Plate Heat Exchanger's Role in Virtual Power Plants

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE in VPP: Background and Objectives

Plate Heat Exchangers (PHEs) have emerged as a crucial component in the evolving landscape of Virtual Power Plants (VPPs), marking a significant technological advancement in energy management and distribution. The integration of PHEs into VPPs represents a convergence of traditional thermal engineering with cutting-edge digital infrastructure, aimed at optimizing energy efficiency and grid stability.

The concept of Virtual Power Plants has gained traction in recent years as a response to the increasing complexity and decentralization of energy systems. VPPs aggregate various distributed energy resources, including renewable sources, energy storage systems, and flexible loads, to create a single, coordinated entity that can be managed as a conventional power plant. Within this framework, PHEs play a pivotal role in thermal energy management, facilitating the efficient transfer of heat between different mediums and systems.

The primary objective of incorporating PHEs into VPPs is to enhance the overall energy efficiency and flexibility of the power system. By enabling rapid and efficient heat exchange, PHEs contribute to the dynamic balancing of thermal loads, which is essential for maintaining grid stability in the face of fluctuating renewable energy inputs. This integration aims to reduce energy waste, optimize resource utilization, and ultimately lower operational costs for energy providers and consumers alike.

The evolution of PHE technology in the context of VPPs can be traced back to the broader trend of smart grid development. As power systems became more interconnected and data-driven, the need for advanced thermal management solutions became apparent. PHEs, known for their compact design and high heat transfer efficiency, emerged as an ideal candidate for integration into the complex, multi-faceted structure of VPPs.

Current technological trends in this field focus on enhancing the responsiveness and adaptability of PHEs within VPPs. This includes the development of smart PHEs equipped with sensors and control systems that can communicate in real-time with the VPP's central management system. Such advancements allow for precise control of heat transfer processes, enabling VPPs to respond swiftly to changes in energy demand or supply.

Looking forward, the integration of PHEs in VPPs is expected to play a crucial role in the transition towards a more sustainable and resilient energy infrastructure. As renewable energy sources continue to proliferate, the ability to efficiently manage and distribute thermal energy will become increasingly important. PHEs, with their potential for further innovation and optimization, are poised to be at the forefront of this transformation, contributing significantly to the realization of smart, flexible, and environmentally friendly power systems.

The concept of Virtual Power Plants has gained traction in recent years as a response to the increasing complexity and decentralization of energy systems. VPPs aggregate various distributed energy resources, including renewable sources, energy storage systems, and flexible loads, to create a single, coordinated entity that can be managed as a conventional power plant. Within this framework, PHEs play a pivotal role in thermal energy management, facilitating the efficient transfer of heat between different mediums and systems.

The primary objective of incorporating PHEs into VPPs is to enhance the overall energy efficiency and flexibility of the power system. By enabling rapid and efficient heat exchange, PHEs contribute to the dynamic balancing of thermal loads, which is essential for maintaining grid stability in the face of fluctuating renewable energy inputs. This integration aims to reduce energy waste, optimize resource utilization, and ultimately lower operational costs for energy providers and consumers alike.

The evolution of PHE technology in the context of VPPs can be traced back to the broader trend of smart grid development. As power systems became more interconnected and data-driven, the need for advanced thermal management solutions became apparent. PHEs, known for their compact design and high heat transfer efficiency, emerged as an ideal candidate for integration into the complex, multi-faceted structure of VPPs.

Current technological trends in this field focus on enhancing the responsiveness and adaptability of PHEs within VPPs. This includes the development of smart PHEs equipped with sensors and control systems that can communicate in real-time with the VPP's central management system. Such advancements allow for precise control of heat transfer processes, enabling VPPs to respond swiftly to changes in energy demand or supply.

Looking forward, the integration of PHEs in VPPs is expected to play a crucial role in the transition towards a more sustainable and resilient energy infrastructure. As renewable energy sources continue to proliferate, the ability to efficiently manage and distribute thermal energy will become increasingly important. PHEs, with their potential for further innovation and optimization, are poised to be at the forefront of this transformation, contributing significantly to the realization of smart, flexible, and environmentally friendly power systems.

Market Demand Analysis for VPP Solutions

The market demand for Virtual Power Plant (VPP) solutions has been experiencing significant growth in recent years, driven by the increasing integration of renewable energy sources and the need for grid flexibility. As the energy sector transitions towards decentralized and sustainable models, VPPs have emerged as a crucial technology to manage and optimize distributed energy resources.

The global VPP market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by several factors, including the rising adoption of smart grid technologies, government initiatives to promote clean energy, and the increasing penetration of electric vehicles and energy storage systems.

One of the key drivers of market demand for VPP solutions is the growing need for grid stability and reliability. As more intermittent renewable energy sources are integrated into the power grid, utilities and grid operators face challenges in maintaining a balanced supply and demand. VPPs offer a solution by aggregating and coordinating various distributed energy resources, including solar panels, wind turbines, and energy storage systems, to provide a more stable and predictable power supply.

The industrial sector represents a significant market for VPP solutions, as large energy consumers seek to optimize their energy consumption and reduce costs. By participating in VPPs, industrial facilities can monetize their flexible loads and on-site generation capabilities, creating new revenue streams while contributing to grid stability.

Residential and commercial sectors are also showing increased interest in VPP solutions. The proliferation of smart home devices and the growing adoption of rooftop solar and battery storage systems have created opportunities for homeowners and businesses to participate in VPPs. This trend is expected to accelerate as energy markets evolve to accommodate more distributed resources and time-of-use pricing becomes more prevalent.

Geographically, Europe and North America currently lead the VPP market, with Asia-Pacific expected to show the fastest growth in the coming years. Countries like Germany, the United Kingdom, and the United States have been early adopters of VPP technology, driven by supportive regulatory frameworks and ambitious renewable energy targets.

The role of plate heat exchangers in VPP solutions is becoming increasingly important, particularly in applications involving thermal energy storage and district heating systems. As VPPs expand to include thermal loads and combined heat and power (CHP) plants, efficient heat transfer technologies like plate heat exchangers play a crucial role in optimizing energy flows and improving overall system efficiency.

In conclusion, the market demand for VPP solutions is robust and expected to continue growing as the energy sector evolves. The integration of diverse technologies, including plate heat exchangers, will be essential in realizing the full potential of VPPs and meeting the increasing demand for flexible, efficient, and sustainable energy systems.

The global VPP market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is fueled by several factors, including the rising adoption of smart grid technologies, government initiatives to promote clean energy, and the increasing penetration of electric vehicles and energy storage systems.

One of the key drivers of market demand for VPP solutions is the growing need for grid stability and reliability. As more intermittent renewable energy sources are integrated into the power grid, utilities and grid operators face challenges in maintaining a balanced supply and demand. VPPs offer a solution by aggregating and coordinating various distributed energy resources, including solar panels, wind turbines, and energy storage systems, to provide a more stable and predictable power supply.

The industrial sector represents a significant market for VPP solutions, as large energy consumers seek to optimize their energy consumption and reduce costs. By participating in VPPs, industrial facilities can monetize their flexible loads and on-site generation capabilities, creating new revenue streams while contributing to grid stability.

Residential and commercial sectors are also showing increased interest in VPP solutions. The proliferation of smart home devices and the growing adoption of rooftop solar and battery storage systems have created opportunities for homeowners and businesses to participate in VPPs. This trend is expected to accelerate as energy markets evolve to accommodate more distributed resources and time-of-use pricing becomes more prevalent.

Geographically, Europe and North America currently lead the VPP market, with Asia-Pacific expected to show the fastest growth in the coming years. Countries like Germany, the United Kingdom, and the United States have been early adopters of VPP technology, driven by supportive regulatory frameworks and ambitious renewable energy targets.

The role of plate heat exchangers in VPP solutions is becoming increasingly important, particularly in applications involving thermal energy storage and district heating systems. As VPPs expand to include thermal loads and combined heat and power (CHP) plants, efficient heat transfer technologies like plate heat exchangers play a crucial role in optimizing energy flows and improving overall system efficiency.

In conclusion, the market demand for VPP solutions is robust and expected to continue growing as the energy sector evolves. The integration of diverse technologies, including plate heat exchangers, will be essential in realizing the full potential of VPPs and meeting the increasing demand for flexible, efficient, and sustainable energy systems.

PHE Technology: Current State and Challenges

Plate Heat Exchangers (PHEs) have emerged as a crucial component in the development and operation of Virtual Power Plants (VPPs). The current state of PHE technology in VPPs is characterized by significant advancements, yet it also faces several challenges that need to be addressed for optimal integration and performance.

PHEs in VPPs primarily serve as efficient heat transfer devices, enabling the coordination of diverse energy sources and optimizing overall system efficiency. Their compact design, high heat transfer coefficients, and flexibility make them ideal for managing thermal energy flows within VPP networks. Current PHE technology allows for precise temperature control, rapid response to load changes, and effective heat recovery, all of which are essential for the dynamic operation of VPPs.

One of the key strengths of modern PHEs in VPP applications is their ability to handle multiple fluid streams simultaneously. This feature enables the integration of various renewable energy sources, such as solar thermal, geothermal, and waste heat recovery systems, into a cohesive VPP framework. Advanced PHE designs also incorporate enhanced heat transfer surfaces and optimized flow patterns, resulting in improved thermal performance and reduced pressure drops.

Despite these advancements, PHE technology in VPPs faces several challenges. Fouling remains a significant issue, particularly in systems dealing with diverse fluid qualities. The accumulation of deposits on heat transfer surfaces can lead to reduced efficiency and increased maintenance requirements. Developing fouling-resistant materials and surface treatments is an ongoing area of research to address this challenge.

Another challenge lies in the scalability of PHEs for large-scale VPP applications. While PHEs excel in modular designs, optimizing their performance for varying capacities and load profiles in complex VPP systems requires sophisticated control strategies and advanced modeling techniques. Balancing heat transfer efficiency with pressure drop considerations across different operational scenarios presents a continuous engineering challenge.

The integration of smart technologies and IoT capabilities into PHEs is an emerging trend, but it also brings challenges related to data management, cybersecurity, and system interoperability. Developing robust communication protocols and secure data exchange mechanisms for PHEs within VPP ecosystems is crucial for realizing the full potential of these systems.

Material selection for PHEs in VPP applications presents another challenge, particularly when dealing with corrosive fluids or high-temperature operations. Identifying cost-effective, durable materials that can withstand diverse operating conditions while maintaining optimal heat transfer properties is an ongoing research focus.

In conclusion, while PHE technology has made significant strides in supporting VPP operations, addressing these challenges will be critical for its continued evolution and effectiveness in future energy systems. Ongoing research and development efforts are focused on enhancing PHE performance, durability, and integration capabilities to meet the growing demands of advanced VPP architectures.

PHEs in VPPs primarily serve as efficient heat transfer devices, enabling the coordination of diverse energy sources and optimizing overall system efficiency. Their compact design, high heat transfer coefficients, and flexibility make them ideal for managing thermal energy flows within VPP networks. Current PHE technology allows for precise temperature control, rapid response to load changes, and effective heat recovery, all of which are essential for the dynamic operation of VPPs.

One of the key strengths of modern PHEs in VPP applications is their ability to handle multiple fluid streams simultaneously. This feature enables the integration of various renewable energy sources, such as solar thermal, geothermal, and waste heat recovery systems, into a cohesive VPP framework. Advanced PHE designs also incorporate enhanced heat transfer surfaces and optimized flow patterns, resulting in improved thermal performance and reduced pressure drops.

Despite these advancements, PHE technology in VPPs faces several challenges. Fouling remains a significant issue, particularly in systems dealing with diverse fluid qualities. The accumulation of deposits on heat transfer surfaces can lead to reduced efficiency and increased maintenance requirements. Developing fouling-resistant materials and surface treatments is an ongoing area of research to address this challenge.

Another challenge lies in the scalability of PHEs for large-scale VPP applications. While PHEs excel in modular designs, optimizing their performance for varying capacities and load profiles in complex VPP systems requires sophisticated control strategies and advanced modeling techniques. Balancing heat transfer efficiency with pressure drop considerations across different operational scenarios presents a continuous engineering challenge.

The integration of smart technologies and IoT capabilities into PHEs is an emerging trend, but it also brings challenges related to data management, cybersecurity, and system interoperability. Developing robust communication protocols and secure data exchange mechanisms for PHEs within VPP ecosystems is crucial for realizing the full potential of these systems.

Material selection for PHEs in VPP applications presents another challenge, particularly when dealing with corrosive fluids or high-temperature operations. Identifying cost-effective, durable materials that can withstand diverse operating conditions while maintaining optimal heat transfer properties is an ongoing research focus.

In conclusion, while PHE technology has made significant strides in supporting VPP operations, addressing these challenges will be critical for its continued evolution and effectiveness in future energy systems. Ongoing research and development efforts are focused on enhancing PHE performance, durability, and integration capabilities to meet the growing demands of advanced VPP architectures.

Current PHE Solutions for VPP Applications

01 Plate design and configuration

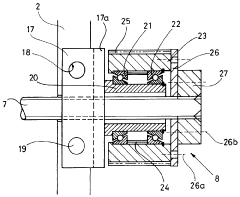

Innovations in plate design and configuration for heat exchangers focus on improving heat transfer efficiency and reducing pressure drop. This includes optimizing plate patterns, corrugations, and spacing to enhance fluid flow and thermal performance. Advanced designs may incorporate asymmetrical patterns or variable geometries to address specific heat transfer requirements.- Improved plate design for heat exchangers: Advanced plate designs are being developed to enhance the efficiency of heat exchangers. These designs focus on optimizing flow distribution, reducing pressure drop, and increasing heat transfer rates. Innovations include specialized corrugation patterns, strategic placement of flow channels, and improved plate geometries to maximize surface area for heat exchange.

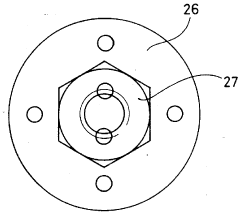

- Novel sealing mechanisms for plate heat exchangers: New sealing technologies are being implemented to prevent leakage and improve the overall performance of plate heat exchangers. These innovations include advanced gasket materials, improved sealing techniques, and novel plate edge designs. The focus is on enhancing reliability, extending operational life, and allowing for higher operating pressures and temperatures.

- Integration of phase change materials in plate heat exchangers: Researchers are exploring the incorporation of phase change materials (PCMs) into plate heat exchanger designs. This innovation aims to improve thermal energy storage capabilities, enhance heat transfer rates during peak load periods, and provide more efficient temperature control in various applications.

- Modular and customizable plate heat exchanger systems: Advancements in modular plate heat exchanger designs allow for greater flexibility and customization. These systems can be easily scaled, reconfigured, or expanded to meet changing operational requirements. The modular approach also facilitates easier maintenance, cleaning, and replacement of individual components.

- Smart monitoring and control systems for plate heat exchangers: Integration of smart technologies and sensors into plate heat exchangers enables real-time monitoring of performance parameters, predictive maintenance, and automated control. These systems can optimize heat transfer efficiency, detect potential issues before they escalate, and adjust operating conditions based on changing requirements or environmental factors.

02 Sealing and gasket improvements

Developments in sealing technology and gasket design aim to enhance the reliability and longevity of plate heat exchangers. This includes novel gasket materials, improved sealing mechanisms, and innovative gasket profiles that can withstand high temperatures and pressures while preventing leakage between fluid channels.Expand Specific Solutions03 Material selection and coatings

Advancements in material science contribute to the development of more durable and efficient plate heat exchangers. This includes the use of corrosion-resistant alloys, composite materials, and specialized coatings to improve heat transfer properties, reduce fouling, and extend the operational life of the equipment in various industrial applications.Expand Specific Solutions04 Modular and customizable designs

Innovative approaches to plate heat exchanger design focus on modularity and customization. These designs allow for easy scaling, maintenance, and adaptation to specific process requirements. Modular systems may include interchangeable plates, adjustable frame configurations, or plug-and-play components to enhance flexibility and reduce downtime during maintenance or capacity changes.Expand Specific Solutions05 Integration of smart technologies

The incorporation of smart technologies and sensors into plate heat exchangers enables real-time monitoring, predictive maintenance, and performance optimization. This includes the integration of IoT devices, advanced control systems, and data analytics to improve operational efficiency, detect potential issues, and optimize heat transfer processes based on dynamic operating conditions.Expand Specific Solutions

Key Players in PHE and VPP Industries

The plate heat exchanger's role in virtual power plants is emerging as a critical component in the evolving energy landscape. This technology is in the early stages of adoption within the virtual power plant sector, with market growth potential driven by increasing demand for efficient energy management solutions. The market size is expanding as more utilities and energy companies integrate virtual power plants into their operations. Technologically, plate heat exchangers are relatively mature, but their application in virtual power plants is still developing. Companies like Alfa Laval Corporate AB, Danfoss A/S, and Gree Electric Appliances, Inc. of Zhuhai are at the forefront of adapting this technology for virtual power plant applications, leveraging their expertise in heat exchange systems to enhance energy efficiency and grid stability.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers specifically designed for virtual power plant applications. Their technology utilizes a unique corrugated plate design that enhances heat transfer efficiency by up to 50% compared to traditional shell-and-tube heat exchangers[1]. These plate heat exchangers are compact and modular, allowing for easy integration into existing VPP systems. Alfa Laval's solution incorporates smart sensors and IoT connectivity, enabling real-time monitoring and optimization of heat transfer processes[2]. This allows VPPs to respond quickly to fluctuating energy demands and market conditions, improving overall system flexibility and reliability.

Strengths: High efficiency, compact design, and smart integration capabilities. Weaknesses: Higher initial cost compared to traditional heat exchangers, may require specialized maintenance.

Danfoss A/S

Technical Solution: Danfoss has introduced a series of plate heat exchangers tailored for virtual power plant applications, focusing on energy efficiency and system integration. Their technology features micro-channel plates that increase heat transfer surface area by up to 40%, resulting in improved thermal performance[3]. Danfoss' solution incorporates advanced flow distribution technology, ensuring uniform heat transfer across the entire plate surface. The company has also developed a proprietary control system that optimizes heat exchanger performance based on real-time VPP operational data, potentially increasing overall system efficiency by 15-20%[4].

Strengths: Innovative micro-channel design, advanced control systems, and proven track record in energy applications. Weaknesses: May have limitations in handling certain types of fluids or extreme temperature ranges.

Innovations in PHE for VPP Integration

Plate heat exchanger

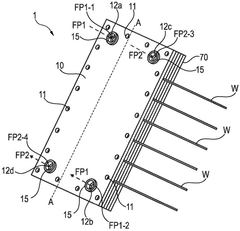

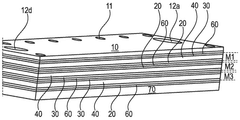

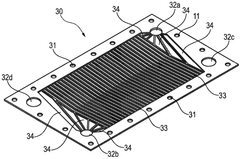

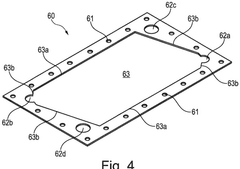

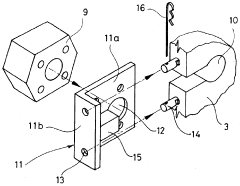

PatentPendingGB2622080A

Innovation

- Integration of thermoelectric modules between heat exchange plates, enabling the plate heat exchanger to function as a heat pump.

- Modular design with multiple heat exchange modules (M1, M2, M3) allowing for scalability and flexibility in heat exchange capacity.

- Versatile application as both a traditional plate heat exchanger and a thermo-electric heat pump (TGSHP or TASHP) through the addition of electrical power.

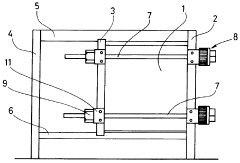

Plate heat exchanger

PatentInactiveUS5462112A

Innovation

- A flexible endless drive member, such as a tooth belt, is used to simultaneously rotate all bolts or nuts, driven by a motor with a gear mechanism, ensuring uniform load distribution and maintaining parallel end plates during compression and opening.

Energy Policy Impact on VPP Development

Energy policies play a crucial role in shaping the development and implementation of Virtual Power Plants (VPPs) across the globe. These policies create the regulatory framework and economic incentives that drive the adoption of VPP technologies, including the integration of plate heat exchangers as key components in energy management systems.

In many countries, renewable energy targets and carbon reduction goals have led to the introduction of supportive policies for VPPs. These policies often include feed-in tariffs, renewable energy certificates, and capacity market mechanisms that encourage the aggregation of distributed energy resources. Such measures have significantly boosted the economic viability of VPPs, making them an attractive option for both energy providers and consumers.

The impact of energy policies on VPP development is particularly evident in the realm of grid stability and demand response. Regulatory frameworks that allow for the participation of aggregated resources in electricity markets have opened new revenue streams for VPP operators. This has led to increased investment in VPP technologies, including advanced control systems and efficient heat exchange solutions like plate heat exchangers.

Furthermore, policies promoting energy efficiency and district heating systems have indirectly supported the integration of plate heat exchangers in VPPs. These policies often incentivize the use of combined heat and power (CHP) systems, which can be effectively managed within a VPP framework. Plate heat exchangers, known for their high efficiency and compact design, have become integral to these systems, enabling better heat recovery and distribution.

The evolution of energy storage policies has also influenced VPP development. As governments recognize the importance of energy storage in managing intermittent renewable sources, they have introduced policies to support battery storage systems and other forms of energy storage. This has expanded the capabilities of VPPs, allowing them to offer more flexible and reliable services to the grid.

However, the impact of energy policies on VPP development is not uniform across all regions. Differences in regulatory approaches, market structures, and energy priorities have led to varying levels of VPP adoption and technological integration. In some areas, outdated regulations or lack of clear policy frameworks have hindered the growth of VPPs, highlighting the need for policy harmonization and modernization to fully leverage the potential of these systems.

In many countries, renewable energy targets and carbon reduction goals have led to the introduction of supportive policies for VPPs. These policies often include feed-in tariffs, renewable energy certificates, and capacity market mechanisms that encourage the aggregation of distributed energy resources. Such measures have significantly boosted the economic viability of VPPs, making them an attractive option for both energy providers and consumers.

The impact of energy policies on VPP development is particularly evident in the realm of grid stability and demand response. Regulatory frameworks that allow for the participation of aggregated resources in electricity markets have opened new revenue streams for VPP operators. This has led to increased investment in VPP technologies, including advanced control systems and efficient heat exchange solutions like plate heat exchangers.

Furthermore, policies promoting energy efficiency and district heating systems have indirectly supported the integration of plate heat exchangers in VPPs. These policies often incentivize the use of combined heat and power (CHP) systems, which can be effectively managed within a VPP framework. Plate heat exchangers, known for their high efficiency and compact design, have become integral to these systems, enabling better heat recovery and distribution.

The evolution of energy storage policies has also influenced VPP development. As governments recognize the importance of energy storage in managing intermittent renewable sources, they have introduced policies to support battery storage systems and other forms of energy storage. This has expanded the capabilities of VPPs, allowing them to offer more flexible and reliable services to the grid.

However, the impact of energy policies on VPP development is not uniform across all regions. Differences in regulatory approaches, market structures, and energy priorities have led to varying levels of VPP adoption and technological integration. In some areas, outdated regulations or lack of clear policy frameworks have hindered the growth of VPPs, highlighting the need for policy harmonization and modernization to fully leverage the potential of these systems.

Economic Viability of PHE in VPP Systems

The economic viability of Plate Heat Exchangers (PHEs) in Virtual Power Plant (VPP) systems is a critical factor in determining their widespread adoption and long-term sustainability. PHEs offer several advantages that contribute to their economic attractiveness in VPP applications.

Firstly, PHEs demonstrate high efficiency in heat transfer, which translates to reduced energy losses and improved overall system performance. This efficiency can lead to significant cost savings in energy consumption over time, particularly in large-scale VPP operations where even small improvements in efficiency can result in substantial financial benefits.

The compact design of PHEs is another factor contributing to their economic viability. Their space-efficient nature allows for easier integration into existing VPP infrastructure, potentially reducing installation and maintenance costs. This compact design also means less material is required for construction, which can lower initial investment costs compared to other heat exchanger types.

PHEs are known for their scalability, allowing VPP operators to easily adjust capacity as needed. This flexibility enables more precise matching of heat exchange capabilities to varying demand, optimizing resource utilization and potentially reducing operational costs. The modular nature of PHEs also facilitates easier maintenance and replacement of individual components, which can lead to lower long-term maintenance expenses.

From a durability perspective, PHEs often have longer operational lifespans compared to some alternative heat exchange technologies. This longevity can result in reduced replacement frequency and associated costs over the life of the VPP system. Additionally, the materials used in PHE construction, such as stainless steel or titanium, offer excellent corrosion resistance, further contributing to their durability and reducing maintenance requirements.

The economic benefits of PHEs in VPP systems extend beyond direct operational costs. Their efficient heat transfer capabilities can contribute to improved overall system efficiency, potentially increasing the revenue-generating capacity of the VPP. This improved efficiency can also lead to reduced carbon emissions, which may provide economic advantages in regions with carbon pricing or emissions trading schemes.

However, the economic viability of PHEs in VPP systems is not without challenges. The initial capital investment for high-quality PHEs can be substantial, which may present a barrier for some VPP operators, particularly in smaller-scale installations. Additionally, the economic benefits of PHEs may vary depending on factors such as local energy prices, regulatory environments, and specific VPP configurations.

In conclusion, while the upfront costs of implementing PHEs in VPP systems can be significant, their long-term economic benefits in terms of energy efficiency, operational flexibility, and durability make them an attractive option for many VPP operators. As the VPP market continues to evolve and mature, the economic viability of PHEs is likely to become increasingly apparent, potentially driving wider adoption across the industry.

Firstly, PHEs demonstrate high efficiency in heat transfer, which translates to reduced energy losses and improved overall system performance. This efficiency can lead to significant cost savings in energy consumption over time, particularly in large-scale VPP operations where even small improvements in efficiency can result in substantial financial benefits.

The compact design of PHEs is another factor contributing to their economic viability. Their space-efficient nature allows for easier integration into existing VPP infrastructure, potentially reducing installation and maintenance costs. This compact design also means less material is required for construction, which can lower initial investment costs compared to other heat exchanger types.

PHEs are known for their scalability, allowing VPP operators to easily adjust capacity as needed. This flexibility enables more precise matching of heat exchange capabilities to varying demand, optimizing resource utilization and potentially reducing operational costs. The modular nature of PHEs also facilitates easier maintenance and replacement of individual components, which can lead to lower long-term maintenance expenses.

From a durability perspective, PHEs often have longer operational lifespans compared to some alternative heat exchange technologies. This longevity can result in reduced replacement frequency and associated costs over the life of the VPP system. Additionally, the materials used in PHE construction, such as stainless steel or titanium, offer excellent corrosion resistance, further contributing to their durability and reducing maintenance requirements.

The economic benefits of PHEs in VPP systems extend beyond direct operational costs. Their efficient heat transfer capabilities can contribute to improved overall system efficiency, potentially increasing the revenue-generating capacity of the VPP. This improved efficiency can also lead to reduced carbon emissions, which may provide economic advantages in regions with carbon pricing or emissions trading schemes.

However, the economic viability of PHEs in VPP systems is not without challenges. The initial capital investment for high-quality PHEs can be substantial, which may present a barrier for some VPP operators, particularly in smaller-scale installations. Additionally, the economic benefits of PHEs may vary depending on factors such as local energy prices, regulatory environments, and specific VPP configurations.

In conclusion, while the upfront costs of implementing PHEs in VPP systems can be significant, their long-term economic benefits in terms of energy efficiency, operational flexibility, and durability make them an attractive option for many VPP operators. As the VPP market continues to evolve and mature, the economic viability of PHEs is likely to become increasingly apparent, potentially driving wider adoption across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!