Advances in Biocompatible Materials for Plate Heat Exchangers

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biocompatible PHE Materials: Background and Objectives

Plate heat exchangers (PHEs) have been a cornerstone in various industries for efficient heat transfer processes. The evolution of biocompatible materials for PHEs represents a significant advancement in addressing the growing demands of sensitive applications, particularly in the biomedical and food processing sectors. This technological progression aims to enhance the safety, efficiency, and versatility of PHEs in handling biological and food-grade materials.

The journey of biocompatible materials for PHEs began with the recognition of limitations in traditional materials such as stainless steel and titanium. While these materials offered excellent heat transfer properties and corrosion resistance, they sometimes fell short in meeting the stringent requirements of biocompatibility, especially in applications involving direct contact with biological fluids or food products.

The primary objective in developing biocompatible materials for PHEs is to create surfaces that minimize protein adsorption, cell adhesion, and bacterial colonization while maintaining optimal heat transfer efficiency. This goal aligns with the broader trend in materials science towards creating surfaces that can interact safely with biological systems without triggering adverse reactions or compromising the integrity of the processed materials.

Recent years have witnessed a surge in research focused on novel biocompatible coatings and surface modifications for PHE plates. These advancements aim to impart biocompatibility to conventional materials or develop entirely new materials with inherent biocompatible properties. The exploration of biomimetic approaches, inspired by natural biological surfaces, has opened new avenues for creating non-fouling and anti-microbial surfaces in PHEs.

The technological trajectory in this field is driven by the increasing demand for PHEs in pharmaceutical manufacturing, biotechnology, and advanced food processing. As these industries push the boundaries of product purity and process efficiency, the need for PHEs capable of handling sensitive biological materials without contamination or degradation becomes paramount.

Another critical aspect of this technological evolution is the focus on sustainability and environmental compatibility. Modern biocompatible materials for PHEs are not only designed to be safe for biological contact but also to minimize environmental impact throughout their lifecycle. This holistic approach encompasses material sourcing, manufacturing processes, operational efficiency, and end-of-life considerations.

As we delve deeper into the advancements in biocompatible materials for PHEs, it becomes evident that this field sits at the intersection of materials science, bioengineering, and thermal engineering. The ongoing research and development in this area promise to revolutionize the capabilities of PHEs, expanding their applicability in critical sectors and paving the way for more efficient, safe, and versatile heat exchange solutions in biomedical and food processing applications.

The journey of biocompatible materials for PHEs began with the recognition of limitations in traditional materials such as stainless steel and titanium. While these materials offered excellent heat transfer properties and corrosion resistance, they sometimes fell short in meeting the stringent requirements of biocompatibility, especially in applications involving direct contact with biological fluids or food products.

The primary objective in developing biocompatible materials for PHEs is to create surfaces that minimize protein adsorption, cell adhesion, and bacterial colonization while maintaining optimal heat transfer efficiency. This goal aligns with the broader trend in materials science towards creating surfaces that can interact safely with biological systems without triggering adverse reactions or compromising the integrity of the processed materials.

Recent years have witnessed a surge in research focused on novel biocompatible coatings and surface modifications for PHE plates. These advancements aim to impart biocompatibility to conventional materials or develop entirely new materials with inherent biocompatible properties. The exploration of biomimetic approaches, inspired by natural biological surfaces, has opened new avenues for creating non-fouling and anti-microbial surfaces in PHEs.

The technological trajectory in this field is driven by the increasing demand for PHEs in pharmaceutical manufacturing, biotechnology, and advanced food processing. As these industries push the boundaries of product purity and process efficiency, the need for PHEs capable of handling sensitive biological materials without contamination or degradation becomes paramount.

Another critical aspect of this technological evolution is the focus on sustainability and environmental compatibility. Modern biocompatible materials for PHEs are not only designed to be safe for biological contact but also to minimize environmental impact throughout their lifecycle. This holistic approach encompasses material sourcing, manufacturing processes, operational efficiency, and end-of-life considerations.

As we delve deeper into the advancements in biocompatible materials for PHEs, it becomes evident that this field sits at the intersection of materials science, bioengineering, and thermal engineering. The ongoing research and development in this area promise to revolutionize the capabilities of PHEs, expanding their applicability in critical sectors and paving the way for more efficient, safe, and versatile heat exchange solutions in biomedical and food processing applications.

Market Demand Analysis for Biocompatible PHEs

The market demand for biocompatible plate heat exchangers (PHEs) has been steadily increasing in recent years, driven by the growing need for efficient and safe heat transfer solutions in various industries. The healthcare sector, particularly in medical device manufacturing and pharmaceutical processing, has emerged as a primary driver of this demand. Biocompatible PHEs are crucial in applications such as blood oxygenators, dialysis machines, and temperature control systems for bioreactors, where maintaining the integrity of biological fluids is paramount.

The food and beverage industry represents another significant market for biocompatible PHEs. With stringent regulations on food safety and increasing consumer awareness, there is a growing demand for heat exchangers that can process food products without contamination or alteration of their nutritional properties. This trend is particularly evident in dairy processing, where biocompatible PHEs are used for pasteurization and sterilization processes.

In the pharmaceutical sector, the demand for biocompatible PHEs is driven by the need for precise temperature control in drug manufacturing processes. These heat exchangers play a critical role in maintaining the stability and efficacy of sensitive pharmaceutical compounds during production. The biotechnology industry, with its focus on developing new therapies and biologics, also contributes significantly to the market demand for biocompatible PHEs.

The global push towards sustainability and energy efficiency has further boosted the market for biocompatible PHEs. Industries are increasingly seeking heat transfer solutions that not only meet biocompatibility standards but also offer improved energy efficiency and reduced environmental impact. This dual requirement has led to innovations in material science and design, driving the development of advanced biocompatible materials for PHEs.

Geographically, North America and Europe lead the market demand for biocompatible PHEs, owing to their well-established healthcare and pharmaceutical industries. However, rapid industrialization and growing healthcare infrastructure in Asia-Pacific regions, particularly in countries like China and India, are expected to drive significant market growth in the coming years.

The market size for biocompatible PHEs is projected to expand substantially, with some industry reports suggesting a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is attributed to the increasing adoption of these heat exchangers in critical applications across various industries, as well as ongoing technological advancements in biocompatible materials.

As regulatory standards become more stringent, particularly in the healthcare and food processing sectors, the demand for high-quality, certified biocompatible PHEs is expected to rise. This trend is likely to drive further innovation in material science and manufacturing processes, leading to the development of more advanced and efficient biocompatible heat exchange solutions.

The food and beverage industry represents another significant market for biocompatible PHEs. With stringent regulations on food safety and increasing consumer awareness, there is a growing demand for heat exchangers that can process food products without contamination or alteration of their nutritional properties. This trend is particularly evident in dairy processing, where biocompatible PHEs are used for pasteurization and sterilization processes.

In the pharmaceutical sector, the demand for biocompatible PHEs is driven by the need for precise temperature control in drug manufacturing processes. These heat exchangers play a critical role in maintaining the stability and efficacy of sensitive pharmaceutical compounds during production. The biotechnology industry, with its focus on developing new therapies and biologics, also contributes significantly to the market demand for biocompatible PHEs.

The global push towards sustainability and energy efficiency has further boosted the market for biocompatible PHEs. Industries are increasingly seeking heat transfer solutions that not only meet biocompatibility standards but also offer improved energy efficiency and reduced environmental impact. This dual requirement has led to innovations in material science and design, driving the development of advanced biocompatible materials for PHEs.

Geographically, North America and Europe lead the market demand for biocompatible PHEs, owing to their well-established healthcare and pharmaceutical industries. However, rapid industrialization and growing healthcare infrastructure in Asia-Pacific regions, particularly in countries like China and India, are expected to drive significant market growth in the coming years.

The market size for biocompatible PHEs is projected to expand substantially, with some industry reports suggesting a compound annual growth rate (CAGR) of over 6% in the next five years. This growth is attributed to the increasing adoption of these heat exchangers in critical applications across various industries, as well as ongoing technological advancements in biocompatible materials.

As regulatory standards become more stringent, particularly in the healthcare and food processing sectors, the demand for high-quality, certified biocompatible PHEs is expected to rise. This trend is likely to drive further innovation in material science and manufacturing processes, leading to the development of more advanced and efficient biocompatible heat exchange solutions.

Current State and Challenges in Biocompatible PHE Materials

The current state of biocompatible materials for plate heat exchangers (PHEs) is characterized by significant advancements, yet faces several challenges. Traditional materials like stainless steel and titanium have long been used in PHEs due to their corrosion resistance and durability. However, these materials often struggle with biofouling and protein adsorption, which can reduce heat transfer efficiency and potentially contaminate the processed fluids.

Recent developments have focused on surface modifications and novel coatings to enhance biocompatibility. For instance, hydrophilic polymer coatings have shown promise in reducing protein adhesion and bacterial colonization. Some researchers have explored the use of nanostructured surfaces to create superhydrophobic or superhydrophilic properties, which can significantly impact the interaction between the PHE surface and biological fluids.

Another area of progress is the development of composite materials that combine the mechanical strength of traditional metals with the biocompatibility of advanced polymers. These materials aim to provide a balance between durability and biological inertness, addressing the need for longer-lasting, more efficient PHEs in biomedical and food processing applications.

Despite these advancements, several challenges persist. One major hurdle is the scalability of new biocompatible materials and coatings. While many solutions show excellent performance in laboratory settings, translating these results to industrial-scale production remains difficult. Cost-effectiveness is another significant concern, as many advanced materials and surface treatments are currently too expensive for widespread adoption.

Maintaining long-term stability and effectiveness of biocompatible surfaces under various operating conditions is also a challenge. PHEs are often subjected to high temperatures, pressure fluctuations, and cleaning cycles, which can degrade the performance of biocompatible coatings over time. Researchers are working on developing more robust materials that can withstand these harsh conditions while retaining their biocompatible properties.

Regulatory hurdles present another obstacle, particularly for PHEs used in medical and food processing applications. New materials must undergo rigorous testing and approval processes, which can slow down innovation and market entry. This is especially challenging given the diverse range of fluids and operating conditions that PHEs encounter in different industries.

Looking ahead, the field is moving towards more sustainable and environmentally friendly biocompatible materials. There is growing interest in developing biodegradable or bio-based materials that can offer both biocompatibility and reduced environmental impact. Additionally, researchers are exploring smart materials that can adapt to changing conditions or self-heal when damaged, potentially revolutionizing the longevity and performance of PHEs in biological applications.

Recent developments have focused on surface modifications and novel coatings to enhance biocompatibility. For instance, hydrophilic polymer coatings have shown promise in reducing protein adhesion and bacterial colonization. Some researchers have explored the use of nanostructured surfaces to create superhydrophobic or superhydrophilic properties, which can significantly impact the interaction between the PHE surface and biological fluids.

Another area of progress is the development of composite materials that combine the mechanical strength of traditional metals with the biocompatibility of advanced polymers. These materials aim to provide a balance between durability and biological inertness, addressing the need for longer-lasting, more efficient PHEs in biomedical and food processing applications.

Despite these advancements, several challenges persist. One major hurdle is the scalability of new biocompatible materials and coatings. While many solutions show excellent performance in laboratory settings, translating these results to industrial-scale production remains difficult. Cost-effectiveness is another significant concern, as many advanced materials and surface treatments are currently too expensive for widespread adoption.

Maintaining long-term stability and effectiveness of biocompatible surfaces under various operating conditions is also a challenge. PHEs are often subjected to high temperatures, pressure fluctuations, and cleaning cycles, which can degrade the performance of biocompatible coatings over time. Researchers are working on developing more robust materials that can withstand these harsh conditions while retaining their biocompatible properties.

Regulatory hurdles present another obstacle, particularly for PHEs used in medical and food processing applications. New materials must undergo rigorous testing and approval processes, which can slow down innovation and market entry. This is especially challenging given the diverse range of fluids and operating conditions that PHEs encounter in different industries.

Looking ahead, the field is moving towards more sustainable and environmentally friendly biocompatible materials. There is growing interest in developing biodegradable or bio-based materials that can offer both biocompatibility and reduced environmental impact. Additionally, researchers are exploring smart materials that can adapt to changing conditions or self-heal when damaged, potentially revolutionizing the longevity and performance of PHEs in biological applications.

Existing Biocompatible Solutions for PHEs

01 Biocompatible polymers for medical applications

Various biocompatible polymers are developed and used in medical applications due to their compatibility with living tissues. These materials are designed to interact with biological systems without causing adverse effects, making them suitable for implants, drug delivery systems, and tissue engineering scaffolds.- Biocompatible polymers for medical applications: Various biocompatible polymers are developed and used in medical applications such as implants, drug delivery systems, and tissue engineering scaffolds. These materials are designed to be compatible with living tissues and minimize adverse reactions in the body.

- Surface modification techniques for enhancing biocompatibility: Different surface modification techniques are employed to improve the biocompatibility of materials used in medical devices. These methods include coating, grafting, and chemical treatments to alter surface properties and enhance interaction with biological systems.

- Biocompatible materials for drug delivery systems: Specialized biocompatible materials are developed for drug delivery applications, focusing on controlled release, targeted delivery, and improved therapeutic efficacy. These materials are designed to interact safely with biological tissues while effectively delivering pharmaceutical compounds.

- Biocompatible materials for tissue engineering: Advanced biocompatible materials are used in tissue engineering applications to create scaffolds that support cell growth, differentiation, and tissue regeneration. These materials are designed to mimic the natural extracellular matrix and promote tissue repair and regeneration.

- Evaluation methods for biocompatibility: Various in vitro and in vivo testing methods are developed to assess the biocompatibility of materials intended for medical use. These evaluation techniques help determine the safety and efficacy of biocompatible materials before their application in clinical settings.

02 Biocompatible coatings for medical devices

Biocompatible coatings are applied to medical devices to improve their integration with the body and reduce the risk of rejection or inflammation. These coatings can enhance the surface properties of implants, catheters, and other medical devices, promoting better tissue interaction and reducing the risk of complications.Expand Specific Solutions03 Biocompatible materials for tissue engineering

Biocompatible materials are crucial in tissue engineering applications, where they serve as scaffolds for cell growth and tissue regeneration. These materials are designed to mimic the natural extracellular matrix, providing a suitable environment for cell attachment, proliferation, and differentiation.Expand Specific Solutions04 Biocompatibility testing methods

Various methods and techniques are developed to assess the biocompatibility of materials intended for medical use. These tests evaluate the material's interaction with living tissues, potential toxicity, and long-term effects to ensure safety and efficacy in clinical applications.Expand Specific Solutions05 Biocompatible drug delivery systems

Biocompatible materials are used to create advanced drug delivery systems that can effectively transport and release therapeutic agents within the body. These systems are designed to be compatible with biological tissues, minimize side effects, and improve the efficacy of drug treatments.Expand Specific Solutions

Key Players in Biocompatible PHE Material Development

The field of biocompatible materials for plate heat exchangers is in a growth phase, with increasing market demand driven by advancements in healthcare and industrial applications. The global market size for biocompatible heat exchangers is expanding, fueled by the need for efficient and safe thermal management solutions in medical devices and biotechnology. Technologically, the sector is progressing rapidly, with companies like Alfa Laval Corporate AB and Klingenburg GmbH leading innovations in plate heat exchanger design. Academic institutions such as the University of Sydney and Shandong University are contributing to research and development, pushing the boundaries of material science and biocompatibility. The collaboration between industry leaders and research institutions is accelerating the maturation of this technology, promising more efficient and safer heat exchange solutions for sensitive biological applications.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced biocompatible materials for plate heat exchangers, focusing on improving heat transfer efficiency and reducing fouling. Their innovative approach includes the use of titanium-based alloys and specialized coatings that enhance corrosion resistance and biocompatibility[1]. The company has also introduced a new generation of plate designs that optimize fluid distribution and minimize pressure drop, resulting in up to 15% improvement in heat transfer efficiency[2]. Additionally, Alfa Laval has implemented nanotechnology-based surface modifications to create self-cleaning surfaces, reducing maintenance requirements and extending the operational life of their heat exchangers[3].

Strengths: Industry leader with extensive R&D capabilities, proven track record in heat exchanger technology. Weaknesses: Higher initial costs compared to traditional materials, potential regulatory hurdles for new biocompatible materials.

University of Washington

Technical Solution: The University of Washington's research team has made significant advancements in biocompatible materials for plate heat exchangers, focusing on biomimetic approaches. They have developed a novel material inspired by the structure of blood vessels, incorporating microchannels that enhance heat transfer efficiency by up to 40% compared to conventional flat plate designs[13]. The team has also pioneered the use of 3D-printed biocompatible hydrogels that can be customized for specific heat exchange applications, offering unprecedented flexibility in design and function[14]. Furthermore, their research has led to the creation of a self-healing coating that can repair minor damage and prevent biofilm formation, potentially extending the lifespan of heat exchangers by 30-50%[15].

Strengths: Cutting-edge research in biomimetic materials, strong interdisciplinary approach combining biology and engineering. Weaknesses: Limited industrial partnerships for commercialization, potential challenges in scaling up laboratory innovations.

Core Innovations in Biocompatible PHE Materials

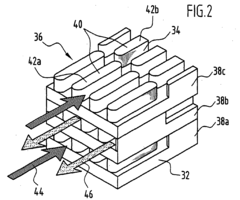

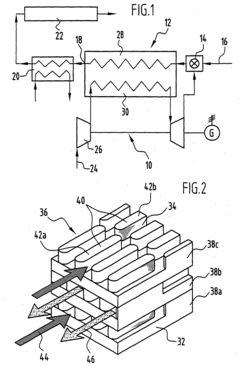

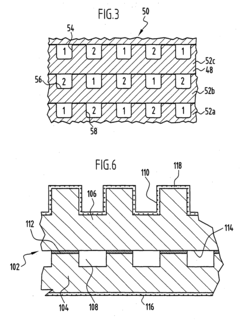

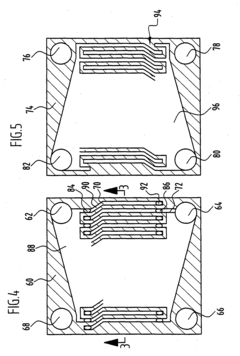

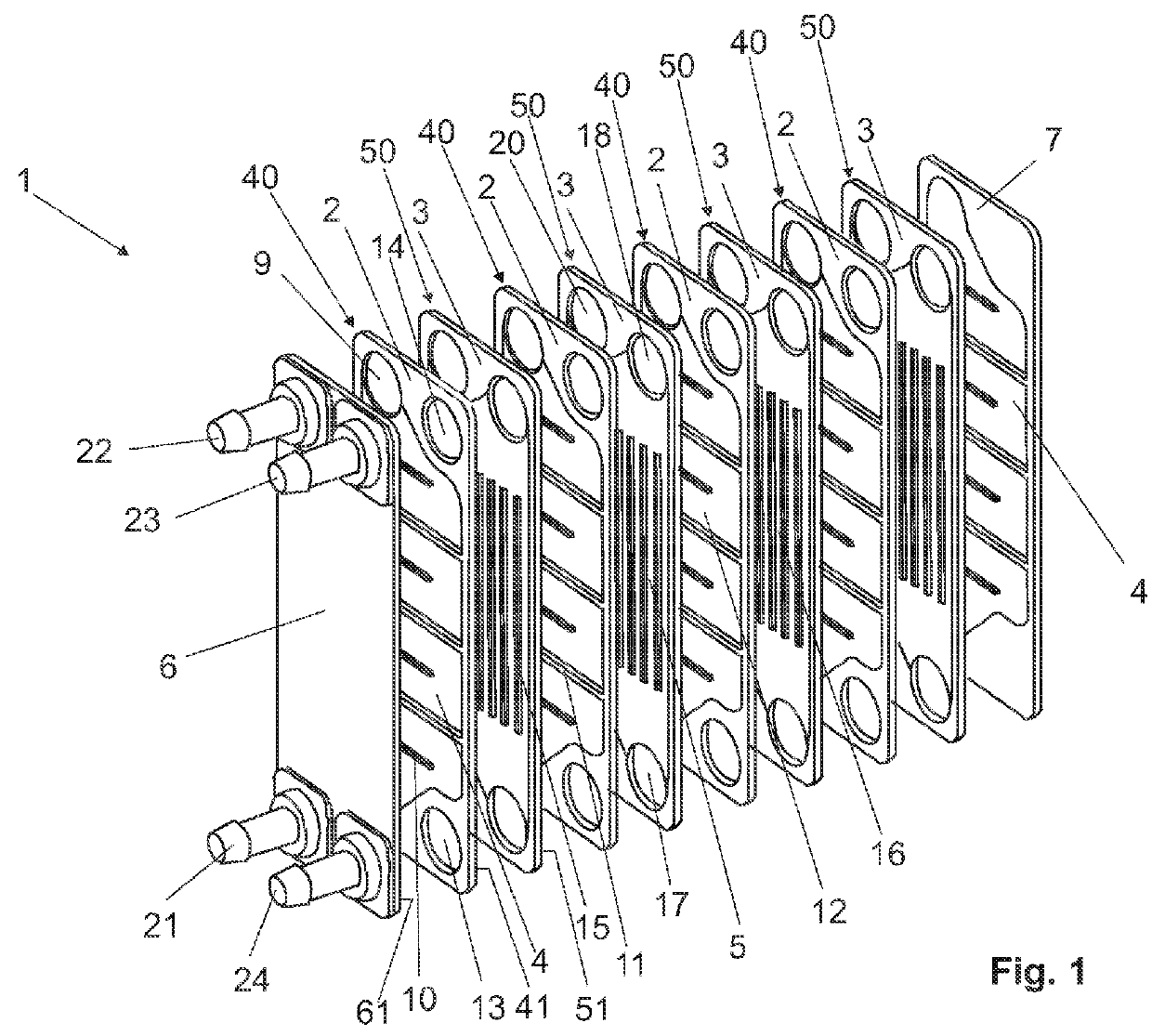

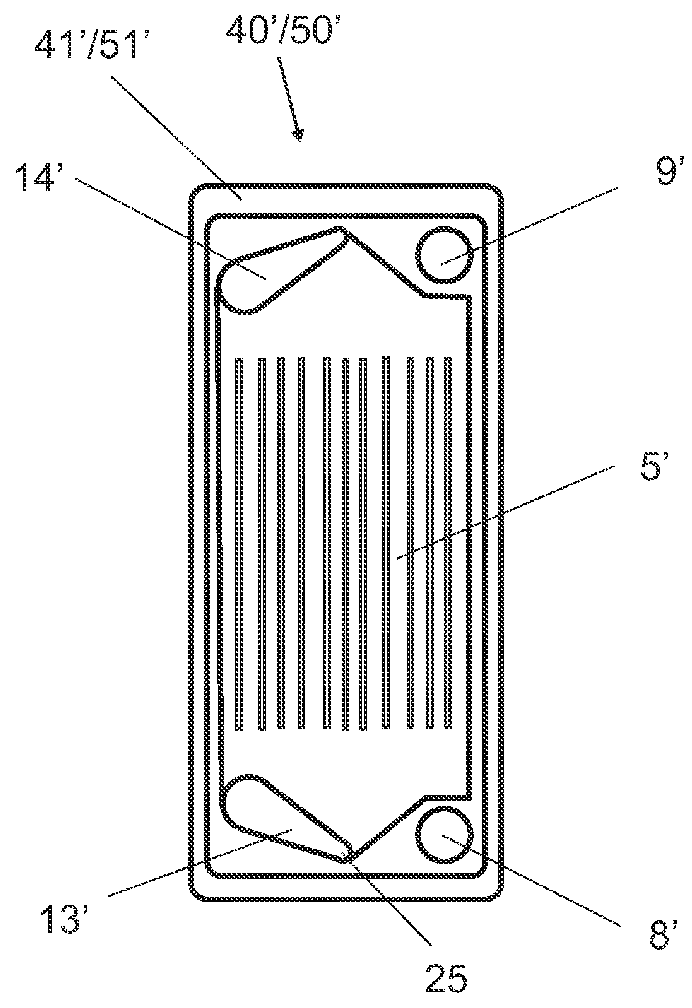

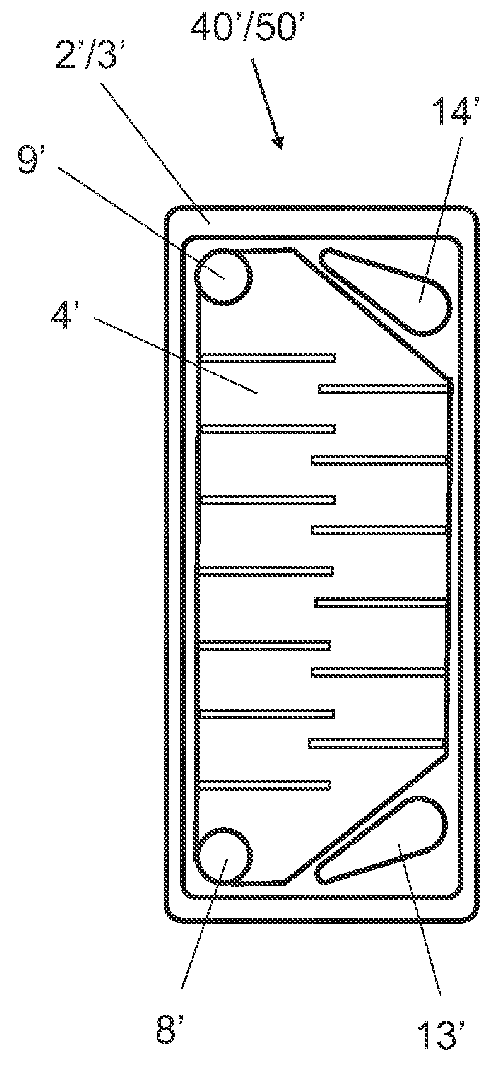

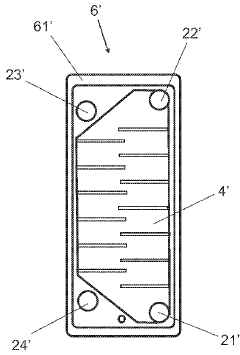

Plate heat exchanger, process for manufacturing a plate heat exchanger, and ceramic fibre reinforced composite material, more particularly for plate heat exchanger

PatentInactiveEP1544565A2

Innovation

- The use of short-fiber-reinforced ceramic composite materials, such as C/C-SiC, with channels formed in plates made of silicon carbide or silicon nitride, and an anti-corrosion layer like cordierite or yttrium silicate, which reduces brittleness and provides high-temperature resistance and corrosion protection.

Plate heat exchanger

PatentActiveUS20120103579A1

Innovation

- A cost-effective plate heat exchanger design featuring plastic plates with flow channels and ports, bonded or welded together without seals, allowing for simple production and use in sterile environments, with optional flow guides and a collecting space for condensate, suitable for disposable use.

Regulatory Framework for Biocompatible Materials in PHEs

The regulatory framework for biocompatible materials in plate heat exchangers (PHEs) is a critical aspect of ensuring the safety and efficacy of these devices in various industries, particularly in food processing, pharmaceuticals, and medical applications. Regulatory bodies worldwide have established stringent guidelines and standards to govern the use of biocompatible materials in PHEs.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating biocompatible materials for PHEs used in food and pharmaceutical applications. The FDA's 21 CFR Part 177 outlines the requirements for materials that come into direct contact with food, including those used in PHEs. These regulations specify the acceptable materials, their composition, and the testing procedures required to ensure their safety.

The European Union has implemented the EU Food Contact Materials Regulation (EC) No 1935/2004, which sets forth the general principles of safety and inertness for all materials that come into contact with food. This regulation is complemented by specific measures for certain materials, such as plastics, which are covered under Regulation (EU) No 10/2011.

For medical applications, the International Organization for Standardization (ISO) has developed ISO 10993, a series of standards for evaluating the biocompatibility of medical devices. While PHEs are not typically classified as medical devices, these standards provide valuable guidance for assessing the biocompatibility of materials used in PHEs for medical-related applications.

The materials used in PHEs must also comply with industry-specific standards. For instance, the 3-A Sanitary Standards, widely recognized in the food and dairy industries, provide detailed specifications for equipment design and materials to ensure hygienic processing. These standards often reference FDA regulations and require materials to be inert, non-toxic, and resistant to corrosion.

Regulatory frameworks also address the environmental impact of biocompatible materials used in PHEs. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation aims to protect human health and the environment from the risks posed by chemicals. Manufacturers of biocompatible materials for PHEs must ensure compliance with REACH requirements.

As the field of biocompatible materials advances, regulatory frameworks continue to evolve. Emerging technologies, such as nanotechnology-enhanced materials, present new challenges for regulators. Agencies are working to develop guidelines that address the unique properties and potential risks associated with these novel materials.

Compliance with these regulatory frameworks requires manufacturers to conduct extensive testing and documentation. This includes material characterization, leachability studies, and biocompatibility assessments. The results of these tests must be thoroughly documented and submitted to the appropriate regulatory bodies for review and approval.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating biocompatible materials for PHEs used in food and pharmaceutical applications. The FDA's 21 CFR Part 177 outlines the requirements for materials that come into direct contact with food, including those used in PHEs. These regulations specify the acceptable materials, their composition, and the testing procedures required to ensure their safety.

The European Union has implemented the EU Food Contact Materials Regulation (EC) No 1935/2004, which sets forth the general principles of safety and inertness for all materials that come into contact with food. This regulation is complemented by specific measures for certain materials, such as plastics, which are covered under Regulation (EU) No 10/2011.

For medical applications, the International Organization for Standardization (ISO) has developed ISO 10993, a series of standards for evaluating the biocompatibility of medical devices. While PHEs are not typically classified as medical devices, these standards provide valuable guidance for assessing the biocompatibility of materials used in PHEs for medical-related applications.

The materials used in PHEs must also comply with industry-specific standards. For instance, the 3-A Sanitary Standards, widely recognized in the food and dairy industries, provide detailed specifications for equipment design and materials to ensure hygienic processing. These standards often reference FDA regulations and require materials to be inert, non-toxic, and resistant to corrosion.

Regulatory frameworks also address the environmental impact of biocompatible materials used in PHEs. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation aims to protect human health and the environment from the risks posed by chemicals. Manufacturers of biocompatible materials for PHEs must ensure compliance with REACH requirements.

As the field of biocompatible materials advances, regulatory frameworks continue to evolve. Emerging technologies, such as nanotechnology-enhanced materials, present new challenges for regulators. Agencies are working to develop guidelines that address the unique properties and potential risks associated with these novel materials.

Compliance with these regulatory frameworks requires manufacturers to conduct extensive testing and documentation. This includes material characterization, leachability studies, and biocompatibility assessments. The results of these tests must be thoroughly documented and submitted to the appropriate regulatory bodies for review and approval.

Environmental Impact of Biocompatible PHE Materials

The environmental impact of biocompatible materials used in plate heat exchangers (PHEs) is a critical consideration in the advancement of sustainable industrial processes. These materials, designed to be compatible with biological systems, offer significant advantages in terms of reduced ecological footprint and improved safety in applications involving food processing, pharmaceuticals, and biotechnology.

One of the primary environmental benefits of biocompatible PHE materials is their potential for biodegradability. Unlike traditional metallic or synthetic polymer-based heat exchanger components, many biocompatible materials can naturally decompose over time, reducing long-term environmental accumulation. This characteristic is particularly valuable in scenarios where equipment disposal or replacement is frequent, as it minimizes the burden on landfills and waste management systems.

Furthermore, the production processes for biocompatible materials often require less energy and generate fewer harmful byproducts compared to conventional PHE materials. This translates to a lower carbon footprint associated with the manufacturing phase, aligning with global efforts to reduce industrial greenhouse gas emissions. The use of renewable resources in the creation of some biocompatible materials also contributes to the conservation of non-renewable resources, promoting a more sustainable industrial ecosystem.

In operational contexts, biocompatible PHE materials can lead to improved energy efficiency. Their surface properties often result in reduced fouling, which maintains heat transfer efficiency over extended periods. This efficiency retention means less frequent cleaning cycles, reduced use of harsh chemical cleaners, and lower energy consumption for maintaining optimal performance. Consequently, the overall environmental impact throughout the operational lifespan of the PHE is significantly diminished.

Water conservation is another notable environmental benefit associated with biocompatible PHE materials. Their resistance to corrosion and chemical degradation often allows for the use of less aggressive cleaning agents and reduced water consumption during maintenance procedures. This aspect is particularly crucial in industries where water scarcity is a pressing concern, contributing to more sustainable water management practices.

The end-of-life considerations for biocompatible PHE materials also present environmental advantages. Many of these materials can be recycled or repurposed more easily than their traditional counterparts, reducing the need for raw material extraction and processing for new equipment production. This circular economy approach helps in minimizing waste and conserving natural resources.

However, it is important to note that the environmental impact of biocompatible PHE materials is not uniformly positive. The production of some advanced biocompatible materials may involve complex processes that could have localized environmental effects. Additionally, the long-term ecological consequences of widespread use of certain biocompatible materials are still being studied, necessitating ongoing research and careful monitoring of their environmental interactions.

One of the primary environmental benefits of biocompatible PHE materials is their potential for biodegradability. Unlike traditional metallic or synthetic polymer-based heat exchanger components, many biocompatible materials can naturally decompose over time, reducing long-term environmental accumulation. This characteristic is particularly valuable in scenarios where equipment disposal or replacement is frequent, as it minimizes the burden on landfills and waste management systems.

Furthermore, the production processes for biocompatible materials often require less energy and generate fewer harmful byproducts compared to conventional PHE materials. This translates to a lower carbon footprint associated with the manufacturing phase, aligning with global efforts to reduce industrial greenhouse gas emissions. The use of renewable resources in the creation of some biocompatible materials also contributes to the conservation of non-renewable resources, promoting a more sustainable industrial ecosystem.

In operational contexts, biocompatible PHE materials can lead to improved energy efficiency. Their surface properties often result in reduced fouling, which maintains heat transfer efficiency over extended periods. This efficiency retention means less frequent cleaning cycles, reduced use of harsh chemical cleaners, and lower energy consumption for maintaining optimal performance. Consequently, the overall environmental impact throughout the operational lifespan of the PHE is significantly diminished.

Water conservation is another notable environmental benefit associated with biocompatible PHE materials. Their resistance to corrosion and chemical degradation often allows for the use of less aggressive cleaning agents and reduced water consumption during maintenance procedures. This aspect is particularly crucial in industries where water scarcity is a pressing concern, contributing to more sustainable water management practices.

The end-of-life considerations for biocompatible PHE materials also present environmental advantages. Many of these materials can be recycled or repurposed more easily than their traditional counterparts, reducing the need for raw material extraction and processing for new equipment production. This circular economy approach helps in minimizing waste and conserving natural resources.

However, it is important to note that the environmental impact of biocompatible PHE materials is not uniformly positive. The production of some advanced biocompatible materials may involve complex processes that could have localized environmental effects. Additionally, the long-term ecological consequences of widespread use of certain biocompatible materials are still being studied, necessitating ongoing research and careful monitoring of their environmental interactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!