Packaging Approaches For VCSELs In Harsh Environments

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Packaging Evolution and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have undergone significant evolution in packaging technologies since their commercial introduction in the 1990s. Initially, these devices were primarily packaged in simple TO-can configurations suitable for data communication applications in controlled environments. As applications expanded, packaging requirements evolved to address thermal management, optical coupling efficiency, and environmental protection challenges.

The early 2000s marked a transition toward more sophisticated packaging approaches as VCSELs found applications in consumer electronics and sensing. This period saw the development of ceramic submounts with improved thermal conductivity and the introduction of hermetic sealing techniques to protect sensitive laser structures from moisture and contaminants.

By the mid-2010s, the proliferation of VCSELs in mobile devices, particularly for 3D sensing applications, drove miniaturization of packaging solutions. Wafer-level packaging emerged as a cost-effective approach for high-volume production, enabling smaller form factors while maintaining essential protection features. Flip-chip bonding techniques became standard practice to minimize parasitic inductance and improve thermal performance.

Current harsh environment applications present unprecedented challenges for VCSEL packaging. Automotive LiDAR systems require packages that withstand extreme temperature cycling (-40°C to +125°C), vibration, and humidity while maintaining precise optical alignment. Industrial sensing applications demand resistance to chemical exposure, dust, and mechanical shock. Medical implantable devices require biocompatible packaging with hermetic sealing capable of surviving decades inside the human body.

The primary objectives for next-generation VCSEL packaging in harsh environments include enhanced thermal management to dissipate heat efficiently while maintaining wavelength stability, improved hermeticity to prevent moisture ingress and contamination, and robust mechanical design to withstand physical stresses without optical misalignment. Additionally, packages must accommodate integrated optical elements such as micro-lenses or diffusers while maintaining reliability.

Cost-effectiveness remains a critical objective, particularly for high-volume applications like automotive LiDAR. Manufacturing processes must be scalable while maintaining tight tolerances and high yields. The packaging solutions must also support higher power densities as VCSEL arrays increase in size and output power for longer-range sensing applications.

Standardization efforts are emerging as another key objective, with industry consortia working to establish common specifications for harsh environment VCSEL packages. These standards aim to ensure interoperability, simplify qualification processes, and accelerate adoption across multiple industries while maintaining the stringent reliability requirements essential for mission-critical applications.

The early 2000s marked a transition toward more sophisticated packaging approaches as VCSELs found applications in consumer electronics and sensing. This period saw the development of ceramic submounts with improved thermal conductivity and the introduction of hermetic sealing techniques to protect sensitive laser structures from moisture and contaminants.

By the mid-2010s, the proliferation of VCSELs in mobile devices, particularly for 3D sensing applications, drove miniaturization of packaging solutions. Wafer-level packaging emerged as a cost-effective approach for high-volume production, enabling smaller form factors while maintaining essential protection features. Flip-chip bonding techniques became standard practice to minimize parasitic inductance and improve thermal performance.

Current harsh environment applications present unprecedented challenges for VCSEL packaging. Automotive LiDAR systems require packages that withstand extreme temperature cycling (-40°C to +125°C), vibration, and humidity while maintaining precise optical alignment. Industrial sensing applications demand resistance to chemical exposure, dust, and mechanical shock. Medical implantable devices require biocompatible packaging with hermetic sealing capable of surviving decades inside the human body.

The primary objectives for next-generation VCSEL packaging in harsh environments include enhanced thermal management to dissipate heat efficiently while maintaining wavelength stability, improved hermeticity to prevent moisture ingress and contamination, and robust mechanical design to withstand physical stresses without optical misalignment. Additionally, packages must accommodate integrated optical elements such as micro-lenses or diffusers while maintaining reliability.

Cost-effectiveness remains a critical objective, particularly for high-volume applications like automotive LiDAR. Manufacturing processes must be scalable while maintaining tight tolerances and high yields. The packaging solutions must also support higher power densities as VCSEL arrays increase in size and output power for longer-range sensing applications.

Standardization efforts are emerging as another key objective, with industry consortia working to establish common specifications for harsh environment VCSEL packages. These standards aim to ensure interoperability, simplify qualification processes, and accelerate adoption across multiple industries while maintaining the stringent reliability requirements essential for mission-critical applications.

Harsh Environment Market Requirements Analysis

The harsh environment market for VCSELs (Vertical-Cavity Surface-Emitting Lasers) encompasses several critical sectors where conventional optoelectronic components face significant operational challenges. Primary markets include automotive, aerospace, defense, industrial manufacturing, and oil and gas exploration, where devices must withstand extreme temperatures, vibration, humidity, and corrosive substances.

In the automotive sector, demand for reliable LiDAR systems capable of operating in temperatures ranging from -40°C to +125°C is growing rapidly, with projections indicating a compound annual growth rate of over 30% through 2028. These systems require VCSELs that maintain consistent performance despite thermal cycling, road vibration, and exposure to road salts and automotive fluids.

Aerospace and defense applications present even more stringent requirements, with components needing to function reliably at altitudes where radiation exposure increases and temperatures can fluctuate dramatically. Military-grade specifications often demand operational stability across temperature ranges of -55°C to +150°C, with resistance to shock loads exceeding 100G.

Industrial manufacturing environments introduce challenges related to particulate contamination, chemical exposure, and continuous high-temperature operation. The industrial automation market, valued at over $200 billion globally, increasingly relies on machine vision systems incorporating VCSELs that must maintain calibration despite these harsh conditions.

Oil and gas exploration represents another significant market, where downhole tools operate in environments exceeding 200°C with exposure to hydrogen sulfide, methane, and other corrosive gases. The reliability requirements in this sector are particularly demanding, as component failure can result in costly operational downtime measured in hundreds of thousands of dollars per day.

Common across all these markets is the requirement for hermetic or near-hermetic packaging solutions that prevent moisture ingress while allowing for thermal management. Reliability metrics typically demand operational lifetimes exceeding 10,000 hours in harsh conditions, with failure rates below 100 FIT (failures in time, per billion device-hours).

The market increasingly values integrated solutions that combine VCSELs with protective packaging and monitoring circuitry to enable predictive maintenance. This trend is particularly evident in safety-critical applications where system redundancy and real-time performance verification are essential requirements.

As these harsh environment applications continue to expand, the premium for ruggedized VCSEL packaging solutions is expected to remain significant, with customers willing to pay 30-50% more for components that demonstrably reduce system-level risks and maintenance costs.

In the automotive sector, demand for reliable LiDAR systems capable of operating in temperatures ranging from -40°C to +125°C is growing rapidly, with projections indicating a compound annual growth rate of over 30% through 2028. These systems require VCSELs that maintain consistent performance despite thermal cycling, road vibration, and exposure to road salts and automotive fluids.

Aerospace and defense applications present even more stringent requirements, with components needing to function reliably at altitudes where radiation exposure increases and temperatures can fluctuate dramatically. Military-grade specifications often demand operational stability across temperature ranges of -55°C to +150°C, with resistance to shock loads exceeding 100G.

Industrial manufacturing environments introduce challenges related to particulate contamination, chemical exposure, and continuous high-temperature operation. The industrial automation market, valued at over $200 billion globally, increasingly relies on machine vision systems incorporating VCSELs that must maintain calibration despite these harsh conditions.

Oil and gas exploration represents another significant market, where downhole tools operate in environments exceeding 200°C with exposure to hydrogen sulfide, methane, and other corrosive gases. The reliability requirements in this sector are particularly demanding, as component failure can result in costly operational downtime measured in hundreds of thousands of dollars per day.

Common across all these markets is the requirement for hermetic or near-hermetic packaging solutions that prevent moisture ingress while allowing for thermal management. Reliability metrics typically demand operational lifetimes exceeding 10,000 hours in harsh conditions, with failure rates below 100 FIT (failures in time, per billion device-hours).

The market increasingly values integrated solutions that combine VCSELs with protective packaging and monitoring circuitry to enable predictive maintenance. This trend is particularly evident in safety-critical applications where system redundancy and real-time performance verification are essential requirements.

As these harsh environment applications continue to expand, the premium for ruggedized VCSEL packaging solutions is expected to remain significant, with customers willing to pay 30-50% more for components that demonstrably reduce system-level risks and maintenance costs.

Current VCSEL Packaging Challenges and Limitations

Despite the significant advancements in VCSEL technology, current packaging approaches face substantial challenges when deployed in harsh environments. Traditional hermetic packaging methods, while effective in controlled settings, often fail to provide adequate protection against extreme temperature fluctuations, high humidity, mechanical shock, and vibration that characterize industrial, automotive, and aerospace applications. The TO-can packages commonly used for VCSELs exhibit thermal management limitations, creating performance bottlenecks when devices operate at high power densities or in elevated ambient temperatures.

Moisture ingress represents a critical vulnerability in existing packaging solutions. Even minor water vapor penetration can lead to catastrophic optical degradation through oxidation of the VCSEL mirrors and active regions. Current hermetic sealing techniques struggle to maintain integrity over extended operational lifetimes in environments with cyclical temperature and humidity variations, resulting in premature device failure.

Electrical interconnection reliability presents another significant limitation. Wire bonds, the predominant connection method, are susceptible to fatigue failure under thermal cycling and mechanical stress. The coefficient of thermal expansion (CTE) mismatch between different packaging materials exacerbates this issue, creating mechanical strain that compromises both electrical connections and optical alignment over time.

Optical window contamination remains an unresolved challenge in harsh environment applications. Dust, chemical vapors, and particulate matter can accumulate on optical surfaces, reducing light transmission efficiency and altering beam characteristics. Current window sealing approaches provide insufficient protection against these contaminants in industrial and outdoor settings.

Cost-effective scaling of robust packaging solutions presents a significant industry bottleneck. While specialized military-grade packaging exists, these approaches typically involve expensive materials and labor-intensive assembly processes that are prohibitive for commercial applications. The industry lacks standardized, economical packaging platforms that can be readily adapted to diverse harsh environment requirements.

Integration challenges with sensing and control systems further complicate VCSEL deployment. Current packages often lack embedded temperature sensors, feedback mechanisms, or protective circuitry that could enhance device resilience. The physical size constraints of many applications demand miniaturized packaging solutions that maintain protection levels while reducing form factor, creating additional engineering complexities.

Qualification and reliability testing methodologies for harsh environment VCSEL packages remain inconsistent across the industry. The absence of standardized accelerated life testing protocols specific to optical devices in extreme conditions makes it difficult to accurately predict field performance and establish meaningful reliability metrics for emerging packaging approaches.

Moisture ingress represents a critical vulnerability in existing packaging solutions. Even minor water vapor penetration can lead to catastrophic optical degradation through oxidation of the VCSEL mirrors and active regions. Current hermetic sealing techniques struggle to maintain integrity over extended operational lifetimes in environments with cyclical temperature and humidity variations, resulting in premature device failure.

Electrical interconnection reliability presents another significant limitation. Wire bonds, the predominant connection method, are susceptible to fatigue failure under thermal cycling and mechanical stress. The coefficient of thermal expansion (CTE) mismatch between different packaging materials exacerbates this issue, creating mechanical strain that compromises both electrical connections and optical alignment over time.

Optical window contamination remains an unresolved challenge in harsh environment applications. Dust, chemical vapors, and particulate matter can accumulate on optical surfaces, reducing light transmission efficiency and altering beam characteristics. Current window sealing approaches provide insufficient protection against these contaminants in industrial and outdoor settings.

Cost-effective scaling of robust packaging solutions presents a significant industry bottleneck. While specialized military-grade packaging exists, these approaches typically involve expensive materials and labor-intensive assembly processes that are prohibitive for commercial applications. The industry lacks standardized, economical packaging platforms that can be readily adapted to diverse harsh environment requirements.

Integration challenges with sensing and control systems further complicate VCSEL deployment. Current packages often lack embedded temperature sensors, feedback mechanisms, or protective circuitry that could enhance device resilience. The physical size constraints of many applications demand miniaturized packaging solutions that maintain protection levels while reducing form factor, creating additional engineering complexities.

Qualification and reliability testing methodologies for harsh environment VCSEL packages remain inconsistent across the industry. The absence of standardized accelerated life testing protocols specific to optical devices in extreme conditions makes it difficult to accurately predict field performance and establish meaningful reliability metrics for emerging packaging approaches.

State-of-the-Art Harsh Environment Packaging Solutions

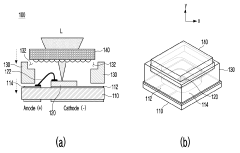

01 Flip-chip packaging for VCSELs

Flip-chip packaging is a common approach for VCSELs where the laser chip is flipped and directly bonded to the substrate or carrier. This method provides excellent thermal management by allowing direct heat dissipation through the substrate. The approach eliminates wire bonds, reducing parasitic inductance and improving high-frequency performance. Flip-chip packaging also enables more compact designs and better optical alignment for VCSEL arrays used in various applications.- Flip-chip packaging for VCSELs: Flip-chip packaging is a common approach for VCSELs where the laser chip is flipped and directly bonded to the substrate or carrier. This method provides better thermal management by allowing direct heat dissipation through the substrate. The approach also enables improved electrical connections with shorter paths, reducing parasitic inductance and resistance. Flip-chip packaging is particularly advantageous for high-power VCSEL arrays where thermal management is critical for performance and reliability.

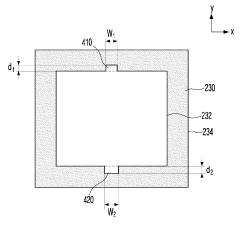

- Hermetic sealing and encapsulation techniques: Hermetic sealing and encapsulation are essential for protecting VCSEL devices from environmental factors such as moisture, dust, and mechanical damage. Various techniques include glass frit bonding, metal sealing, and polymer encapsulation. These methods create a protective barrier around the VCSEL while maintaining optical transparency for the laser beam path. Proper encapsulation extends device lifetime and ensures stable performance in various operating conditions.

- Integration with optical elements: VCSEL packaging often incorporates various optical elements to control and direct the laser output. These elements include micro-lenses, diffusers, collimators, and beam-shaping components that can be integrated directly into the package. Advanced packaging approaches allow for precise alignment of these optical elements with the VCSEL emission area, enabling optimized beam characteristics for specific applications such as sensing, data communication, or illumination.

- Array packaging solutions: VCSEL array packaging involves arranging multiple VCSEL elements in specific patterns to achieve higher output power or specialized beam profiles. These packaging solutions address challenges such as thermal crosstalk between elements, uniform current distribution, and optical interference management. Advanced array packaging may incorporate individual addressability of elements, allowing for dynamic control of the emission pattern. These approaches are particularly important for applications requiring high-power density or beam steering capabilities.

- Thermal management packaging: Thermal management is critical in VCSEL packaging to maintain device performance and reliability. Advanced packaging approaches incorporate heat spreaders, thermal vias, and specialized submounts made from materials with high thermal conductivity. Some designs utilize active cooling elements integrated into the package. Effective thermal packaging prevents performance degradation, wavelength drift, and premature device failure by efficiently dissipating heat generated during VCSEL operation, especially in high-power applications.

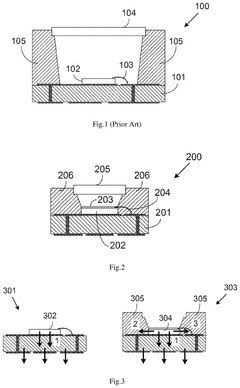

02 TO-can and hermetic packaging solutions

Traditional TO-can (Transistor Outline) packages provide hermetic sealing for VCSELs, protecting them from environmental factors like moisture and contaminants. These packages typically include a metal housing with a window for light emission, and often incorporate thermal management features. Hermetic packaging is crucial for ensuring long-term reliability and stable performance of VCSELs, particularly in harsh environments or mission-critical applications. These packages may also include integrated monitoring photodiodes for feedback control.Expand Specific Solutions03 Array packaging and integration techniques

VCSEL array packaging involves mounting multiple VCSEL elements in a single package for applications requiring multiple light sources. These packages often incorporate specialized optics to collimate or focus the emitted light from each element. Advanced array packaging techniques enable high-density integration while managing thermal issues and maintaining uniform performance across all elements. This approach is particularly important for applications in 3D sensing, LiDAR, and high-speed data communications where multiple synchronized light sources are required.Expand Specific Solutions04 Thermal management solutions in VCSEL packaging

Effective thermal management is critical in VCSEL packaging to maintain performance and extend device lifetime. Packaging approaches include integration of heat spreaders, thermal vias, and specialized submounts made of materials with high thermal conductivity. Some designs incorporate active cooling elements or optimize the package geometry to enhance heat dissipation. Advanced thermal management solutions address the challenges of heat concentration in high-power VCSEL arrays while maintaining compact form factors required for modern applications.Expand Specific Solutions05 Optical coupling and alignment techniques

VCSEL packaging often requires precise optical alignment with other components such as lenses, optical fibers, or waveguides. Various approaches include passive alignment using mechanical features, active alignment techniques during assembly, and integrated micro-optical elements within the package. Some packaging solutions incorporate specialized coupling structures to optimize light extraction and beam shaping. These techniques are essential for maintaining optical performance while enabling cost-effective manufacturing of VCSEL-based devices for applications in sensing, communications, and consumer electronics.Expand Specific Solutions

Leading VCSEL Packaging Manufacturers and Suppliers

The VCSEL packaging for harsh environments market is in a growth phase, characterized by increasing demand across automotive, aerospace, and industrial sectors. The market size is expanding rapidly, driven by applications in LiDAR, 3D sensing, and data communications requiring robust environmental protection. Technologically, the field is advancing from early maturity toward standardization, with companies like Lumentum, II-VI (Coherent), and ams-OSRAM leading with established solutions. Apple and Intel represent major end-users driving requirements, while specialized players like Vixar (acquired by II-VI) and Finisar focus on niche harsh environment applications. Chinese companies including Huaxin Semiconductor and Fujian Huixin Laser are rapidly advancing their capabilities, particularly in automotive-grade packaging solutions, creating a competitive landscape balanced between established Western manufacturers and emerging Asian competitors.

Lumentum Operations LLC

Technical Solution: Lumentum has developed advanced hermetic packaging solutions for VCSELs operating in harsh environments. Their approach utilizes gold-tin (AuSn) eutectic bonding combined with specialized ceramic or metal packages that provide superior hermeticity and thermal management. The company's VCSEL packages incorporate multi-layer ceramic substrates with integrated thermal vias to efficiently dissipate heat while maintaining optical alignment precision. For extreme temperature applications, Lumentum employs proprietary stress compensation techniques to minimize thermally-induced mechanical stresses on the VCSEL die. Their packages also feature specialized optical windows with anti-reflection coatings optimized for specific wavelengths, enhancing optical efficiency while providing environmental protection. For automotive and industrial applications, Lumentum has developed packages that meet AEC-Q102 qualification standards, withstanding temperature cycling from -40°C to +125°C and high humidity conditions.

Strengths: Superior hermeticity and thermal management through advanced materials and bonding techniques; excellent optical alignment maintenance under thermal stress; AEC-Q102 qualification for automotive applications. Weaknesses: Higher manufacturing costs compared to non-hermetic solutions; larger package footprint than consumer-grade alternatives; more complex assembly process requiring specialized equipment.

ams-Osram International GmbH

Technical Solution: ams-Osram has pioneered robust VCSEL packaging solutions specifically designed for automotive and industrial harsh environments. Their approach centers on a proprietary ceramic-based package platform that provides exceptional thermal stability across extreme temperature ranges (-40°C to +125°C). The company utilizes advanced die-attach materials with matched coefficient of thermal expansion (CTE) to minimize stress on the VCSEL chip during thermal cycling. Their packages incorporate specialized lens systems directly integrated into hermetically sealed caps, maintaining precise optical alignment despite vibration and shock. For automotive LiDAR applications, ams-Osram has developed packages with integrated temperature sensors and monitoring circuits that enable real-time performance optimization under varying environmental conditions. Their manufacturing process includes 100% hermeticity testing using helium leak detection methods to ensure package integrity. Additionally, ams-Osram employs specialized passivation techniques to protect bond pads and interconnects from corrosion in high-humidity environments.

Strengths: Excellent thermal stability through CTE-matched materials; integrated optical components maintaining alignment in high-vibration environments; comprehensive environmental testing protocols ensuring reliability. Weaknesses: Higher unit cost compared to consumer-grade solutions; limited customization options for specialized applications; larger form factor than non-hermetic alternatives.

Critical Patents and Innovations in VCSEL Protection

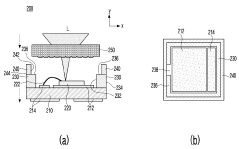

Package of Vertical Cavity Surface Emitting Laser Having Out-gassing Passage and Method Thereof

PatentActiveKR1020200116300A

Innovation

- A VCSEL package design featuring a diffuser-supporting housing formed as a panel with integrated outgas passages, eliminating the need for injection molding and allowing gas discharge, using a DPC substrate with AlN and a micro lens array, and a second housing with curvature to prevent gas passage blockage.

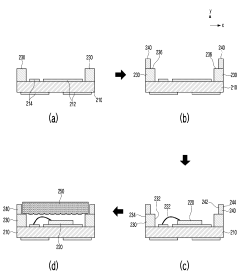

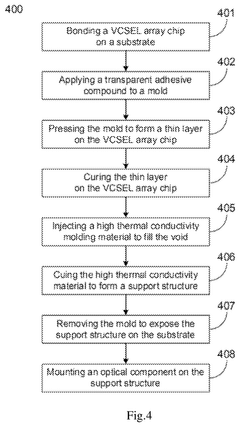

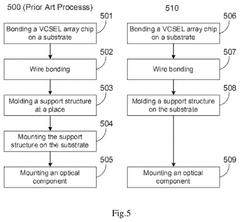

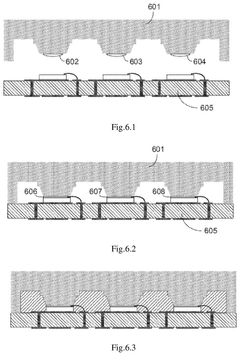

Vertical cavity surface emitting laser (VCSEL) array package and manufacturing method

PatentActiveUS12107387B2

Innovation

- A VCSEL array package design that includes a VCSEL array chip bonded on a substrate with a support structure molded from high thermal conductivity material, covering the side surfaces of the chip to create additional thermal paths and eliminate gaps, and a transparent thin layer to prevent beam obstruction and reflection.

Reliability Testing Standards for Harsh Environments

Reliability testing standards for harsh environments are critical for ensuring VCSEL packaging solutions can withstand extreme conditions while maintaining performance integrity. Industry standards such as MIL-STD-810 provide comprehensive environmental testing protocols specifically designed for military and aerospace applications, covering temperature cycling, mechanical shock, vibration, and humidity resistance. These standards establish minimum performance thresholds that VCSEL packages must meet to be considered reliable in harsh operational settings.

The Telcordia GR-468 standard, widely adopted in telecommunications, outlines specific reliability requirements for optoelectronic devices including VCSELs. It prescribes accelerated aging tests, temperature cycling parameters, and humidity exposure protocols that are particularly relevant for VCSEL packages intended for harsh environment deployment. The standard's qualification methodology includes sequential stress testing that simulates real-world conditions over extended periods.

Automotive-grade testing standards like AEC-Q102, specifically developed for optoelectronic components, have become increasingly important as VCSELs find applications in advanced driver assistance systems and LiDAR. These standards mandate rigorous temperature cycling (-40°C to +125°C), power cycling endurance, and mechanical shock resistance (up to 1500G) that VCSEL packages must withstand to achieve automotive qualification.

For industrial applications, IEC 60068 provides a comprehensive framework for environmental testing of electronic components, including specific protocols for testing resistance to salt spray, dust, and industrial chemicals—all critical factors for VCSELs deployed in manufacturing environments. The standard's structured approach to reliability assessment ensures consistent evaluation across different packaging solutions.

Hermetic packaging solutions for VCSELs typically undergo hermeticity testing according to MIL-STD-883 Method 1014, which establishes procedures for fine and gross leak detection to verify package integrity. This standard is particularly important for VCSEL applications in aerospace and defense, where package hermeticity directly impacts device longevity and mission-critical performance.

Emerging standards are also addressing radiation hardness testing requirements, particularly important for space applications where VCSELs may be exposed to cosmic radiation. These standards typically specify total ionizing dose (TID) testing protocols and single event effect (SEE) evaluation methodologies to ensure VCSEL packages can maintain functionality in radiation-intensive environments without performance degradation or catastrophic failure.

The Telcordia GR-468 standard, widely adopted in telecommunications, outlines specific reliability requirements for optoelectronic devices including VCSELs. It prescribes accelerated aging tests, temperature cycling parameters, and humidity exposure protocols that are particularly relevant for VCSEL packages intended for harsh environment deployment. The standard's qualification methodology includes sequential stress testing that simulates real-world conditions over extended periods.

Automotive-grade testing standards like AEC-Q102, specifically developed for optoelectronic components, have become increasingly important as VCSELs find applications in advanced driver assistance systems and LiDAR. These standards mandate rigorous temperature cycling (-40°C to +125°C), power cycling endurance, and mechanical shock resistance (up to 1500G) that VCSEL packages must withstand to achieve automotive qualification.

For industrial applications, IEC 60068 provides a comprehensive framework for environmental testing of electronic components, including specific protocols for testing resistance to salt spray, dust, and industrial chemicals—all critical factors for VCSELs deployed in manufacturing environments. The standard's structured approach to reliability assessment ensures consistent evaluation across different packaging solutions.

Hermetic packaging solutions for VCSELs typically undergo hermeticity testing according to MIL-STD-883 Method 1014, which establishes procedures for fine and gross leak detection to verify package integrity. This standard is particularly important for VCSEL applications in aerospace and defense, where package hermeticity directly impacts device longevity and mission-critical performance.

Emerging standards are also addressing radiation hardness testing requirements, particularly important for space applications where VCSELs may be exposed to cosmic radiation. These standards typically specify total ionizing dose (TID) testing protocols and single event effect (SEE) evaluation methodologies to ensure VCSEL packages can maintain functionality in radiation-intensive environments without performance degradation or catastrophic failure.

Thermal Management Strategies for VCSEL Longevity

Thermal management represents a critical factor in ensuring the longevity and reliability of VCSEL (Vertical-Cavity Surface-Emitting Laser) devices operating in harsh environments. As these semiconductor lasers generate significant heat during operation, effective thermal dissipation strategies become essential to prevent performance degradation and premature failure.

The fundamental challenge in VCSEL thermal management stems from their compact size and high power density. When operating in harsh environments characterized by extreme temperatures, humidity, or mechanical stress, conventional cooling approaches often prove inadequate. Industry data indicates that for every 10°C increase in junction temperature, VCSEL lifetime may decrease by approximately 50%, highlighting the critical importance of thermal control.

Current thermal management strategies for VCSELs can be categorized into passive and active approaches. Passive techniques include advanced substrate materials with superior thermal conductivity, such as diamond-copper composites that offer thermal conductivity values exceeding 600 W/mK compared to traditional materials. Thermal interface materials (TIMs) with optimized formulations represent another passive solution, reducing thermal resistance at critical junctions by up to 30%.

Active cooling technologies have evolved significantly, with thermoelectric coolers (TECs) emerging as a preferred solution for precision temperature control in high-reliability applications. Miniaturized liquid cooling systems, though more complex, demonstrate superior heat dissipation capabilities, removing up to 500 W/cm² in laboratory settings. These systems prove particularly valuable for high-power VCSEL arrays operating in thermally challenging environments.

Innovative packaging architectures specifically designed for harsh environment applications incorporate multi-layer thermal management solutions. These designs feature strategically placed thermal vias, embedded heat spreaders, and specialized die-attach materials that collectively optimize heat flow paths away from the active region. Recent developments include phase-change materials integrated within packages that absorb thermal energy during peak operation periods.

Simulation-driven design has become instrumental in optimizing thermal management strategies. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) tools enable precise modeling of thermal behavior under various environmental conditions, allowing engineers to identify potential hotspots and optimize cooling solutions before physical prototyping.

Looking forward, emerging technologies such as graphene-based thermal interfaces and microfluidic cooling channels embedded directly within packaging structures show promise for next-generation VCSEL thermal management. These approaches could potentially increase heat dissipation efficiency by 40-60% compared to current solutions, significantly extending VCSEL operational lifetime in the most demanding environmental conditions.

The fundamental challenge in VCSEL thermal management stems from their compact size and high power density. When operating in harsh environments characterized by extreme temperatures, humidity, or mechanical stress, conventional cooling approaches often prove inadequate. Industry data indicates that for every 10°C increase in junction temperature, VCSEL lifetime may decrease by approximately 50%, highlighting the critical importance of thermal control.

Current thermal management strategies for VCSELs can be categorized into passive and active approaches. Passive techniques include advanced substrate materials with superior thermal conductivity, such as diamond-copper composites that offer thermal conductivity values exceeding 600 W/mK compared to traditional materials. Thermal interface materials (TIMs) with optimized formulations represent another passive solution, reducing thermal resistance at critical junctions by up to 30%.

Active cooling technologies have evolved significantly, with thermoelectric coolers (TECs) emerging as a preferred solution for precision temperature control in high-reliability applications. Miniaturized liquid cooling systems, though more complex, demonstrate superior heat dissipation capabilities, removing up to 500 W/cm² in laboratory settings. These systems prove particularly valuable for high-power VCSEL arrays operating in thermally challenging environments.

Innovative packaging architectures specifically designed for harsh environment applications incorporate multi-layer thermal management solutions. These designs feature strategically placed thermal vias, embedded heat spreaders, and specialized die-attach materials that collectively optimize heat flow paths away from the active region. Recent developments include phase-change materials integrated within packages that absorb thermal energy during peak operation periods.

Simulation-driven design has become instrumental in optimizing thermal management strategies. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) tools enable precise modeling of thermal behavior under various environmental conditions, allowing engineers to identify potential hotspots and optimize cooling solutions before physical prototyping.

Looking forward, emerging technologies such as graphene-based thermal interfaces and microfluidic cooling channels embedded directly within packaging structures show promise for next-generation VCSEL thermal management. These approaches could potentially increase heat dissipation efficiency by 40-60% compared to current solutions, significantly extending VCSEL operational lifetime in the most demanding environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!