Impact of Polymer Materials on Plate Heat Exchanger Innovation

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Heat Exchanger Evolution and Objectives

Polymer materials have revolutionized the field of heat exchanger technology, particularly in plate heat exchangers, over the past few decades. The evolution of polymer heat exchangers can be traced back to the 1970s when the first attempts to use polymers in heat transfer applications were made. Initially, these efforts were met with skepticism due to the inherent limitations of polymers, such as lower thermal conductivity compared to traditional metallic materials.

However, as polymer science advanced, so did the potential for their use in heat exchangers. The 1980s and 1990s saw significant improvements in polymer formulations, leading to the development of high-performance thermoplastics with enhanced thermal properties. This period marked a turning point in the industry, as researchers and engineers began to recognize the unique advantages that polymers could offer, such as corrosion resistance, lightweight construction, and cost-effectiveness.

The early 2000s witnessed a surge in research and development activities focused on polymer-based plate heat exchangers. This era was characterized by the exploration of various polymer types, including polypropylene, polyethylene, and fluoropolymers, each offering distinct benefits for specific applications. The primary objective during this phase was to overcome the thermal conductivity limitations of polymers while capitalizing on their other advantageous properties.

As we entered the 2010s, the focus shifted towards optimizing the design of polymer plate heat exchangers. Engineers began experimenting with innovative geometries and surface modifications to enhance heat transfer efficiency. The integration of advanced manufacturing techniques, such as 3D printing and injection molding, opened up new possibilities for creating complex and highly efficient heat exchanger designs that were previously unattainable with traditional materials.

Currently, the objectives in polymer heat exchanger development are multifaceted. One primary goal is to further improve the thermal performance of polymer materials, bringing them closer to the efficiency levels of metallic heat exchangers. This involves ongoing research into polymer nanocomposites and the incorporation of thermally conductive fillers to enhance heat transfer properties.

Another critical objective is to expand the application range of polymer heat exchangers. While they have found success in low to medium temperature applications, there is a push to develop polymers capable of withstanding higher temperatures and pressures, potentially opening up new markets in industries such as chemical processing and power generation.

Sustainability has also emerged as a key focus area. The development of bio-based and recyclable polymers for heat exchanger applications aligns with global efforts to reduce environmental impact. This objective not only addresses ecological concerns but also positions polymer heat exchangers as a more sustainable alternative in various industrial processes.

Looking ahead, the evolution of polymer heat exchangers is expected to continue, driven by advancements in material science, manufacturing technologies, and a growing emphasis on energy efficiency and environmental sustainability. The ultimate goal remains to create heat exchange solutions that offer superior performance, durability, and cost-effectiveness while minimizing environmental footprint.

However, as polymer science advanced, so did the potential for their use in heat exchangers. The 1980s and 1990s saw significant improvements in polymer formulations, leading to the development of high-performance thermoplastics with enhanced thermal properties. This period marked a turning point in the industry, as researchers and engineers began to recognize the unique advantages that polymers could offer, such as corrosion resistance, lightweight construction, and cost-effectiveness.

The early 2000s witnessed a surge in research and development activities focused on polymer-based plate heat exchangers. This era was characterized by the exploration of various polymer types, including polypropylene, polyethylene, and fluoropolymers, each offering distinct benefits for specific applications. The primary objective during this phase was to overcome the thermal conductivity limitations of polymers while capitalizing on their other advantageous properties.

As we entered the 2010s, the focus shifted towards optimizing the design of polymer plate heat exchangers. Engineers began experimenting with innovative geometries and surface modifications to enhance heat transfer efficiency. The integration of advanced manufacturing techniques, such as 3D printing and injection molding, opened up new possibilities for creating complex and highly efficient heat exchanger designs that were previously unattainable with traditional materials.

Currently, the objectives in polymer heat exchanger development are multifaceted. One primary goal is to further improve the thermal performance of polymer materials, bringing them closer to the efficiency levels of metallic heat exchangers. This involves ongoing research into polymer nanocomposites and the incorporation of thermally conductive fillers to enhance heat transfer properties.

Another critical objective is to expand the application range of polymer heat exchangers. While they have found success in low to medium temperature applications, there is a push to develop polymers capable of withstanding higher temperatures and pressures, potentially opening up new markets in industries such as chemical processing and power generation.

Sustainability has also emerged as a key focus area. The development of bio-based and recyclable polymers for heat exchanger applications aligns with global efforts to reduce environmental impact. This objective not only addresses ecological concerns but also positions polymer heat exchangers as a more sustainable alternative in various industrial processes.

Looking ahead, the evolution of polymer heat exchangers is expected to continue, driven by advancements in material science, manufacturing technologies, and a growing emphasis on energy efficiency and environmental sustainability. The ultimate goal remains to create heat exchange solutions that offer superior performance, durability, and cost-effectiveness while minimizing environmental footprint.

Market Demand Analysis for Polymer Heat Exchangers

The market demand for polymer heat exchangers has been steadily increasing in recent years, driven by several key factors. The growing emphasis on energy efficiency and sustainability across industries has led to a surge in interest for lightweight, corrosion-resistant, and cost-effective heat exchange solutions. Polymer heat exchangers, with their unique properties, are well-positioned to meet these evolving market needs.

In the chemical processing industry, there is a significant demand for heat exchangers that can withstand aggressive chemicals and operate in corrosive environments. Polymer heat exchangers offer superior chemical resistance compared to traditional metal-based alternatives, making them highly attractive for applications involving acids, bases, and other corrosive fluids. This has led to increased adoption in sectors such as pharmaceuticals, specialty chemicals, and water treatment.

The food and beverage industry has also shown growing interest in polymer heat exchangers due to their non-contaminating nature and ease of cleaning. These properties are crucial for maintaining product quality and meeting stringent hygiene standards. As a result, polymer heat exchangers are finding applications in pasteurization, sterilization, and temperature control processes within the food processing sector.

In the automotive industry, the shift towards electric vehicles (EVs) has created new opportunities for polymer heat exchangers. The need for efficient thermal management systems in EVs, coupled with the desire for lightweight components to extend battery range, has driven interest in polymer-based solutions. Polymer heat exchangers are being explored for battery cooling, power electronics thermal management, and cabin climate control systems in electric and hybrid vehicles.

The HVAC (Heating, Ventilation, and Air Conditioning) sector represents another significant market for polymer heat exchangers. The demand for energy-efficient and compact heating and cooling systems in residential and commercial buildings has led to increased adoption of polymer-based heat exchange technologies. These systems offer benefits such as reduced weight, improved thermal efficiency, and resistance to scale formation, addressing key pain points in HVAC applications.

Geographically, the market demand for polymer heat exchangers is particularly strong in regions with stringent environmental regulations and a focus on energy efficiency. North America and Europe are currently leading markets, with Asia-Pacific showing rapid growth potential due to increasing industrialization and adoption of advanced technologies.

Despite the growing demand, challenges remain in terms of market penetration. Traditional metal-based heat exchangers still dominate many sectors due to their established track record and familiarity among engineers. Overcoming this inertia and demonstrating the long-term benefits of polymer heat exchangers will be crucial for expanding market share. Additionally, educating end-users about the performance capabilities and durability of polymer materials in heat exchange applications will be essential for driving wider adoption across industries.

In the chemical processing industry, there is a significant demand for heat exchangers that can withstand aggressive chemicals and operate in corrosive environments. Polymer heat exchangers offer superior chemical resistance compared to traditional metal-based alternatives, making them highly attractive for applications involving acids, bases, and other corrosive fluids. This has led to increased adoption in sectors such as pharmaceuticals, specialty chemicals, and water treatment.

The food and beverage industry has also shown growing interest in polymer heat exchangers due to their non-contaminating nature and ease of cleaning. These properties are crucial for maintaining product quality and meeting stringent hygiene standards. As a result, polymer heat exchangers are finding applications in pasteurization, sterilization, and temperature control processes within the food processing sector.

In the automotive industry, the shift towards electric vehicles (EVs) has created new opportunities for polymer heat exchangers. The need for efficient thermal management systems in EVs, coupled with the desire for lightweight components to extend battery range, has driven interest in polymer-based solutions. Polymer heat exchangers are being explored for battery cooling, power electronics thermal management, and cabin climate control systems in electric and hybrid vehicles.

The HVAC (Heating, Ventilation, and Air Conditioning) sector represents another significant market for polymer heat exchangers. The demand for energy-efficient and compact heating and cooling systems in residential and commercial buildings has led to increased adoption of polymer-based heat exchange technologies. These systems offer benefits such as reduced weight, improved thermal efficiency, and resistance to scale formation, addressing key pain points in HVAC applications.

Geographically, the market demand for polymer heat exchangers is particularly strong in regions with stringent environmental regulations and a focus on energy efficiency. North America and Europe are currently leading markets, with Asia-Pacific showing rapid growth potential due to increasing industrialization and adoption of advanced technologies.

Despite the growing demand, challenges remain in terms of market penetration. Traditional metal-based heat exchangers still dominate many sectors due to their established track record and familiarity among engineers. Overcoming this inertia and demonstrating the long-term benefits of polymer heat exchangers will be crucial for expanding market share. Additionally, educating end-users about the performance capabilities and durability of polymer materials in heat exchange applications will be essential for driving wider adoption across industries.

Current Polymer Material Challenges in Heat Exchangers

Polymer materials have gained significant attention in plate heat exchanger innovation due to their unique properties and potential advantages. However, several challenges persist in their application, hindering widespread adoption and optimal performance. One of the primary challenges is the limited thermal conductivity of polymers compared to traditional metallic materials. This inherent property restricts heat transfer efficiency, potentially compromising the overall performance of plate heat exchangers.

Another critical challenge lies in the long-term durability and stability of polymer materials under varying operational conditions. Heat exchangers often operate in harsh environments, exposed to high temperatures, pressure fluctuations, and corrosive fluids. Polymer materials may experience degradation, deformation, or loss of mechanical properties over time, raising concerns about their reliability and lifespan in industrial applications.

The chemical compatibility of polymer materials with various working fluids presents another significant hurdle. While polymers offer excellent corrosion resistance to certain substances, they may be susceptible to chemical attack or swelling when exposed to specific fluids or solvents. This limitation narrows the range of applications and requires careful material selection based on the intended operating conditions.

Manufacturing processes for polymer-based plate heat exchangers also pose challenges. Traditional fabrication methods used for metallic heat exchangers may not be directly applicable to polymers, necessitating the development of new manufacturing techniques. Ensuring consistent quality, dimensional accuracy, and surface finish in polymer components can be more complex and costly compared to their metallic counterparts.

The mechanical strength and pressure resistance of polymer materials are additional concerns in heat exchanger design. High-pressure applications may require thicker polymer plates or reinforcement strategies, potentially offsetting the weight advantages typically associated with polymers. Balancing mechanical robustness with thermal performance remains a key challenge for engineers and material scientists.

Furthermore, the long-term fouling behavior of polymer surfaces in heat exchangers is not yet fully understood. While some polymers exhibit fouling-resistant properties, the accumulation of deposits on heat transfer surfaces over time can significantly impact performance. Developing effective cleaning and maintenance protocols for polymer-based heat exchangers is crucial for ensuring sustained efficiency.

Lastly, the environmental impact and end-of-life considerations for polymer heat exchangers present challenges in terms of recyclability and disposal. As sustainability becomes increasingly important in industrial applications, addressing these concerns is essential for the widespread adoption of polymer materials in plate heat exchanger technology.

Another critical challenge lies in the long-term durability and stability of polymer materials under varying operational conditions. Heat exchangers often operate in harsh environments, exposed to high temperatures, pressure fluctuations, and corrosive fluids. Polymer materials may experience degradation, deformation, or loss of mechanical properties over time, raising concerns about their reliability and lifespan in industrial applications.

The chemical compatibility of polymer materials with various working fluids presents another significant hurdle. While polymers offer excellent corrosion resistance to certain substances, they may be susceptible to chemical attack or swelling when exposed to specific fluids or solvents. This limitation narrows the range of applications and requires careful material selection based on the intended operating conditions.

Manufacturing processes for polymer-based plate heat exchangers also pose challenges. Traditional fabrication methods used for metallic heat exchangers may not be directly applicable to polymers, necessitating the development of new manufacturing techniques. Ensuring consistent quality, dimensional accuracy, and surface finish in polymer components can be more complex and costly compared to their metallic counterparts.

The mechanical strength and pressure resistance of polymer materials are additional concerns in heat exchanger design. High-pressure applications may require thicker polymer plates or reinforcement strategies, potentially offsetting the weight advantages typically associated with polymers. Balancing mechanical robustness with thermal performance remains a key challenge for engineers and material scientists.

Furthermore, the long-term fouling behavior of polymer surfaces in heat exchangers is not yet fully understood. While some polymers exhibit fouling-resistant properties, the accumulation of deposits on heat transfer surfaces over time can significantly impact performance. Developing effective cleaning and maintenance protocols for polymer-based heat exchangers is crucial for ensuring sustained efficiency.

Lastly, the environmental impact and end-of-life considerations for polymer heat exchangers present challenges in terms of recyclability and disposal. As sustainability becomes increasingly important in industrial applications, addressing these concerns is essential for the widespread adoption of polymer materials in plate heat exchanger technology.

Existing Polymer Solutions for Heat Exchangers

01 Innovative polymer materials for energy storage

Development of novel polymer materials for use in energy storage devices such as batteries and capacitors. These materials aim to improve energy density, charge/discharge rates, and overall performance of energy storage systems.- Innovative polymer materials for energy storage: Development of new polymer materials for improved energy storage applications, focusing on enhancing battery performance, durability, and efficiency. These innovations may include novel polymer electrolytes, separators, or electrode materials that contribute to better energy density, cycle life, and safety in various energy storage devices.

- Smart polymers for responsive applications: Creation of intelligent polymer materials that can respond to external stimuli such as temperature, pH, light, or electrical fields. These smart polymers have potential applications in drug delivery systems, self-healing materials, and adaptive structures, offering new possibilities for various industries including healthcare and aerospace.

- Sustainable and biodegradable polymer innovations: Development of eco-friendly polymer materials that are biodegradable, recyclable, or derived from renewable resources. These innovations aim to reduce environmental impact and promote sustainability in various applications, including packaging, textiles, and consumer products.

- Advanced polymer composites for structural applications: Creation of high-performance polymer composites with enhanced mechanical properties, lightweight characteristics, and improved durability. These materials can be used in automotive, aerospace, and construction industries to replace traditional materials and offer superior performance in demanding environments.

- Polymer-based functional coatings and surfaces: Innovation in polymer-based coatings and surface treatments that provide specific functionalities such as self-cleaning, anti-fouling, or corrosion resistance. These advancements can be applied to various substrates and have applications in industries ranging from marine engineering to consumer electronics.

02 Biodegradable and sustainable polymer innovations

Creation of environmentally friendly polymer materials that are biodegradable or derived from renewable sources. These innovations focus on reducing environmental impact while maintaining or improving material properties for various applications.Expand Specific Solutions03 Smart and responsive polymer materials

Development of polymer materials that can respond to external stimuli such as temperature, pH, light, or electrical signals. These materials have potential applications in sensors, drug delivery systems, and adaptive structures.Expand Specific Solutions04 Polymer nanocomposites for enhanced properties

Innovation in polymer nanocomposites by incorporating nanoscale fillers or reinforcements to enhance mechanical, thermal, electrical, or barrier properties of the materials. These advancements lead to improved performance in various applications.Expand Specific Solutions05 Polymer materials for 3D printing and additive manufacturing

Development of specialized polymer materials optimized for 3D printing and additive manufacturing processes. These materials focus on improving printability, resolution, and final product properties for rapid prototyping and production applications.Expand Specific Solutions

Key Players in Polymer Heat Exchanger Industry

The impact of polymer materials on plate heat exchanger innovation is shaping a competitive landscape in an industry transitioning from mature to growth phase. The market is expanding due to increasing demand for energy-efficient heat transfer solutions across various sectors. While the technology is well-established, ongoing research by key players like Alfa Laval, NOVA Chemicals, and Dow Global Technologies is driving advancements in polymer-based heat exchangers. These companies are focusing on developing high-performance, corrosion-resistant materials to enhance efficiency and durability. Academic institutions such as Zhengzhou University and Shandong University are also contributing to the field, indicating a growing interest in polymer applications for heat exchange technology.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed innovative polymer-based plate heat exchangers that significantly improve heat transfer efficiency. Their AlfaNova fusion-bonded plate heat exchanger combines the durability of stainless steel with the corrosion resistance of polymers[1]. This hybrid approach allows for thinner plate designs, increasing heat transfer surface area while reducing material costs. The company has also introduced polymer coatings on traditional metal plates to enhance chemical resistance and reduce fouling[2]. These coatings are applied using advanced plasma spray techniques, ensuring uniform coverage and strong adhesion to the metal substrate.

Strengths: Improved corrosion resistance, reduced fouling, and increased efficiency. Weaknesses: Potential limitations in high-temperature applications compared to all-metal designs.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered the development of advanced polymer materials specifically designed for plate heat exchangers. Their DOWLEX™ resin technology enables the production of thin-walled, high-strength polymer plates that offer excellent thermal conductivity[3]. These plates are manufactured using a proprietary injection molding process that ensures uniform thickness and optimal heat transfer characteristics. Dow has also developed specialized polymer additives that enhance the thermal stability and chemical resistance of the plates, allowing them to operate in a wider range of industrial environments[4]. The company's research has shown that these polymer-based heat exchangers can achieve up to 30% higher overall heat transfer coefficients compared to traditional metal designs in certain applications.

Strengths: Lightweight, corrosion-resistant, and cost-effective. Weaknesses: May have limitations in extremely high-temperature or high-pressure applications.

Core Innovations in Polymer Heat Transfer Materials

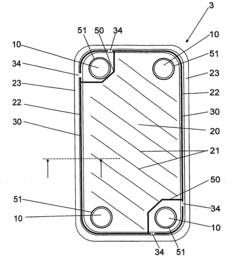

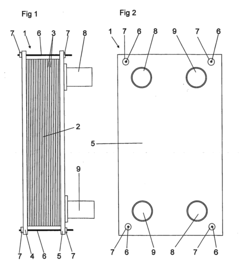

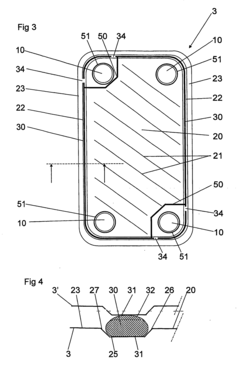

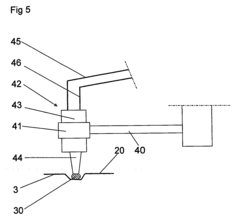

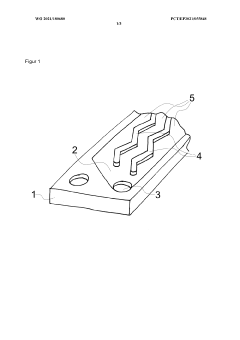

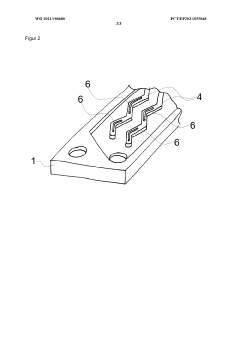

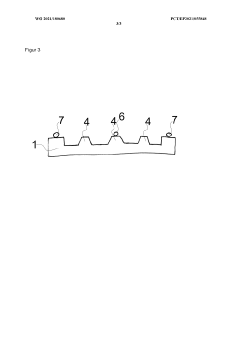

Heat exchanger plate, a plate heat exchanger and a method for manufacturing a heat exchanger plate

PatentInactiveUS20050269058A1

Innovation

- Applying a curable polymer material, such as Liquid Silicon Rubber, to the border area of heat exchanger plates to form a gasket that provides tight abutment and adhesion, eliminating the need for separate gaskets and enabling automated manufacturing.

Plate heat exchanger

PatentWO2021180680A1

Innovation

- A plate heat exchanger design featuring two heat exchange plates with a channel system sealed by a support element and a sealing element, where the support element is spaced apart from the sealing element, using fluoropolymer materials for both, and a detachable joint connection to ensure stability and reliability under high pressures.

Environmental Impact of Polymer Heat Exchangers

The adoption of polymer materials in plate heat exchangers has significant environmental implications, both positive and negative. One of the primary advantages is the reduction in energy consumption during manufacturing processes. Polymer heat exchangers typically require less energy to produce compared to their metal counterparts, resulting in a lower carbon footprint during the production phase.

Furthermore, the lightweight nature of polymer materials contributes to reduced transportation costs and associated emissions. This aspect becomes particularly relevant when considering the entire life cycle of heat exchangers, from production to installation and eventual replacement.

Polymer heat exchangers also demonstrate improved corrosion resistance compared to traditional metal designs. This enhanced durability translates to longer operational lifespans, reducing the frequency of replacements and, consequently, the environmental impact associated with manufacturing and disposing of heat exchanger units.

However, the environmental benefits of polymer heat exchangers are not without challenges. The end-of-life disposal of polymer materials presents a significant concern. Unlike metals, which can be readily recycled, many polymers used in heat exchangers are not easily recyclable or biodegradable. This limitation could potentially lead to increased landfill waste if proper recycling technologies and infrastructure are not developed alongside the adoption of polymer heat exchangers.

Another environmental consideration is the potential for microplastic pollution. As polymer heat exchangers age and degrade, there is a risk of microplastic particles being released into the environment, particularly in applications involving water systems. This issue requires careful monitoring and the development of mitigation strategies to prevent long-term environmental damage.

On the positive side, polymer heat exchangers often exhibit superior fouling resistance compared to metal alternatives. This characteristic reduces the need for frequent cleaning and maintenance, which in turn minimizes the use of potentially harmful chemical cleaning agents and reduces water consumption associated with cleaning processes.

The environmental impact of polymer heat exchangers also extends to their operational efficiency. In certain applications, polymer materials can provide better heat transfer performance, leading to increased energy efficiency in the systems they serve. This improved efficiency can result in reduced energy consumption and lower greenhouse gas emissions over the operational lifetime of the equipment.

In conclusion, while polymer heat exchangers offer several environmental benefits, including reduced energy consumption in manufacturing and improved operational efficiency, they also present challenges related to end-of-life disposal and potential microplastic pollution. As the technology continues to evolve, addressing these environmental concerns will be crucial for ensuring the sustainable adoption of polymer materials in plate heat exchanger innovations.

Furthermore, the lightweight nature of polymer materials contributes to reduced transportation costs and associated emissions. This aspect becomes particularly relevant when considering the entire life cycle of heat exchangers, from production to installation and eventual replacement.

Polymer heat exchangers also demonstrate improved corrosion resistance compared to traditional metal designs. This enhanced durability translates to longer operational lifespans, reducing the frequency of replacements and, consequently, the environmental impact associated with manufacturing and disposing of heat exchanger units.

However, the environmental benefits of polymer heat exchangers are not without challenges. The end-of-life disposal of polymer materials presents a significant concern. Unlike metals, which can be readily recycled, many polymers used in heat exchangers are not easily recyclable or biodegradable. This limitation could potentially lead to increased landfill waste if proper recycling technologies and infrastructure are not developed alongside the adoption of polymer heat exchangers.

Another environmental consideration is the potential for microplastic pollution. As polymer heat exchangers age and degrade, there is a risk of microplastic particles being released into the environment, particularly in applications involving water systems. This issue requires careful monitoring and the development of mitigation strategies to prevent long-term environmental damage.

On the positive side, polymer heat exchangers often exhibit superior fouling resistance compared to metal alternatives. This characteristic reduces the need for frequent cleaning and maintenance, which in turn minimizes the use of potentially harmful chemical cleaning agents and reduces water consumption associated with cleaning processes.

The environmental impact of polymer heat exchangers also extends to their operational efficiency. In certain applications, polymer materials can provide better heat transfer performance, leading to increased energy efficiency in the systems they serve. This improved efficiency can result in reduced energy consumption and lower greenhouse gas emissions over the operational lifetime of the equipment.

In conclusion, while polymer heat exchangers offer several environmental benefits, including reduced energy consumption in manufacturing and improved operational efficiency, they also present challenges related to end-of-life disposal and potential microplastic pollution. As the technology continues to evolve, addressing these environmental concerns will be crucial for ensuring the sustainable adoption of polymer materials in plate heat exchanger innovations.

Cost-Benefit Analysis of Polymer vs. Traditional Materials

The cost-benefit analysis of polymer materials versus traditional materials in plate heat exchanger innovation reveals significant advantages and potential drawbacks. Polymer materials, such as high-performance thermoplastics, offer several cost-saving benefits compared to traditional metallic materials like stainless steel or titanium.

One of the primary advantages of polymer materials is their lower raw material cost. Polymers are generally less expensive to produce and process than metals, leading to reduced manufacturing expenses. Additionally, the lightweight nature of polymers contributes to lower transportation and installation costs, further enhancing their economic appeal.

Polymer plate heat exchangers also demonstrate superior corrosion resistance compared to their metallic counterparts. This characteristic translates into reduced maintenance costs and extended operational lifespans, ultimately lowering the total cost of ownership. The enhanced durability of polymer materials in aggressive environments can significantly decrease the frequency of replacements and repairs.

From an energy efficiency perspective, polymer materials often exhibit better thermal insulation properties than metals. This can lead to improved heat transfer efficiency and reduced energy consumption during operation, resulting in long-term cost savings for end-users.

However, the initial investment in polymer-based plate heat exchangers may be higher due to the specialized manufacturing processes and equipment required. The development of high-performance polymers suitable for heat exchanger applications also involves substantial research and development costs, which can impact the final product price.

Another consideration is the potential limitation in operating temperatures and pressures for polymer materials compared to traditional metallic options. While advancements in polymer technology have expanded their operational range, certain high-temperature or high-pressure applications may still require metallic solutions, potentially limiting the cost-saving benefits in specific scenarios.

The environmental impact and sustainability aspects also factor into the cost-benefit analysis. Polymer materials often have a lower carbon footprint in production and can be more easily recycled at the end of their lifecycle, potentially offering long-term environmental and economic benefits.

In terms of market acceptance, there may be initial resistance to adopting polymer-based heat exchangers in industries traditionally reliant on metallic solutions. This could necessitate additional marketing and education efforts, impacting the overall cost structure for manufacturers and distributors.

Ultimately, the cost-benefit analysis of polymer materials in plate heat exchanger innovation suggests a favorable outlook, with potential for significant cost savings and performance improvements. However, careful consideration of specific application requirements, market dynamics, and long-term environmental impacts is crucial for a comprehensive evaluation of their economic viability.

One of the primary advantages of polymer materials is their lower raw material cost. Polymers are generally less expensive to produce and process than metals, leading to reduced manufacturing expenses. Additionally, the lightweight nature of polymers contributes to lower transportation and installation costs, further enhancing their economic appeal.

Polymer plate heat exchangers also demonstrate superior corrosion resistance compared to their metallic counterparts. This characteristic translates into reduced maintenance costs and extended operational lifespans, ultimately lowering the total cost of ownership. The enhanced durability of polymer materials in aggressive environments can significantly decrease the frequency of replacements and repairs.

From an energy efficiency perspective, polymer materials often exhibit better thermal insulation properties than metals. This can lead to improved heat transfer efficiency and reduced energy consumption during operation, resulting in long-term cost savings for end-users.

However, the initial investment in polymer-based plate heat exchangers may be higher due to the specialized manufacturing processes and equipment required. The development of high-performance polymers suitable for heat exchanger applications also involves substantial research and development costs, which can impact the final product price.

Another consideration is the potential limitation in operating temperatures and pressures for polymer materials compared to traditional metallic options. While advancements in polymer technology have expanded their operational range, certain high-temperature or high-pressure applications may still require metallic solutions, potentially limiting the cost-saving benefits in specific scenarios.

The environmental impact and sustainability aspects also factor into the cost-benefit analysis. Polymer materials often have a lower carbon footprint in production and can be more easily recycled at the end of their lifecycle, potentially offering long-term environmental and economic benefits.

In terms of market acceptance, there may be initial resistance to adopting polymer-based heat exchangers in industries traditionally reliant on metallic solutions. This could necessitate additional marketing and education efforts, impacting the overall cost structure for manufacturers and distributors.

Ultimately, the cost-benefit analysis of polymer materials in plate heat exchanger innovation suggests a favorable outlook, with potential for significant cost savings and performance improvements. However, careful consideration of specific application requirements, market dynamics, and long-term environmental impacts is crucial for a comprehensive evaluation of their economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!