VCSEL Array Drive Electronics And Thermal Coupling

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Array Technology Background and Objectives

Vertical-Cavity Surface-Emitting Laser (VCSEL) arrays have emerged as a transformative technology in photonics, evolving from single-element devices to sophisticated multi-element arrays capable of high-power, high-speed operation. The historical trajectory of VCSEL technology began in the late 1970s with theoretical proposals, followed by practical demonstrations in the late 1980s, and has since undergone remarkable advancement in terms of performance, reliability, and integration capabilities.

The evolution of VCSEL arrays has been driven by increasing demands across multiple application domains, including data communications, sensing, illumination, and emerging fields such as 3D sensing for facial recognition and augmented reality. This technological progression has been characterized by continuous improvements in output power, beam quality, modulation bandwidth, and energy efficiency, enabling VCSELs to compete with and often surpass edge-emitting laser technologies in many applications.

Current VCSEL array technology faces two critical and interconnected challenges: drive electronics integration and thermal management. The drive electronics must deliver precise current control to multiple elements simultaneously while maintaining high-speed modulation capabilities. Meanwhile, thermal coupling between array elements presents significant design challenges as heat generated during operation can cause wavelength shifts, reduced efficiency, and accelerated device degradation.

The primary technical objectives in VCSEL array development focus on optimizing the interplay between electronic driving circuits and thermal management systems. Specifically, research aims to develop integrated driver solutions that can provide individual addressability to array elements while minimizing parasitic capacitance and inductance that limit modulation bandwidth. Concurrently, thermal engineering efforts seek to enhance heat dissipation pathways and reduce thermal crosstalk between elements.

Advanced packaging solutions represent a key area of development, with objectives centered on creating platforms that simultaneously address electrical interconnection requirements and thermal management needs. These include the integration of microchannels for active cooling, implementation of thermally conductive substrates, and development of flip-chip bonding techniques that optimize both electrical and thermal performance.

Looking forward, the technology roadmap for VCSEL arrays envisions greater integration density, improved power efficiency, and enhanced thermal stability. Emerging objectives include the development of monolithically integrated driver circuits, implementation of wavelength-stabilized designs that maintain performance across temperature variations, and creation of intelligent thermal management systems that dynamically respond to operating conditions.

The ultimate goal is to establish VCSEL array technologies that can deliver unprecedented combinations of power, speed, and beam quality while maintaining reliability under diverse operating conditions. This will enable next-generation applications in fields ranging from high-speed optical interconnects to advanced LiDAR systems for autonomous vehicles and sophisticated biometric sensing platforms.

The evolution of VCSEL arrays has been driven by increasing demands across multiple application domains, including data communications, sensing, illumination, and emerging fields such as 3D sensing for facial recognition and augmented reality. This technological progression has been characterized by continuous improvements in output power, beam quality, modulation bandwidth, and energy efficiency, enabling VCSELs to compete with and often surpass edge-emitting laser technologies in many applications.

Current VCSEL array technology faces two critical and interconnected challenges: drive electronics integration and thermal management. The drive electronics must deliver precise current control to multiple elements simultaneously while maintaining high-speed modulation capabilities. Meanwhile, thermal coupling between array elements presents significant design challenges as heat generated during operation can cause wavelength shifts, reduced efficiency, and accelerated device degradation.

The primary technical objectives in VCSEL array development focus on optimizing the interplay between electronic driving circuits and thermal management systems. Specifically, research aims to develop integrated driver solutions that can provide individual addressability to array elements while minimizing parasitic capacitance and inductance that limit modulation bandwidth. Concurrently, thermal engineering efforts seek to enhance heat dissipation pathways and reduce thermal crosstalk between elements.

Advanced packaging solutions represent a key area of development, with objectives centered on creating platforms that simultaneously address electrical interconnection requirements and thermal management needs. These include the integration of microchannels for active cooling, implementation of thermally conductive substrates, and development of flip-chip bonding techniques that optimize both electrical and thermal performance.

Looking forward, the technology roadmap for VCSEL arrays envisions greater integration density, improved power efficiency, and enhanced thermal stability. Emerging objectives include the development of monolithically integrated driver circuits, implementation of wavelength-stabilized designs that maintain performance across temperature variations, and creation of intelligent thermal management systems that dynamically respond to operating conditions.

The ultimate goal is to establish VCSEL array technologies that can deliver unprecedented combinations of power, speed, and beam quality while maintaining reliability under diverse operating conditions. This will enable next-generation applications in fields ranging from high-speed optical interconnects to advanced LiDAR systems for autonomous vehicles and sophisticated biometric sensing platforms.

Market Analysis for VCSEL Array Applications

The VCSEL (Vertical-Cavity Surface-Emitting Laser) array market has experienced significant growth in recent years, primarily driven by increasing adoption in consumer electronics, automotive applications, and data communication sectors. The global VCSEL market reached approximately $2.1 billion in 2022 and is projected to grow at a compound annual growth rate of 17.3% through 2028, with VCSEL arrays representing a substantial portion of this market.

Consumer electronics remains the dominant application segment, accounting for over 40% of the VCSEL array market. This is largely attributed to the widespread implementation of 3D sensing technologies in smartphones and tablets for facial recognition, augmented reality applications, and improved camera autofocus systems. Apple's integration of VCSEL arrays in iPhones for Face ID has been a major catalyst for market expansion since 2017.

The automotive sector represents the fastest-growing application segment for VCSEL arrays, with a growth rate exceeding 25% annually. LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles are driving this surge. The superior performance of VCSEL arrays in terms of reliability, compact size, and cost-effectiveness compared to edge-emitting lasers makes them particularly suitable for automotive applications where environmental robustness is critical.

Data communication applications, particularly in data centers, constitute another significant market segment. The demand for higher bandwidth and faster data transmission rates has led to increased adoption of VCSEL arrays in optical interconnects. Their ability to operate at high speeds while consuming minimal power makes them ideal for short-reach optical communication links within data centers.

Industrial applications, including machine vision, industrial heating, and material processing, represent an emerging market for VCSEL arrays. The precise control of beam characteristics and the ability to scale power through arrays make VCSELs attractive for these applications.

Geographically, North America leads the VCSEL array market with approximately 35% share, followed closely by Asia-Pacific at 33%. The Asia-Pacific region, particularly China, is expected to witness the highest growth rate due to the expanding consumer electronics manufacturing base and increasing investments in automotive and data center infrastructure.

Key market challenges include thermal management issues in high-power VCSEL arrays and the complex drive electronics required for precise control of individual emitters. These technical challenges directly impact product performance, reliability, and cost, creating significant market entry barriers but also opportunities for innovation in VCSEL array drive electronics and thermal coupling solutions.

Consumer electronics remains the dominant application segment, accounting for over 40% of the VCSEL array market. This is largely attributed to the widespread implementation of 3D sensing technologies in smartphones and tablets for facial recognition, augmented reality applications, and improved camera autofocus systems. Apple's integration of VCSEL arrays in iPhones for Face ID has been a major catalyst for market expansion since 2017.

The automotive sector represents the fastest-growing application segment for VCSEL arrays, with a growth rate exceeding 25% annually. LiDAR systems for advanced driver-assistance systems (ADAS) and autonomous vehicles are driving this surge. The superior performance of VCSEL arrays in terms of reliability, compact size, and cost-effectiveness compared to edge-emitting lasers makes them particularly suitable for automotive applications where environmental robustness is critical.

Data communication applications, particularly in data centers, constitute another significant market segment. The demand for higher bandwidth and faster data transmission rates has led to increased adoption of VCSEL arrays in optical interconnects. Their ability to operate at high speeds while consuming minimal power makes them ideal for short-reach optical communication links within data centers.

Industrial applications, including machine vision, industrial heating, and material processing, represent an emerging market for VCSEL arrays. The precise control of beam characteristics and the ability to scale power through arrays make VCSELs attractive for these applications.

Geographically, North America leads the VCSEL array market with approximately 35% share, followed closely by Asia-Pacific at 33%. The Asia-Pacific region, particularly China, is expected to witness the highest growth rate due to the expanding consumer electronics manufacturing base and increasing investments in automotive and data center infrastructure.

Key market challenges include thermal management issues in high-power VCSEL arrays and the complex drive electronics required for precise control of individual emitters. These technical challenges directly impact product performance, reliability, and cost, creating significant market entry barriers but also opportunities for innovation in VCSEL array drive electronics and thermal coupling solutions.

Current Challenges in VCSEL Drive Electronics

Despite significant advancements in VCSEL array technology, the drive electronics domain faces several critical challenges that impede optimal performance and widespread adoption. The primary challenge lies in achieving uniform current distribution across multiple emitters in large VCSEL arrays. Current crowding and non-uniform current injection lead to inconsistent optical output, reduced beam quality, and accelerated device degradation. This becomes particularly problematic as array sizes increase to meet higher power requirements.

High-speed modulation presents another significant hurdle. As applications demand faster data rates and more precise timing control, drive electronics must support modulation frequencies in the multi-GHz range while maintaining signal integrity. The parasitic capacitance and inductance inherent in interconnects between drivers and VCSEL elements create bandwidth limitations and signal distortion, particularly challenging for applications requiring precise timing such as LiDAR and high-speed optical communications.

Power efficiency remains a persistent concern, especially for battery-operated and mobile applications. Current VCSEL driver circuits exhibit substantial power losses during high-current operation, with efficiency typically below 70% for most commercial solutions. This inefficiency manifests as heat generation, further complicating thermal management challenges and creating a negative feedback loop that affects device performance and reliability.

Integration density presents a growing challenge as applications demand more compact form factors. The physical space required for driver electronics often exceeds that of the VCSEL array itself, creating packaging constraints and limiting miniaturization efforts. This becomes particularly problematic in consumer electronics and automotive applications where space is at a premium.

The thermal coupling between drive electronics and VCSEL arrays represents perhaps the most complex challenge. Heat generated by driver circuits directly impacts VCSEL performance through wavelength shifts, threshold current variations, and accelerated aging. Conventional thermal isolation approaches often conflict with requirements for compact packaging and high-speed electrical performance.

Manufacturing scalability and cost considerations further complicate matters. Current driver solutions often require specialized processes that are difficult to integrate with standard semiconductor manufacturing flows, leading to increased production costs and limited economies of scale. This creates a significant barrier to widespread adoption in price-sensitive consumer markets.

Finally, reliability under varying operating conditions remains problematic. Driver electronics must maintain consistent performance across wide temperature ranges and operating environments while ensuring the long-term reliability expected in mission-critical applications such as automotive LiDAR and medical devices.

High-speed modulation presents another significant hurdle. As applications demand faster data rates and more precise timing control, drive electronics must support modulation frequencies in the multi-GHz range while maintaining signal integrity. The parasitic capacitance and inductance inherent in interconnects between drivers and VCSEL elements create bandwidth limitations and signal distortion, particularly challenging for applications requiring precise timing such as LiDAR and high-speed optical communications.

Power efficiency remains a persistent concern, especially for battery-operated and mobile applications. Current VCSEL driver circuits exhibit substantial power losses during high-current operation, with efficiency typically below 70% for most commercial solutions. This inefficiency manifests as heat generation, further complicating thermal management challenges and creating a negative feedback loop that affects device performance and reliability.

Integration density presents a growing challenge as applications demand more compact form factors. The physical space required for driver electronics often exceeds that of the VCSEL array itself, creating packaging constraints and limiting miniaturization efforts. This becomes particularly problematic in consumer electronics and automotive applications where space is at a premium.

The thermal coupling between drive electronics and VCSEL arrays represents perhaps the most complex challenge. Heat generated by driver circuits directly impacts VCSEL performance through wavelength shifts, threshold current variations, and accelerated aging. Conventional thermal isolation approaches often conflict with requirements for compact packaging and high-speed electrical performance.

Manufacturing scalability and cost considerations further complicate matters. Current driver solutions often require specialized processes that are difficult to integrate with standard semiconductor manufacturing flows, leading to increased production costs and limited economies of scale. This creates a significant barrier to widespread adoption in price-sensitive consumer markets.

Finally, reliability under varying operating conditions remains problematic. Driver electronics must maintain consistent performance across wide temperature ranges and operating environments while ensuring the long-term reliability expected in mission-critical applications such as automotive LiDAR and medical devices.

Drive Electronics Solutions and Architectures

01 VCSEL Array Drive Circuit Design

Drive electronics for VCSEL arrays require specialized circuit designs to efficiently control multiple emitters simultaneously. These circuits manage current distribution, modulation timing, and power delivery across the array elements. Advanced driver designs incorporate features like individual element addressing, pulse shaping capabilities, and protection against thermal runaway conditions. Proper drive circuit design is essential for maintaining uniform emission characteristics across the array while optimizing power consumption.- VCSEL Array Drive Circuit Design: Drive electronics for VCSEL arrays require specialized circuit designs to efficiently control multiple emitters simultaneously. These circuits manage current distribution, modulation, and timing synchronization across the array elements. Advanced driver designs incorporate feedback mechanisms to maintain consistent output despite temperature variations, and may include programmable features to adjust individual emitter characteristics for optimal beam formation and power efficiency.

- Thermal Management Solutions: Effective thermal coupling and heat dissipation are critical for VCSEL array performance and reliability. Various thermal management approaches include integrated heat sinks, thermal vias, specialized substrate materials, and active cooling systems. These solutions help maintain optimal operating temperatures, prevent thermal crosstalk between array elements, and extend device lifetime by reducing thermal stress on components.

- Integration of Control and Monitoring Systems: Advanced VCSEL array systems incorporate integrated control and monitoring capabilities to optimize performance. These systems include temperature sensors, photodetectors for output monitoring, and microcontrollers that dynamically adjust drive parameters based on real-time feedback. Such integration enables adaptive operation under varying conditions, compensates for aging effects, and provides diagnostic capabilities for system maintenance.

- Optical Coupling and Beam Formation: VCSEL arrays require specialized optical coupling techniques to effectively combine and direct output from multiple emitters. These include micro-lens arrays, diffractive optical elements, and waveguide structures that shape and steer the combined beam. Advanced designs address challenges of beam uniformity, divergence control, and efficient power coupling while maintaining compact form factors suitable for integrated applications.

- Power Distribution and Management: Efficient power distribution is essential for high-density VCSEL arrays, particularly in mobile or battery-powered applications. Advanced power management techniques include dynamic power scaling, selective activation of array elements, and intelligent power sequencing to minimize consumption during standby periods. These systems balance performance requirements with thermal constraints and available power budgets to optimize overall system efficiency.

02 Thermal Management Solutions for VCSEL Arrays

Effective thermal management is critical for VCSEL array performance and reliability. Solutions include specialized heat sinks, thermal interface materials, and active cooling systems designed to dissipate heat generated during operation. Advanced thermal coupling techniques ensure efficient heat transfer from the active regions to cooling structures. Proper thermal design prevents performance degradation, wavelength drift, and premature device failure by maintaining optimal operating temperatures across the array elements.Expand Specific Solutions03 Integration of Control Electronics with VCSEL Arrays

Integration approaches combine VCSEL arrays with their drive electronics in compact packages to minimize signal path lengths and improve performance. These integrated solutions incorporate driver ICs, control logic, and thermal management in unified assemblies. Advanced designs feature flip-chip bonding, through-silicon vias, or interposer technologies to optimize electrical and thermal connections. Integrated solutions offer benefits including reduced parasitic effects, improved signal integrity, and enhanced thermal coupling between components.Expand Specific Solutions04 Current Distribution and Modulation Techniques

Specialized current distribution and modulation techniques ensure uniform performance across VCSEL array elements. These include balanced current steering circuits, impedance-matched transmission lines, and synchronized timing control systems. Advanced modulation approaches support high-speed operation while maintaining thermal stability across the array. Proper current distribution is essential for achieving consistent optical output, beam quality, and spectral characteristics from all elements in the array.Expand Specific Solutions05 Thermal Coupling Between VCSEL Arrays and Substrates

Effective thermal coupling between VCSEL arrays and their mounting substrates is crucial for heat dissipation and device reliability. Advanced coupling techniques include specialized bonding materials, submounts with high thermal conductivity, and engineered thermal paths. These approaches minimize thermal resistance between heat-generating active regions and cooling structures. Proper thermal coupling design considers material interfaces, expansion coefficient matching, and heat spreading to maintain optimal operating temperatures across the array.Expand Specific Solutions

Key Industry Players in VCSEL Ecosystem

The VCSEL Array Drive Electronics and Thermal Coupling technology landscape is currently in a growth phase, with the market expanding rapidly due to increasing applications in 3D sensing, automotive LiDAR, and data communications. The global market size is projected to reach significant scale as consumer electronics and autonomous vehicle sectors drive demand. From a technical maturity perspective, industry leaders like Lumentum Operations, ams-OSRAM, and II-VI Delaware (Coherent) have established advanced capabilities in high-density VCSEL arrays, while companies such as Sony Semiconductor Solutions and Infineon Technologies are making strides in integrated drive electronics. Thermal management remains a critical challenge, with Murata Manufacturing and Furukawa Electric developing innovative coupling solutions. Academic institutions like Beijing University of Technology and research organizations such as Electronics & Telecommunications Research Institute are contributing fundamental advancements to address power efficiency and thermal stability issues.

Lumentum Operations LLC

Technical Solution: Lumentum has developed advanced VCSEL array drive electronics featuring integrated temperature compensation circuits that dynamically adjust drive current based on real-time thermal feedback. Their solution incorporates multi-channel driver ICs with individual channel control for precise beam steering applications. The company's thermal management approach includes innovative substrate materials with high thermal conductivity and embedded micro-channel cooling structures that efficiently dissipate heat from high-density arrays. Lumentum's proprietary thermal decoupling techniques minimize thermal crosstalk between adjacent emitters, maintaining wavelength stability across the array. Their drive electronics feature programmable pulse shaping capabilities that optimize optical output while minimizing thermal transients during high-frequency operation[1]. The company has also implemented advanced packaging solutions that integrate thermal sensors directly within the VCSEL array for accurate temperature monitoring.

Strengths: Superior thermal management expertise with industry-leading heat dissipation efficiency; highly integrated driver solutions reduce system complexity. Weaknesses: Higher cost compared to competitors; custom solutions may require specialized manufacturing processes that limit scalability for mass production.

Infineon Technologies AG

Technical Solution: Infineon has developed a comprehensive VCSEL array drive solution centered around their high-performance GaN and SiC power semiconductor technology. Their driver architecture features integrated power management with ultra-fast switching capabilities that enable precise current control with minimal power dissipation. For thermal management, Infineon employs a sophisticated approach combining diamond-filled composite substrates with microchannel liquid cooling structures that achieve thermal resistance values below 0.5 K/W for high-power arrays. Their drive electronics incorporate adaptive frequency control algorithms that dynamically adjust switching parameters based on thermal feedback, preventing hotspot formation while maintaining optical performance. Infineon's packaging technology utilizes advanced copper pillar interconnects with specialized thermal interface materials that minimize thermal resistance across the entire thermal path[4]. Their solution also features integrated protection circuits that monitor multiple temperature points across the array, implementing graduated response protocols to thermal events ranging from drive current reduction to emergency shutdown.

Strengths: Industry-leading power semiconductor technology enables highly efficient drive solutions; extensive automotive qualification experience ensures reliability in harsh environments. Weaknesses: Less vertical integration in optical components compared to pure-play photonics companies; solutions sometimes prioritize robustness over absolute performance metrics.

Thermal Management Innovations for VCSEL Arrays

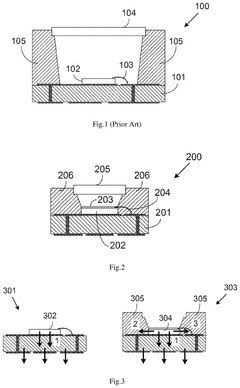

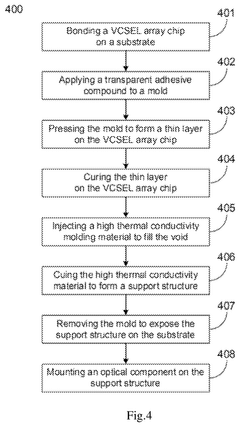

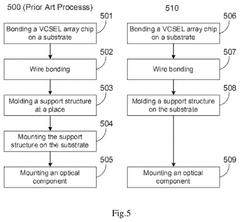

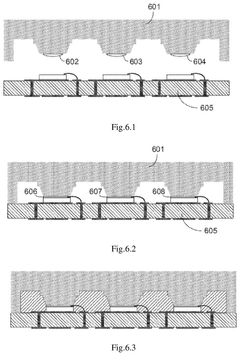

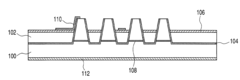

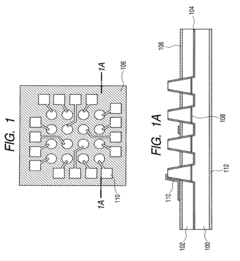

Vertical cavity surface emitting laser (VCSEL) array package and manufacturing method

PatentActiveUS12107387B2

Innovation

- A VCSEL array package design that includes a VCSEL array chip bonded on a substrate with a support structure molded from high thermal conductivity material, covering the side surfaces of the chip to create additional thermal paths and eliminate gaps, and a transparent thin layer to prevent beam obstruction and reflection.

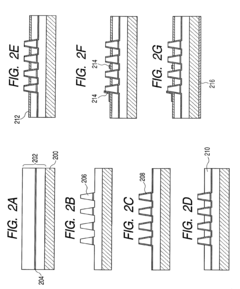

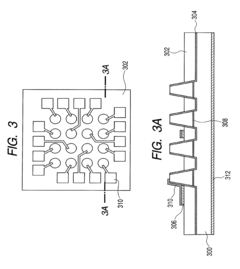

Surface emitting laser array, production process thereof, and image forming apparatus having surface emitting laser array

PatentInactiveUS8000369B2

Innovation

- A surface emitting laser array design featuring a semiconductor layer with a first metal material layer for heat dissipation and a second metal material layer for current injection, both isolated by insulating layers, allowing for efficient heat dissipation and independent device operation without electrical connection, with the heat dissipation metal layer being commonly shared among devices.

Power Efficiency Optimization Strategies

Power efficiency optimization in VCSEL array systems represents a critical area of focus for next-generation photonic applications. The integration of efficient drive electronics with thermal management strategies can significantly reduce power consumption while maintaining optimal performance. Current optimization approaches primarily focus on three interconnected areas: circuit-level enhancements, system architecture improvements, and thermal-aware design methodologies.

Circuit-level optimizations include implementing advanced modulation schemes that reduce switching losses during high-frequency operation. Pulse-width modulation techniques with adaptive duty cycles have demonstrated power savings of 15-20% compared to conventional driving methods. Additionally, the incorporation of high-efficiency CMOS drivers with reduced parasitic capacitances minimizes power dissipation during switching transitions, particularly beneficial for high-density VCSEL arrays operating at gigahertz frequencies.

System architecture improvements leverage intelligent power management strategies such as selective array activation and dynamic bias adjustment. By activating only the necessary VCSEL elements based on application requirements, overall power consumption can be reduced by up to 30% in typical usage scenarios. Furthermore, implementing sleep modes and rapid wake-up capabilities for intermittent operation patterns significantly decreases standby power consumption without compromising response time.

Thermal-aware design methodologies address the critical relationship between temperature and VCSEL efficiency. Advanced thermal simulation techniques enable precise prediction of heat distribution across the array, allowing for optimized heat sink designs and strategic placement of thermal vias. Recent developments in phase-change materials integrated into VCSEL packaging have demonstrated enhanced thermal conductivity while maintaining electrical isolation, resulting in more uniform temperature profiles and reduced thermal resistance.

Cross-domain optimization approaches that simultaneously consider electrical and thermal factors show particular promise. For instance, temperature-compensated driving circuits that dynamically adjust bias currents based on real-time thermal feedback can maintain optimal operating conditions despite environmental variations. These adaptive systems have demonstrated efficiency improvements of 12-18% in variable ambient temperature environments while extending device lifetime by reducing thermal stress.

The integration of wide-bandgap semiconductors such as GaN in driver circuits offers significant efficiency advantages, particularly for high-power VCSEL arrays. These materials enable higher switching frequencies with reduced losses, allowing for smaller passive components and more compact overall designs. Recent prototypes have achieved driver efficiencies exceeding 92% at operating currents suitable for telecommunications and LiDAR applications.

Circuit-level optimizations include implementing advanced modulation schemes that reduce switching losses during high-frequency operation. Pulse-width modulation techniques with adaptive duty cycles have demonstrated power savings of 15-20% compared to conventional driving methods. Additionally, the incorporation of high-efficiency CMOS drivers with reduced parasitic capacitances minimizes power dissipation during switching transitions, particularly beneficial for high-density VCSEL arrays operating at gigahertz frequencies.

System architecture improvements leverage intelligent power management strategies such as selective array activation and dynamic bias adjustment. By activating only the necessary VCSEL elements based on application requirements, overall power consumption can be reduced by up to 30% in typical usage scenarios. Furthermore, implementing sleep modes and rapid wake-up capabilities for intermittent operation patterns significantly decreases standby power consumption without compromising response time.

Thermal-aware design methodologies address the critical relationship between temperature and VCSEL efficiency. Advanced thermal simulation techniques enable precise prediction of heat distribution across the array, allowing for optimized heat sink designs and strategic placement of thermal vias. Recent developments in phase-change materials integrated into VCSEL packaging have demonstrated enhanced thermal conductivity while maintaining electrical isolation, resulting in more uniform temperature profiles and reduced thermal resistance.

Cross-domain optimization approaches that simultaneously consider electrical and thermal factors show particular promise. For instance, temperature-compensated driving circuits that dynamically adjust bias currents based on real-time thermal feedback can maintain optimal operating conditions despite environmental variations. These adaptive systems have demonstrated efficiency improvements of 12-18% in variable ambient temperature environments while extending device lifetime by reducing thermal stress.

The integration of wide-bandgap semiconductors such as GaN in driver circuits offers significant efficiency advantages, particularly for high-power VCSEL arrays. These materials enable higher switching frequencies with reduced losses, allowing for smaller passive components and more compact overall designs. Recent prototypes have achieved driver efficiencies exceeding 92% at operating currents suitable for telecommunications and LiDAR applications.

Reliability Testing Standards for VCSEL Systems

Reliability testing standards for VCSEL systems have evolved significantly to address the unique challenges posed by the integration of drive electronics and thermal management in VCSEL array applications. Industry standards such as Telcordia GR-468, AEC-Q102, and MIL-STD-883 provide comprehensive frameworks for evaluating VCSEL reliability, though they require specific adaptations for array configurations with complex driving circuits.

The thermal-electrical interdependence in VCSEL arrays necessitates specialized testing protocols that simultaneously evaluate both electrical performance degradation and thermal stability. Temperature cycling tests (typically -40°C to +85°C for consumer applications and -55°C to +125°C for automotive/military applications) must be conducted while monitoring key electrical parameters including threshold current, slope efficiency, and spectral characteristics.

High-temperature operating life (HTOL) testing represents a critical reliability standard for VCSEL arrays, typically requiring 1,000 to 5,000 hours of continuous operation at elevated temperatures (85°C to 125°C) while maintaining specified optical output power. This test specifically evaluates the long-term stability of the drive electronics and thermal coupling mechanisms under sustained operation.

Accelerated stress testing methodologies have been standardized to compress lifetime evaluation timeframes, with temperature-humidity-bias (THB) tests exposing devices to 85°C/85% relative humidity while electrically biased. These conditions accelerate potential failure mechanisms at the critical interface between the VCSEL array and its driving electronics.

Electrostatic discharge (ESD) testing standards have been adapted specifically for VCSEL arrays, recognizing their heightened sensitivity compared to single emitters. Human Body Model (HBM) testing typically requires 2kV tolerance, while Charged Device Model (CDM) standards specify 500V minimum thresholds for automotive applications.

Pulsed operation reliability standards are particularly relevant for VCSEL arrays in sensing applications, where rapid on-off cycling can induce thermal-mechanical stress. These standards mandate cycle count testing (typically 100,000 to 1 million cycles) while monitoring beam profile stability and drive circuit performance degradation.

Recent developments in reliability standards have incorporated specific provisions for evaluating thermal coupling efficiency over time, recognizing this as a primary failure mechanism in high-density VCSEL arrays. These standards typically require demonstration of less than 10% degradation in thermal resistance after 1,000 hours of operation at maximum rated power and temperature.

The thermal-electrical interdependence in VCSEL arrays necessitates specialized testing protocols that simultaneously evaluate both electrical performance degradation and thermal stability. Temperature cycling tests (typically -40°C to +85°C for consumer applications and -55°C to +125°C for automotive/military applications) must be conducted while monitoring key electrical parameters including threshold current, slope efficiency, and spectral characteristics.

High-temperature operating life (HTOL) testing represents a critical reliability standard for VCSEL arrays, typically requiring 1,000 to 5,000 hours of continuous operation at elevated temperatures (85°C to 125°C) while maintaining specified optical output power. This test specifically evaluates the long-term stability of the drive electronics and thermal coupling mechanisms under sustained operation.

Accelerated stress testing methodologies have been standardized to compress lifetime evaluation timeframes, with temperature-humidity-bias (THB) tests exposing devices to 85°C/85% relative humidity while electrically biased. These conditions accelerate potential failure mechanisms at the critical interface between the VCSEL array and its driving electronics.

Electrostatic discharge (ESD) testing standards have been adapted specifically for VCSEL arrays, recognizing their heightened sensitivity compared to single emitters. Human Body Model (HBM) testing typically requires 2kV tolerance, while Charged Device Model (CDM) standards specify 500V minimum thresholds for automotive applications.

Pulsed operation reliability standards are particularly relevant for VCSEL arrays in sensing applications, where rapid on-off cycling can induce thermal-mechanical stress. These standards mandate cycle count testing (typically 100,000 to 1 million cycles) while monitoring beam profile stability and drive circuit performance degradation.

Recent developments in reliability standards have incorporated specific provisions for evaluating thermal coupling efficiency over time, recognizing this as a primary failure mechanism in high-density VCSEL arrays. These standards typically require demonstration of less than 10% degradation in thermal resistance after 1,000 hours of operation at maximum rated power and temperature.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!