VCSEL Laser Safety And Packaging Enclosure Design

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Technology Background and Safety Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as a transformative technology in the optoelectronics industry since their initial development in the late 1970s. Unlike traditional edge-emitting lasers, VCSELs emit light perpendicular to their surface, offering advantages in manufacturing, testing, and integration capabilities. The evolution of VCSEL technology has accelerated significantly over the past decade, driven by increasing demands in consumer electronics, automotive sensing, and data communications applications.

The fundamental structure of VCSELs consists of multiple quantum wells sandwiched between distributed Bragg reflector mirrors, creating a resonant cavity that enables efficient light emission. This unique architecture allows for precise wavelength control, typically in the 850-940nm range for consumer applications and 1310-1550nm for telecommunications. The technology has progressively advanced from single-element devices to sophisticated arrays capable of emitting patterns of light for 3D sensing and other applications.

Safety considerations have become increasingly critical as VCSEL deployment expands into consumer-facing applications. The primary safety concern relates to potential eye damage from direct or reflected laser exposure. International safety standards, particularly IEC 60825-1 and ANSI Z136.1, classify lasers based on their potential to cause harm, with most consumer VCSELs falling under Class 1 or Class 1M, requiring appropriate enclosure designs to maintain this classification during normal operation and foreseeable failure conditions.

The packaging enclosure for VCSELs serves dual purposes: protecting the sensitive semiconductor components from environmental factors while simultaneously ensuring user safety through proper beam containment and management. As applications diversify, packaging solutions must evolve to address varying form factor constraints, thermal management requirements, and optical performance specifications while maintaining stringent safety standards.

The primary technical objective in VCSEL packaging design is to develop enclosures that effectively balance multiple competing requirements: optical performance optimization, thermal management, mechanical robustness, manufacturing scalability, and laser safety compliance. This requires innovative approaches to materials selection, optical design, and manufacturing processes.

Recent technological trends indicate a move toward more integrated solutions where the VCSEL array, driver electronics, and safety monitoring systems are combined into single modules with sophisticated fault detection capabilities. This integration trend presents both opportunities and challenges for enclosure design, as it enables more comprehensive safety features but increases complexity in thermal management and manufacturing.

The ultimate goal of VCSEL packaging development is to enable widespread adoption across diverse applications by creating solutions that maintain Class 1 safety classification while meeting application-specific performance requirements and cost targets. This requires a holistic approach that considers the entire product lifecycle from design through manufacturing to end-user deployment.

The fundamental structure of VCSELs consists of multiple quantum wells sandwiched between distributed Bragg reflector mirrors, creating a resonant cavity that enables efficient light emission. This unique architecture allows for precise wavelength control, typically in the 850-940nm range for consumer applications and 1310-1550nm for telecommunications. The technology has progressively advanced from single-element devices to sophisticated arrays capable of emitting patterns of light for 3D sensing and other applications.

Safety considerations have become increasingly critical as VCSEL deployment expands into consumer-facing applications. The primary safety concern relates to potential eye damage from direct or reflected laser exposure. International safety standards, particularly IEC 60825-1 and ANSI Z136.1, classify lasers based on their potential to cause harm, with most consumer VCSELs falling under Class 1 or Class 1M, requiring appropriate enclosure designs to maintain this classification during normal operation and foreseeable failure conditions.

The packaging enclosure for VCSELs serves dual purposes: protecting the sensitive semiconductor components from environmental factors while simultaneously ensuring user safety through proper beam containment and management. As applications diversify, packaging solutions must evolve to address varying form factor constraints, thermal management requirements, and optical performance specifications while maintaining stringent safety standards.

The primary technical objective in VCSEL packaging design is to develop enclosures that effectively balance multiple competing requirements: optical performance optimization, thermal management, mechanical robustness, manufacturing scalability, and laser safety compliance. This requires innovative approaches to materials selection, optical design, and manufacturing processes.

Recent technological trends indicate a move toward more integrated solutions where the VCSEL array, driver electronics, and safety monitoring systems are combined into single modules with sophisticated fault detection capabilities. This integration trend presents both opportunities and challenges for enclosure design, as it enables more comprehensive safety features but increases complexity in thermal management and manufacturing.

The ultimate goal of VCSEL packaging development is to enable widespread adoption across diverse applications by creating solutions that maintain Class 1 safety classification while meeting application-specific performance requirements and cost targets. This requires a holistic approach that considers the entire product lifecycle from design through manufacturing to end-user deployment.

Market Demand Analysis for VCSEL Applications

The VCSEL (Vertical-Cavity Surface-Emitting Laser) market has experienced significant growth in recent years, driven primarily by increasing adoption in consumer electronics, automotive applications, and data communication sectors. The global VCSEL market was valued at approximately 2.1 billion USD in 2021 and is projected to reach 5.7 billion USD by 2027, representing a compound annual growth rate of 18.2% during the forecast period.

Consumer electronics represents the largest application segment for VCSELs, accounting for over 40% of the market share. This dominance is primarily attributed to the widespread integration of 3D sensing technology in smartphones for facial recognition, augmented reality applications, and camera autofocus systems. Major smartphone manufacturers have incorporated VCSEL arrays in their flagship devices, creating a substantial and stable demand base.

The automotive sector presents a rapidly expanding market for VCSEL technology, particularly in advanced driver-assistance systems (ADAS) and autonomous driving applications. LiDAR systems utilizing VCSEL technology offer superior performance in terms of range, accuracy, and reliability compared to traditional sensing technologies. Industry analysts predict that the automotive VCSEL market segment will grow at a CAGR of 23% through 2026, outpacing overall market growth.

Data communication applications, including high-speed optical interconnects in data centers and enterprise networks, constitute another significant market segment. The increasing bandwidth requirements and the transition to higher data rates in cloud computing infrastructure have accelerated the adoption of VCSEL-based optical transceivers. This segment is expected to maintain steady growth as global data traffic continues to expand exponentially.

Industrial applications, including machine vision, industrial heating, and material processing, represent emerging opportunities for VCSEL technology. The precision, reliability, and energy efficiency of VCSEL-based systems make them increasingly attractive alternatives to traditional technologies in manufacturing environments.

From a regional perspective, North America and Asia-Pacific dominate the VCSEL market, collectively accounting for over 70% of global demand. The concentration of consumer electronics manufacturing in Asia-Pacific, particularly in China, Taiwan, and South Korea, drives significant regional demand. Meanwhile, North America leads in research and development activities, with substantial investments in next-generation VCSEL technologies for emerging applications.

Market trends indicate growing demand for higher-power VCSEL arrays, improved beam quality, and enhanced reliability for safety-critical applications. As VCSEL technology continues to mature, cost reduction through manufacturing optimization and economies of scale will likely expand addressable markets and enable new applications across various industries.

Consumer electronics represents the largest application segment for VCSELs, accounting for over 40% of the market share. This dominance is primarily attributed to the widespread integration of 3D sensing technology in smartphones for facial recognition, augmented reality applications, and camera autofocus systems. Major smartphone manufacturers have incorporated VCSEL arrays in their flagship devices, creating a substantial and stable demand base.

The automotive sector presents a rapidly expanding market for VCSEL technology, particularly in advanced driver-assistance systems (ADAS) and autonomous driving applications. LiDAR systems utilizing VCSEL technology offer superior performance in terms of range, accuracy, and reliability compared to traditional sensing technologies. Industry analysts predict that the automotive VCSEL market segment will grow at a CAGR of 23% through 2026, outpacing overall market growth.

Data communication applications, including high-speed optical interconnects in data centers and enterprise networks, constitute another significant market segment. The increasing bandwidth requirements and the transition to higher data rates in cloud computing infrastructure have accelerated the adoption of VCSEL-based optical transceivers. This segment is expected to maintain steady growth as global data traffic continues to expand exponentially.

Industrial applications, including machine vision, industrial heating, and material processing, represent emerging opportunities for VCSEL technology. The precision, reliability, and energy efficiency of VCSEL-based systems make them increasingly attractive alternatives to traditional technologies in manufacturing environments.

From a regional perspective, North America and Asia-Pacific dominate the VCSEL market, collectively accounting for over 70% of global demand. The concentration of consumer electronics manufacturing in Asia-Pacific, particularly in China, Taiwan, and South Korea, drives significant regional demand. Meanwhile, North America leads in research and development activities, with substantial investments in next-generation VCSEL technologies for emerging applications.

Market trends indicate growing demand for higher-power VCSEL arrays, improved beam quality, and enhanced reliability for safety-critical applications. As VCSEL technology continues to mature, cost reduction through manufacturing optimization and economies of scale will likely expand addressable markets and enable new applications across various industries.

Current VCSEL Safety Standards and Design Challenges

VCSEL (Vertical-Cavity Surface-Emitting Laser) technology has gained significant traction in various applications, including facial recognition, LiDAR systems, and data communications. However, as these devices emit laser radiation, they present inherent safety concerns that must be addressed through rigorous standards and design considerations.

The International Electrotechnical Commission (IEC) has established the IEC 60825 standard specifically for laser product safety, which classifies lasers into different categories based on their potential hazards. VCSELs typically fall under Class 1, 1M, 3R, or 3B depending on their power output and beam characteristics. Compliance with these standards requires manufacturers to implement appropriate engineering controls, labeling, and user information.

A significant challenge in VCSEL packaging design stems from the need to balance optical performance with safety requirements. The enclosure must allow for efficient light emission while preventing direct exposure to harmful radiation. This becomes particularly complex in consumer electronics applications where space constraints and aesthetic considerations add additional design limitations.

Thermal management presents another critical challenge in VCSEL packaging. As these devices generate considerable heat during operation, inadequate thermal dissipation can lead to wavelength shifts, reduced efficiency, and shortened device lifespan. The safety enclosure must therefore incorporate effective thermal management solutions without compromising the protective function.

The miniaturization trend in consumer electronics further complicates VCSEL safety design. As devices become smaller, engineers must develop increasingly compact safety enclosures that maintain compliance with international standards. This miniaturization often requires innovative approaches to materials selection and structural design.

Eye safety considerations represent perhaps the most stringent requirement for VCSEL packaging. Near-infrared VCSELs, commonly used in facial recognition systems, operate at wavelengths that can penetrate the eye and potentially damage the retina. Consequently, diffusers and beam-shaping optics must be integrated into the enclosure design to ensure safe operation under all conditions.

Manufacturing variability introduces additional challenges to VCSEL safety compliance. Slight variations in the production process can affect beam characteristics and power output, potentially altering the safety classification of the device. Robust quality control measures and safety margins in the design are therefore essential to ensure consistent compliance.

Environmental factors such as temperature fluctuations, humidity, and mechanical stress can impact the integrity of VCSEL packaging over time. Safety enclosures must be designed to withstand these conditions throughout the product's intended lifetime, maintaining their protective capabilities despite environmental challenges.

The International Electrotechnical Commission (IEC) has established the IEC 60825 standard specifically for laser product safety, which classifies lasers into different categories based on their potential hazards. VCSELs typically fall under Class 1, 1M, 3R, or 3B depending on their power output and beam characteristics. Compliance with these standards requires manufacturers to implement appropriate engineering controls, labeling, and user information.

A significant challenge in VCSEL packaging design stems from the need to balance optical performance with safety requirements. The enclosure must allow for efficient light emission while preventing direct exposure to harmful radiation. This becomes particularly complex in consumer electronics applications where space constraints and aesthetic considerations add additional design limitations.

Thermal management presents another critical challenge in VCSEL packaging. As these devices generate considerable heat during operation, inadequate thermal dissipation can lead to wavelength shifts, reduced efficiency, and shortened device lifespan. The safety enclosure must therefore incorporate effective thermal management solutions without compromising the protective function.

The miniaturization trend in consumer electronics further complicates VCSEL safety design. As devices become smaller, engineers must develop increasingly compact safety enclosures that maintain compliance with international standards. This miniaturization often requires innovative approaches to materials selection and structural design.

Eye safety considerations represent perhaps the most stringent requirement for VCSEL packaging. Near-infrared VCSELs, commonly used in facial recognition systems, operate at wavelengths that can penetrate the eye and potentially damage the retina. Consequently, diffusers and beam-shaping optics must be integrated into the enclosure design to ensure safe operation under all conditions.

Manufacturing variability introduces additional challenges to VCSEL safety compliance. Slight variations in the production process can affect beam characteristics and power output, potentially altering the safety classification of the device. Robust quality control measures and safety margins in the design are therefore essential to ensure consistent compliance.

Environmental factors such as temperature fluctuations, humidity, and mechanical stress can impact the integrity of VCSEL packaging over time. Safety enclosures must be designed to withstand these conditions throughout the product's intended lifetime, maintaining their protective capabilities despite environmental challenges.

Current Enclosure Design Solutions for Laser Safety

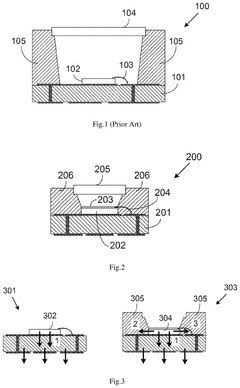

01 Hermetic packaging for VCSEL safety

Hermetic packaging designs for VCSELs provide protection against environmental factors that could compromise laser safety and performance. These packages typically include sealed enclosures with specialized materials to prevent moisture ingress and contamination. The hermetic sealing helps maintain the integrity of the laser device, ensuring consistent optical output and preventing degradation that could lead to safety hazards. These packaging solutions often incorporate thermal management features to dissipate heat effectively, further enhancing safety by preventing overheating.- Hermetic packaging for VCSEL safety: Hermetic packaging designs for VCSELs provide protection against environmental factors that could compromise laser safety and performance. These enclosures typically use materials like ceramics or metals to create airtight seals that prevent moisture ingress and contamination. The hermetic packaging also helps maintain stable operating temperatures and protects the sensitive optical components from mechanical stress, ensuring consistent beam quality and preventing safety hazards from degraded performance.

- Thermal management solutions for VCSEL enclosures: Effective thermal management is critical for VCSEL safety and reliability. Specialized packaging designs incorporate heat sinks, thermal vias, and advanced materials with high thermal conductivity to dissipate heat efficiently. These thermal management solutions prevent overheating that could lead to wavelength shifts, reduced output power, or catastrophic failure. Some designs include active cooling elements or thermally optimized submounts that maintain safe operating temperatures even under high-power operation conditions.

- Optical safety features in VCSEL packaging: VCSEL packages incorporate various optical safety features to prevent hazardous radiation exposure. These include integrated optical filters that block harmful wavelengths, beam shaping elements that control divergence angles, and power monitoring photodiodes that enable automatic shutdown if output exceeds safe levels. Some enclosures also feature mechanical shutters or electronically controlled attenuation mechanisms that can rapidly reduce beam intensity in response to safety concerns, particularly important in consumer applications where eye safety is paramount.

- Integrated circuit packaging for VCSEL arrays: Advanced packaging solutions for VCSEL arrays combine multiple emitters in compact, safety-compliant enclosures. These integrated packages often incorporate driver electronics, control circuitry, and safety monitoring systems within a single module. The designs feature electrical isolation to prevent shorts and specialized interconnects that maintain signal integrity while operating at high frequencies. Some packages include built-in fault detection mechanisms that can disable individual emitters or entire arrays if abnormal operation is detected, preventing potential safety hazards.

- Consumer device safety compliance for VCSEL modules: VCSEL packaging for consumer electronics incorporates specific design elements to meet stringent safety standards and regulations. These enclosures typically feature multiple redundant safety mechanisms, including current limiting circuits, temperature sensors, and automatic power reduction systems. The packages are designed to maintain eye-safe operation even under fault conditions, with physical barriers that prevent direct beam access and diffusers that reduce beam intensity. Some designs include tamper-evident features that help ensure the safety systems cannot be bypassed or modified after manufacturing.

02 Integrated safety monitoring systems

Advanced VCSEL packages incorporate integrated monitoring systems that continuously assess operational parameters to ensure safety. These systems may include photodetectors to monitor optical output power, temperature sensors to detect overheating, and feedback circuits that can automatically adjust laser operation or shut down the device if unsafe conditions are detected. Such monitoring capabilities are particularly important in high-power VCSEL applications where eye safety is a concern. The integration of these safety features directly into the packaging enclosure provides real-time protection against potential hazards.Expand Specific Solutions03 Eye-safe VCSEL enclosure designs

Specialized enclosure designs for VCSELs focus on ensuring eye safety, particularly important for consumer applications. These designs may incorporate diffusers, beam shapers, or optical limiters that reduce the risk of eye damage from direct exposure. Some enclosures include mechanical shutters or electronic safety interlocks that disable the laser when the enclosure is compromised. The packaging may also feature warning indicators and compliance with international laser safety standards. These eye-safe designs balance the need for effective optical performance while minimizing potential hazards to users.Expand Specific Solutions04 Thermal management solutions for VCSEL packages

Effective thermal management is critical for VCSEL safety, as excessive heat can lead to performance degradation and potential failures. Advanced packaging solutions incorporate heat sinks, thermal vias, and specialized materials with high thermal conductivity to efficiently dissipate heat away from the laser device. Some designs feature active cooling elements for high-power applications. Proper thermal management not only extends the operational lifetime of the VCSEL but also prevents thermal runaway conditions that could pose safety risks. These solutions are particularly important in dense array configurations where multiple VCSELs operate in close proximity.Expand Specific Solutions05 Ruggedized VCSEL packaging for harsh environments

Ruggedized packaging solutions protect VCSELs in challenging operational environments while maintaining safety standards. These enclosures are designed to withstand mechanical shock, vibration, extreme temperatures, and other harsh conditions that could compromise laser safety. Special attention is given to maintaining optical alignment and structural integrity under stress. Some designs incorporate reinforced materials, shock absorbers, and specialized mounting techniques. These ruggedized packages are particularly important for automotive, industrial, and aerospace applications where environmental conditions can be severe and reliability is critical for safe operation.Expand Specific Solutions

Leading VCSEL Manufacturers and Industry Landscape

The VCSEL laser safety and packaging enclosure design market is currently in a growth phase, with increasing adoption across biomedical, automotive, consumer electronics, and industrial applications. The global market is expanding rapidly, driven by 3D sensing, facial recognition, and LiDAR technologies. Leading players like Lumentum, Trumpf Photonic Components, and Vixar have established mature safety and packaging solutions, while companies such as Huawei, Samsung, and OSRAM are investing heavily in proprietary designs. Asian manufacturers including Vertilite, Truelight, and Lextar are gaining market share with cost-effective solutions. Technical challenges remain in balancing safety requirements with miniaturization demands, particularly for high-power applications requiring sophisticated thermal management and eye-safety features.

Vixar, Inc.

Technical Solution: Vixar has developed specialized VCSEL packaging solutions focused on medical and sensing applications requiring precise safety controls. Their approach centers on hermetically sealed TO-can packages with integrated monitoring photodiodes that continuously track emission levels. Vixar's designs incorporate proprietary current-limiting structures directly at the chip level, creating inherently eye-safe devices even under fault conditions. For medical applications, they've engineered specialized enclosures with controlled numerical aperture optics that maintain beam quality while preventing hazardous exposure. Their multi-layer safety approach includes redundant monitoring circuits, thermal shutdown mechanisms, and specialized optical feedback systems that detect and respond to any anomalous emission patterns. Vixar has pioneered specialized testing methodologies that verify safety compliance across extended operating lifetimes, ensuring devices remain within Class 1 laser safety parameters even after thousands of hours of operation. Their packaging designs also incorporate specialized materials that provide both optical and electromagnetic isolation to prevent interference with sensitive medical equipment.

Strengths: Industry-leading expertise in high-reliability applications where safety is critical; specialized solutions for medical and sensing markets not well-served by consumer-focused competitors. Weaknesses: Smaller scale production capabilities compared to larger competitors; specialized focus may limit applicability across broader market segments.

Lumentum Operations LLC

Technical Solution: Lumentum has developed advanced VCSEL packaging solutions with integrated safety monitoring circuits that continuously track laser output power and temperature to prevent hazardous emission levels. Their enclosure designs incorporate multiple redundant safety mechanisms including automatic power reduction circuits, optical feedback loops, and fault detection systems. Lumentum's approach includes hermetically sealed TO-can packages with precise optical alignment and specialized heat dissipation structures to maintain beam quality while ensuring Class 1 laser safety compliance. For consumer applications, they've pioneered low-profile surface-mount packages with built-in diffusers and beam shaping optics that inherently limit maximum accessible emission. Their multi-cavity designs enable controlled beam patterns while maintaining eye-safe operation across various use conditions.

Strengths: Industry-leading thermal management capabilities allow higher power operation while maintaining safety margins; proprietary hermetic sealing technology provides exceptional reliability in harsh environments. Weaknesses: Higher manufacturing costs compared to competitors; some designs require more complex assembly processes that may limit production scalability.

Key Patents in VCSEL Packaging and Safety Mechanisms

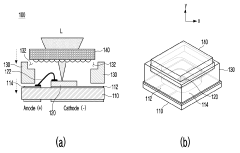

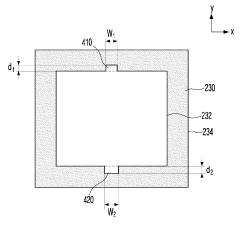

Package of Vertical Cavity Surface Emitting Laser Having Out-gassing Passage and Method Thereof

PatentActiveKR1020200116300A

Innovation

- A VCSEL package design featuring a diffuser-supporting housing formed as a panel with integrated outgas passages, eliminating the need for injection molding and allowing gas discharge, using a DPC substrate with AlN and a micro lens array, and a second housing with curvature to prevent gas passage blockage.

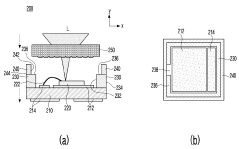

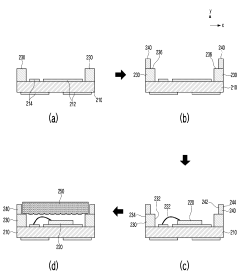

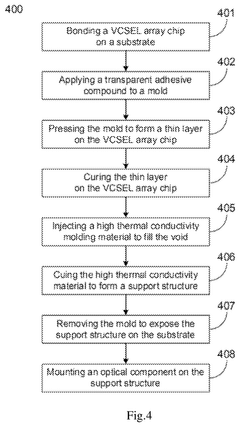

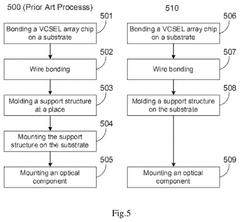

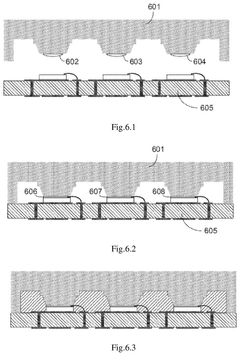

Vertical cavity surface emitting laser (VCSEL) array package and manufacturing method

PatentActiveUS12107387B2

Innovation

- A VCSEL array package design that includes a VCSEL array chip bonded on a substrate with a support structure molded from high thermal conductivity material, covering the side surfaces of the chip to create additional thermal paths and eliminate gaps, and a transparent thin layer to prevent beam obstruction and reflection.

Regulatory Compliance Framework for Laser Products

The regulatory landscape for VCSEL (Vertical-Cavity Surface-Emitting Laser) products is complex and multifaceted, requiring manufacturers to navigate various international standards and compliance requirements. At the forefront of these regulations is the International Electrotechnical Commission (IEC) 60825-1 standard, which provides comprehensive guidelines for laser product safety classification, hazard evaluation, and user protection requirements. This standard categorizes lasers into classes (1, 1M, 2, 2M, 3R, 3B, and 4) based on their potential to cause harm, with VCSELs typically falling into Classes 1, 1M, or 3R depending on their power output and application.

In the United States, the Food and Drug Administration (FDA) enforces laser safety through the Center for Devices and Radiological Health (CDRH), which requires manufacturers to submit reports and maintain compliance with 21 CFR 1040.10 and 1040.11. These regulations mandate specific labeling, safety features, and performance standards for all laser products sold in the US market.

The European Union regulates laser products through the Low Voltage Directive (LVD) 2014/35/EU and the Radio Equipment Directive (RED) 2014/53/EU, which incorporate the EN 60825-1 standard (European adaptation of IEC 60825-1). Compliance with these directives is mandatory for CE marking, allowing products to be sold within the European Economic Area.

For VCSEL packaging enclosure design, these regulatory frameworks impose specific requirements regarding accessible emission limits, protective housings, safety interlocks, emission indicators, and user information. The enclosure must be designed to prevent unauthorized access to laser radiation above the permissible exposure limits for the product's classification.

Additionally, industry-specific standards may apply depending on the VCSEL application. For instance, automotive LiDAR systems using VCSELs must comply with ISO 26262 for functional safety, while medical applications require adherence to IEC 60601-1 for medical electrical equipment safety.

Emerging markets like China have established their own regulatory frameworks, such as GB 7247.1, which closely aligns with IEC standards but includes country-specific requirements. Manufacturers targeting global markets must account for these regional variations in their packaging enclosure designs.

The regulatory landscape continues to evolve with technological advancements. Recent updates to IEC 60825-1 (Edition 3.0) have introduced new considerations for pulsed lasers and scanning systems, which are particularly relevant for VCSEL applications in sensing and imaging. Manufacturers must maintain vigilance regarding regulatory changes and ensure their packaging enclosure designs remain compliant with the latest standards.

In the United States, the Food and Drug Administration (FDA) enforces laser safety through the Center for Devices and Radiological Health (CDRH), which requires manufacturers to submit reports and maintain compliance with 21 CFR 1040.10 and 1040.11. These regulations mandate specific labeling, safety features, and performance standards for all laser products sold in the US market.

The European Union regulates laser products through the Low Voltage Directive (LVD) 2014/35/EU and the Radio Equipment Directive (RED) 2014/53/EU, which incorporate the EN 60825-1 standard (European adaptation of IEC 60825-1). Compliance with these directives is mandatory for CE marking, allowing products to be sold within the European Economic Area.

For VCSEL packaging enclosure design, these regulatory frameworks impose specific requirements regarding accessible emission limits, protective housings, safety interlocks, emission indicators, and user information. The enclosure must be designed to prevent unauthorized access to laser radiation above the permissible exposure limits for the product's classification.

Additionally, industry-specific standards may apply depending on the VCSEL application. For instance, automotive LiDAR systems using VCSELs must comply with ISO 26262 for functional safety, while medical applications require adherence to IEC 60601-1 for medical electrical equipment safety.

Emerging markets like China have established their own regulatory frameworks, such as GB 7247.1, which closely aligns with IEC standards but includes country-specific requirements. Manufacturers targeting global markets must account for these regional variations in their packaging enclosure designs.

The regulatory landscape continues to evolve with technological advancements. Recent updates to IEC 60825-1 (Edition 3.0) have introduced new considerations for pulsed lasers and scanning systems, which are particularly relevant for VCSEL applications in sensing and imaging. Manufacturers must maintain vigilance regarding regulatory changes and ensure their packaging enclosure designs remain compliant with the latest standards.

Thermal Management Strategies in VCSEL Packaging

Thermal management represents a critical aspect of VCSEL (Vertical-Cavity Surface-Emitting Laser) packaging design, directly impacting device performance, reliability, and safety. VCSELs generate significant heat during operation, with thermal densities often exceeding 1 kW/cm² in high-power applications. Without proper thermal management, these devices can experience wavelength shifts, reduced output power, accelerated aging, and catastrophic optical damage.

The primary thermal management approaches in VCSEL packaging include passive and active cooling strategies. Passive cooling relies on materials with high thermal conductivity to efficiently dissipate heat. Copper, aluminum nitride, and diamond-based composites are commonly employed as submounts and heat spreaders, offering thermal conductivity values ranging from 150 to 2000 W/m·K. These materials create effective thermal pathways from the active region to the package exterior.

Active cooling techniques incorporate thermoelectric coolers (TECs) or micro-channel liquid cooling systems. TECs provide precise temperature control through the Peltier effect but add complexity and power consumption to the overall system. Micro-channel cooling, though more complex to implement, can handle heat fluxes up to 1000 W/cm² by circulating coolant through miniature channels directly beneath the VCSEL array.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between package components. Advanced metal solders, thermal greases, and phase-change materials are selected based on application requirements, with thermal conductivities ranging from 3 to 80 W/m·K. The selection criteria include not only thermal performance but also mechanical compliance to accommodate thermal expansion mismatches.

Computational fluid dynamics (CFD) and finite element analysis (FEA) have become essential tools in optimizing VCSEL thermal management. These simulation techniques enable designers to identify hotspots, evaluate thermal gradients, and optimize heat dissipation pathways before physical prototyping. Industry standards typically require maintaining junction temperatures below 85°C for consumer applications and below 125°C for industrial applications.

Recent innovations in VCSEL thermal management include embedded micro heat pipes, graphene-based thermal spreaders, and conformal vapor chamber technologies. These approaches aim to address the increasing thermal challenges posed by higher-power VCSEL arrays used in emerging applications such as LiDAR, facial recognition, and high-speed data communication. The thermal management strategy must be considered holistically within the context of the overall packaging enclosure design to ensure both optimal performance and laser safety compliance.

The primary thermal management approaches in VCSEL packaging include passive and active cooling strategies. Passive cooling relies on materials with high thermal conductivity to efficiently dissipate heat. Copper, aluminum nitride, and diamond-based composites are commonly employed as submounts and heat spreaders, offering thermal conductivity values ranging from 150 to 2000 W/m·K. These materials create effective thermal pathways from the active region to the package exterior.

Active cooling techniques incorporate thermoelectric coolers (TECs) or micro-channel liquid cooling systems. TECs provide precise temperature control through the Peltier effect but add complexity and power consumption to the overall system. Micro-channel cooling, though more complex to implement, can handle heat fluxes up to 1000 W/cm² by circulating coolant through miniature channels directly beneath the VCSEL array.

Thermal interface materials (TIMs) play a crucial role in minimizing contact resistance between package components. Advanced metal solders, thermal greases, and phase-change materials are selected based on application requirements, with thermal conductivities ranging from 3 to 80 W/m·K. The selection criteria include not only thermal performance but also mechanical compliance to accommodate thermal expansion mismatches.

Computational fluid dynamics (CFD) and finite element analysis (FEA) have become essential tools in optimizing VCSEL thermal management. These simulation techniques enable designers to identify hotspots, evaluate thermal gradients, and optimize heat dissipation pathways before physical prototyping. Industry standards typically require maintaining junction temperatures below 85°C for consumer applications and below 125°C for industrial applications.

Recent innovations in VCSEL thermal management include embedded micro heat pipes, graphene-based thermal spreaders, and conformal vapor chamber technologies. These approaches aim to address the increasing thermal challenges posed by higher-power VCSEL arrays used in emerging applications such as LiDAR, facial recognition, and high-speed data communication. The thermal management strategy must be considered holistically within the context of the overall packaging enclosure design to ensure both optimal performance and laser safety compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!