk. This phenomenon results in non-uniform thermal profiles across the array, causing inconsistent wavelength emission and beam characteristics that compromise system-level performance in applications requiring precise optical output.

State-of-the-Art Thermal Mitigation Solutions

01 Thermal management materials for VCSEL packaging

Specialized thermal management materials are used in VCSEL packaging to mitigate thermal drift issues. These materials include high thermal conductivity substrates, heat spreaders, and thermal interface materials that efficiently dissipate heat generated during VCSEL operation. Proper thermal management is crucial for maintaining wavelength stability and preventing performance degradation due to temperature fluctuations.- Thermal management materials for VCSEL packaging: Specialized thermal management materials are used in VCSEL packaging to mitigate thermal drift. These materials include high thermal conductivity substrates, heat spreaders, and thermally conductive adhesives that efficiently dissipate heat generated during VCSEL operation. Proper thermal management is critical as VCSELs are temperature-sensitive devices, and their wavelength and performance characteristics can drift significantly with temperature changes.

- Hermetic sealing and encapsulation techniques: Hermetic sealing and encapsulation materials protect VCSELs from environmental factors that can contribute to thermal drift. These packaging solutions include glass-to-metal seals, ceramic packages, and specialized polymer encapsulants that maintain stable internal environments. The hermetic packaging prevents moisture ingress and contamination while providing thermal isolation, which helps maintain consistent VCSEL performance across varying external conditions.

- Temperature compensation structures in VCSEL packages: Advanced packaging designs incorporate temperature compensation structures to actively counteract thermal drift effects. These include integrated temperature sensors, thermoelectric coolers, and materials with complementary thermal expansion coefficients. Such structures work to maintain stable operating temperatures or compensate for wavelength shifts caused by temperature variations, ensuring consistent VCSEL performance in applications requiring high precision.

- Multi-layer substrate materials for thermal stability: Multi-layer substrate materials in VCSEL packaging provide enhanced thermal stability. These substrates typically combine different materials with carefully engineered thermal properties to create balanced thermal expansion and efficient heat dissipation pathways. The layered approach allows for customized thermal management solutions that address the specific thermal drift challenges of different VCSEL applications, from telecommunications to sensing and consumer electronics.

- Optical coupling materials with thermal stability: Specialized optical coupling materials are used in VCSEL packages to maintain beam characteristics despite thermal variations. These materials include thermally stable optical adhesives, lens systems with athermal designs, and waveguide structures that compensate for thermal expansion. By maintaining consistent optical coupling efficiency across temperature ranges, these materials help minimize the impact of thermal drift on the overall performance of VCSEL-based systems.

02 Hermetic sealing and encapsulation techniques

Hermetic sealing and encapsulation techniques protect VCSELs from environmental factors that can contribute to thermal drift. These packaging approaches use materials like ceramics, metals, and specialized polymers to create airtight seals that prevent moisture ingress while providing thermal stability. The encapsulation materials are selected for their thermal expansion properties to minimize stress during temperature fluctuations.Expand Specific Solutions03 Temperature compensation mechanisms

Advanced packaging materials incorporate temperature compensation mechanisms to actively counteract thermal drift in VCSELs. These include materials with negative temperature coefficients that balance the positive temperature coefficients of VCSELs, thermoelectric coolers integrated into packages, and feedback control systems. These mechanisms help maintain stable operating conditions despite ambient temperature changes.Expand Specific Solutions04 Multi-layer composite packaging structures

Multi-layer composite structures in VCSEL packaging combine different materials to optimize thermal performance. These structures typically include layers of ceramics, metals, and specialized polymers arranged to manage heat flow paths and thermal expansion mismatches. The strategic arrangement of materials with complementary thermal properties helps minimize stress and maintain alignment precision during temperature fluctuations.Expand Specific Solutions05 Novel materials for next-generation VCSEL packaging

Emerging materials for next-generation VCSEL packaging focus on enhanced thermal stability. These include diamond-based substrates, carbon nanotubes, graphene-enhanced composites, and advanced ceramic materials. These novel materials offer superior thermal conductivity, reduced thermal expansion, and improved long-term reliability, addressing the thermal drift challenges in high-power and high-frequency VCSEL applications.Expand Specific Solutions

Leading VCSEL Packaging Material Manufacturers

The VCSEL thermal drift mitigation packaging materials market is in a growth phase, with increasing demand driven by applications in consumer electronics, automotive, and telecommunications. The market is expected to expand significantly as VCSELs become more prevalent in 3D sensing, facial recognition, and LiDAR systems. Leading players include Samsung Electronics and Samsung Semiconductor, leveraging their vertical integration capabilities, alongside specialized manufacturers like Lumentum Operations and ams-Osram. Academic institutions such as Beijing University of Technology and Peking University contribute to technological advancements. Material innovation leaders include Henkel IP & Holding, ThreeBond, and Aspen Aerogels, focusing on developing advanced thermal management solutions to enhance VCSEL performance stability and reliability across varying environmental conditions.

Lumentum Operations LLC

Technical Solution: Lumentum has developed advanced thermal management packaging solutions for VCSELs that incorporate multi-layer ceramic substrates with optimized thermal conductivity pathways. Their approach includes specialized submounts with integrated thermal vias and heat spreading layers that efficiently channel heat away from the active region of the VCSEL. The company employs proprietary hermetic sealing techniques that maintain package integrity while allowing for efficient heat dissipation. Lumentum's packaging incorporates thermally compensating materials with opposing coefficients of thermal expansion to counteract wavelength drift across operating temperature ranges. Their designs feature precision temperature sensors embedded within close proximity to the VCSEL die, enabling real-time thermal monitoring and feedback for wavelength stabilization systems. Additionally, Lumentum utilizes advanced thermal interface materials (TIMs) with high thermal conductivity and low thermal resistance to optimize heat transfer from the VCSEL to the package substrate.

Strengths: Superior thermal management expertise from years of optical communications experience; proprietary hermetic sealing technology maintains package integrity while allowing efficient heat dissipation; integrated thermal monitoring capabilities enable active compensation. Weaknesses: Higher manufacturing costs compared to standard packaging solutions; complex multi-layer designs may present yield challenges in high-volume production environments.

Sony Group Corp.

Technical Solution: Sony Group has developed a sophisticated thermal management packaging solution for VCSELs called "ThermoStable Array Technology" (TSAT). This approach utilizes advanced ceramic-metal composite substrates with precisely engineered thermal expansion properties to match the VCSEL semiconductor materials. Sony's packaging incorporates proprietary high-thermal-conductivity die-attach materials (exceeding 200 W/mK) that create an efficient thermal interface between the VCSEL and substrate. Their design features multi-layer heat spreading structures with embedded micro heat pipes that efficiently distribute and dissipate heat away from the active region. Sony has pioneered the use of diamond-like carbon (DLC) coatings within the package to enhance thermal conductivity while maintaining electrical isolation where needed. The TSAT solution also incorporates specialized wavelength-stabilizing optical elements that compensate for thermal drift through passive mechanical counterbalancing. Sony's packaging design includes thermally optimized wire bonding techniques and materials that minimize additional heat introduction while ensuring reliable electrical connections. Their comprehensive approach addresses both steady-state thermal management and transient thermal behavior to maintain wavelength stability under dynamic operating conditions.

Strengths: Exceptional thermal performance through innovative material combinations; comprehensive approach addressing both steady-state and transient thermal behavior; integration with Sony's broader optoelectronic ecosystem. Weaknesses: Premium solution with higher associated costs; complex manufacturing process requires specialized equipment; some advanced materials have limited suppliers, potentially affecting supply chain resilience.

Critical Patents in VCSEL Thermal Packaging

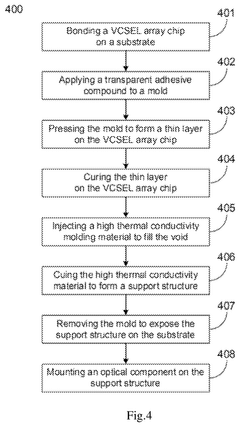

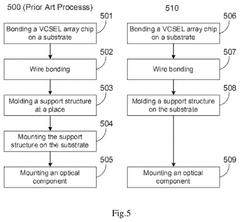

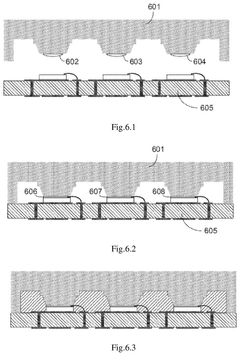

Vertical cavity surface emitting laser (VCSEL) array package and manufacturing method

PatentActiveUS12107387B2

Innovation

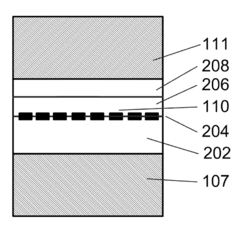

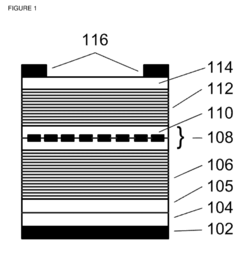

- A VCSEL array package design that includes a VCSEL array chip bonded on a substrate with a support structure molded from high thermal conductivity material, covering the side surfaces of the chip to create additional thermal paths and eliminate gaps, and a transparent thin layer to prevent beam obstruction and reflection.

Vertical-Cavity Surface-Emitting Laser

PatentActiveUS20180054041A1

Innovation

- A VCSEL design incorporating gallium arsenide antimonide nanostructures with quantum rings in the active region, surrounded by aluminium gallium arsenide layers with a composition gradient, which enhances thermal conductivity and reduces strain, allowing for efficient laser emission within the 1260 to 1675 nm range without the need for active cooling.

Environmental Impact of Packaging Materials

The environmental impact of packaging materials used in VCSEL thermal management is becoming increasingly significant as sustainability concerns grow across the electronics industry. Traditional packaging materials often contain various metals, ceramics, and synthetic compounds that pose substantial environmental challenges throughout their lifecycle. The extraction of raw materials for these packages, particularly rare metals and petroleum-based compounds, contributes to habitat destruction, energy consumption, and greenhouse gas emissions.

Manufacturing processes for VCSEL packaging materials typically involve energy-intensive procedures, chemical treatments, and precision engineering that generate considerable carbon footprints. Particularly concerning are the high-temperature processes required for ceramic substrates and metal-based heat spreaders, which consume significant energy resources and release atmospheric pollutants.

The use of halogenated flame retardants and lead-based solders in conventional packaging presents serious toxicity concerns. While industry regulations like RoHS have driven reductions in hazardous substances, many thermal management materials still contain compounds that can leach into ecosystems when improperly disposed of. The semiconductor industry's rapid product cycles exacerbate this issue, as devices containing VCSELs are frequently replaced and discarded.

End-of-life considerations reveal further environmental challenges. Most current VCSEL packaging materials have limited recyclability due to their complex, multi-material composition. The intricate integration of metals, ceramics, and polymers makes separation difficult and economically unfeasible, resulting in significant electronic waste that often ends up in landfills or is shipped to regions with less stringent environmental regulations.

Emerging alternatives show promise for reducing environmental impact. Bio-based polymers, recyclable metal alloys, and carbon-based materials like graphene offer potential pathways to more sustainable packaging solutions. These materials can potentially deliver the thermal management properties required for VCSEL operation while reducing environmental footprint. Additionally, design approaches that facilitate disassembly and material recovery are gaining traction in research communities.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of electronic components. The European Union's WEEE Directive, Extended Producer Responsibility policies, and emerging circular economy initiatives are pushing manufacturers to consider the full lifecycle environmental impact of packaging materials. Companies developing VCSEL technology must navigate these evolving requirements while maintaining thermal performance specifications.

Manufacturing processes for VCSEL packaging materials typically involve energy-intensive procedures, chemical treatments, and precision engineering that generate considerable carbon footprints. Particularly concerning are the high-temperature processes required for ceramic substrates and metal-based heat spreaders, which consume significant energy resources and release atmospheric pollutants.

The use of halogenated flame retardants and lead-based solders in conventional packaging presents serious toxicity concerns. While industry regulations like RoHS have driven reductions in hazardous substances, many thermal management materials still contain compounds that can leach into ecosystems when improperly disposed of. The semiconductor industry's rapid product cycles exacerbate this issue, as devices containing VCSELs are frequently replaced and discarded.

End-of-life considerations reveal further environmental challenges. Most current VCSEL packaging materials have limited recyclability due to their complex, multi-material composition. The intricate integration of metals, ceramics, and polymers makes separation difficult and economically unfeasible, resulting in significant electronic waste that often ends up in landfills or is shipped to regions with less stringent environmental regulations.

Emerging alternatives show promise for reducing environmental impact. Bio-based polymers, recyclable metal alloys, and carbon-based materials like graphene offer potential pathways to more sustainable packaging solutions. These materials can potentially deliver the thermal management properties required for VCSEL operation while reducing environmental footprint. Additionally, design approaches that facilitate disassembly and material recovery are gaining traction in research communities.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of electronic components. The European Union's WEEE Directive, Extended Producer Responsibility policies, and emerging circular economy initiatives are pushing manufacturers to consider the full lifecycle environmental impact of packaging materials. Companies developing VCSEL technology must navigate these evolving requirements while maintaining thermal performance specifications.

Reliability Testing Standards for VCSEL Packages

Reliability testing standards for VCSEL packages have evolved significantly to address the unique challenges posed by thermal drift in these critical optoelectronic components. Industry standards such as Telcordia GR-468, MIL-STD-883, and AEC-Q102 provide comprehensive frameworks for evaluating VCSEL package reliability under various environmental conditions, with particular emphasis on thermal performance.

The temperature cycling test (TCT) represents a cornerstone of VCSEL package reliability assessment, typically requiring devices to withstand 500-1000 cycles between -40°C and +85°C (or more extreme temperatures for automotive applications). This test specifically evaluates how packaging materials respond to repeated thermal expansion and contraction, directly correlating to their ability to mitigate thermal drift.

High-temperature operating life (HTOL) testing complements TCT by subjecting packaged VCSELs to elevated temperatures (typically 85°C to 125°C) while operating at rated current for 1000-5000 hours. This accelerated aging process reveals how packaging materials perform in maintaining thermal stability over extended periods, with measurements of wavelength shift serving as a critical indicator of thermal drift mitigation effectiveness.

Humidity testing standards, including 85°C/85% relative humidity tests for 1000 hours, assess moisture penetration resistance—a critical factor as moisture ingress can dramatically alter the thermal properties of packaging materials and exacerbate thermal drift issues. For automotive and industrial applications, additional tests including temperature-humidity-bias (THB) and highly accelerated stress testing (HAST) provide more rigorous evaluation.

Mechanical shock and vibration testing standards (e.g., MIL-STD-883 Method 2002) evaluate the robustness of thermal interfaces within the package, as degradation of these interfaces directly impacts thermal management capabilities. These tests typically involve subjecting devices to controlled mechanical stresses while monitoring for changes in thermal resistance or wavelength stability.

Recent developments in reliability standards have introduced more specialized tests for VCSEL packages, including power cycling tests that more accurately simulate real-world operating conditions with rapid temperature fluctuations. Additionally, combined stress testing methodologies that simultaneously apply multiple stressors (temperature, humidity, electrical bias) provide more realistic assessment of packaging material performance in mitigating thermal drift under complex environmental conditions.

The temperature cycling test (TCT) represents a cornerstone of VCSEL package reliability assessment, typically requiring devices to withstand 500-1000 cycles between -40°C and +85°C (or more extreme temperatures for automotive applications). This test specifically evaluates how packaging materials respond to repeated thermal expansion and contraction, directly correlating to their ability to mitigate thermal drift.

High-temperature operating life (HTOL) testing complements TCT by subjecting packaged VCSELs to elevated temperatures (typically 85°C to 125°C) while operating at rated current for 1000-5000 hours. This accelerated aging process reveals how packaging materials perform in maintaining thermal stability over extended periods, with measurements of wavelength shift serving as a critical indicator of thermal drift mitigation effectiveness.

Humidity testing standards, including 85°C/85% relative humidity tests for 1000 hours, assess moisture penetration resistance—a critical factor as moisture ingress can dramatically alter the thermal properties of packaging materials and exacerbate thermal drift issues. For automotive and industrial applications, additional tests including temperature-humidity-bias (THB) and highly accelerated stress testing (HAST) provide more rigorous evaluation.

Mechanical shock and vibration testing standards (e.g., MIL-STD-883 Method 2002) evaluate the robustness of thermal interfaces within the package, as degradation of these interfaces directly impacts thermal management capabilities. These tests typically involve subjecting devices to controlled mechanical stresses while monitoring for changes in thermal resistance or wavelength stability.

Recent developments in reliability standards have introduced more specialized tests for VCSEL packages, including power cycling tests that more accurately simulate real-world operating conditions with rapid temperature fluctuations. Additionally, combined stress testing methodologies that simultaneously apply multiple stressors (temperature, humidity, electrical bias) provide more realistic assessment of packaging material performance in mitigating thermal drift under complex environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!