VCSEL Aging Mechanisms Under Elevated Temperature Cycling

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Aging Mechanisms and Research Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various optoelectronic applications, including data communications, sensing, and consumer electronics. The evolution of VCSEL technology spans several decades, beginning with theoretical conceptualization in the 1970s, followed by practical demonstrations in the 1980s, and commercial deployment starting in the 1990s. Understanding aging mechanisms under elevated temperature cycling has become increasingly important as applications demand higher reliability in harsh operating environments.

The aging of VCSELs represents a complex interplay of multiple degradation pathways that affect device performance and lifetime. These mechanisms include dark line defect propagation, oxide aperture degradation, mirror interface deterioration, and active region compositional changes. Temperature cycling particularly exacerbates these issues by inducing thermal stress that accelerates defect formation and migration within the device structure.

Recent technological trends indicate a growing focus on developing VCSELs with enhanced thermal stability and reliability for emerging applications in automotive LiDAR, biometric authentication, and industrial sensing. The industry is witnessing a shift toward more robust epitaxial designs, advanced passivation techniques, and novel materials to mitigate temperature-induced degradation effects.

Our research objectives encompass several critical dimensions of VCSEL reliability under thermal stress. First, we aim to characterize the fundamental physical mechanisms driving degradation during temperature cycling, with particular emphasis on differentiating between reversible and irreversible changes in device performance. Second, we seek to develop accelerated testing methodologies that accurately predict long-term reliability while reducing evaluation timeframes.

Additionally, we intend to investigate the correlation between specific manufacturing processes and subsequent temperature-cycling resilience. This includes examining how epitaxial growth conditions, device geometry, and passivation techniques influence aging behavior. The ultimate goal is to establish design guidelines and process optimizations that enhance VCSEL robustness in thermally challenging environments.

Furthermore, our research aims to explore novel characterization techniques that can provide early indicators of impending device failure under temperature cycling stress. This includes developing non-destructive in-situ monitoring approaches and identifying key performance parameters that serve as reliable predictors of device lifetime.

By addressing these research objectives, we anticipate developing next-generation VCSELs with significantly improved reliability under temperature cycling conditions, thereby enabling their deployment in more demanding applications where thermal stability is paramount.

The aging of VCSELs represents a complex interplay of multiple degradation pathways that affect device performance and lifetime. These mechanisms include dark line defect propagation, oxide aperture degradation, mirror interface deterioration, and active region compositional changes. Temperature cycling particularly exacerbates these issues by inducing thermal stress that accelerates defect formation and migration within the device structure.

Recent technological trends indicate a growing focus on developing VCSELs with enhanced thermal stability and reliability for emerging applications in automotive LiDAR, biometric authentication, and industrial sensing. The industry is witnessing a shift toward more robust epitaxial designs, advanced passivation techniques, and novel materials to mitigate temperature-induced degradation effects.

Our research objectives encompass several critical dimensions of VCSEL reliability under thermal stress. First, we aim to characterize the fundamental physical mechanisms driving degradation during temperature cycling, with particular emphasis on differentiating between reversible and irreversible changes in device performance. Second, we seek to develop accelerated testing methodologies that accurately predict long-term reliability while reducing evaluation timeframes.

Additionally, we intend to investigate the correlation between specific manufacturing processes and subsequent temperature-cycling resilience. This includes examining how epitaxial growth conditions, device geometry, and passivation techniques influence aging behavior. The ultimate goal is to establish design guidelines and process optimizations that enhance VCSEL robustness in thermally challenging environments.

Furthermore, our research aims to explore novel characterization techniques that can provide early indicators of impending device failure under temperature cycling stress. This includes developing non-destructive in-situ monitoring approaches and identifying key performance parameters that serve as reliable predictors of device lifetime.

By addressing these research objectives, we anticipate developing next-generation VCSELs with significantly improved reliability under temperature cycling conditions, thereby enabling their deployment in more demanding applications where thermal stability is paramount.

Market Demand Analysis for Reliable VCSEL Technology

The global market for Vertical-Cavity Surface-Emitting Lasers (VCSELs) has experienced remarkable growth, driven primarily by their expanding applications in consumer electronics, data communications, and sensing technologies. Current market projections indicate the VCSEL market will reach approximately $3.7 billion by 2025, with a compound annual growth rate exceeding 17% from 2020. This substantial growth underscores the critical importance of addressing reliability challenges, particularly aging mechanisms under elevated temperature cycling.

Consumer electronics represents the largest market segment for VCSEL technology, with 3D sensing applications in smartphones and tablets driving significant demand. Apple's implementation of Face ID technology utilizing VCSEL arrays has established a benchmark for secure biometric authentication, creating a ripple effect across the industry. Market research indicates that over 45% of smartphones shipped in 2022 incorporated some form of 3D sensing technology, with this percentage expected to increase to 65% by 2026.

The automotive sector presents another rapidly expanding market for reliable VCSEL technology. LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles require VCSELs capable of withstanding extreme temperature variations while maintaining consistent performance. Industry analysts project the automotive LiDAR market to grow at a CAGR of 28% through 2028, with VCSEL-based solutions gaining market share due to their cost-effectiveness and compact form factor.

Data center applications represent a third critical market segment demanding highly reliable VCSEL technology. The transition to higher data rates in optical interconnects (100G, 400G, and beyond) places stringent requirements on VCSEL performance stability. Temperature fluctuations in data center environments directly impact VCSEL reliability, with each 10°C increase potentially reducing device lifetime by 50%. This relationship between temperature cycling and device longevity translates directly to operational costs and system reliability.

Market research indicates that customers across all segments are willing to pay a premium of 15-20% for VCSELs with demonstrated resilience to temperature cycling, highlighting the economic value of solving aging mechanism challenges. Furthermore, regulatory requirements in automotive and aerospace applications are becoming increasingly stringent regarding component reliability under variable environmental conditions.

The geographical distribution of VCSEL demand shows North America leading with approximately 35% market share, followed by Asia-Pacific at 32% and Europe at 25%. However, the fastest growth is occurring in the Asia-Pacific region, where manufacturing of consumer electronics and automotive components is concentrated, further emphasizing the need for temperature-resilient VCSEL technology in diverse manufacturing and operating environments.

Consumer electronics represents the largest market segment for VCSEL technology, with 3D sensing applications in smartphones and tablets driving significant demand. Apple's implementation of Face ID technology utilizing VCSEL arrays has established a benchmark for secure biometric authentication, creating a ripple effect across the industry. Market research indicates that over 45% of smartphones shipped in 2022 incorporated some form of 3D sensing technology, with this percentage expected to increase to 65% by 2026.

The automotive sector presents another rapidly expanding market for reliable VCSEL technology. LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles require VCSELs capable of withstanding extreme temperature variations while maintaining consistent performance. Industry analysts project the automotive LiDAR market to grow at a CAGR of 28% through 2028, with VCSEL-based solutions gaining market share due to their cost-effectiveness and compact form factor.

Data center applications represent a third critical market segment demanding highly reliable VCSEL technology. The transition to higher data rates in optical interconnects (100G, 400G, and beyond) places stringent requirements on VCSEL performance stability. Temperature fluctuations in data center environments directly impact VCSEL reliability, with each 10°C increase potentially reducing device lifetime by 50%. This relationship between temperature cycling and device longevity translates directly to operational costs and system reliability.

Market research indicates that customers across all segments are willing to pay a premium of 15-20% for VCSELs with demonstrated resilience to temperature cycling, highlighting the economic value of solving aging mechanism challenges. Furthermore, regulatory requirements in automotive and aerospace applications are becoming increasingly stringent regarding component reliability under variable environmental conditions.

The geographical distribution of VCSEL demand shows North America leading with approximately 35% market share, followed by Asia-Pacific at 32% and Europe at 25%. However, the fastest growth is occurring in the Asia-Pacific region, where manufacturing of consumer electronics and automotive components is concentrated, further emphasizing the need for temperature-resilient VCSEL technology in diverse manufacturing and operating environments.

Current Challenges in VCSEL Reliability Under Thermal Stress

Despite significant advancements in VCSEL technology, reliability under thermal stress remains a critical challenge for widespread commercial deployment. Current VCSELs exhibit several degradation mechanisms when subjected to elevated temperature cycling, which substantially impacts their operational lifetime and performance stability. The primary challenge stems from the complex interplay between thermal expansion, material interfaces, and current flow dynamics within these miniaturized devices.

Thermal cycling induces mechanical stress at heterojunction interfaces, particularly between the active region and distributed Bragg reflectors (DBRs). This stress manifests as microcracks and dislocations that propagate during operation, leading to gradual performance deterioration. Research indicates that devices experiencing temperature fluctuations between -40°C and 125°C show accelerated degradation compared to those maintained at stable temperatures, even when the maximum temperature is identical.

Dark line defect (DLD) formation represents another significant reliability challenge. These defects originate from point defects in the active region that expand under thermal stress, creating non-radiative recombination centers that reduce quantum efficiency. Current manufacturing processes struggle to eliminate these initial defect sites completely, making DLD formation a persistent reliability concern during thermal cycling.

Oxide aperture degradation presents a particularly troublesome challenge for modern VCSELs. The aluminum oxide confinement layer, critical for current channeling, undergoes compositional changes during thermal cycling. This results in altered electrical properties and mechanical integrity, affecting both the beam profile and threshold current over time. Recent studies have documented up to 15% threshold current increase after 1000 thermal cycles in high-power VCSELs.

Contact metallization reliability under thermal stress constitutes another major concern. The repeated expansion and contraction of metal contacts leads to delamination and increased contact resistance. This phenomenon is especially pronounced in high-current-density applications where localized heating compounds the external thermal cycling effects, creating a feedback loop of accelerated degradation.

Facet oxidation during high-temperature exposure represents a persistent challenge despite advances in passivation techniques. Oxygen penetration at elevated temperatures leads to non-radiative recombination sites at the semiconductor-air interface, reducing output power and altering spectral characteristics. Current passivation methods provide insufficient protection during extended thermal cycling, particularly in humid environments.

The industry also faces significant challenges in developing standardized reliability testing protocols that accurately predict real-world performance under thermal stress. Accelerated life testing methodologies often fail to capture the complex failure modes that emerge during actual operation, leading to discrepancies between laboratory qualification and field reliability.

Thermal cycling induces mechanical stress at heterojunction interfaces, particularly between the active region and distributed Bragg reflectors (DBRs). This stress manifests as microcracks and dislocations that propagate during operation, leading to gradual performance deterioration. Research indicates that devices experiencing temperature fluctuations between -40°C and 125°C show accelerated degradation compared to those maintained at stable temperatures, even when the maximum temperature is identical.

Dark line defect (DLD) formation represents another significant reliability challenge. These defects originate from point defects in the active region that expand under thermal stress, creating non-radiative recombination centers that reduce quantum efficiency. Current manufacturing processes struggle to eliminate these initial defect sites completely, making DLD formation a persistent reliability concern during thermal cycling.

Oxide aperture degradation presents a particularly troublesome challenge for modern VCSELs. The aluminum oxide confinement layer, critical for current channeling, undergoes compositional changes during thermal cycling. This results in altered electrical properties and mechanical integrity, affecting both the beam profile and threshold current over time. Recent studies have documented up to 15% threshold current increase after 1000 thermal cycles in high-power VCSELs.

Contact metallization reliability under thermal stress constitutes another major concern. The repeated expansion and contraction of metal contacts leads to delamination and increased contact resistance. This phenomenon is especially pronounced in high-current-density applications where localized heating compounds the external thermal cycling effects, creating a feedback loop of accelerated degradation.

Facet oxidation during high-temperature exposure represents a persistent challenge despite advances in passivation techniques. Oxygen penetration at elevated temperatures leads to non-radiative recombination sites at the semiconductor-air interface, reducing output power and altering spectral characteristics. Current passivation methods provide insufficient protection during extended thermal cycling, particularly in humid environments.

The industry also faces significant challenges in developing standardized reliability testing protocols that accurately predict real-world performance under thermal stress. Accelerated life testing methodologies often fail to capture the complex failure modes that emerge during actual operation, leading to discrepancies between laboratory qualification and field reliability.

Current Methodologies for VCSEL Reliability Enhancement

01 Thermal degradation mechanisms in VCSELs

Thermal degradation is a primary aging mechanism in VCSELs, occurring when the device operates at elevated temperatures over time. This leads to defect formation in the active region, degradation of mirror interfaces, and changes in the semiconductor material properties. The heat generated during operation can cause expansion of materials, leading to mechanical stress and eventual failure. Proper thermal management and heat dissipation designs are critical to mitigate these effects and extend VCSEL lifetime.- Thermal aging mechanisms in VCSELs: Thermal aging is a significant degradation mechanism in VCSELs, caused by heat generation during operation. Elevated temperatures can lead to defect formation, material diffusion, and changes in the active region. These thermal effects can cause a gradual decrease in output power, wavelength shifts, and increased threshold current. Long-term exposure to high temperatures accelerates the aging process, reducing the device lifetime and reliability. Thermal management strategies are essential to mitigate these effects and extend VCSEL operational life.

- Optical degradation and mirror damage: The optical components of VCSELs, particularly the distributed Bragg reflector (DBR) mirrors, are susceptible to aging. High optical power densities can cause catastrophic optical damage to the mirrors, especially at the semiconductor-air interface. Oxidation processes at mirror interfaces can lead to increased absorption and scattering losses. Over time, these degradation mechanisms result in decreased reflectivity, increased threshold current, and reduced output power. Mirror damage is often accelerated by the presence of defects or contaminants introduced during manufacturing.

- Electromigration and contact degradation: Electrical contacts and interconnects in VCSELs are subject to electromigration effects during operation. The high current densities can cause metal atoms to migrate, leading to void formation and increased resistance in contacts. This degradation mechanism affects the electrical characteristics of the device, resulting in higher operating voltages and reduced efficiency. Contact degradation can also create localized heating, which further accelerates other aging mechanisms. Proper contact design and current distribution are critical to minimize these effects.

- Active region degradation and recombination-enhanced defects: The active region of VCSELs, typically consisting of quantum wells, is particularly vulnerable to aging effects. Non-radiative recombination processes can enhance defect formation and propagation, known as recombination-enhanced defect reactions. These defects act as non-radiative recombination centers, reducing internal quantum efficiency. Over time, the accumulation of defects in the active region leads to increased threshold current, decreased slope efficiency, and eventual device failure. The rate of active region degradation is strongly dependent on current density and operating temperature.

- Reliability testing and lifetime prediction methods: Various methodologies have been developed to assess VCSEL reliability and predict device lifetime. Accelerated aging tests under elevated temperature and current conditions help identify failure modes and estimate mean time to failure. Statistical models based on Arrhenius equations are commonly used to extrapolate device lifetime under normal operating conditions. Real-time monitoring of key parameters such as threshold current, slope efficiency, and spectral characteristics provides early indicators of degradation. Advanced characterization techniques including electroluminescence mapping and electron microscopy help identify specific aging mechanisms and failure modes.

02 Current-induced degradation and electromigration

High current densities in VCSELs can lead to electromigration, where metal atoms in contacts and interconnects gradually move, creating voids and hillocks that affect device performance. This mechanism is particularly significant in smaller devices operating at high power. Additionally, current crowding can create localized hot spots that accelerate aging. The continuous flow of carriers through the active region can also lead to recombination-enhanced defect formation, further degrading device performance over time.Expand Specific Solutions03 Oxidation and environmental effects

VCSELs are susceptible to oxidation processes that affect both the semiconductor materials and metal contacts. Moisture and contaminants can penetrate packaging and accelerate corrosion, particularly at elevated temperatures. The aluminum oxide apertures used in many VCSEL designs may experience continued oxidation during operation, changing the optical and electrical properties of the device. Environmental factors such as humidity and atmospheric contaminants can infiltrate non-hermetically sealed packages, accelerating degradation mechanisms.Expand Specific Solutions04 Optical degradation and facet damage

The optical surfaces and distributed Bragg reflectors (DBRs) in VCSELs can degrade over time due to high photon densities. This includes catastrophic optical damage at mirror interfaces, particularly at higher power densities. Photon-assisted oxidation can occur at the semiconductor-air interface, gradually changing the reflectivity of mirrors. Additionally, optical absorption can generate heat that contributes to other degradation mechanisms. The quality and stability of the cavity mirrors are critical factors in determining the long-term reliability of VCSELs.Expand Specific Solutions05 Reliability testing and lifetime prediction methods

Accelerated aging tests are commonly used to predict VCSEL lifetime under normal operating conditions. These tests typically involve operating devices at elevated temperatures and currents to accelerate degradation mechanisms. Statistical models are then applied to extrapolate expected lifetimes under normal conditions. Burn-in procedures are often employed to identify early failures before devices are deployed in applications. Advanced monitoring techniques, including optical spectrum analysis and electrical parameter tracking, help identify degradation signatures before catastrophic failure occurs.Expand Specific Solutions

Key Industry Players in VCSEL Manufacturing and Testing

The VCSEL aging mechanisms under elevated temperature cycling market is currently in a growth phase, with increasing demand driven by applications in data centers, 3D sensing, and automotive LiDAR. The global market is projected to expand significantly as VCSEL technology becomes critical for next-generation communication and sensing systems. Technologically, the field shows moderate maturity with ongoing research to address reliability challenges. Key players demonstrate varying levels of expertise: Lumentum Operations and II-VI (Coherent) lead with advanced reliability testing capabilities, while Huaxin Semiconductor and Fujian Huixin Laser are rapidly developing competitive technologies. Intel and ams-OSRAM are investing heavily in temperature-resistant VCSEL solutions. Academic institutions like HKUST and Beijing University of Technology are contributing fundamental research on aging mechanisms, creating a collaborative ecosystem between industry and academia to overcome thermal cycling challenges.

II-VI Delaware, Inc.

Technical Solution: II-VI has developed advanced VCSEL aging mitigation technologies focusing on material science innovations to address temperature cycling challenges. Their approach includes proprietary epitaxial growth techniques that create more thermally stable quantum well structures with reduced defect densities. The company employs specialized annealing processes during manufacturing that pre-condition devices against thermal stress. II-VI has pioneered multi-quantum barrier designs that improve carrier confinement even during temperature fluctuations, maintaining consistent threshold currents across operating conditions. Their research has identified critical interfaces within the VCSEL structure where thermal expansion coefficient mismatches create stress points during cycling, leading to the development of gradient composition layers that minimize these effects. II-VI implements comprehensive reliability screening with automated optical and electrical parameter tracking during accelerated aging tests, allowing for early identification of degradation signatures specific to thermal cycling failures.

Strengths: Vertically integrated manufacturing capabilities providing complete control over material quality and processing parameters critical for reliability. Extensive materials science expertise enabling fundamental solutions to thermal cycling challenges. Weaknesses: Their broad product portfolio across multiple photonics segments may sometimes result in less specialized focus on VCSEL-specific aging mechanisms compared to VCSEL-only competitors.

Lumentum Operations LLC

Technical Solution: Lumentum has developed comprehensive VCSEL reliability testing protocols specifically addressing aging mechanisms under elevated temperature cycling. Their approach combines accelerated aging tests with real-time monitoring systems that track performance degradation patterns. The company employs specialized thermal cycling chambers capable of precise temperature control between -40°C to +125°C with rapid ramp rates to simulate extreme operational conditions. Lumentum's proprietary aging models incorporate both electrical and optical degradation factors, allowing for accurate lifetime predictions across various application scenarios. Their research has identified critical failure modes including oxide aperture degradation, mirror reflectivity reduction, and active region deterioration that occur specifically during thermal cycling events. Lumentum has implemented specialized burn-in procedures that pre-stress devices to eliminate early failures while establishing statistical models for long-term reliability prediction.

Strengths: Industry-leading reliability testing infrastructure with advanced in-situ monitoring capabilities. Extensive database of aging characteristics across multiple VCSEL designs enabling accurate lifetime modeling. Weaknesses: Their solutions may be optimized primarily for telecom applications rather than emerging consumer electronics use cases, potentially limiting applicability in some high-volume markets.

Critical Patents and Research on VCSEL Degradation Mechanisms

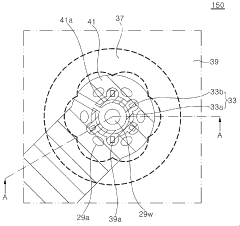

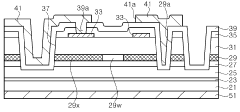

Surface-emitting laser

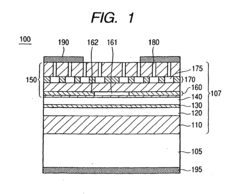

PatentInactiveEP2020712B1

Innovation

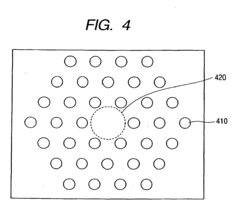

- A surface-emitting laser design featuring a two-dimensional photonic crystal structure with microholes that penetrate from the upper surface of a low refractive index portion to the upper semiconductor multilayer reflection mirror, reducing the cross-sectional area of the holes and minimizing refractive index changes, thereby reducing resonance performance degradation and reflectance loss.

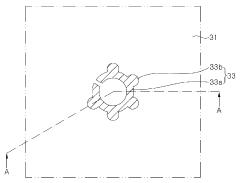

vertical cavity surface emitting laser

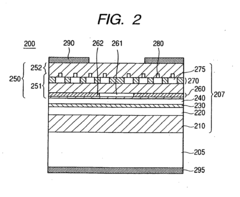

PatentInactiveJP2022522695A

Innovation

- A VCSEL design featuring a ring-shaped trench and oxide holes within isolation regions, allowing precise aperture formation without trench defects, and a symmetrical ohmic contact layer with protrusions to enhance connection reliability.

Material Science Advancements for VCSEL Longevity

Recent advancements in material science have significantly contributed to enhancing VCSEL longevity, particularly when devices are subjected to elevated temperature cycling conditions. The development of novel epitaxial materials with improved thermal stability has been a critical breakthrough in addressing aging mechanisms. Researchers have successfully engineered quantum well structures with higher indium content and optimized barrier compositions that demonstrate superior resistance to thermally-induced degradation.

Innovative strain-compensation techniques have emerged as another promising approach, effectively mitigating the formation and propagation of dislocations during thermal cycling. These techniques involve the strategic incorporation of strain-balancing layers that counteract the inherent lattice mismatch between active region materials, thereby preserving structural integrity over extended operational periods.

Surface passivation technologies have evolved substantially, with atomic layer deposition (ALD) methods now enabling the creation of ultra-thin, highly conformal protective layers. These advanced passivation materials effectively shield the VCSEL's sensitive facets from oxidation and contamination, which are accelerated under elevated temperature conditions. The incorporation of novel dielectric materials with tailored thermal expansion coefficients has further enhanced the resilience of these protective barriers.

The interface between the active region and distributed Bragg reflectors (DBRs) has been identified as a critical failure point during temperature cycling. Material scientists have developed gradient composition transition layers that smooth the abrupt changes in material properties, reducing thermal stress concentrations and preventing delamination. These engineered interfaces demonstrate significantly improved reliability under thermal stress conditions.

Metal contact systems have also undergone substantial refinement, with the introduction of diffusion barrier layers composed of refractory metals and their nitrides. These advanced metallization schemes prevent the migration of contact materials into the semiconductor layers during high-temperature operation, eliminating a common degradation pathway in VCSELs. Additionally, the development of self-aligned contact architectures has reduced current crowding effects that typically accelerate device aging.

Researchers have also made significant progress in developing composite heat-spreading materials that can be integrated directly with VCSEL structures. These materials, often incorporating diamond-based compounds or advanced ceramic composites, provide enhanced thermal management capabilities that reduce the peak temperatures experienced by the active region during operation, thereby extending device lifetime under demanding thermal conditions.

Innovative strain-compensation techniques have emerged as another promising approach, effectively mitigating the formation and propagation of dislocations during thermal cycling. These techniques involve the strategic incorporation of strain-balancing layers that counteract the inherent lattice mismatch between active region materials, thereby preserving structural integrity over extended operational periods.

Surface passivation technologies have evolved substantially, with atomic layer deposition (ALD) methods now enabling the creation of ultra-thin, highly conformal protective layers. These advanced passivation materials effectively shield the VCSEL's sensitive facets from oxidation and contamination, which are accelerated under elevated temperature conditions. The incorporation of novel dielectric materials with tailored thermal expansion coefficients has further enhanced the resilience of these protective barriers.

The interface between the active region and distributed Bragg reflectors (DBRs) has been identified as a critical failure point during temperature cycling. Material scientists have developed gradient composition transition layers that smooth the abrupt changes in material properties, reducing thermal stress concentrations and preventing delamination. These engineered interfaces demonstrate significantly improved reliability under thermal stress conditions.

Metal contact systems have also undergone substantial refinement, with the introduction of diffusion barrier layers composed of refractory metals and their nitrides. These advanced metallization schemes prevent the migration of contact materials into the semiconductor layers during high-temperature operation, eliminating a common degradation pathway in VCSELs. Additionally, the development of self-aligned contact architectures has reduced current crowding effects that typically accelerate device aging.

Researchers have also made significant progress in developing composite heat-spreading materials that can be integrated directly with VCSEL structures. These materials, often incorporating diamond-based compounds or advanced ceramic composites, provide enhanced thermal management capabilities that reduce the peak temperatures experienced by the active region during operation, thereby extending device lifetime under demanding thermal conditions.

Standardization and Testing Protocols for VCSEL Reliability

The standardization of testing protocols for VCSEL reliability represents a critical foundation for industry-wide quality assurance and performance benchmarking. Current industry standards primarily follow guidelines established by organizations such as JEDEC, Telcordia, and AEC-Q102, which provide frameworks for evaluating semiconductor device reliability under various stress conditions.

For VCSEL reliability assessment under elevated temperature cycling specifically, standardized protocols typically include temperature range specifications (commonly -40°C to +125°C for automotive applications), dwell times at temperature extremes, ramp rates, and minimum cycle counts. These parameters must be carefully controlled to ensure reproducible results across different testing facilities and manufacturers.

Key reliability metrics monitored during standardized testing include threshold current shift, slope efficiency degradation, spectral drift, beam divergence changes, and far-field pattern stability. The industry has established acceptance criteria for each parameter, though these may vary depending on the application domain (consumer electronics, automotive, medical, or telecommunications).

Testing methodologies have evolved to incorporate both accelerated life testing (ALT) and highly accelerated life testing (HALT) approaches. These methodologies employ statistical models such as Arrhenius equations and Weibull distributions to extrapolate device lifetime under normal operating conditions from accelerated test data. The acceleration factor calculations must follow standardized mathematical models to ensure consistency in lifetime predictions.

In-situ monitoring techniques have become increasingly important in standardized protocols, allowing for real-time observation of degradation mechanisms during temperature cycling. These techniques include automated optical power measurements, spectral analysis, near-field and far-field pattern recording, and electrical parameter monitoring throughout the test duration.

Documentation requirements for standardized testing are equally rigorous, mandating detailed recording of test conditions, equipment calibration records, measurement uncertainties, and statistical analysis methodologies. This documentation ensures traceability and reproducibility of results, which is essential for qualification processes and failure analysis investigations.

Recent developments in standardization efforts have focused on harmonizing testing protocols across different application domains and addressing emerging reliability concerns specific to new VCSEL designs, such as multi-junction arrays and long-wavelength devices. Industry consortia are actively working to establish new standards that account for the unique aging mechanisms observed in these advanced VCSEL structures under complex stress conditions.

For VCSEL reliability assessment under elevated temperature cycling specifically, standardized protocols typically include temperature range specifications (commonly -40°C to +125°C for automotive applications), dwell times at temperature extremes, ramp rates, and minimum cycle counts. These parameters must be carefully controlled to ensure reproducible results across different testing facilities and manufacturers.

Key reliability metrics monitored during standardized testing include threshold current shift, slope efficiency degradation, spectral drift, beam divergence changes, and far-field pattern stability. The industry has established acceptance criteria for each parameter, though these may vary depending on the application domain (consumer electronics, automotive, medical, or telecommunications).

Testing methodologies have evolved to incorporate both accelerated life testing (ALT) and highly accelerated life testing (HALT) approaches. These methodologies employ statistical models such as Arrhenius equations and Weibull distributions to extrapolate device lifetime under normal operating conditions from accelerated test data. The acceleration factor calculations must follow standardized mathematical models to ensure consistency in lifetime predictions.

In-situ monitoring techniques have become increasingly important in standardized protocols, allowing for real-time observation of degradation mechanisms during temperature cycling. These techniques include automated optical power measurements, spectral analysis, near-field and far-field pattern recording, and electrical parameter monitoring throughout the test duration.

Documentation requirements for standardized testing are equally rigorous, mandating detailed recording of test conditions, equipment calibration records, measurement uncertainties, and statistical analysis methodologies. This documentation ensures traceability and reproducibility of results, which is essential for qualification processes and failure analysis investigations.

Recent developments in standardization efforts have focused on harmonizing testing protocols across different application domains and addressing emerging reliability concerns specific to new VCSEL designs, such as multi-junction arrays and long-wavelength devices. Industry consortia are actively working to establish new standards that account for the unique aging mechanisms observed in these advanced VCSEL structures under complex stress conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!