Interposer Materials And Thermal Interface Materials For VCSELs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VCSEL Interposer Background and Objectives

Vertical-Cavity Surface-Emitting Lasers (VCSELs) have emerged as critical components in various optoelectronic applications, including facial recognition systems, LiDAR for autonomous vehicles, and high-speed optical communications. The evolution of VCSEL technology has been marked by continuous improvements in performance, reliability, and integration capabilities since their initial development in the late 1970s and commercial introduction in the 1990s.

The interposer serves as a critical interface between the VCSEL array and the underlying electronic circuitry, providing electrical connections, mechanical support, and thermal management. As VCSEL applications expand into higher-power and higher-density configurations, the demands on interposer materials have intensified, driving innovation in material science and packaging technologies.

Current technological trends indicate a shift toward more sophisticated interposer designs that can accommodate increasing power densities while maintaining optimal operating temperatures. The industry is witnessing a convergence of advanced ceramic materials, metal-matrix composites, and engineered polymers that offer superior thermal conductivity and electrical isolation properties compared to traditional materials.

The thermal management of VCSELs represents a significant challenge as these devices convert approximately 50-70% of input electrical power into heat rather than light output. This heat generation, if not properly managed, leads to wavelength shifts, reduced output power, and accelerated device degradation. Consequently, the development of advanced Thermal Interface Materials (TIMs) has become paramount to ensuring VCSEL reliability and performance stability.

The primary objective of this research is to comprehensively evaluate existing and emerging interposer materials and TIMs specifically designed for VCSEL applications. We aim to identify materials that offer optimal combinations of thermal conductivity, coefficient of thermal expansion (CTE) matching, electrical performance, and manufacturability at scale.

Additionally, this investigation seeks to establish clear performance metrics and testing methodologies for evaluating interposer materials and TIMs in VCSEL applications, addressing the current lack of standardized assessment protocols in the industry. By developing these benchmarks, we intend to facilitate more meaningful comparisons between different material solutions.

Furthermore, this research aims to forecast technological trajectories in interposer and TIM development, identifying promising research directions that could lead to step-change improvements in VCSEL thermal management. This includes exploration of novel material compositions, innovative manufacturing techniques, and integration strategies that could potentially revolutionize VCSEL packaging approaches.

The interposer serves as a critical interface between the VCSEL array and the underlying electronic circuitry, providing electrical connections, mechanical support, and thermal management. As VCSEL applications expand into higher-power and higher-density configurations, the demands on interposer materials have intensified, driving innovation in material science and packaging technologies.

Current technological trends indicate a shift toward more sophisticated interposer designs that can accommodate increasing power densities while maintaining optimal operating temperatures. The industry is witnessing a convergence of advanced ceramic materials, metal-matrix composites, and engineered polymers that offer superior thermal conductivity and electrical isolation properties compared to traditional materials.

The thermal management of VCSELs represents a significant challenge as these devices convert approximately 50-70% of input electrical power into heat rather than light output. This heat generation, if not properly managed, leads to wavelength shifts, reduced output power, and accelerated device degradation. Consequently, the development of advanced Thermal Interface Materials (TIMs) has become paramount to ensuring VCSEL reliability and performance stability.

The primary objective of this research is to comprehensively evaluate existing and emerging interposer materials and TIMs specifically designed for VCSEL applications. We aim to identify materials that offer optimal combinations of thermal conductivity, coefficient of thermal expansion (CTE) matching, electrical performance, and manufacturability at scale.

Additionally, this investigation seeks to establish clear performance metrics and testing methodologies for evaluating interposer materials and TIMs in VCSEL applications, addressing the current lack of standardized assessment protocols in the industry. By developing these benchmarks, we intend to facilitate more meaningful comparisons between different material solutions.

Furthermore, this research aims to forecast technological trajectories in interposer and TIM development, identifying promising research directions that could lead to step-change improvements in VCSEL thermal management. This includes exploration of novel material compositions, innovative manufacturing techniques, and integration strategies that could potentially revolutionize VCSEL packaging approaches.

Market Analysis for VCSEL Applications

The VCSEL (Vertical-Cavity Surface-Emitting Laser) market has experienced significant growth in recent years, primarily driven by increasing adoption in consumer electronics, automotive applications, and data communication sectors. The global VCSEL market was valued at approximately $2.1 billion in 2022 and is projected to reach $5.3 billion by 2028, growing at a CAGR of around 16.5% during the forecast period.

Consumer electronics represents the largest application segment for VCSELs, accounting for over 40% of the market share. This dominance is largely attributed to the widespread integration of VCSELs in facial recognition systems, proximity sensors, and 3D sensing applications in smartphones and tablets. Apple's implementation of Face ID technology has been a major catalyst for VCSEL adoption in the consumer sector.

The automotive industry is emerging as a rapidly growing market for VCSEL technology. Advanced driver-assistance systems (ADAS), LiDAR sensors for autonomous vehicles, and in-cabin monitoring systems are increasingly incorporating VCSELs. Industry analysts predict that automotive VCSEL applications will grow at a CAGR of approximately 22% through 2028, outpacing other application segments.

Data communication remains a critical application area for VCSELs, particularly in data centers and high-speed optical interconnects. The increasing demand for higher bandwidth and faster data transmission rates in cloud computing infrastructure is driving the adoption of VCSEL arrays in optical transceivers. This segment is expected to grow steadily at around 14% annually.

Geographically, North America and Asia-Pacific dominate the VCSEL market, collectively accounting for over 75% of global market share. The strong presence of major smartphone manufacturers and data center operators in these regions contributes significantly to this dominance. Europe is witnessing accelerated growth, particularly in automotive applications, as European automakers increasingly adopt advanced sensing technologies.

The demand for improved thermal management solutions and interposer materials for VCSELs is directly correlated with the performance requirements of these applications. As VCSEL arrays become more powerful and densely packed, especially in sensing and LiDAR applications, thermal interface materials that can efficiently dissipate heat become critical for maintaining device reliability and performance. Market research indicates that approximately 30% of VCSEL failures in high-power applications are related to thermal management issues, highlighting the significant market opportunity for advanced thermal interface materials.

Consumer electronics represents the largest application segment for VCSELs, accounting for over 40% of the market share. This dominance is largely attributed to the widespread integration of VCSELs in facial recognition systems, proximity sensors, and 3D sensing applications in smartphones and tablets. Apple's implementation of Face ID technology has been a major catalyst for VCSEL adoption in the consumer sector.

The automotive industry is emerging as a rapidly growing market for VCSEL technology. Advanced driver-assistance systems (ADAS), LiDAR sensors for autonomous vehicles, and in-cabin monitoring systems are increasingly incorporating VCSELs. Industry analysts predict that automotive VCSEL applications will grow at a CAGR of approximately 22% through 2028, outpacing other application segments.

Data communication remains a critical application area for VCSELs, particularly in data centers and high-speed optical interconnects. The increasing demand for higher bandwidth and faster data transmission rates in cloud computing infrastructure is driving the adoption of VCSEL arrays in optical transceivers. This segment is expected to grow steadily at around 14% annually.

Geographically, North America and Asia-Pacific dominate the VCSEL market, collectively accounting for over 75% of global market share. The strong presence of major smartphone manufacturers and data center operators in these regions contributes significantly to this dominance. Europe is witnessing accelerated growth, particularly in automotive applications, as European automakers increasingly adopt advanced sensing technologies.

The demand for improved thermal management solutions and interposer materials for VCSELs is directly correlated with the performance requirements of these applications. As VCSEL arrays become more powerful and densely packed, especially in sensing and LiDAR applications, thermal interface materials that can efficiently dissipate heat become critical for maintaining device reliability and performance. Market research indicates that approximately 30% of VCSEL failures in high-power applications are related to thermal management issues, highlighting the significant market opportunity for advanced thermal interface materials.

Current Challenges in VCSEL Thermal Management

Thermal management has emerged as one of the most critical challenges in VCSEL (Vertical-Cavity Surface-Emitting Laser) technology development. As VCSELs continue to advance toward higher power densities and more compact form factors, heat dissipation issues have become increasingly problematic. The primary concern stems from the inherent thermal sensitivity of these devices, where even modest temperature increases can significantly impact wavelength stability, threshold current, and overall reliability.

Current VCSEL designs face several interconnected thermal challenges. First, the thermal resistance between the active region and heat sink remains stubbornly high in many package configurations. This bottleneck restricts efficient heat flow away from the critical laser junction, leading to localized hotspots that can accelerate device degradation. Industry measurements indicate that junction temperatures can exceed ambient temperatures by 30-50°C under normal operating conditions, with this differential expanding dramatically at higher power outputs.

Material limitations constitute another significant barrier. Traditional thermal interface materials (TIMs) used in VCSEL packaging often exhibit thermal conductivity values below 5 W/m·K, which proves inadequate for next-generation high-power applications. The thermal boundary resistance at material interfaces further compounds this issue, creating multiple heat transfer bottlenecks throughout the thermal pathway.

Package-level thermal management presents additional complications. As VCSELs are increasingly integrated into space-constrained consumer electronics, the available volume for heat sinks and thermal management structures has diminished considerably. This spatial limitation forces designers to achieve more efficient thermal dissipation within smaller footprints, often requiring complex trade-offs between optical performance and thermal management.

The multi-device arrays commonly deployed in sensing and illumination applications introduce further thermal challenges. These arrays create complex thermal profiles with significant cross-heating effects between adjacent emitters. Current simulation models struggle to accurately predict these thermal interactions, particularly in dynamic operating conditions where power levels fluctuate rapidly.

Reliability concerns also stem from thermal cycling effects. The coefficient of thermal expansion (CTE) mismatch between different package materials creates mechanical stress during temperature fluctuations, potentially leading to delamination, cracking, or bond failures over time. This reliability challenge becomes particularly acute in automotive and industrial applications where wide temperature ranges and frequent thermal cycling are expected.

Finally, cost considerations constrain potential solutions. While advanced cooling technologies like microchannel coolers or diamond heat spreaders offer superior thermal performance, their implementation costs remain prohibitively high for mass-market applications. The industry continues to search for cost-effective thermal management approaches that can be scaled to high-volume production without compromising device performance or reliability.

Current VCSEL designs face several interconnected thermal challenges. First, the thermal resistance between the active region and heat sink remains stubbornly high in many package configurations. This bottleneck restricts efficient heat flow away from the critical laser junction, leading to localized hotspots that can accelerate device degradation. Industry measurements indicate that junction temperatures can exceed ambient temperatures by 30-50°C under normal operating conditions, with this differential expanding dramatically at higher power outputs.

Material limitations constitute another significant barrier. Traditional thermal interface materials (TIMs) used in VCSEL packaging often exhibit thermal conductivity values below 5 W/m·K, which proves inadequate for next-generation high-power applications. The thermal boundary resistance at material interfaces further compounds this issue, creating multiple heat transfer bottlenecks throughout the thermal pathway.

Package-level thermal management presents additional complications. As VCSELs are increasingly integrated into space-constrained consumer electronics, the available volume for heat sinks and thermal management structures has diminished considerably. This spatial limitation forces designers to achieve more efficient thermal dissipation within smaller footprints, often requiring complex trade-offs between optical performance and thermal management.

The multi-device arrays commonly deployed in sensing and illumination applications introduce further thermal challenges. These arrays create complex thermal profiles with significant cross-heating effects between adjacent emitters. Current simulation models struggle to accurately predict these thermal interactions, particularly in dynamic operating conditions where power levels fluctuate rapidly.

Reliability concerns also stem from thermal cycling effects. The coefficient of thermal expansion (CTE) mismatch between different package materials creates mechanical stress during temperature fluctuations, potentially leading to delamination, cracking, or bond failures over time. This reliability challenge becomes particularly acute in automotive and industrial applications where wide temperature ranges and frequent thermal cycling are expected.

Finally, cost considerations constrain potential solutions. While advanced cooling technologies like microchannel coolers or diamond heat spreaders offer superior thermal performance, their implementation costs remain prohibitively high for mass-market applications. The industry continues to search for cost-effective thermal management approaches that can be scaled to high-volume production without compromising device performance or reliability.

State-of-the-Art Interposer and TIM Solutions

01 Thermal interface materials for interposers

Thermal interface materials (TIMs) are used in interposer structures to enhance heat dissipation from semiconductor devices. These materials are designed to fill gaps between the interposer and adjacent components, reducing thermal resistance and improving overall thermal management. Advanced TIMs may incorporate materials such as metal particles, carbon nanotubes, or phase change materials to optimize thermal conductivity while maintaining necessary mechanical properties for reliable operation in electronic packages.- Advanced Interposer Materials for Semiconductor Packaging: Interposers serve as intermediate substrates between semiconductor dies and circuit boards, facilitating electrical connections and thermal management. Advanced materials used in interposers include silicon, glass, and organic compounds that provide improved electrical performance, reduced signal loss, and enhanced thermal conductivity. These materials enable higher integration density and better overall performance in semiconductor packages.

- Thermal Interface Materials with Enhanced Conductivity: Thermal interface materials (TIMs) are designed to efficiently transfer heat from electronic components to heat sinks or other cooling structures. Advanced TIMs incorporate materials such as metal-filled polymers, phase change materials, and graphene-based composites to achieve superior thermal conductivity. These materials minimize thermal resistance at interfaces, enabling more effective heat dissipation and improved device reliability under thermal stress.

- Integration of Interposers with Thermal Management Solutions: Modern semiconductor packages integrate interposers with built-in thermal management features. These designs incorporate thermal vias, embedded heat spreaders, and specialized thermal interface layers directly into the interposer structure. This integration approach enables more efficient heat transfer paths from heat-generating components to cooling systems, reducing thermal bottlenecks and improving overall system performance.

- Novel Composite Materials for Thermal and Electrical Performance: Composite materials combining multiple functional properties are increasingly used in both interposers and thermal interfaces. These include ceramic-polymer composites, metal-matrix materials, and carbon-based nanostructured materials. Such composites offer customizable combinations of thermal conductivity, electrical insulation or conductivity, coefficient of thermal expansion matching, and mechanical stability, addressing multiple design requirements simultaneously.

- Testing and Reliability of Interposer and Thermal Interface Materials: Specialized testing methodologies and reliability assessment techniques have been developed for interposer materials and thermal interfaces. These include accelerated aging tests, thermal cycling evaluations, and performance characterization under various operating conditions. Advanced analytical techniques help predict long-term material behavior, degradation mechanisms, and failure modes, ensuring that materials maintain their thermal and electrical properties throughout the product lifecycle.

02 Interposer materials for semiconductor packaging

Various materials are used in the fabrication of interposers for semiconductor packaging, including silicon, glass, ceramics, and organic substrates. These materials are selected based on their electrical, thermal, and mechanical properties to provide optimal performance in specific applications. Silicon interposers offer excellent thermal conductivity and coefficient of thermal expansion matching with silicon chips, while glass interposers provide good electrical insulation and RF performance. Organic interposers are typically more cost-effective but may have limitations in terms of thermal performance.Expand Specific Solutions03 Advanced cooling solutions for interposer structures

Advanced cooling solutions for interposer structures include integrated microfluidic channels, embedded heat pipes, and specialized thermal vias. These technologies enable more efficient heat removal from high-power density semiconductor devices. Microfluidic cooling channels can be incorporated directly into the interposer to provide localized cooling near heat sources. Thermal vias and through-silicon vias (TSVs) filled with thermally conductive materials create efficient heat transfer paths through the interposer structure, significantly improving thermal management in 2.5D and 3D integrated circuits.Expand Specific Solutions04 Novel composite materials for thermal management

Novel composite materials combining polymers with high thermal conductivity fillers are being developed for use in interposer applications. These composites offer improved thermal performance while maintaining necessary electrical insulation properties. Materials incorporating graphene, boron nitride, aluminum nitride, or diamond particles can achieve thermal conductivities several times higher than conventional polymer-based thermal interface materials. These advanced composites can be tailored to provide specific thermal, electrical, and mechanical properties required for different interposer applications while addressing challenges related to coefficient of thermal expansion matching and reliability.Expand Specific Solutions05 Testing and reliability of interposer thermal solutions

Testing methodologies and reliability assessment techniques are crucial for evaluating the performance of interposer materials and thermal interface materials in electronic packages. These include thermal resistance measurements, thermal cycling tests, power cycling tests, and accelerated aging studies to predict long-term reliability. Advanced characterization techniques such as infrared thermography, laser flash analysis, and scanning thermal microscopy are used to evaluate thermal performance at the component and system levels. Reliability testing helps identify potential failure mechanisms such as pump-out, dry-out, or delamination of thermal interface materials, enabling the development of more robust thermal management solutions for interposer-based electronic packages.Expand Specific Solutions

Leading Manufacturers in VCSEL Packaging Industry

The VCSEL interposer and thermal interface materials market is currently in a growth phase, with increasing applications in consumer electronics, data communications, and automotive sectors driving expansion. The global market size is projected to grow significantly due to rising demand for VCSELs in 3D sensing, facial recognition, and LiDAR applications. Leading players include established industrial giants like Henkel AG, IBM, Intel, and 3M who bring mature thermal management solutions, alongside specialized VCSEL manufacturers such as Yangzhou Changelight and RaySea Technology. The technology landscape shows varying maturity levels, with companies like Honeywell and Murata offering advanced packaging solutions, while newer entrants like Arieca and Kuprion are developing innovative nanomaterial-based thermal interfaces to address increasing power density challenges in next-generation VCSEL arrays.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed specialized thermal interface materials for VCSEL applications under their BERGQUIST and LOCTITE brands. Their portfolio includes phase-change materials with thermal conductivities ranging from 1.4 to 5.0 W/m·K that become soft and conformable at operating temperatures, ensuring excellent wetting and minimal thermal resistance. For high-power VCSEL arrays, Henkel offers metal-filled silicone-based TIMs with thermal conductivities up to 10 W/m·K while maintaining low modulus properties to reduce mechanical stress on delicate optoelectronic components. Their gap filling materials feature controlled bond line thickness to maintain optical alignment in VCSEL packages. Henkel's liquid dispensable thermal interface materials allow for precise application in complex geometries, with some formulations incorporating silver particles for enhanced thermal performance. For interposer applications, Henkel has developed specialized die attach materials with controlled flow characteristics and thermal conductivities exceeding 50 W/m·K, specifically designed to withstand the thermal cycling conditions experienced in VCSEL operations while maintaining reliable electrical and mechanical connections.

Strengths: Comprehensive portfolio addressing various VCSEL thermal management needs; established manufacturing processes ensuring consistent quality; materials optimized for automated dispensing; strong reliability testing capabilities. Weaknesses: Some high-performance formulations have limited pot life; potential for silicone migration with certain formulations; higher cost for metal-filled variants compared to standard thermal greases.

Dow Global Technologies LLC

Technical Solution: Dow has developed specialized silicone-based thermal interface materials optimized for VCSEL applications. Their DOWSIL™ TC series features thermal conductivities ranging from 2.0 to 6.5 W/m·K with carefully controlled viscosity profiles to ensure proper wetting of VCSEL surfaces without causing optical misalignment. For high-power VCSEL arrays, Dow has engineered thermally conductive adhesives that combine structural bonding with thermal management, achieving bond strengths exceeding 8 MPa while maintaining thermal performance. Their latest innovation includes hybrid organic-silicone TIMs with enhanced temperature stability (-55°C to +200°C) and minimal pump-out under thermal cycling conditions. Dow's research has demonstrated that their advanced TIMs can reduce VCSEL junction temperatures by up to 12°C compared to conventional materials, directly improving device reliability and performance. For interposer applications, Dow has developed specialized underfill materials with thermal conductivities up to 1.8 W/m·K that provide both mechanical support and supplementary thermal pathways. These materials feature controlled flow characteristics to ensure complete filling of the interposer-substrate interface without interfering with electrical connections or optical pathways, while their coefficient of thermal expansion is engineered to minimize stress on solder joints during thermal cycling.

Strengths: Industry-leading silicone chemistry expertise; materials engineered for long-term reliability; excellent stability under thermal cycling; global manufacturing capabilities ensuring consistent supply. Weaknesses: Lower thermal conductivity compared to metal-based solutions; some formulations require specialized dispensing equipment; potential for silicone outgassing affecting optical components if not properly cured.

Key Patents in VCSEL Thermal Interface Materials

Vertical-Cavity Surface-Emitting Laser

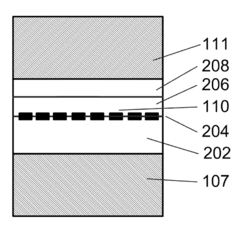

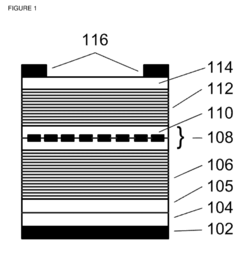

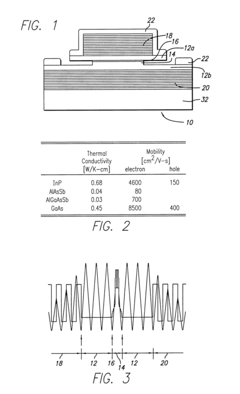

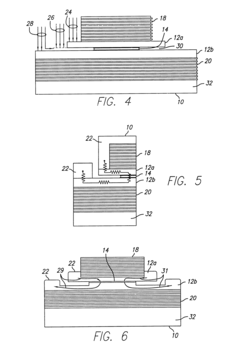

PatentActiveUS20180054041A1

Innovation

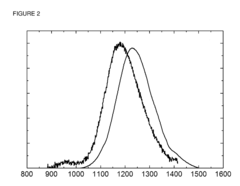

- A VCSEL design incorporating gallium arsenide antimonide nanostructures with quantum rings in the active region, surrounded by aluminium gallium arsenide layers with a composition gradient, which enhances thermal conductivity and reduces strain, allowing for efficient laser emission within the 1260 to 1675 nm range without the need for active cooling.

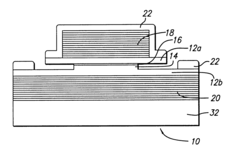

Contact scheme for intracavity-contacted vertical-cavity surface-emitting laser

PatentInactiveUS6714573B2

Innovation

- A double-intracavity contacted VCSEL design with thick indium phosphide (InP) cladding layers and very thin, heavily-doped contact layers, along with a tunnel junction, reduces impedance and optical loss by bypassing poor conducting mirror stacks and confining current and heat through InP layers, enabling room temperature continuous-wave operation.

Reliability Testing Methods for VCSEL Assemblies

Reliability testing for VCSEL assemblies is critical to ensure performance consistency and longevity in various applications. The testing methodologies must comprehensively evaluate both the VCSEL device and the supporting materials, including interposers and thermal interface materials (TIMs). Standard reliability tests include high-temperature operating life (HTOL) testing, where VCSELs are operated at elevated temperatures (typically 85°C to 125°C) for extended periods (1,000 to 5,000 hours) to accelerate aging mechanisms and identify potential failure modes.

Temperature cycling tests are particularly important for evaluating the integrity of interposer materials and TIMs. These tests involve subjecting the VCSEL assembly to rapid temperature fluctuations (typically -40°C to 125°C) for hundreds or thousands of cycles. This process stresses the interfaces between different materials with varying coefficients of thermal expansion (CTEs), revealing potential delamination or cracking issues that could compromise thermal management or electrical connectivity.

Humidity testing, such as the 85°C/85% relative humidity test, assesses the susceptibility of VCSEL assemblies to moisture-induced degradation. This is particularly relevant for evaluating the moisture resistance of interposer materials and the long-term stability of TIMs under humid conditions. For applications requiring hermetic sealing, hermeticity tests using helium leak detection methods are employed to verify package integrity.

Power cycling tests specifically target the thermal fatigue resistance of TIMs by repeatedly turning the VCSEL on and off. This creates thermal expansion and contraction cycles that can lead to pump-out or dry-out phenomena in TIMs, potentially degrading their thermal performance over time. Monitoring the thermal resistance during these tests provides valuable data on TIM reliability.

Mechanical shock and vibration testing evaluates the robustness of VCSEL assemblies under physical stress conditions, which is particularly important for automotive and industrial applications. These tests can reveal weaknesses in the mechanical bonding between the VCSEL, interposer, and substrate.

Advanced reliability characterization techniques include acoustic microscopy for non-destructive inspection of internal interfaces, thermal transient testing for real-time thermal resistance monitoring, and in-situ optical power monitoring during reliability tests. These methods provide deeper insights into degradation mechanisms affecting the interposer materials and TIMs in VCSEL assemblies.

Accelerated life testing models, such as the Arrhenius model for temperature effects and the Coffin-Manson model for thermal cycling, are employed to extrapolate test results to predict real-world reliability. These models help establish meaningful correlations between accelerated test conditions and expected field performance of VCSEL assemblies with specific interposer materials and TIMs.

Temperature cycling tests are particularly important for evaluating the integrity of interposer materials and TIMs. These tests involve subjecting the VCSEL assembly to rapid temperature fluctuations (typically -40°C to 125°C) for hundreds or thousands of cycles. This process stresses the interfaces between different materials with varying coefficients of thermal expansion (CTEs), revealing potential delamination or cracking issues that could compromise thermal management or electrical connectivity.

Humidity testing, such as the 85°C/85% relative humidity test, assesses the susceptibility of VCSEL assemblies to moisture-induced degradation. This is particularly relevant for evaluating the moisture resistance of interposer materials and the long-term stability of TIMs under humid conditions. For applications requiring hermetic sealing, hermeticity tests using helium leak detection methods are employed to verify package integrity.

Power cycling tests specifically target the thermal fatigue resistance of TIMs by repeatedly turning the VCSEL on and off. This creates thermal expansion and contraction cycles that can lead to pump-out or dry-out phenomena in TIMs, potentially degrading their thermal performance over time. Monitoring the thermal resistance during these tests provides valuable data on TIM reliability.

Mechanical shock and vibration testing evaluates the robustness of VCSEL assemblies under physical stress conditions, which is particularly important for automotive and industrial applications. These tests can reveal weaknesses in the mechanical bonding between the VCSEL, interposer, and substrate.

Advanced reliability characterization techniques include acoustic microscopy for non-destructive inspection of internal interfaces, thermal transient testing for real-time thermal resistance monitoring, and in-situ optical power monitoring during reliability tests. These methods provide deeper insights into degradation mechanisms affecting the interposer materials and TIMs in VCSEL assemblies.

Accelerated life testing models, such as the Arrhenius model for temperature effects and the Coffin-Manson model for thermal cycling, are employed to extrapolate test results to predict real-world reliability. These models help establish meaningful correlations between accelerated test conditions and expected field performance of VCSEL assemblies with specific interposer materials and TIMs.

Environmental Impact of VCSEL Packaging Materials

The environmental impact of VCSEL packaging materials has become increasingly significant as the production and deployment of these devices continue to expand across various industries. The materials used in VCSEL packaging, including interposers and thermal interface materials (TIMs), contribute to environmental concerns throughout their lifecycle from manufacturing to disposal.

Manufacturing processes for ceramic interposers, commonly used in VCSEL packaging, require high-temperature firing that consumes substantial energy and produces greenhouse gas emissions. Silicon interposers, while offering better thermal performance, involve energy-intensive semiconductor fabrication processes and utilize hazardous chemicals such as hydrofluoric acid and various solvents that require careful handling and disposal.

Metal-based interposers containing copper, aluminum, and sometimes gold present mining-related environmental impacts, including habitat destruction, water pollution, and energy consumption. The extraction and processing of these metals contribute significantly to carbon emissions and ecological disruption in mining regions.

Thermal interface materials pose their own environmental challenges. Traditional indium-based solders contain metals that are becoming increasingly scarce, raising sustainability concerns about resource depletion. Additionally, many TIMs incorporate silver particles that have both resource scarcity implications and potential environmental toxicity when improperly disposed of.

Polymer-based TIMs often contain compounds that are not biodegradable and may release microplastics into the environment. Some formulations include flame retardants and other additives that can be persistent environmental pollutants. The manufacturing of these materials frequently involves petroleum-derived components, further increasing their carbon footprint.

End-of-life considerations for VCSEL packaging materials present significant challenges for electronic waste management. The complex integration of different materials makes recycling difficult, with many valuable and potentially harmful substances ending up in landfills. The miniaturized nature of these components complicates material separation and recovery processes.

Recent regulatory developments, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, are driving the industry toward more environmentally friendly alternatives. Companies are increasingly exploring lead-free solders, bio-based polymers, and designs that facilitate easier disassembly and recycling.

The industry is witnessing a gradual shift toward more sustainable packaging solutions, including biodegradable polymers for TIMs and interposer materials with reduced environmental impact. Life cycle assessment (LCA) methodologies are being adopted to quantify and minimize the environmental footprint of VCSEL packaging materials throughout their production, use, and disposal phases.

Manufacturing processes for ceramic interposers, commonly used in VCSEL packaging, require high-temperature firing that consumes substantial energy and produces greenhouse gas emissions. Silicon interposers, while offering better thermal performance, involve energy-intensive semiconductor fabrication processes and utilize hazardous chemicals such as hydrofluoric acid and various solvents that require careful handling and disposal.

Metal-based interposers containing copper, aluminum, and sometimes gold present mining-related environmental impacts, including habitat destruction, water pollution, and energy consumption. The extraction and processing of these metals contribute significantly to carbon emissions and ecological disruption in mining regions.

Thermal interface materials pose their own environmental challenges. Traditional indium-based solders contain metals that are becoming increasingly scarce, raising sustainability concerns about resource depletion. Additionally, many TIMs incorporate silver particles that have both resource scarcity implications and potential environmental toxicity when improperly disposed of.

Polymer-based TIMs often contain compounds that are not biodegradable and may release microplastics into the environment. Some formulations include flame retardants and other additives that can be persistent environmental pollutants. The manufacturing of these materials frequently involves petroleum-derived components, further increasing their carbon footprint.

End-of-life considerations for VCSEL packaging materials present significant challenges for electronic waste management. The complex integration of different materials makes recycling difficult, with many valuable and potentially harmful substances ending up in landfills. The miniaturized nature of these components complicates material separation and recovery processes.

Recent regulatory developments, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, are driving the industry toward more environmentally friendly alternatives. Companies are increasingly exploring lead-free solders, bio-based polymers, and designs that facilitate easier disassembly and recycling.

The industry is witnessing a gradual shift toward more sustainable packaging solutions, including biodegradable polymers for TIMs and interposer materials with reduced environmental impact. Life cycle assessment (LCA) methodologies are being adopted to quantify and minimize the environmental footprint of VCSEL packaging materials throughout their production, use, and disposal phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!