VCSEL Temperature Compensation Circuit Design Guide

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Temperature Compensation Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various applications including facial recognition, LiDAR systems, optical communications, and consumer electronics. Since their commercial introduction in the 1990s, VCSELs have evolved from niche applications to mainstream optoelectronic devices due to their unique advantages such as low threshold current, circular beam profile, and cost-effective manufacturing.

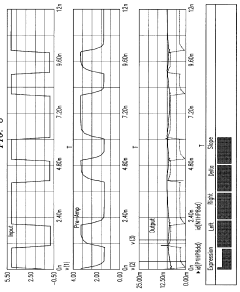

Temperature sensitivity represents one of the most significant challenges in VCSEL implementation. As temperature fluctuates, VCSEL performance parameters including wavelength, threshold current, and output power experience substantial variations. These temperature-induced changes can severely impact system reliability and performance in critical applications. For instance, in facial recognition systems, wavelength shifts can reduce detection accuracy, while in data communication, they may increase bit error rates.

The evolution of temperature compensation techniques has progressed through several generations. Early approaches relied on passive thermal management and basic feedback mechanisms. Current solutions incorporate more sophisticated integrated circuit designs that actively monitor and adjust operating parameters in real-time. This technological progression has been driven by increasingly demanding applications requiring stable performance across wider temperature ranges.

The primary objective of VCSEL temperature compensation circuit design is to maintain consistent optical output characteristics across varying environmental and operational temperature conditions. This involves developing circuits that can detect temperature changes and dynamically adjust driving parameters to counteract temperature-induced variations. The ultimate goal is to achieve wavelength stability within ±0.5nm and power fluctuation below ±5% across industrial temperature ranges (-40°C to +85°C).

Market trends indicate a growing demand for temperature-stable VCSELs in automotive LiDAR, consumer electronics, and data centers. These applications require not only performance stability but also miniaturization of compensation circuits to accommodate space constraints in modern devices. Additionally, power efficiency has become increasingly important as many target applications are battery-powered or have strict thermal management requirements.

Recent technological advancements have enabled more integrated approaches to temperature compensation, including monolithic integration of sensing elements and compensation circuits with the VCSEL itself. These developments align with the industry trend toward system-on-chip solutions that reduce footprint, power consumption, and manufacturing complexity while improving reliability.

The field continues to evolve with research focusing on novel materials, advanced feedback algorithms, and machine learning approaches to predict and compensate for temperature effects more accurately. These innovations aim to extend the operational temperature range while reducing the complexity and power requirements of compensation circuits.

Temperature sensitivity represents one of the most significant challenges in VCSEL implementation. As temperature fluctuates, VCSEL performance parameters including wavelength, threshold current, and output power experience substantial variations. These temperature-induced changes can severely impact system reliability and performance in critical applications. For instance, in facial recognition systems, wavelength shifts can reduce detection accuracy, while in data communication, they may increase bit error rates.

The evolution of temperature compensation techniques has progressed through several generations. Early approaches relied on passive thermal management and basic feedback mechanisms. Current solutions incorporate more sophisticated integrated circuit designs that actively monitor and adjust operating parameters in real-time. This technological progression has been driven by increasingly demanding applications requiring stable performance across wider temperature ranges.

The primary objective of VCSEL temperature compensation circuit design is to maintain consistent optical output characteristics across varying environmental and operational temperature conditions. This involves developing circuits that can detect temperature changes and dynamically adjust driving parameters to counteract temperature-induced variations. The ultimate goal is to achieve wavelength stability within ±0.5nm and power fluctuation below ±5% across industrial temperature ranges (-40°C to +85°C).

Market trends indicate a growing demand for temperature-stable VCSELs in automotive LiDAR, consumer electronics, and data centers. These applications require not only performance stability but also miniaturization of compensation circuits to accommodate space constraints in modern devices. Additionally, power efficiency has become increasingly important as many target applications are battery-powered or have strict thermal management requirements.

Recent technological advancements have enabled more integrated approaches to temperature compensation, including monolithic integration of sensing elements and compensation circuits with the VCSEL itself. These developments align with the industry trend toward system-on-chip solutions that reduce footprint, power consumption, and manufacturing complexity while improving reliability.

The field continues to evolve with research focusing on novel materials, advanced feedback algorithms, and machine learning approaches to predict and compensate for temperature effects more accurately. These innovations aim to extend the operational temperature range while reducing the complexity and power requirements of compensation circuits.

Market Demand Analysis for Temperature-Stable VCSELs

The global market for temperature-stable VCSELs (Vertical-Cavity Surface-Emitting Lasers) has experienced significant growth in recent years, driven primarily by expanding applications in consumer electronics, automotive LiDAR systems, and data communications. Market research indicates that the overall VCSEL market is projected to reach $3.7 billion by 2025, with a compound annual growth rate exceeding 17% between 2020-2025.

Temperature stability has emerged as a critical market differentiator in this landscape. Consumer electronics manufacturers, particularly smartphone producers implementing facial recognition and augmented reality features, demand VCSELs that maintain consistent performance across varying environmental conditions. Market surveys reveal that over 85% of smartphone manufacturers consider temperature stability a top-three requirement when selecting VCSEL suppliers.

The automotive sector represents another substantial growth vector for temperature-stable VCSELs. As autonomous driving technologies advance, LiDAR systems require increasingly reliable optical components that can function precisely across extreme temperature ranges from -40°C to +125°C. Industry forecasts suggest that automotive applications will account for approximately 23% of the total VCSEL market by 2025, up from just 8% in 2020.

Data center operators and telecommunications companies constitute the third major market segment. With the ongoing expansion of cloud computing and 5G networks, high-speed optical interconnects utilizing VCSELs must maintain consistent performance despite significant heat generation in dense computing environments. The data communications segment currently represents the largest market share at 41%, though consumer applications are rapidly closing this gap.

Geographically, North America and Asia-Pacific dominate the market demand, collectively accounting for over 70% of global consumption. China's aggressive investment in 5G infrastructure and domestic semiconductor capabilities has accelerated regional demand for advanced VCSEL technologies with enhanced temperature stability characteristics.

Market analysis reveals a clear price premium for temperature-stable solutions. VCSELs with integrated temperature compensation circuits command 15-30% higher prices compared to standard variants, reflecting the significant value manufacturers place on this feature. This premium has remained stable despite overall price erosion in the broader VCSEL market, indicating strong sustained demand.

Industry surveys highlight that end-users increasingly prefer integrated temperature compensation solutions rather than external compensation circuits, as integration reduces system complexity, improves reliability, and decreases overall footprint. This trend is particularly pronounced in space-constrained applications like wearable devices and smartphone components, where 78% of design engineers favor fully integrated solutions.

Temperature stability has emerged as a critical market differentiator in this landscape. Consumer electronics manufacturers, particularly smartphone producers implementing facial recognition and augmented reality features, demand VCSELs that maintain consistent performance across varying environmental conditions. Market surveys reveal that over 85% of smartphone manufacturers consider temperature stability a top-three requirement when selecting VCSEL suppliers.

The automotive sector represents another substantial growth vector for temperature-stable VCSELs. As autonomous driving technologies advance, LiDAR systems require increasingly reliable optical components that can function precisely across extreme temperature ranges from -40°C to +125°C. Industry forecasts suggest that automotive applications will account for approximately 23% of the total VCSEL market by 2025, up from just 8% in 2020.

Data center operators and telecommunications companies constitute the third major market segment. With the ongoing expansion of cloud computing and 5G networks, high-speed optical interconnects utilizing VCSELs must maintain consistent performance despite significant heat generation in dense computing environments. The data communications segment currently represents the largest market share at 41%, though consumer applications are rapidly closing this gap.

Geographically, North America and Asia-Pacific dominate the market demand, collectively accounting for over 70% of global consumption. China's aggressive investment in 5G infrastructure and domestic semiconductor capabilities has accelerated regional demand for advanced VCSEL technologies with enhanced temperature stability characteristics.

Market analysis reveals a clear price premium for temperature-stable solutions. VCSELs with integrated temperature compensation circuits command 15-30% higher prices compared to standard variants, reflecting the significant value manufacturers place on this feature. This premium has remained stable despite overall price erosion in the broader VCSEL market, indicating strong sustained demand.

Industry surveys highlight that end-users increasingly prefer integrated temperature compensation solutions rather than external compensation circuits, as integration reduces system complexity, improves reliability, and decreases overall footprint. This trend is particularly pronounced in space-constrained applications like wearable devices and smartphone components, where 78% of design engineers favor fully integrated solutions.

Current Challenges in VCSEL Temperature Compensation

VCSEL (Vertical-Cavity Surface-Emitting Laser) technology faces significant temperature-related challenges that impact performance stability and reliability. The primary issue stems from the inherent temperature sensitivity of VCSEL devices, where output power can decrease by approximately 1-2% per degree Celsius increase. This sensitivity creates substantial operational difficulties in applications requiring consistent optical output, such as data communications, sensing, and facial recognition systems.

The temperature coefficient of threshold current presents a major technical hurdle, as it typically increases exponentially with temperature. This phenomenon necessitates sophisticated compensation mechanisms to maintain stable operation across varying thermal conditions. Current compensation circuits often struggle to accurately track and adjust for rapid temperature fluctuations, particularly in mobile devices where thermal gradients can change quickly.

Power consumption optimization remains problematic for temperature compensation circuits. Traditional approaches using thermoelectric coolers (TECs) provide effective temperature stabilization but consume significant power, making them unsuitable for battery-powered applications. Alternative low-power compensation methods frequently sacrifice accuracy or response time, creating an unresolved design trade-off.

Integration density poses another substantial challenge. As VCSEL arrays become increasingly compact in modern applications, the physical space available for temperature sensing and compensation circuitry diminishes. This spatial constraint limits the implementation of comprehensive compensation solutions, particularly in consumer electronics where miniaturization is paramount.

The accuracy of temperature sensing directly impacts compensation effectiveness. Current sensing technologies often exhibit non-linear responses or suffer from self-heating effects that introduce measurement errors. These inaccuracies propagate through the compensation system, resulting in suboptimal VCSEL performance despite the presence of compensation circuits.

Manufacturing variations compound these challenges by introducing device-to-device differences in temperature sensitivity. This variability necessitates either individual calibration—increasing production costs—or the development of adaptive compensation algorithms capable of self-calibration, which adds complexity to circuit design.

Response time limitations represent another critical issue. The thermal time constants of sensing elements typically lag behind rapid changes in VCSEL junction temperature, creating temporal mismatches between actual operating conditions and applied compensation. This delay can cause transient performance degradation during dynamic operating conditions, particularly problematic in high-speed applications requiring rapid on/off switching.

The temperature coefficient of threshold current presents a major technical hurdle, as it typically increases exponentially with temperature. This phenomenon necessitates sophisticated compensation mechanisms to maintain stable operation across varying thermal conditions. Current compensation circuits often struggle to accurately track and adjust for rapid temperature fluctuations, particularly in mobile devices where thermal gradients can change quickly.

Power consumption optimization remains problematic for temperature compensation circuits. Traditional approaches using thermoelectric coolers (TECs) provide effective temperature stabilization but consume significant power, making them unsuitable for battery-powered applications. Alternative low-power compensation methods frequently sacrifice accuracy or response time, creating an unresolved design trade-off.

Integration density poses another substantial challenge. As VCSEL arrays become increasingly compact in modern applications, the physical space available for temperature sensing and compensation circuitry diminishes. This spatial constraint limits the implementation of comprehensive compensation solutions, particularly in consumer electronics where miniaturization is paramount.

The accuracy of temperature sensing directly impacts compensation effectiveness. Current sensing technologies often exhibit non-linear responses or suffer from self-heating effects that introduce measurement errors. These inaccuracies propagate through the compensation system, resulting in suboptimal VCSEL performance despite the presence of compensation circuits.

Manufacturing variations compound these challenges by introducing device-to-device differences in temperature sensitivity. This variability necessitates either individual calibration—increasing production costs—or the development of adaptive compensation algorithms capable of self-calibration, which adds complexity to circuit design.

Response time limitations represent another critical issue. The thermal time constants of sensing elements typically lag behind rapid changes in VCSEL junction temperature, creating temporal mismatches between actual operating conditions and applied compensation. This delay can cause transient performance degradation during dynamic operating conditions, particularly problematic in high-speed applications requiring rapid on/off switching.

Existing VCSEL Temperature Compensation Circuit Solutions

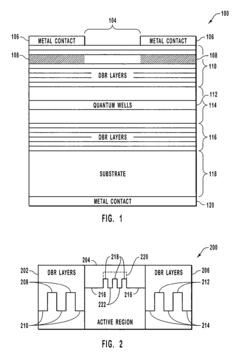

01 Temperature compensation circuits for VCSEL drivers

Temperature compensation circuits are integrated into VCSEL driver designs to maintain stable laser output across varying temperatures. These circuits typically monitor temperature changes and adjust the driving current accordingly to compensate for the VCSEL's temperature-dependent characteristics. This approach ensures consistent optical output power and wavelength stability, which is critical for applications requiring precise light emission such as optical communications and sensing systems.- Temperature compensation circuits for VCSEL drivers: Temperature compensation circuits are designed for VCSEL (Vertical-Cavity Surface-Emitting Laser) drivers to maintain stable operation across varying temperatures. These circuits adjust the driving current to the VCSEL based on temperature changes, ensuring consistent optical output power and wavelength stability. The compensation mechanisms typically involve temperature sensing elements and feedback control systems that modify the bias current according to predetermined temperature-dependent characteristics.

- Thermal sensing and feedback mechanisms: Thermal sensing components are integrated into VCSEL systems to monitor temperature fluctuations in real-time. These sensors provide feedback to compensation circuits, enabling dynamic adjustments to operational parameters. Common sensing technologies include thermistors, temperature-dependent resistors, and integrated temperature sensors. The feedback mechanisms process temperature data and generate control signals that modify the VCSEL driving conditions to counteract thermal effects on laser performance.

- Current adjustment techniques for temperature stability: Various current adjustment techniques are employed to maintain VCSEL temperature stability. These include proportional current control, lookup table-based adjustments, and analog compensation circuits. The techniques modify the bias and modulation currents supplied to the VCSEL based on temperature readings, ensuring that the optical output remains within specified parameters despite ambient temperature variations. Advanced implementations may incorporate multiple adjustment stages for fine-tuned compensation across wide temperature ranges.

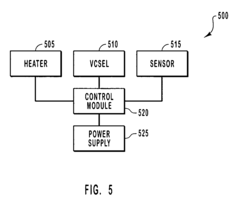

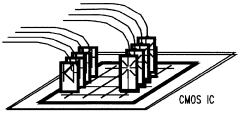

- Integrated temperature compensation solutions: Integrated temperature compensation solutions combine sensing, processing, and control functions within a single package or chip. These solutions offer compact form factors and improved reliability for VCSEL applications. The integration may include temperature sensors, analog-to-digital converters, digital signal processors, and driver circuits. Such integrated approaches reduce component count, minimize signal delays, and enhance the overall temperature compensation performance in VCSEL-based systems.

- Calibration methods for temperature compensation circuits: Calibration methods are essential for optimizing temperature compensation circuit performance. These methods involve characterizing the VCSEL's temperature-dependent behavior and programming the compensation parameters accordingly. Calibration techniques include factory calibration, self-calibration during operation, and adaptive calibration that learns from historical data. Properly calibrated compensation circuits ensure accurate temperature tracking and appropriate current adjustments throughout the VCSEL's operational temperature range.

02 Feedback-based temperature compensation methods

Feedback mechanisms are employed to dynamically adjust VCSEL operating parameters based on real-time temperature measurements. These systems typically use temperature sensors to monitor the VCSEL's operating temperature and feed this information back to control circuitry. The control system then modifies bias current or other parameters to maintain optimal performance. This closed-loop approach provides more accurate compensation than open-loop methods, especially in environments with rapid temperature fluctuations.Expand Specific Solutions03 Integrated temperature sensing and compensation solutions

Advanced VCSEL designs incorporate on-chip or closely integrated temperature sensors and compensation circuits to minimize thermal effects. These integrated solutions reduce system complexity and improve response time to temperature changes. By placing the sensing elements in close proximity to the laser cavity, these designs achieve more accurate temperature readings and more effective compensation. This approach is particularly valuable in compact devices where space constraints limit external compensation options.Expand Specific Solutions04 Bias current adjustment techniques for temperature stability

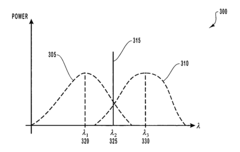

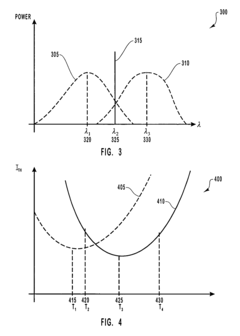

Specific methods for adjusting VCSEL bias current based on temperature variations help maintain consistent performance across operating conditions. These techniques often employ temperature-dependent resistive networks or active components that automatically modify current flow as temperature changes. Some implementations use lookup tables or mathematical models to determine the optimal bias current for a given temperature. This approach directly addresses the VCSEL's tendency to require higher threshold current at elevated temperatures.Expand Specific Solutions05 Temperature compensation for wavelength stability in VCSELs

Specialized circuits focus on maintaining wavelength stability of VCSELs across temperature variations, which is critical for wavelength-sensitive applications. These systems typically adjust operating parameters to counteract the natural wavelength drift that occurs with temperature changes in semiconductor lasers. Some designs incorporate wavelength monitoring elements that provide additional feedback for more precise control. This approach is particularly important in dense wavelength division multiplexing and sensing applications where wavelength accuracy directly impacts system performance.Expand Specific Solutions

Leading VCSEL Circuit Design Companies and Competitors

The VCSEL temperature compensation circuit design market is currently in a growth phase, with increasing adoption across automotive, consumer electronics, and telecommunications sectors. The market size is estimated to be expanding at a CAGR of 15-20%, driven by applications in 3D sensing, facial recognition, and LiDAR systems. From a technical maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like Trumpf Photonic Components, II-VI Delaware, and Vixar have established robust temperature compensation solutions, while companies such as Texas Instruments, NXP, and Analog Devices are leveraging their semiconductor expertise to develop integrated circuit approaches. Academic institutions including Beijing University of Technology and Xi'an Jiaotong University are contributing fundamental research, suggesting the technology still has significant room for innovation and optimization in thermal stability and power efficiency.

Trumpf Photonic Components GmbH

Technical Solution: Trumpf Photonic Components has developed advanced VCSEL temperature compensation circuits that integrate both analog and digital approaches. Their solution employs a combination of thermistor-based sensing with proprietary ASIC designs that dynamically adjust bias current based on real-time temperature measurements. The company's circuits feature multi-point calibration technology that maintains wavelength stability across a wide temperature range (-40°C to +125°C) with deviation less than ±0.5nm. Their latest designs incorporate an embedded microcontroller that executes adaptive algorithms to predict and compensate for temperature-induced wavelength shifts before they occur, particularly valuable for high-precision sensing applications. Trumpf's circuits also implement automatic power control (APC) loops that work in conjunction with temperature compensation to maintain consistent optical output power regardless of ambient conditions.

Strengths: Superior wavelength stability across extreme temperature ranges; predictive compensation algorithms reduce response latency; integrated solution requires minimal external components. Weaknesses: Higher cost compared to simpler solutions; increased power consumption due to active compensation circuitry; requires initial factory calibration.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered a comprehensive VCSEL temperature compensation approach using their proprietary BiCMOS process technology. Their solution integrates temperature sensing, analog signal conditioning, and digital calibration on a single chip. TI's circuits employ a bandgap reference-based architecture that provides a temperature-stable current source with precision better than ±1% across the industrial temperature range. The design incorporates a programmable lookup table that allows for non-linear compensation curves, addressing the complex relationship between temperature, current, and VCSEL wavelength. TI's circuits feature automatic power control loops with temperature feed-forward compensation that anticipates output power changes before they occur. Their latest generation includes an I²C interface for real-time monitoring and adjustment of compensation parameters, enabling adaptive control in dynamic thermal environments.

Strengths: High integration level reduces BOM cost and footprint; programmable compensation curves allow customization for different VCSEL types; excellent stability across industrial temperature range. Weaknesses: Requires detailed characterization of each VCSEL batch for optimal performance; higher complexity increases design-in time; limited flexibility for extremely specialized applications.

Key Patents in VCSEL Temperature Compensation Techniques

Wide temperature range vertical cavity surface emitting laser

PatentInactiveUS7356057B2

Innovation

- A VCSEL module is designed to operate over a wide temperature range by tuning the VCSEL to operate efficiently at higher temperatures and incorporating a heater and temperature sensor to maintain optimal temperature, reducing current requirements and extending the module's lifetime without degrading signal quality.

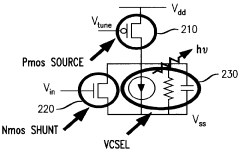

Vertical cavity surface emitting laser driving circuit

PatentInactiveUS6067307A

Innovation

- A current driver circuit for VCSELs, comprising a P-channel metal-oxide semiconductor (PMOS) source transistor and an N-channel metal-oxide semiconductor (NMOS) shunt transistor, which supplies and modulates current to the VCSEL under control of tuning voltage, ensuring current above the lasing threshold and enabling high-speed modulation.

Reliability Testing Standards for VCSEL Circuits

Reliability testing is a critical component in the development and validation of VCSEL temperature compensation circuits. Industry standards have evolved to ensure these circuits can withstand various environmental stresses while maintaining optimal performance. The Joint Electron Device Engineering Council (JEDEC) provides comprehensive standards for semiconductor device qualification, with JESD22-A104 specifically addressing temperature cycling reliability. This standard outlines procedures for subjecting VCSEL circuits to extreme temperature variations, typically ranging from -40°C to +125°C, to evaluate their thermal endurance.

The Automotive Electronics Council (AEC) has established the AEC-Q100 standard, which is particularly relevant for VCSEL circuits used in automotive applications. This standard defines stress test qualifications for integrated circuits, including specific requirements for temperature compensation circuits that must operate reliably in harsh automotive environments. The AEC-Q100 Grade 1 qualification requires devices to function within a temperature range of -40°C to +125°C, while Grade 0 extends this to -40°C to +150°C for more demanding applications.

Telcordia GR-468 provides another important set of reliability standards, focusing on optoelectronic devices used in telecommunications. These standards specify rigorous testing methodologies including high-temperature operating life (HTOL) tests, where VCSEL circuits must operate continuously at elevated temperatures (typically 85°C to 125°C) for 1,000 to 5,000 hours while maintaining performance within specified parameters.

Military standards such as MIL-STD-883 establish even more stringent reliability requirements for electronic components used in defense applications. These standards include detailed procedures for temperature shock testing, where VCSEL circuits are rapidly transferred between extreme temperature environments to assess their resistance to thermal stress-induced failures.

Humidity testing represents another critical aspect of reliability assessment, with standards like JEDEC JESD22-A101 specifying conditions for temperature-humidity bias (THB) testing. VCSEL temperature compensation circuits must demonstrate resistance to moisture-induced degradation, typically through exposure to 85°C/85% relative humidity environments for extended periods (500-1000 hours).

Accelerated life testing methodologies are increasingly employed to predict long-term reliability. These approaches use elevated stress conditions to induce failures more rapidly, with mathematical models then applied to extrapolate expected lifetime under normal operating conditions. The Arrhenius model is commonly used to relate temperature acceleration factors to activation energy, enabling more accurate lifetime predictions for VCSEL temperature compensation circuits.

Emerging standards are beginning to address reliability concerns specific to new VCSEL applications, such as facial recognition systems and autonomous vehicle LiDAR. These applications demand enhanced reliability testing protocols that consider factors like rapid power cycling, optical output stability over temperature, and long-term wavelength drift—all critical parameters for maintaining system performance across varying environmental conditions.

The Automotive Electronics Council (AEC) has established the AEC-Q100 standard, which is particularly relevant for VCSEL circuits used in automotive applications. This standard defines stress test qualifications for integrated circuits, including specific requirements for temperature compensation circuits that must operate reliably in harsh automotive environments. The AEC-Q100 Grade 1 qualification requires devices to function within a temperature range of -40°C to +125°C, while Grade 0 extends this to -40°C to +150°C for more demanding applications.

Telcordia GR-468 provides another important set of reliability standards, focusing on optoelectronic devices used in telecommunications. These standards specify rigorous testing methodologies including high-temperature operating life (HTOL) tests, where VCSEL circuits must operate continuously at elevated temperatures (typically 85°C to 125°C) for 1,000 to 5,000 hours while maintaining performance within specified parameters.

Military standards such as MIL-STD-883 establish even more stringent reliability requirements for electronic components used in defense applications. These standards include detailed procedures for temperature shock testing, where VCSEL circuits are rapidly transferred between extreme temperature environments to assess their resistance to thermal stress-induced failures.

Humidity testing represents another critical aspect of reliability assessment, with standards like JEDEC JESD22-A101 specifying conditions for temperature-humidity bias (THB) testing. VCSEL temperature compensation circuits must demonstrate resistance to moisture-induced degradation, typically through exposure to 85°C/85% relative humidity environments for extended periods (500-1000 hours).

Accelerated life testing methodologies are increasingly employed to predict long-term reliability. These approaches use elevated stress conditions to induce failures more rapidly, with mathematical models then applied to extrapolate expected lifetime under normal operating conditions. The Arrhenius model is commonly used to relate temperature acceleration factors to activation energy, enabling more accurate lifetime predictions for VCSEL temperature compensation circuits.

Emerging standards are beginning to address reliability concerns specific to new VCSEL applications, such as facial recognition systems and autonomous vehicle LiDAR. These applications demand enhanced reliability testing protocols that consider factors like rapid power cycling, optical output stability over temperature, and long-term wavelength drift—all critical parameters for maintaining system performance across varying environmental conditions.

Power Efficiency Considerations in Compensation Design

Power efficiency represents a critical design parameter in VCSEL temperature compensation circuits, particularly for battery-powered and portable applications. The compensation circuitry must maintain optimal VCSEL performance across temperature variations while minimizing additional power consumption. Traditional compensation methods often create significant power overhead, reducing overall system efficiency and battery life.

When designing temperature compensation circuits, engineers must carefully balance the power consumed by the compensation mechanism against the benefits of improved VCSEL performance. Passive compensation networks generally offer superior power efficiency compared to active solutions, as they require no additional current draw. However, their compensation accuracy may be limited across wide temperature ranges.

Active compensation circuits provide more precise temperature tracking but introduce power penalties through operational amplifiers, reference voltage generators, and sensing elements. Modern designs increasingly employ low-power microcontrollers or ASICs with sleep/wake capabilities to minimize power consumption during inactive periods. These intelligent systems activate compensation only when necessary, significantly reducing average power consumption.

The selection of temperature sensing elements also impacts power efficiency. While thermistors offer simplicity, their continuous current requirements can be problematic in low-power designs. Alternatively, digital temperature sensors with periodic sampling capabilities provide more efficient operation at the cost of increased complexity.

Recent innovations focus on integrating compensation directly within VCSEL driver ICs, eliminating redundant components and reducing overall power consumption. These integrated solutions often implement sophisticated power management techniques such as dynamic biasing and adaptive compensation that adjust power allocation based on operating conditions.

For battery-powered applications, compensation circuit designers must consider the entire power profile, including startup transients and stabilization periods. Fast-settling compensation circuits minimize energy waste during frequent power cycling. Additionally, the compensation circuit's quiescent current becomes particularly significant in standby modes, where it may dominate the system's power budget.

Advanced compensation designs now incorporate temperature prediction algorithms that reduce sensing frequency based on thermal models of the system. By anticipating temperature changes rather than constantly measuring them, these systems achieve substantial power savings while maintaining compensation accuracy.

When designing temperature compensation circuits, engineers must carefully balance the power consumed by the compensation mechanism against the benefits of improved VCSEL performance. Passive compensation networks generally offer superior power efficiency compared to active solutions, as they require no additional current draw. However, their compensation accuracy may be limited across wide temperature ranges.

Active compensation circuits provide more precise temperature tracking but introduce power penalties through operational amplifiers, reference voltage generators, and sensing elements. Modern designs increasingly employ low-power microcontrollers or ASICs with sleep/wake capabilities to minimize power consumption during inactive periods. These intelligent systems activate compensation only when necessary, significantly reducing average power consumption.

The selection of temperature sensing elements also impacts power efficiency. While thermistors offer simplicity, their continuous current requirements can be problematic in low-power designs. Alternatively, digital temperature sensors with periodic sampling capabilities provide more efficient operation at the cost of increased complexity.

Recent innovations focus on integrating compensation directly within VCSEL driver ICs, eliminating redundant components and reducing overall power consumption. These integrated solutions often implement sophisticated power management techniques such as dynamic biasing and adaptive compensation that adjust power allocation based on operating conditions.

For battery-powered applications, compensation circuit designers must consider the entire power profile, including startup transients and stabilization periods. Fast-settling compensation circuits minimize energy waste during frequent power cycling. Additionally, the compensation circuit's quiescent current becomes particularly significant in standby modes, where it may dominate the system's power budget.

Advanced compensation designs now incorporate temperature prediction algorithms that reduce sensing frequency based on thermal models of the system. By anticipating temperature changes rather than constantly measuring them, these systems achieve substantial power savings while maintaining compensation accuracy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!