Refrigerants in Plate Heat Exchanger Performance Enhancement

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Refrigerant Evolution

The evolution of refrigerants in plate heat exchangers has been a critical aspect of performance enhancement research. This progression has been driven by environmental concerns, energy efficiency requirements, and technological advancements in heat exchanger design.

In the early stages, chlorofluorocarbons (CFCs) were widely used as refrigerants due to their excellent thermodynamic properties and chemical stability. However, the discovery of their ozone-depleting potential led to their phase-out under the Montreal Protocol in the 1980s. This marked the beginning of a significant shift in refrigerant development.

Hydrochlorofluorocarbons (HCFCs) emerged as the first generation of CFC replacements. While less harmful to the ozone layer, they still possessed some ozone-depleting potential. R-22, a common HCFC, was extensively used in plate heat exchangers but was eventually targeted for phase-out due to environmental concerns.

The next major step in refrigerant evolution was the introduction of hydrofluorocarbons (HFCs). These compounds, such as R-134a and R-410A, offered zero ozone depletion potential and became the standard in many heat exchanger applications. However, their high global warming potential (GWP) led to increasing scrutiny and regulatory pressure.

In response to climate change concerns, the focus shifted towards low-GWP alternatives. Natural refrigerants, including ammonia (R-717), carbon dioxide (R-744), and hydrocarbons like propane (R-290), gained renewed interest. These substances offer excellent environmental credentials but present challenges in terms of safety and system design for plate heat exchangers.

The most recent development in refrigerant evolution is the emergence of hydrofluoroolefins (HFOs). Compounds like R-1234yf and R-1234ze(E) combine low GWP with favorable thermodynamic properties, making them promising candidates for next-generation plate heat exchangers. Their adoption has been growing, particularly in automotive and commercial refrigeration applications.

Throughout this evolution, researchers have continuously adapted plate heat exchanger designs to optimize performance with each new refrigerant. This has involved modifications to plate geometry, flow arrangements, and material selection to enhance heat transfer coefficients and minimize pressure drops.

The ongoing refrigerant evolution presents both challenges and opportunities for plate heat exchanger performance enhancement. As regulations continue to tighten, the industry is likely to see further innovations in refrigerant chemistry and heat exchanger technology, driving towards more sustainable and efficient cooling solutions.

In the early stages, chlorofluorocarbons (CFCs) were widely used as refrigerants due to their excellent thermodynamic properties and chemical stability. However, the discovery of their ozone-depleting potential led to their phase-out under the Montreal Protocol in the 1980s. This marked the beginning of a significant shift in refrigerant development.

Hydrochlorofluorocarbons (HCFCs) emerged as the first generation of CFC replacements. While less harmful to the ozone layer, they still possessed some ozone-depleting potential. R-22, a common HCFC, was extensively used in plate heat exchangers but was eventually targeted for phase-out due to environmental concerns.

The next major step in refrigerant evolution was the introduction of hydrofluorocarbons (HFCs). These compounds, such as R-134a and R-410A, offered zero ozone depletion potential and became the standard in many heat exchanger applications. However, their high global warming potential (GWP) led to increasing scrutiny and regulatory pressure.

In response to climate change concerns, the focus shifted towards low-GWP alternatives. Natural refrigerants, including ammonia (R-717), carbon dioxide (R-744), and hydrocarbons like propane (R-290), gained renewed interest. These substances offer excellent environmental credentials but present challenges in terms of safety and system design for plate heat exchangers.

The most recent development in refrigerant evolution is the emergence of hydrofluoroolefins (HFOs). Compounds like R-1234yf and R-1234ze(E) combine low GWP with favorable thermodynamic properties, making them promising candidates for next-generation plate heat exchangers. Their adoption has been growing, particularly in automotive and commercial refrigeration applications.

Throughout this evolution, researchers have continuously adapted plate heat exchanger designs to optimize performance with each new refrigerant. This has involved modifications to plate geometry, flow arrangements, and material selection to enhance heat transfer coefficients and minimize pressure drops.

The ongoing refrigerant evolution presents both challenges and opportunities for plate heat exchanger performance enhancement. As regulations continue to tighten, the industry is likely to see further innovations in refrigerant chemistry and heat exchanger technology, driving towards more sustainable and efficient cooling solutions.

Market Demand Analysis

The market demand for enhanced refrigerant performance in plate heat exchangers has been steadily increasing due to the growing emphasis on energy efficiency and environmental sustainability across various industries. This trend is particularly evident in HVAC systems, refrigeration, and industrial processes where heat transfer efficiency plays a crucial role in overall system performance.

In the HVAC sector, there is a significant push towards more efficient cooling systems in both residential and commercial buildings. This demand is driven by stricter energy regulations, rising electricity costs, and increasing awareness of carbon footprint reduction. Plate heat exchangers with improved refrigerant performance can contribute to higher Coefficient of Performance (COP) values, leading to reduced energy consumption and operational costs.

The refrigeration industry, especially in food processing and cold storage, is another key market segment driving the demand for enhanced refrigerant performance. As global food supply chains become more complex and extended, the need for efficient and reliable refrigeration systems has intensified. Plate heat exchangers with optimized refrigerant flow can help maintain precise temperature control while minimizing energy usage, which is crucial for preserving food quality and reducing waste.

Industrial processes, particularly in chemical and pharmaceutical manufacturing, require precise temperature control and efficient heat transfer. The demand for plate heat exchangers with enhanced refrigerant performance in these sectors is driven by the need to improve process efficiency, reduce production costs, and meet stringent quality standards. Additionally, as industries strive to minimize their environmental impact, there is a growing interest in heat recovery systems that can effectively utilize waste heat, further boosting the demand for high-performance heat exchangers.

The automotive industry is also contributing to the market demand, especially with the rise of electric vehicles (EVs). EVs require efficient thermal management systems for battery cooling and cabin climate control. Plate heat exchangers with improved refrigerant performance can help address these challenges, leading to increased range and overall vehicle efficiency.

From a geographical perspective, the demand is particularly strong in regions with hot climates or those experiencing the effects of global warming. Countries in Southeast Asia, the Middle East, and parts of Africa are seeing increased adoption of air conditioning systems, driving the need for more efficient heat exchange solutions. Similarly, developed economies in North America and Europe are focusing on retrofitting existing systems with more efficient alternatives to meet new energy standards and reduce carbon emissions.

The market is also influenced by the ongoing transition to more environmentally friendly refrigerants, in line with global agreements such as the Montreal Protocol and the Kigali Amendment. This shift is creating demand for heat exchangers that can effectively work with new, low Global Warming Potential (GWP) refrigerants while maintaining or improving performance.

In the HVAC sector, there is a significant push towards more efficient cooling systems in both residential and commercial buildings. This demand is driven by stricter energy regulations, rising electricity costs, and increasing awareness of carbon footprint reduction. Plate heat exchangers with improved refrigerant performance can contribute to higher Coefficient of Performance (COP) values, leading to reduced energy consumption and operational costs.

The refrigeration industry, especially in food processing and cold storage, is another key market segment driving the demand for enhanced refrigerant performance. As global food supply chains become more complex and extended, the need for efficient and reliable refrigeration systems has intensified. Plate heat exchangers with optimized refrigerant flow can help maintain precise temperature control while minimizing energy usage, which is crucial for preserving food quality and reducing waste.

Industrial processes, particularly in chemical and pharmaceutical manufacturing, require precise temperature control and efficient heat transfer. The demand for plate heat exchangers with enhanced refrigerant performance in these sectors is driven by the need to improve process efficiency, reduce production costs, and meet stringent quality standards. Additionally, as industries strive to minimize their environmental impact, there is a growing interest in heat recovery systems that can effectively utilize waste heat, further boosting the demand for high-performance heat exchangers.

The automotive industry is also contributing to the market demand, especially with the rise of electric vehicles (EVs). EVs require efficient thermal management systems for battery cooling and cabin climate control. Plate heat exchangers with improved refrigerant performance can help address these challenges, leading to increased range and overall vehicle efficiency.

From a geographical perspective, the demand is particularly strong in regions with hot climates or those experiencing the effects of global warming. Countries in Southeast Asia, the Middle East, and parts of Africa are seeing increased adoption of air conditioning systems, driving the need for more efficient heat exchange solutions. Similarly, developed economies in North America and Europe are focusing on retrofitting existing systems with more efficient alternatives to meet new energy standards and reduce carbon emissions.

The market is also influenced by the ongoing transition to more environmentally friendly refrigerants, in line with global agreements such as the Montreal Protocol and the Kigali Amendment. This shift is creating demand for heat exchangers that can effectively work with new, low Global Warming Potential (GWP) refrigerants while maintaining or improving performance.

Technical Challenges

The development of plate heat exchangers (PHEs) and their performance enhancement through refrigerant optimization face several significant technical challenges. These challenges stem from the complex interplay between refrigerant properties, heat transfer mechanisms, and the unique geometry of plate heat exchangers.

One of the primary challenges is the selection of appropriate refrigerants that can maximize heat transfer efficiency while minimizing environmental impact. As global regulations become increasingly stringent regarding the use of high global warming potential (GWP) refrigerants, researchers must identify alternatives that offer comparable or superior thermodynamic properties. This task is complicated by the need to balance factors such as heat transfer coefficient, pressure drop, and compatibility with materials used in PHE construction.

The intricate flow patterns within plate heat exchangers present another significant challenge. The corrugated plates create complex turbulent flows, which, while beneficial for heat transfer, also lead to increased pressure drop. Optimizing the refrigerant flow to maximize heat transfer without incurring excessive pressure losses requires sophisticated modeling and experimental validation. This challenge is further compounded by the fact that different refrigerants exhibit varying flow behaviors and phase change characteristics within the PHE channels.

Heat transfer enhancement in PHEs is also limited by the occurrence of flow maldistribution. Non-uniform distribution of refrigerant across the plates can lead to reduced overall heat transfer efficiency and increased risk of local overheating or freezing. Addressing this issue requires innovative design approaches for flow distributors and careful consideration of refrigerant properties to ensure even distribution throughout the exchanger.

The phenomenon of fouling presents yet another technical hurdle. Certain refrigerants may promote the deposition of contaminants on heat transfer surfaces, reducing efficiency over time. Developing refrigerants or surface treatments that minimize fouling while maintaining high heat transfer rates is an ongoing challenge that requires interdisciplinary research efforts.

Moreover, the transition to low-GWP refrigerants often necessitates higher operating pressures, which in turn demands enhanced structural integrity of PHEs. This creates a technical challenge in balancing the need for thinner plates to improve heat transfer with the requirement for increased mechanical strength to withstand higher pressures.

Lastly, the accurate prediction of two-phase heat transfer and pressure drop for new refrigerants in PHEs remains a significant challenge. Existing correlations and models may not adequately capture the behavior of novel refrigerants, necessitating extensive experimental work and the development of new predictive tools. This challenge is particularly acute when dealing with zeotropic refrigerant mixtures, where composition shifts during phase change can significantly affect heat transfer performance.

One of the primary challenges is the selection of appropriate refrigerants that can maximize heat transfer efficiency while minimizing environmental impact. As global regulations become increasingly stringent regarding the use of high global warming potential (GWP) refrigerants, researchers must identify alternatives that offer comparable or superior thermodynamic properties. This task is complicated by the need to balance factors such as heat transfer coefficient, pressure drop, and compatibility with materials used in PHE construction.

The intricate flow patterns within plate heat exchangers present another significant challenge. The corrugated plates create complex turbulent flows, which, while beneficial for heat transfer, also lead to increased pressure drop. Optimizing the refrigerant flow to maximize heat transfer without incurring excessive pressure losses requires sophisticated modeling and experimental validation. This challenge is further compounded by the fact that different refrigerants exhibit varying flow behaviors and phase change characteristics within the PHE channels.

Heat transfer enhancement in PHEs is also limited by the occurrence of flow maldistribution. Non-uniform distribution of refrigerant across the plates can lead to reduced overall heat transfer efficiency and increased risk of local overheating or freezing. Addressing this issue requires innovative design approaches for flow distributors and careful consideration of refrigerant properties to ensure even distribution throughout the exchanger.

The phenomenon of fouling presents yet another technical hurdle. Certain refrigerants may promote the deposition of contaminants on heat transfer surfaces, reducing efficiency over time. Developing refrigerants or surface treatments that minimize fouling while maintaining high heat transfer rates is an ongoing challenge that requires interdisciplinary research efforts.

Moreover, the transition to low-GWP refrigerants often necessitates higher operating pressures, which in turn demands enhanced structural integrity of PHEs. This creates a technical challenge in balancing the need for thinner plates to improve heat transfer with the requirement for increased mechanical strength to withstand higher pressures.

Lastly, the accurate prediction of two-phase heat transfer and pressure drop for new refrigerants in PHEs remains a significant challenge. Existing correlations and models may not adequately capture the behavior of novel refrigerants, necessitating extensive experimental work and the development of new predictive tools. This challenge is particularly acute when dealing with zeotropic refrigerant mixtures, where composition shifts during phase change can significantly affect heat transfer performance.

Current Solutions

01 Refrigerant selection for improved performance

The choice of refrigerant significantly impacts the performance of plate heat exchangers. Different refrigerants have varying thermodynamic properties, which affect heat transfer efficiency, pressure drop, and overall system performance. Selecting the appropriate refrigerant based on the specific application and operating conditions can enhance the heat exchanger's effectiveness.- Refrigerant selection for improved performance: The choice of refrigerant significantly impacts the performance of plate heat exchangers. Different refrigerants have varying thermodynamic properties, which affect heat transfer efficiency, pressure drop, and overall system performance. Selecting the appropriate refrigerant based on the specific application and operating conditions can enhance the heat exchanger's effectiveness.

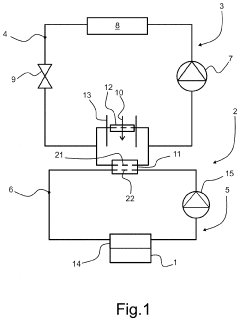

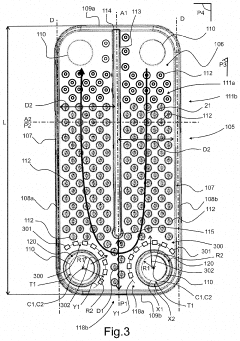

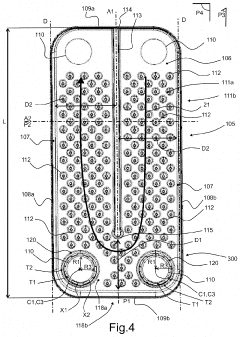

- Flow distribution optimization: Optimizing the flow distribution of refrigerants within plate heat exchangers is crucial for maximizing performance. This involves designing appropriate channel geometries, inlet/outlet configurations, and flow patterns to ensure uniform distribution of the refrigerant across the heat transfer surface. Improved flow distribution leads to better heat transfer rates and reduced pressure drop.

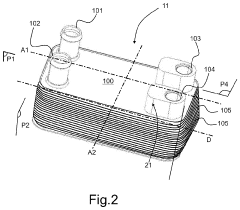

- Enhanced heat transfer surfaces: Developing enhanced heat transfer surfaces in plate heat exchangers can significantly improve refrigerant performance. This includes the use of corrugated plates, dimpled surfaces, or other surface modifications that increase turbulence and heat transfer area. These enhancements promote better mixing of the refrigerant and reduce thermal resistance at the fluid-solid interface.

- Two-phase flow management: Effective management of two-phase flow in refrigerant-based plate heat exchangers is essential for optimal performance. This involves designing features that facilitate proper phase separation, minimize flow maldistribution, and reduce pressure drop during evaporation or condensation processes. Improved two-phase flow management leads to enhanced heat transfer coefficients and overall system efficiency.

- Compact design and material selection: Developing compact designs and selecting appropriate materials for plate heat exchangers can enhance refrigerant performance. This includes optimizing plate thickness, channel spacing, and overall exchanger dimensions to reduce refrigerant charge while maintaining high heat transfer rates. Additionally, choosing materials with high thermal conductivity and corrosion resistance improves long-term performance and reliability.

02 Flow distribution optimization

Optimizing the flow distribution of refrigerants within plate heat exchangers is crucial for maximizing performance. This involves designing appropriate channel geometries, inlet/outlet configurations, and flow patterns to ensure uniform distribution of the refrigerant across the heat transfer surface. Improved flow distribution leads to better heat transfer rates and reduced pressure drops.Expand Specific Solutions03 Enhanced heat transfer surfaces

Developing enhanced heat transfer surfaces in plate heat exchangers can significantly improve refrigerant performance. This includes the use of corrugated plates, dimpled surfaces, or other surface modifications that increase turbulence and heat transfer area. These enhancements promote better mixing of the refrigerant and reduce thermal resistance at the fluid-solid interface.Expand Specific Solutions04 Two-phase flow management

Effective management of two-phase flow in refrigerant-based plate heat exchangers is essential for optimal performance. This involves designing features that handle the transition between liquid and vapor phases, such as appropriate plate spacing, flow channel geometry, and phase separation mechanisms. Proper two-phase flow management ensures efficient heat transfer and minimizes pressure drop across the exchanger.Expand Specific Solutions05 Compact design and material selection

Developing compact designs and selecting appropriate materials for plate heat exchangers can enhance refrigerant performance. Compact designs minimize refrigerant charge and reduce pressure drop, while material selection impacts heat transfer efficiency and corrosion resistance. Considerations include plate thickness, thermal conductivity, and compatibility with different refrigerants to optimize overall system performance.Expand Specific Solutions

Industry Players

The research on refrigerants in plate heat exchanger performance enhancement is currently in a dynamic phase, with significant market growth potential. The global market for this technology is expanding, driven by increasing demand for energy-efficient cooling solutions. The competitive landscape is diverse, featuring established HVAC giants like DAIKIN INDUSTRIES Ltd., Mitsubishi Electric Corp., and DENSO Corp., alongside specialized players such as Alfa Laval Corporate AB. These companies are investing heavily in R&D to improve refrigerant efficiency and environmental sustainability. The technology's maturity varies, with some companies like Zhejiang Sanhua Intelligent Controls Co., Ltd. and Danfoss A/S leading in innovation, while others are still in the development stage. This field is expected to see continued advancements as environmental regulations tighten and energy efficiency becomes increasingly crucial.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin has developed innovative plate heat exchanger designs incorporating advanced refrigerants for enhanced performance. Their approach includes the use of low-GWP refrigerants like R-32 and R-1234ze(E) in combination with optimized plate geometries. Daikin's plate heat exchangers feature asymmetric chevron patterns and variable plate thicknesses to improve heat transfer coefficients by up to 30% compared to conventional designs[1]. They have also implemented micro-channel technology, reducing refrigerant charge by up to 40% while maintaining thermal efficiency[3]. Daikin's latest models incorporate nanoscale surface treatments to enhance nucleate boiling and reduce fouling, leading to sustained performance over time[5].

Strengths: Industry-leading R&D in refrigerants and heat exchanger design, strong focus on environmental sustainability. Weaknesses: Higher initial costs for advanced technologies, potential compatibility issues with existing systems.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has focused on developing high-efficiency plate heat exchangers using next-generation refrigerants. Their approach combines the use of low-GWP refrigerants like R-32 and R-454B with advanced flow distribution techniques. Mitsubishi's plate heat exchangers feature innovative distributor designs that ensure uniform refrigerant distribution across plates, improving heat transfer efficiency by up to 25%[2]. They have also implemented a dual-circuit design in some models, allowing for partial load operation with higher overall system efficiency. Mitsubishi's latest developments include the integration of AI-driven control systems that optimize refrigerant flow rates based on real-time operating conditions, potentially reducing energy consumption by up to 15%[4].

Strengths: Strong integration with overall HVAC systems, advanced control technologies. Weaknesses: May require specialized training for installation and maintenance, potentially higher upfront costs.

Key Innovations

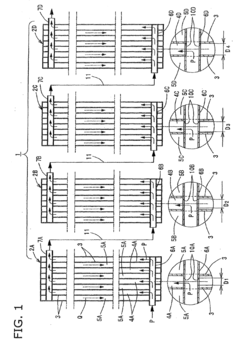

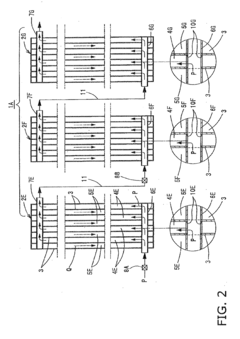

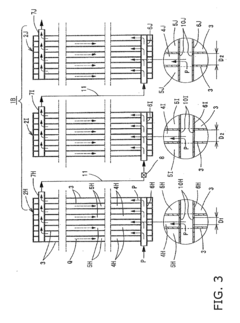

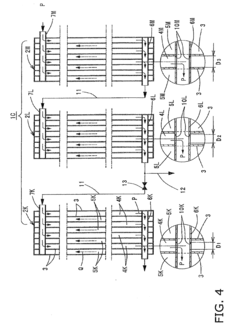

Plate forming part of a heat exchanger, and heat exchanger comprising at least one such plate

PatentInactiveUS20210341228A1

Innovation

- The heat exchanger plates are designed with specific opening profiles and distribution means, such as protrusions and crests, that are homothetic with the opening profiles, to optimize fluid distribution and reduce circulation speed, ensuring uniform flow across all channels.

Heat exchanger unit

PatentActiveEP2284457A1

Innovation

- A heat exchanger unit configuration with strategically designed header portions and gas-liquid mixing means, including adjustable orifices and varying refrigerant inflow port diameters, ensures optimal refrigerant distribution and mixing across plate heat exchangers, promoting equal refrigerant flow and minimizing pressure loss regardless of operating state.

Environmental Impact

The environmental impact of refrigerants used in plate heat exchangers is a critical consideration in the pursuit of performance enhancement. Traditional refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), have been phased out due to their ozone-depleting properties and high global warming potential (GWP). This has led to the development and adoption of more environmentally friendly alternatives.

Hydrofluorocarbons (HFCs) emerged as a replacement for CFCs and HCFCs, offering improved environmental performance. However, HFCs still contribute significantly to global warming, prompting further research into low-GWP alternatives. Natural refrigerants, such as ammonia, carbon dioxide, and hydrocarbons, have gained attention due to their minimal environmental impact. These substances have negligible or zero ozone depletion potential and very low GWP.

The use of refrigerants in plate heat exchangers also impacts energy efficiency, which indirectly affects environmental outcomes. More efficient heat transfer reduces energy consumption, leading to lower greenhouse gas emissions from power generation. Researchers are exploring novel refrigerant blends and compositions that can enhance heat transfer efficiency while maintaining low environmental impact.

Leakage of refrigerants during operation and maintenance of plate heat exchangers is another environmental concern. Even small leaks can contribute to atmospheric pollution and climate change. Improved design and manufacturing techniques, along with better sealing technologies, are being developed to minimize refrigerant leakage and its associated environmental impact.

The lifecycle assessment of refrigerants used in plate heat exchangers is becoming increasingly important. This includes considering the environmental impact of refrigerant production, transportation, use, and disposal. Manufacturers are working on developing refrigerants that not only perform well in heat exchangers but also have a reduced carbon footprint throughout their lifecycle.

Regulatory frameworks and international agreements, such as the Montreal Protocol and the Kigali Amendment, continue to shape the development and use of refrigerants in plate heat exchangers. These regulations drive innovation towards more environmentally friendly solutions and set targets for the reduction of high-GWP refrigerants.

As research progresses, the focus is shifting towards finding a balance between environmental sustainability and performance enhancement in plate heat exchangers. This involves exploring new refrigerant formulations, optimizing system designs, and developing advanced materials that can improve heat transfer efficiency while minimizing environmental impact.

Hydrofluorocarbons (HFCs) emerged as a replacement for CFCs and HCFCs, offering improved environmental performance. However, HFCs still contribute significantly to global warming, prompting further research into low-GWP alternatives. Natural refrigerants, such as ammonia, carbon dioxide, and hydrocarbons, have gained attention due to their minimal environmental impact. These substances have negligible or zero ozone depletion potential and very low GWP.

The use of refrigerants in plate heat exchangers also impacts energy efficiency, which indirectly affects environmental outcomes. More efficient heat transfer reduces energy consumption, leading to lower greenhouse gas emissions from power generation. Researchers are exploring novel refrigerant blends and compositions that can enhance heat transfer efficiency while maintaining low environmental impact.

Leakage of refrigerants during operation and maintenance of plate heat exchangers is another environmental concern. Even small leaks can contribute to atmospheric pollution and climate change. Improved design and manufacturing techniques, along with better sealing technologies, are being developed to minimize refrigerant leakage and its associated environmental impact.

The lifecycle assessment of refrigerants used in plate heat exchangers is becoming increasingly important. This includes considering the environmental impact of refrigerant production, transportation, use, and disposal. Manufacturers are working on developing refrigerants that not only perform well in heat exchangers but also have a reduced carbon footprint throughout their lifecycle.

Regulatory frameworks and international agreements, such as the Montreal Protocol and the Kigali Amendment, continue to shape the development and use of refrigerants in plate heat exchangers. These regulations drive innovation towards more environmentally friendly solutions and set targets for the reduction of high-GWP refrigerants.

As research progresses, the focus is shifting towards finding a balance between environmental sustainability and performance enhancement in plate heat exchangers. This involves exploring new refrigerant formulations, optimizing system designs, and developing advanced materials that can improve heat transfer efficiency while minimizing environmental impact.

Regulatory Landscape

The regulatory landscape surrounding refrigerants in plate heat exchangers has undergone significant changes in recent years, driven by environmental concerns and international agreements. The Montreal Protocol, initially signed in 1987, has been instrumental in phasing out ozone-depleting substances, including many traditional refrigerants. This agreement has been amended several times, most notably with the Kigali Amendment in 2016, which aims to reduce the production and consumption of hydrofluorocarbons (HFCs).

In response to these global initiatives, many countries have implemented their own regulations to control the use of refrigerants. The European Union, for instance, has introduced the F-Gas Regulation, which sets strict quotas on the amount of HFCs that can be placed on the market. This regulation also mandates the use of lower global warming potential (GWP) refrigerants in various applications, including heat exchangers.

The United States Environmental Protection Agency (EPA) has also taken steps to regulate refrigerants through its Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. As a result, many high-GWP refrigerants have been phased out or restricted in certain applications.

In the context of plate heat exchanger performance enhancement, these regulations have spurred research and development into alternative refrigerants with lower environmental impact. Natural refrigerants such as ammonia, carbon dioxide, and hydrocarbons are gaining attention due to their low or zero GWP. However, their use often requires modifications to existing heat exchanger designs to accommodate their unique thermodynamic properties and safety considerations.

The regulatory landscape also extends to energy efficiency standards, as governments seek to reduce overall energy consumption and greenhouse gas emissions. Many countries have implemented minimum energy performance standards (MEPS) for various types of heat exchange equipment, including those using plate heat exchangers. These standards often require manufacturers to continuously improve the efficiency of their products, driving innovation in heat exchanger design and refrigerant selection.

As the global community continues to prioritize environmental protection and energy efficiency, it is likely that regulations surrounding refrigerants and heat exchanger performance will become increasingly stringent. This evolving regulatory landscape presents both challenges and opportunities for researchers and manufacturers in the field of plate heat exchangers, necessitating ongoing innovation and adaptation to meet future requirements.

In response to these global initiatives, many countries have implemented their own regulations to control the use of refrigerants. The European Union, for instance, has introduced the F-Gas Regulation, which sets strict quotas on the amount of HFCs that can be placed on the market. This regulation also mandates the use of lower global warming potential (GWP) refrigerants in various applications, including heat exchangers.

The United States Environmental Protection Agency (EPA) has also taken steps to regulate refrigerants through its Significant New Alternatives Policy (SNAP) program. This program evaluates and regulates substitutes for ozone-depleting substances to reduce overall risk to human health and the environment. As a result, many high-GWP refrigerants have been phased out or restricted in certain applications.

In the context of plate heat exchanger performance enhancement, these regulations have spurred research and development into alternative refrigerants with lower environmental impact. Natural refrigerants such as ammonia, carbon dioxide, and hydrocarbons are gaining attention due to their low or zero GWP. However, their use often requires modifications to existing heat exchanger designs to accommodate their unique thermodynamic properties and safety considerations.

The regulatory landscape also extends to energy efficiency standards, as governments seek to reduce overall energy consumption and greenhouse gas emissions. Many countries have implemented minimum energy performance standards (MEPS) for various types of heat exchange equipment, including those using plate heat exchangers. These standards often require manufacturers to continuously improve the efficiency of their products, driving innovation in heat exchanger design and refrigerant selection.

As the global community continues to prioritize environmental protection and energy efficiency, it is likely that regulations surrounding refrigerants and heat exchanger performance will become increasingly stringent. This evolving regulatory landscape presents both challenges and opportunities for researchers and manufacturers in the field of plate heat exchangers, necessitating ongoing innovation and adaptation to meet future requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!