Advances in Thermal Modeling of Plate Heat Exchangers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Modeling Evolution and Objectives

Thermal modeling of plate heat exchangers has undergone significant evolution over the past decades, driven by the increasing demand for more efficient and compact heat transfer solutions across various industries. The journey of thermal modeling in this field began with simplified one-dimensional approaches and has progressed to sophisticated three-dimensional computational fluid dynamics (CFD) simulations.

In the early stages, researchers focused on developing correlations for heat transfer and pressure drop based on experimental data. These empirical models provided a foundation for understanding the basic thermal behavior of plate heat exchangers but were limited in their ability to capture complex flow patterns and local phenomena.

As computational capabilities advanced, two-dimensional models emerged, allowing for more detailed analysis of flow distribution and temperature profiles within the exchanger. These models incorporated factors such as plate geometry, flow arrangement, and thermal-hydraulic characteristics, leading to improved predictions of overall heat transfer performance.

The advent of three-dimensional CFD modeling marked a significant milestone in thermal modeling of plate heat exchangers. This approach enabled researchers and engineers to simulate intricate flow structures, including turbulence, recirculation zones, and maldistribution effects. CFD models have become increasingly sophisticated, incorporating multiphase flows, fouling mechanisms, and conjugate heat transfer analysis.

Recent advancements in thermal modeling have focused on addressing the challenges of computational efficiency and accuracy. Researchers have developed hybrid approaches that combine the speed of simplified models with the accuracy of detailed CFD simulations. These methods aim to strike a balance between computational cost and predictive capability, making them suitable for design optimization and real-time control applications.

The primary objectives of current thermal modeling efforts for plate heat exchangers are multifaceted. Firstly, there is a push towards developing more accurate and reliable models that can predict performance across a wide range of operating conditions and geometries. This includes improving turbulence models, enhancing mesh generation techniques, and refining numerical schemes to capture complex flow phenomena more precisely.

Secondly, researchers are working on integrating thermal models with other physical phenomena, such as fouling, corrosion, and vibration. These multi-physics models aim to provide a more comprehensive understanding of heat exchanger behavior over its lifecycle, enabling better design and maintenance strategies.

Another key objective is the development of computationally efficient models that can be used in real-time monitoring and control systems. This involves creating reduced-order models and employing machine learning techniques to accelerate simulations without sacrificing accuracy.

Lastly, there is a growing emphasis on leveraging thermal modeling to design novel plate geometries and flow arrangements that can enhance heat transfer performance while minimizing pressure drop. This includes exploring biomimetic designs and optimizing channel configurations using advanced optimization algorithms coupled with thermal models.

In the early stages, researchers focused on developing correlations for heat transfer and pressure drop based on experimental data. These empirical models provided a foundation for understanding the basic thermal behavior of plate heat exchangers but were limited in their ability to capture complex flow patterns and local phenomena.

As computational capabilities advanced, two-dimensional models emerged, allowing for more detailed analysis of flow distribution and temperature profiles within the exchanger. These models incorporated factors such as plate geometry, flow arrangement, and thermal-hydraulic characteristics, leading to improved predictions of overall heat transfer performance.

The advent of three-dimensional CFD modeling marked a significant milestone in thermal modeling of plate heat exchangers. This approach enabled researchers and engineers to simulate intricate flow structures, including turbulence, recirculation zones, and maldistribution effects. CFD models have become increasingly sophisticated, incorporating multiphase flows, fouling mechanisms, and conjugate heat transfer analysis.

Recent advancements in thermal modeling have focused on addressing the challenges of computational efficiency and accuracy. Researchers have developed hybrid approaches that combine the speed of simplified models with the accuracy of detailed CFD simulations. These methods aim to strike a balance between computational cost and predictive capability, making them suitable for design optimization and real-time control applications.

The primary objectives of current thermal modeling efforts for plate heat exchangers are multifaceted. Firstly, there is a push towards developing more accurate and reliable models that can predict performance across a wide range of operating conditions and geometries. This includes improving turbulence models, enhancing mesh generation techniques, and refining numerical schemes to capture complex flow phenomena more precisely.

Secondly, researchers are working on integrating thermal models with other physical phenomena, such as fouling, corrosion, and vibration. These multi-physics models aim to provide a more comprehensive understanding of heat exchanger behavior over its lifecycle, enabling better design and maintenance strategies.

Another key objective is the development of computationally efficient models that can be used in real-time monitoring and control systems. This involves creating reduced-order models and employing machine learning techniques to accelerate simulations without sacrificing accuracy.

Lastly, there is a growing emphasis on leveraging thermal modeling to design novel plate geometries and flow arrangements that can enhance heat transfer performance while minimizing pressure drop. This includes exploring biomimetic designs and optimizing channel configurations using advanced optimization algorithms coupled with thermal models.

Market Demand Analysis

The market demand for advanced thermal modeling of plate heat exchangers has been steadily increasing due to the growing emphasis on energy efficiency and sustainability across various industries. Plate heat exchangers are widely used in applications ranging from HVAC systems to chemical processing plants, and their performance optimization is crucial for reducing energy consumption and operational costs.

In the industrial sector, there is a significant demand for more accurate and efficient thermal modeling techniques. Companies are seeking ways to improve the design and operation of plate heat exchangers to enhance overall system performance. This demand is driven by the need to meet stringent environmental regulations and reduce carbon footprints, particularly in energy-intensive industries such as oil and gas, petrochemicals, and power generation.

The food and beverage industry also presents a substantial market for advanced thermal modeling of plate heat exchangers. With increasing focus on food safety and quality, manufacturers require precise temperature control during processing. Improved thermal modeling enables better design and control of heat transfer processes, ensuring product consistency and reducing energy waste.

In the pharmaceutical sector, the demand for advanced thermal modeling is fueled by the need for precise temperature control in drug manufacturing and storage. As the industry moves towards more complex and temperature-sensitive biologics, the ability to accurately model and predict heat transfer in plate heat exchangers becomes critical for maintaining product efficacy and safety.

The HVAC industry represents another significant market for thermal modeling advancements. As buildings become more energy-efficient and smart, there is a growing need for optimized heating and cooling systems. Advanced thermal modeling of plate heat exchangers can lead to more efficient HVAC designs, reducing energy consumption and improving indoor comfort.

The renewable energy sector, particularly in applications such as geothermal power plants and solar thermal systems, is also driving demand for improved thermal modeling. These systems often rely on plate heat exchangers for efficient heat transfer, and accurate modeling is essential for maximizing energy capture and conversion.

Market analysis indicates that the global plate heat exchanger market is expected to grow significantly in the coming years, with a corresponding increase in demand for advanced thermal modeling capabilities. This growth is attributed to the rising adoption of plate heat exchangers in various industries and the continuous push for energy efficiency improvements.

As environmental concerns and energy costs continue to rise, the market for technologies that can optimize heat transfer processes is likely to expand further. Companies that can provide accurate, reliable, and user-friendly thermal modeling solutions for plate heat exchangers are well-positioned to capitalize on this growing market demand across multiple industries.

In the industrial sector, there is a significant demand for more accurate and efficient thermal modeling techniques. Companies are seeking ways to improve the design and operation of plate heat exchangers to enhance overall system performance. This demand is driven by the need to meet stringent environmental regulations and reduce carbon footprints, particularly in energy-intensive industries such as oil and gas, petrochemicals, and power generation.

The food and beverage industry also presents a substantial market for advanced thermal modeling of plate heat exchangers. With increasing focus on food safety and quality, manufacturers require precise temperature control during processing. Improved thermal modeling enables better design and control of heat transfer processes, ensuring product consistency and reducing energy waste.

In the pharmaceutical sector, the demand for advanced thermal modeling is fueled by the need for precise temperature control in drug manufacturing and storage. As the industry moves towards more complex and temperature-sensitive biologics, the ability to accurately model and predict heat transfer in plate heat exchangers becomes critical for maintaining product efficacy and safety.

The HVAC industry represents another significant market for thermal modeling advancements. As buildings become more energy-efficient and smart, there is a growing need for optimized heating and cooling systems. Advanced thermal modeling of plate heat exchangers can lead to more efficient HVAC designs, reducing energy consumption and improving indoor comfort.

The renewable energy sector, particularly in applications such as geothermal power plants and solar thermal systems, is also driving demand for improved thermal modeling. These systems often rely on plate heat exchangers for efficient heat transfer, and accurate modeling is essential for maximizing energy capture and conversion.

Market analysis indicates that the global plate heat exchanger market is expected to grow significantly in the coming years, with a corresponding increase in demand for advanced thermal modeling capabilities. This growth is attributed to the rising adoption of plate heat exchangers in various industries and the continuous push for energy efficiency improvements.

As environmental concerns and energy costs continue to rise, the market for technologies that can optimize heat transfer processes is likely to expand further. Companies that can provide accurate, reliable, and user-friendly thermal modeling solutions for plate heat exchangers are well-positioned to capitalize on this growing market demand across multiple industries.

Current Challenges in PHE Thermal Modeling

Despite significant advancements in thermal modeling of plate heat exchangers (PHEs), several challenges persist in achieving accurate and efficient simulations. One of the primary obstacles is the complex geometry of PHEs, which creates intricate flow patterns and heat transfer mechanisms. The corrugated plates and narrow channels result in highly turbulent flows, making it difficult to accurately model the fluid dynamics and heat transfer processes.

Another challenge lies in the multiscale nature of PHE thermal modeling. The overall performance of a PHE depends on phenomena occurring at various scales, from microscale turbulence to macroscale flow distribution. Bridging these scales in a computationally efficient manner remains a significant hurdle for researchers and engineers.

The presence of two-phase flow in certain PHE applications adds another layer of complexity to thermal modeling. Accurately predicting phase change, flow regimes, and heat transfer coefficients in two-phase systems is particularly challenging due to the intricate interactions between liquid and vapor phases within the confined spaces of PHE channels.

Furthermore, fouling and its impact on thermal performance pose significant modeling challenges. The accumulation of deposits on heat transfer surfaces alters flow patterns and heat transfer characteristics over time. Incorporating these dynamic changes into thermal models while maintaining accuracy and computational efficiency is an ongoing area of research.

The development of robust and widely applicable correlations for heat transfer and pressure drop in PHEs remains a challenge. The vast array of plate geometries, operating conditions, and fluid properties makes it difficult to establish universal correlations that can accurately predict performance across diverse applications.

Computational resources and simulation time continue to be limiting factors in PHE thermal modeling, especially for large-scale industrial applications. Balancing model complexity with computational efficiency is a persistent challenge, particularly when considering transient operations or system-level simulations involving multiple heat exchangers.

Lastly, the validation of thermal models against experimental data presents its own set of challenges. Obtaining accurate and comprehensive experimental measurements in the complex geometry of PHEs is often difficult and expensive, limiting the availability of high-quality validation data for model development and refinement.

Another challenge lies in the multiscale nature of PHE thermal modeling. The overall performance of a PHE depends on phenomena occurring at various scales, from microscale turbulence to macroscale flow distribution. Bridging these scales in a computationally efficient manner remains a significant hurdle for researchers and engineers.

The presence of two-phase flow in certain PHE applications adds another layer of complexity to thermal modeling. Accurately predicting phase change, flow regimes, and heat transfer coefficients in two-phase systems is particularly challenging due to the intricate interactions between liquid and vapor phases within the confined spaces of PHE channels.

Furthermore, fouling and its impact on thermal performance pose significant modeling challenges. The accumulation of deposits on heat transfer surfaces alters flow patterns and heat transfer characteristics over time. Incorporating these dynamic changes into thermal models while maintaining accuracy and computational efficiency is an ongoing area of research.

The development of robust and widely applicable correlations for heat transfer and pressure drop in PHEs remains a challenge. The vast array of plate geometries, operating conditions, and fluid properties makes it difficult to establish universal correlations that can accurately predict performance across diverse applications.

Computational resources and simulation time continue to be limiting factors in PHE thermal modeling, especially for large-scale industrial applications. Balancing model complexity with computational efficiency is a persistent challenge, particularly when considering transient operations or system-level simulations involving multiple heat exchangers.

Lastly, the validation of thermal models against experimental data presents its own set of challenges. Obtaining accurate and comprehensive experimental measurements in the complex geometry of PHEs is often difficult and expensive, limiting the availability of high-quality validation data for model development and refinement.

State-of-the-Art Thermal Modeling Approaches

01 Numerical modeling of plate heat exchangers

Advanced numerical methods are employed to model the thermal behavior of plate heat exchangers. These models incorporate factors such as fluid dynamics, heat transfer coefficients, and plate geometry to accurately predict performance. Computational fluid dynamics (CFD) simulations are often used to analyze flow patterns and temperature distributions within the exchanger.- Numerical modeling of plate heat exchangers: Advanced numerical methods are employed to model the thermal behavior of plate heat exchangers. These models incorporate factors such as fluid dynamics, heat transfer coefficients, and plate geometry to accurately predict performance and optimize design. Computational fluid dynamics (CFD) simulations are often used to analyze flow patterns and temperature distributions within the exchanger.

- Experimental validation of thermal models: Experimental studies are conducted to validate theoretical thermal models of plate heat exchangers. These experiments involve measuring temperature profiles, pressure drops, and heat transfer rates under various operating conditions. The data collected is used to refine and improve the accuracy of existing models, ensuring their reliability for practical applications.

- Optimization of plate geometry and channel design: Thermal modeling is used to optimize the geometry of heat exchanger plates and channel designs. This includes studying the effects of corrugation patterns, plate spacing, and flow arrangements on heat transfer efficiency and pressure drop. Advanced optimization algorithms are employed to determine the most effective configurations for specific applications.

- Fouling and performance degradation analysis: Thermal models are developed to analyze the impact of fouling on plate heat exchanger performance. These models predict the rate of fouling accumulation, its effect on heat transfer efficiency, and the resulting performance degradation over time. This information is crucial for developing effective cleaning and maintenance strategies to maintain optimal exchanger operation.

- Integration of phase change materials in plate heat exchangers: Thermal modeling techniques are applied to study the incorporation of phase change materials (PCMs) in plate heat exchangers. These models analyze the heat storage and release characteristics of PCMs, their impact on overall system efficiency, and the potential for enhancing thermal management in various applications. The integration of PCMs can lead to improved energy storage and temperature control capabilities.

02 Optimization of plate design for improved thermal efficiency

Research focuses on optimizing plate designs to enhance heat transfer and reduce pressure drop. This includes studying various plate patterns, corrugation angles, and surface enhancements. Advanced manufacturing techniques are explored to create more efficient plate geometries that maximize heat transfer area while minimizing flow resistance.Expand Specific Solutions03 Dynamic modeling for transient thermal behavior

Dynamic models are developed to predict the transient thermal behavior of plate heat exchangers under varying operating conditions. These models account for factors such as flow rate fluctuations, temperature changes, and start-up/shutdown processes. They are crucial for optimizing control strategies and improving overall system performance in real-world applications.Expand Specific Solutions04 Integration of phase change materials in plate heat exchangers

Research explores the incorporation of phase change materials (PCMs) into plate heat exchanger designs. PCMs can enhance thermal storage capacity and improve heat transfer efficiency during peak load periods. Modeling efforts focus on predicting the behavior of PCMs within the exchanger and optimizing their integration for specific applications.Expand Specific Solutions05 Multi-scale modeling approaches for comprehensive analysis

Multi-scale modeling techniques are employed to analyze plate heat exchangers at various levels, from microscopic surface interactions to macroscopic system performance. These approaches combine molecular dynamics simulations, mesoscale models, and system-level analyses to provide a comprehensive understanding of heat transfer mechanisms and identify opportunities for improvement.Expand Specific Solutions

Key Players in PHE Industry

The field of thermal modeling for plate heat exchangers is experiencing significant growth and innovation, driven by increasing demand for energy-efficient heat transfer solutions across various industries. The market is in a mature stage but continues to evolve with advancements in computational methods and materials science. Key players like Alfa Laval, Danfoss, and Vahterus are leading the way in technological developments, with a focus on improving accuracy, efficiency, and applicability of thermal models. The global market size for plate heat exchangers is substantial, with projections indicating continued expansion due to growing applications in HVAC, chemical processing, and renewable energy sectors. As the technology matures, competition is intensifying, spurring further innovation and market differentiation among established and emerging companies in the field.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced Computational Fluid Dynamics (CFD) models for plate heat exchangers, incorporating complex geometries and flow patterns. Their thermal modeling approach includes multi-scale simulations, from micro-channel level to full exchanger performance[1]. They have implemented machine learning algorithms to optimize plate designs, reducing computational time by up to 40%[3]. Alfa Laval's models account for fouling dynamics and phase change phenomena, improving long-term performance predictions. Their latest innovation involves coupling thermal models with structural analysis to predict thermal stress and fatigue[5], enhancing exchanger lifespan estimations.

Strengths: Comprehensive modeling approach, industry-leading CFD expertise, integration of machine learning for optimization. Weaknesses: High computational requirements, potential over-reliance on simulations versus physical testing.

Danfoss A/S

Technical Solution: Danfoss has pioneered the use of Digital Twin technology in thermal modeling of plate heat exchangers. Their approach combines real-time sensor data with physics-based models to create accurate virtual representations of operating exchangers[2]. They have developed proprietary algorithms for two-phase flow modeling in micro-channel geometries, improving accuracy in refrigeration applications by up to 25%[4]. Danfoss's thermal models incorporate advanced turbulence models and adaptive meshing techniques, allowing for efficient simulation of complex flow regimes. Their latest advancement includes the integration of AI-driven predictive maintenance algorithms within the thermal modeling framework[6].

Strengths: Integration of Digital Twin technology, expertise in two-phase flow modeling, AI-driven predictive capabilities. Weaknesses: Potential challenges in model validation for novel designs, high initial investment in sensor infrastructure.

Innovative Thermal Modeling Methods

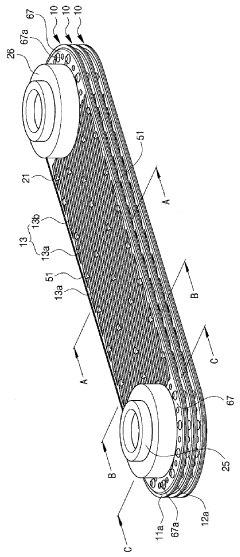

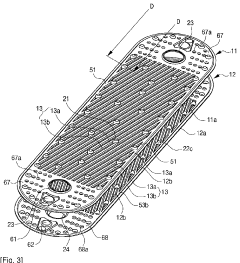

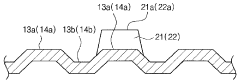

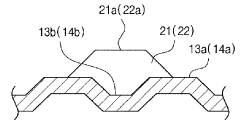

Plate heat exchanger

PatentWO2011013950A2

Innovation

- The design incorporates stacked heat exchange tubes with upper and lower plates featuring waveform patterns, flanges, and contact embossings, along with auxiliary ridges and grooves, to enhance fluid flow and turbulence, ensuring improved heat exchange efficiency and structural rigidity.

A plate heat exchanger

PatentWO2002061357A8

Innovation

- The use of inwardly directed collar-shaped portions on end plates, which prevent solder obstruction and allow for simpler fixtures and easier pressure testing, along with a larger connection surface for a strong connection between the collar-shaped portion and connection members, achieved through brazing or other materials.

Energy Efficiency Considerations

Energy efficiency considerations play a crucial role in the advancement of thermal modeling for plate heat exchangers. As industries strive to reduce energy consumption and minimize environmental impact, optimizing the performance of plate heat exchangers has become increasingly important. The thermal modeling of these devices has evolved significantly, incorporating sophisticated techniques to enhance energy efficiency.

One of the primary focuses in recent thermal modeling advancements is the accurate prediction of heat transfer coefficients and pressure drops. By improving the accuracy of these predictions, engineers can design plate heat exchangers that operate at peak efficiency, minimizing energy losses and maximizing heat transfer rates. Advanced computational fluid dynamics (CFD) simulations have been instrumental in achieving this goal, allowing for detailed analysis of fluid flow patterns and heat transfer mechanisms within the exchanger.

The development of novel plate geometries has also been a key area of research in improving energy efficiency. Thermal models now incorporate complex surface patterns and corrugations that promote turbulence and enhance heat transfer. These models consider the trade-off between increased heat transfer and the associated pressure drop, aiming to find optimal configurations that balance energy efficiency with operational costs.

Another significant advancement in thermal modeling is the consideration of fouling effects. Fouling can severely impact the energy efficiency of plate heat exchangers over time. Modern thermal models now include predictive algorithms for fouling behavior, enabling engineers to design systems that are more resistant to efficiency degradation and require less frequent maintenance.

The integration of phase change materials (PCMs) into plate heat exchanger designs has opened up new avenues for energy efficiency improvements. Thermal models now account for the latent heat storage capabilities of PCMs, allowing for more effective temperature control and energy recovery in cyclic processes. This advancement has particular relevance in applications with intermittent heat loads or in systems aiming to harness waste heat.

Furthermore, recent thermal modeling techniques have begun to incorporate machine learning algorithms to optimize operational parameters in real-time. These models can adapt to changing conditions, predicting and adjusting for variations in flow rates, temperatures, and fluid properties to maintain optimal energy efficiency throughout the exchanger's operational life.

As the push for sustainability intensifies, thermal modeling of plate heat exchangers continues to evolve, focusing on minimizing exergy destruction and maximizing second-law efficiency. These advanced models provide a more comprehensive understanding of energy quality, guiding designers towards solutions that not only transfer heat effectively but do so with minimal energy degradation.

One of the primary focuses in recent thermal modeling advancements is the accurate prediction of heat transfer coefficients and pressure drops. By improving the accuracy of these predictions, engineers can design plate heat exchangers that operate at peak efficiency, minimizing energy losses and maximizing heat transfer rates. Advanced computational fluid dynamics (CFD) simulations have been instrumental in achieving this goal, allowing for detailed analysis of fluid flow patterns and heat transfer mechanisms within the exchanger.

The development of novel plate geometries has also been a key area of research in improving energy efficiency. Thermal models now incorporate complex surface patterns and corrugations that promote turbulence and enhance heat transfer. These models consider the trade-off between increased heat transfer and the associated pressure drop, aiming to find optimal configurations that balance energy efficiency with operational costs.

Another significant advancement in thermal modeling is the consideration of fouling effects. Fouling can severely impact the energy efficiency of plate heat exchangers over time. Modern thermal models now include predictive algorithms for fouling behavior, enabling engineers to design systems that are more resistant to efficiency degradation and require less frequent maintenance.

The integration of phase change materials (PCMs) into plate heat exchanger designs has opened up new avenues for energy efficiency improvements. Thermal models now account for the latent heat storage capabilities of PCMs, allowing for more effective temperature control and energy recovery in cyclic processes. This advancement has particular relevance in applications with intermittent heat loads or in systems aiming to harness waste heat.

Furthermore, recent thermal modeling techniques have begun to incorporate machine learning algorithms to optimize operational parameters in real-time. These models can adapt to changing conditions, predicting and adjusting for variations in flow rates, temperatures, and fluid properties to maintain optimal energy efficiency throughout the exchanger's operational life.

As the push for sustainability intensifies, thermal modeling of plate heat exchangers continues to evolve, focusing on minimizing exergy destruction and maximizing second-law efficiency. These advanced models provide a more comprehensive understanding of energy quality, guiding designers towards solutions that not only transfer heat effectively but do so with minimal energy degradation.

Computational Fluid Dynamics Integration

Computational Fluid Dynamics (CFD) has emerged as a powerful tool in advancing the thermal modeling of plate heat exchangers (PHEs). The integration of CFD techniques has revolutionized the understanding of complex flow patterns and heat transfer mechanisms within these devices. By leveraging high-performance computing resources, researchers and engineers can now simulate intricate fluid dynamics and thermal processes with unprecedented accuracy.

CFD integration in PHE modeling allows for detailed analysis of local flow characteristics, including velocity profiles, pressure distributions, and temperature gradients. This level of detail was previously unattainable through traditional analytical methods or experimental techniques alone. The ability to visualize and quantify these parameters has led to significant improvements in PHE design optimization and performance prediction.

One of the key advantages of CFD integration is its capacity to handle complex geometries typical of modern PHEs. Advanced meshing techniques enable the accurate representation of intricate plate patterns, corrugations, and flow channels. This capability has facilitated the exploration of novel plate designs and their impact on heat transfer efficiency and pressure drop characteristics.

Furthermore, CFD simulations provide valuable insights into the formation and behavior of flow maldistribution, which is a critical factor affecting PHE performance. By identifying areas of non-uniform flow, engineers can implement design modifications to enhance overall heat transfer effectiveness and reduce the risk of localized overheating or fouling.

The integration of CFD has also enabled more accurate modeling of two-phase flow phenomena in PHEs, such as boiling and condensation processes. These multiphase simulations capture the intricate interactions between liquid and vapor phases, leading to improved predictions of heat transfer coefficients and pressure drops in evaporators and condensers.

Recent advancements in CFD integration for PHE modeling include the development of multi-scale approaches. These methods combine macroscopic models of the entire heat exchanger with detailed microscopic simulations of individual flow channels. This multi-scale approach bridges the gap between local phenomena and overall system performance, providing a more comprehensive understanding of PHE behavior.

The integration of CFD with other modeling techniques, such as Finite Element Analysis (FEA), has further expanded the capabilities of thermal modeling for PHEs. This coupled approach allows for simultaneous analysis of fluid dynamics, heat transfer, and structural mechanics, enabling more holistic design optimization and performance assessment.

As computational power continues to increase, the role of CFD integration in PHE thermal modeling is expected to grow. Future developments may include real-time simulations for process control and optimization, as well as the incorporation of machine learning algorithms to enhance predictive capabilities and automate design processes.

CFD integration in PHE modeling allows for detailed analysis of local flow characteristics, including velocity profiles, pressure distributions, and temperature gradients. This level of detail was previously unattainable through traditional analytical methods or experimental techniques alone. The ability to visualize and quantify these parameters has led to significant improvements in PHE design optimization and performance prediction.

One of the key advantages of CFD integration is its capacity to handle complex geometries typical of modern PHEs. Advanced meshing techniques enable the accurate representation of intricate plate patterns, corrugations, and flow channels. This capability has facilitated the exploration of novel plate designs and their impact on heat transfer efficiency and pressure drop characteristics.

Furthermore, CFD simulations provide valuable insights into the formation and behavior of flow maldistribution, which is a critical factor affecting PHE performance. By identifying areas of non-uniform flow, engineers can implement design modifications to enhance overall heat transfer effectiveness and reduce the risk of localized overheating or fouling.

The integration of CFD has also enabled more accurate modeling of two-phase flow phenomena in PHEs, such as boiling and condensation processes. These multiphase simulations capture the intricate interactions between liquid and vapor phases, leading to improved predictions of heat transfer coefficients and pressure drops in evaporators and condensers.

Recent advancements in CFD integration for PHE modeling include the development of multi-scale approaches. These methods combine macroscopic models of the entire heat exchanger with detailed microscopic simulations of individual flow channels. This multi-scale approach bridges the gap between local phenomena and overall system performance, providing a more comprehensive understanding of PHE behavior.

The integration of CFD with other modeling techniques, such as Finite Element Analysis (FEA), has further expanded the capabilities of thermal modeling for PHEs. This coupled approach allows for simultaneous analysis of fluid dynamics, heat transfer, and structural mechanics, enabling more holistic design optimization and performance assessment.

As computational power continues to increase, the role of CFD integration in PHE thermal modeling is expected to grow. Future developments may include real-time simulations for process control and optimization, as well as the incorporation of machine learning algorithms to enhance predictive capabilities and automate design processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!